Biofuel particle normal-temperature forming machine

A biofuel and molding machine technology, which is applied to material molding presses, presses, manufacturing tools, etc., can solve problems such as environmental pollution and waste of resources, and achieve the effects of convenient maintenance, no maintenance, and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

[0023] In order to achieve the above object, the technical scheme adopted in the present invention is as follows:

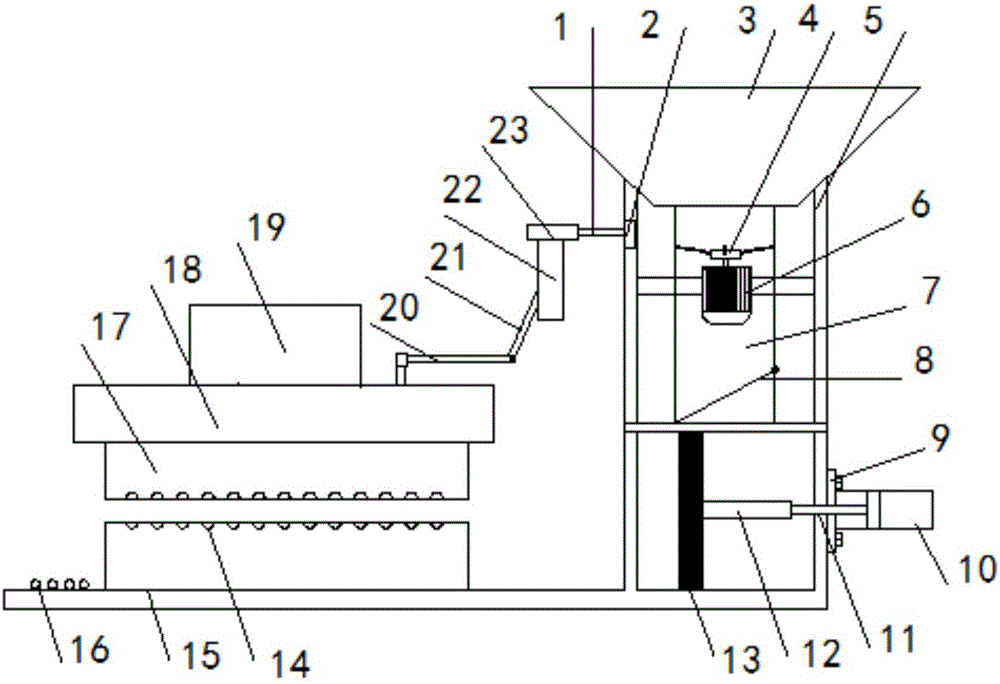

[0024] The normal temperature molding machine for biofuel particles includes a rotating shaft 1, a bearing 2, a feed port 3, a crushing head 4, a frame 5, a motor 6, a barrel 7, a baffle plate 8, a mounting plate 9, a cylinder 10, a piston rod 11, Push rod 12, feeding pusher 13, material hole 14, lower pressing plate 15, discharge port 16, upper pressing plate 17, cam 18, counterweight 19, rod A20, rod B21, worm 22 and turbine 23, the lower The material hole 14 is fixed on the pressing plate 15 and the upper pressing plate 17, the upper pressing plate 17 is welded with the cam 18, the rod A20 is hinged with the cam 18, the rod A20 is hinged with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com