A heat-resistant and highly transparent cpvc composition

A technology of CPVC resin and composition, applied in the field of chlorinated polyvinyl chloride composition, can solve the problems of limited application, low light transmittance, limited application of heat-resistant and high-transparency CPVC, etc., and achieves high Vicat softening temperature and uniform distribution. , enhance the effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

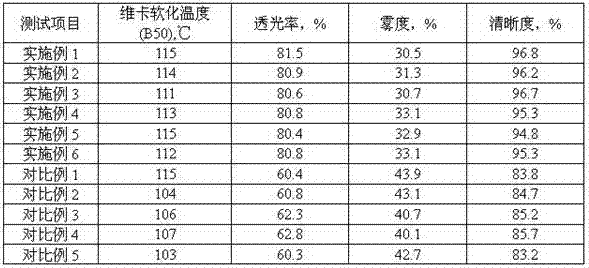

[0023] The heat-resistant and highly transparent CPVC composition of the present invention will be further described below through specific examples, wherein Example 1 is the best example.

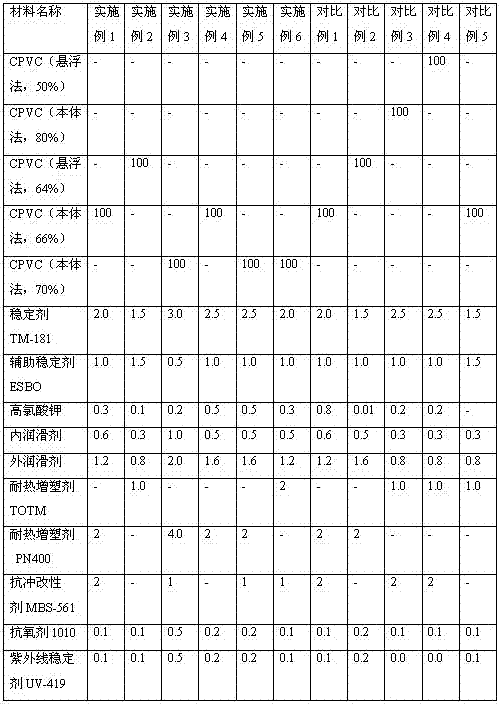

[0024] The material proportions of Examples 1-6 and Comparative Examples 1-5 are shown in Table 1.

[0025] Table 1 Embodiment and comparative ratio proportioning (by weight)

[0026]

[0027] Preparation method, first weigh each component of each embodiment and comparative example according to the above weight parts, put the materials into a high-speed mixer at 800~1000r / min, mix and heat up to 100~120°C, at 10~ After 15 minutes, put it into a low-speed mixer and cool it down to 40° C., then discharge, and then extrude or cast to obtain a finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com