Precise water resource reclaiming machine

A recycling machine and water resource technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of copper powder being difficult to remove, unsuitable for recycling devices, and waste liquid leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

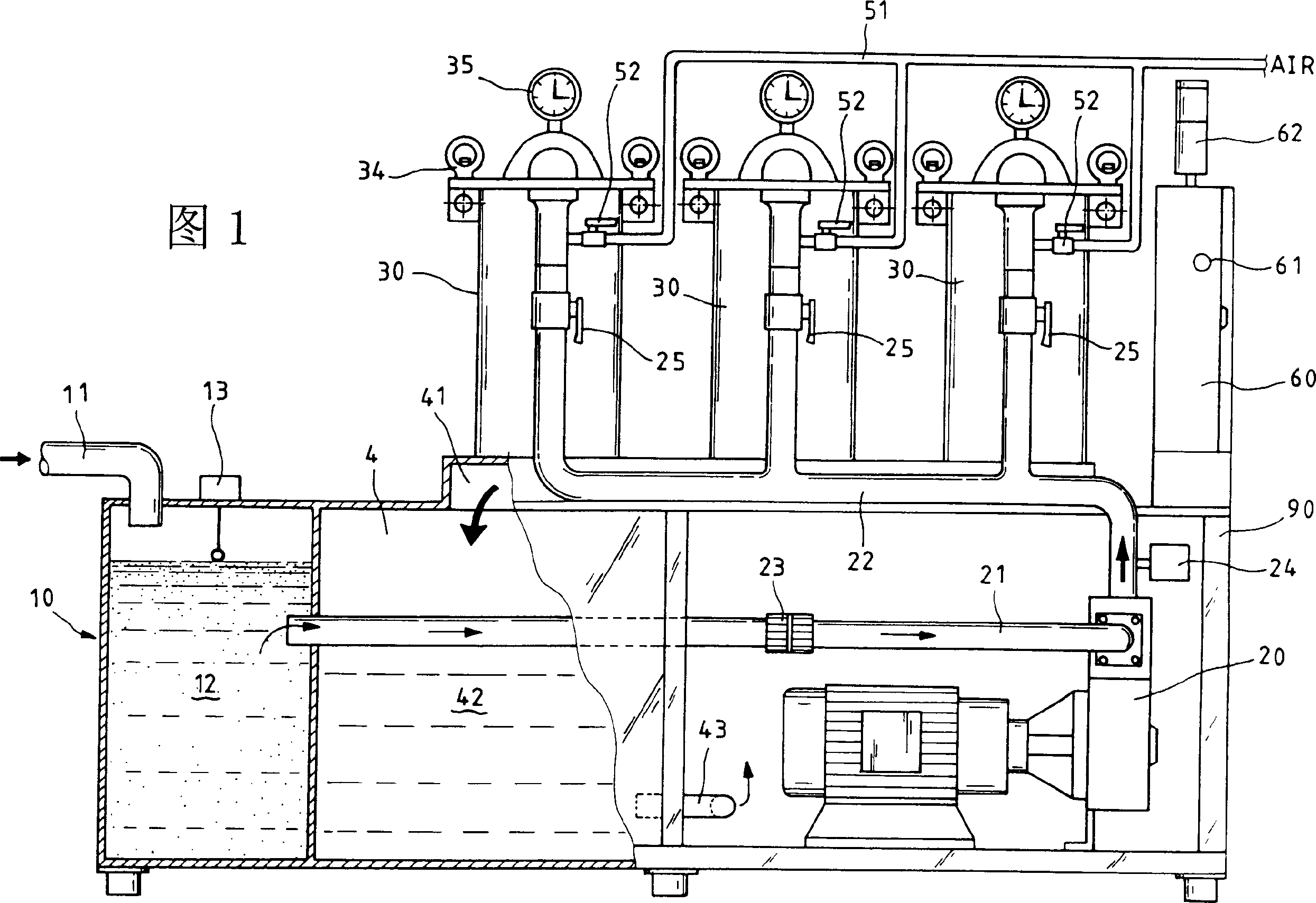

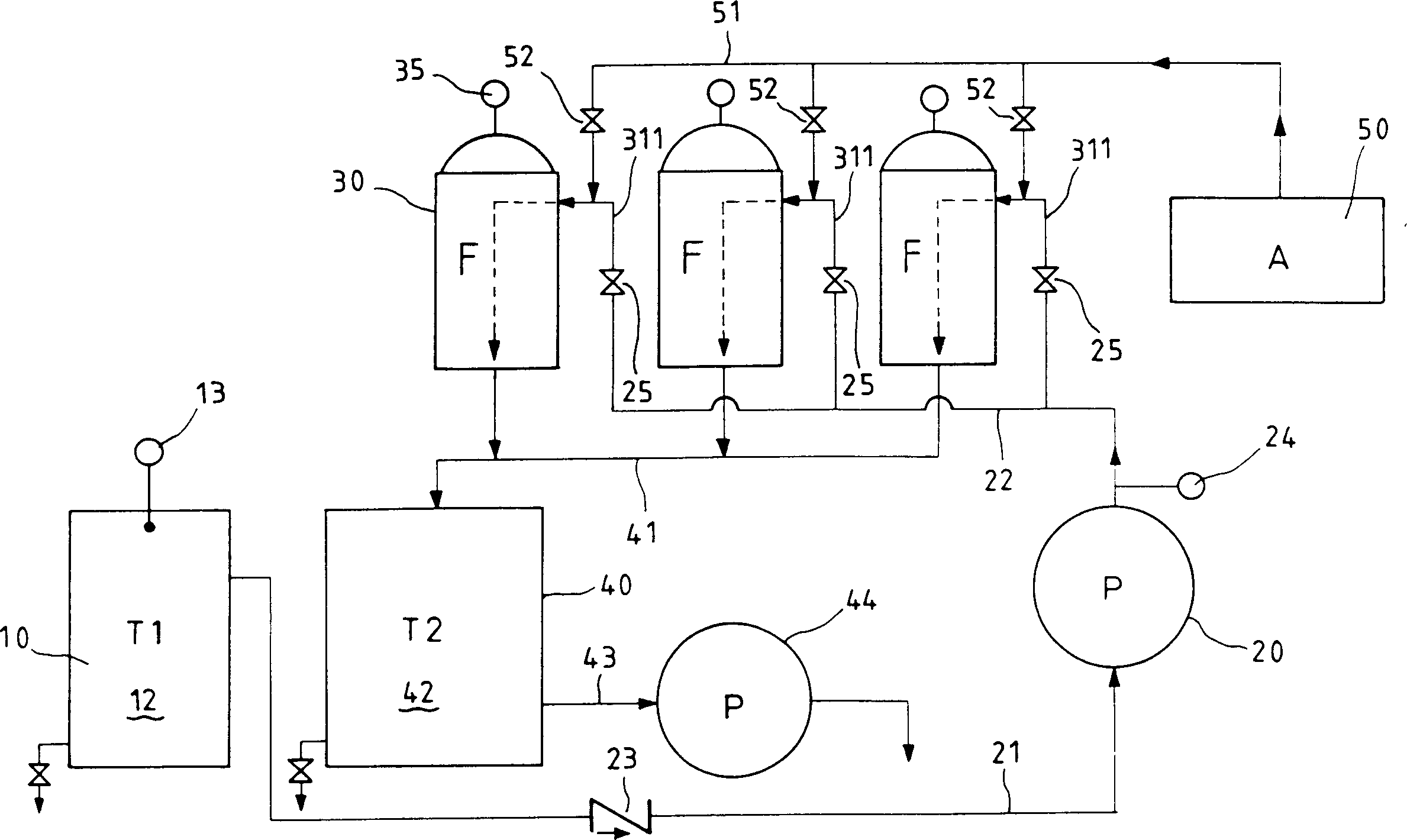

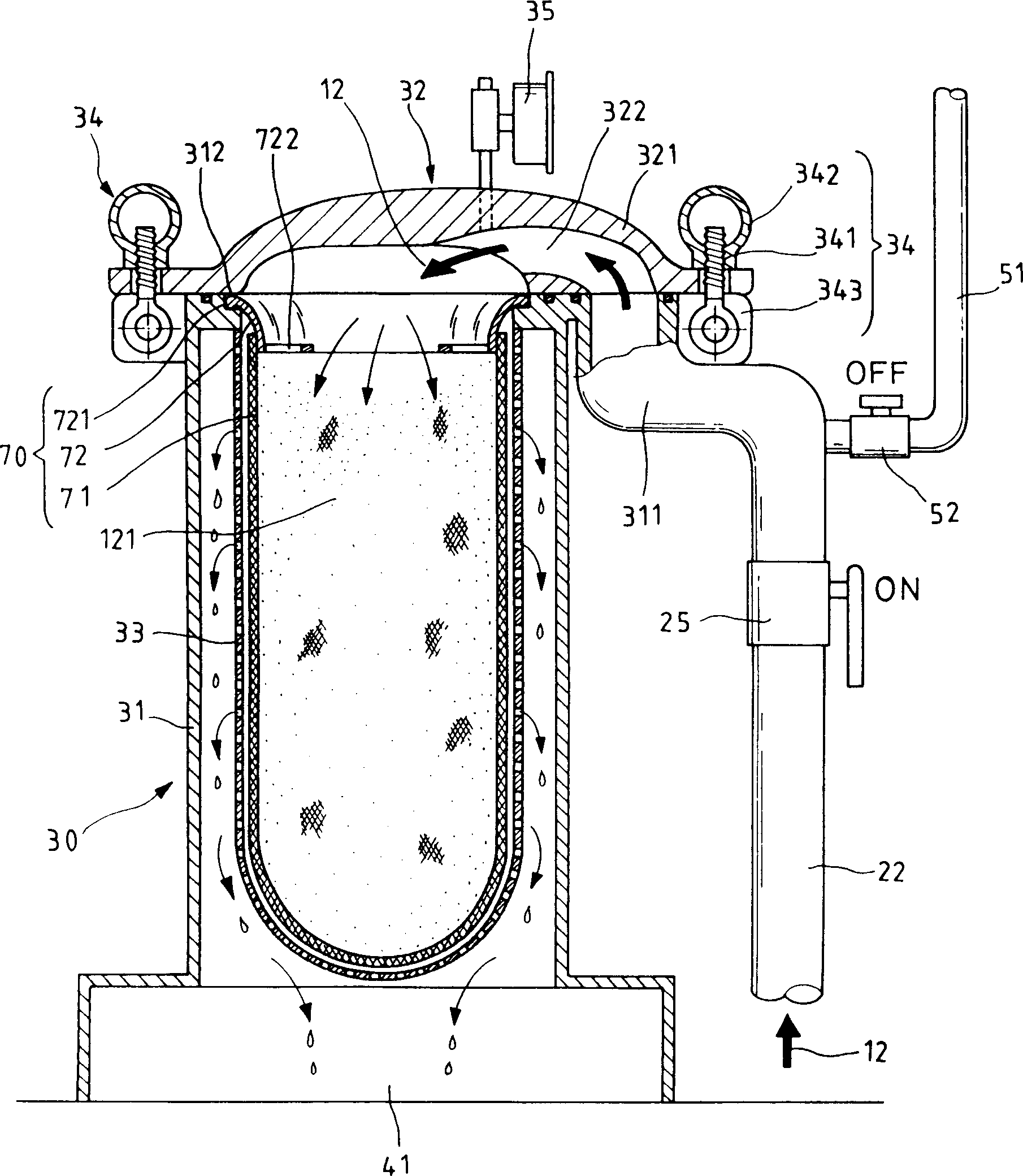

[0029] First of all, referring to Fig. 1, it is a schematic diagram of an embodiment of the present invention, and referring to figure 2As shown, it is a schematic diagram of the filtration process flow of the present invention. The main structure of the present invention includes: a waste liquid collection tank 10, which is used to hold the waste liquid 12 discharged through the pipeline 11 during the preparation process. The preparation process refers to printed circuit board etching or Grinding, the waste liquid produced in this preparation process will contain copper powder or other metal powder; a pump 20, its suction end is connected with the aforementioned waste liquid collection tank 10 through a suction pipe 21, and its output end is conveyed through a The pipe 22 is connected with a predetermined number of filter cartridges 30, so that the waste liquid 12 is sent into the filter cartridge 30 for filtration to separate the metal powder, and the waste liquid 12 becomes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com