Patents

Literature

60results about How to "Guaranteed not to be polluted" patented technology

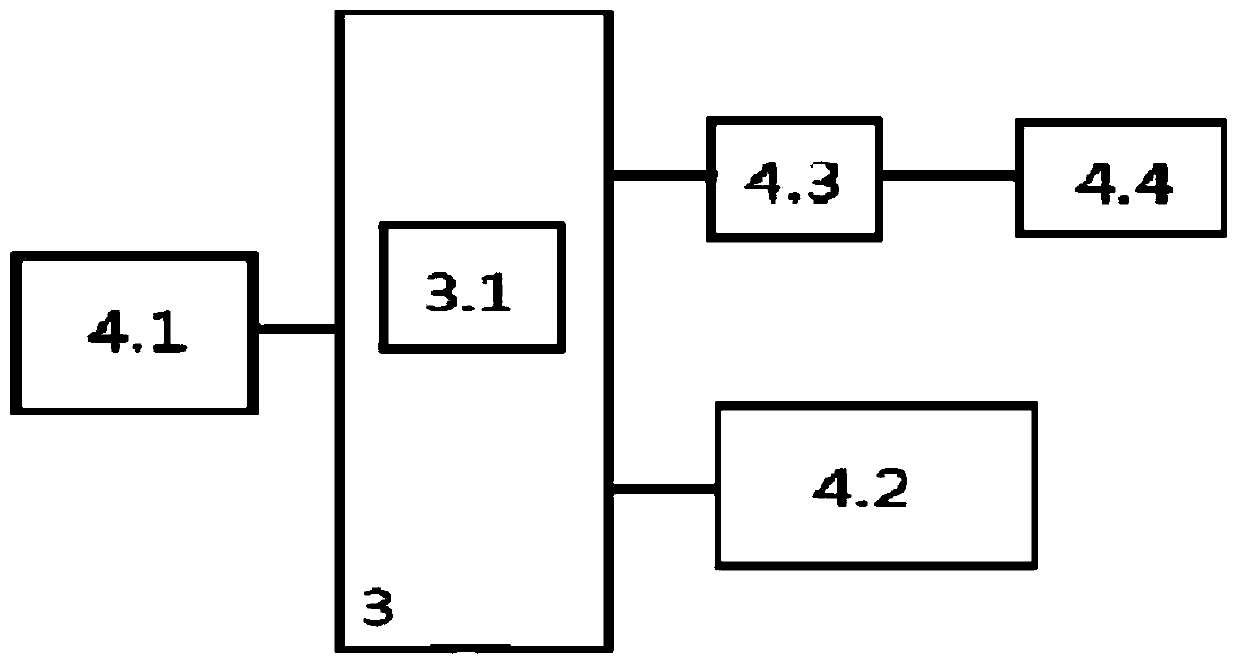

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

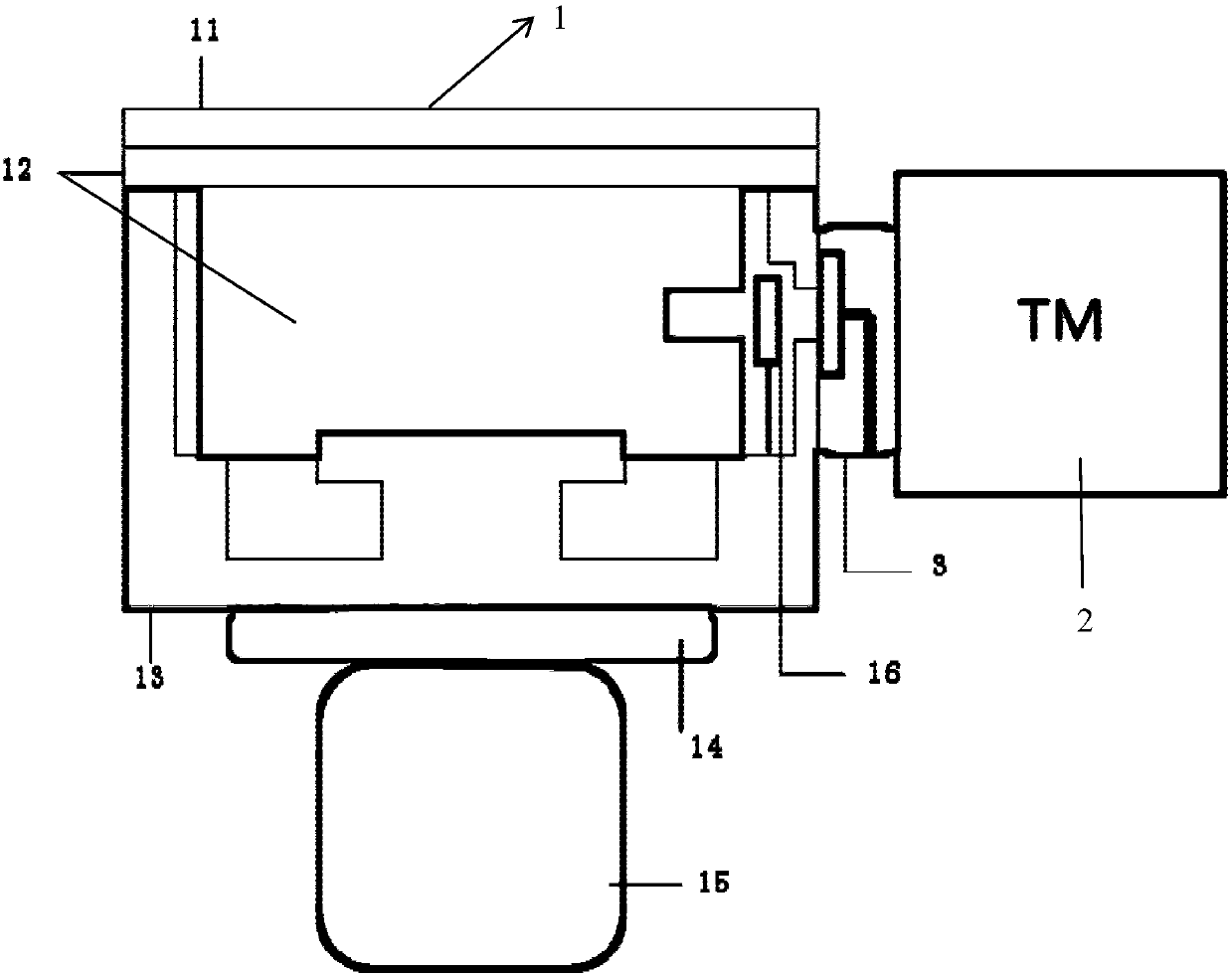

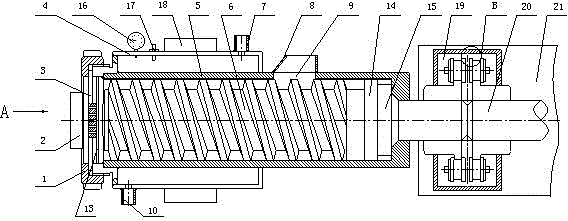

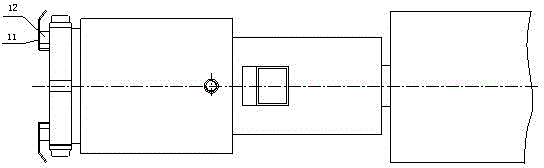

Multifunctional magnetic control sputtering film plating device

InactiveCN101709455AFulfil requirementsGuaranteed not to be pollutedVacuum evaporation coatingSputtering coatingSputteringMiniaturization

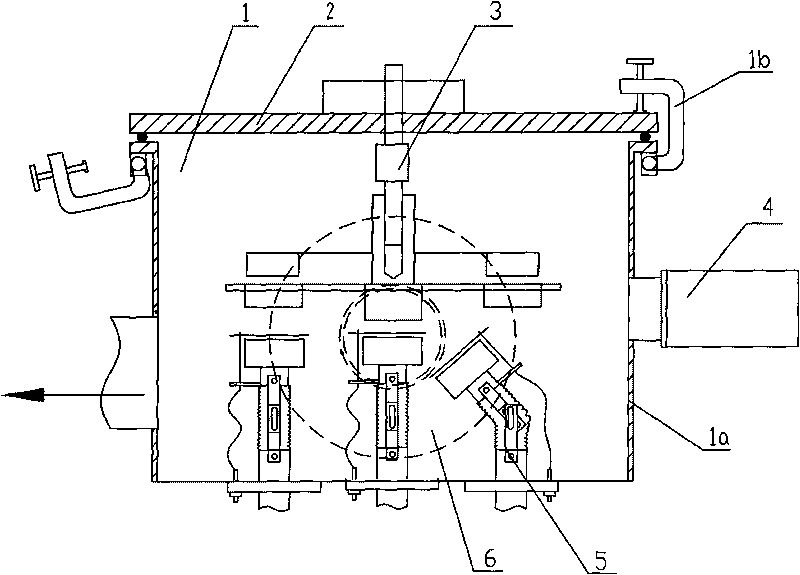

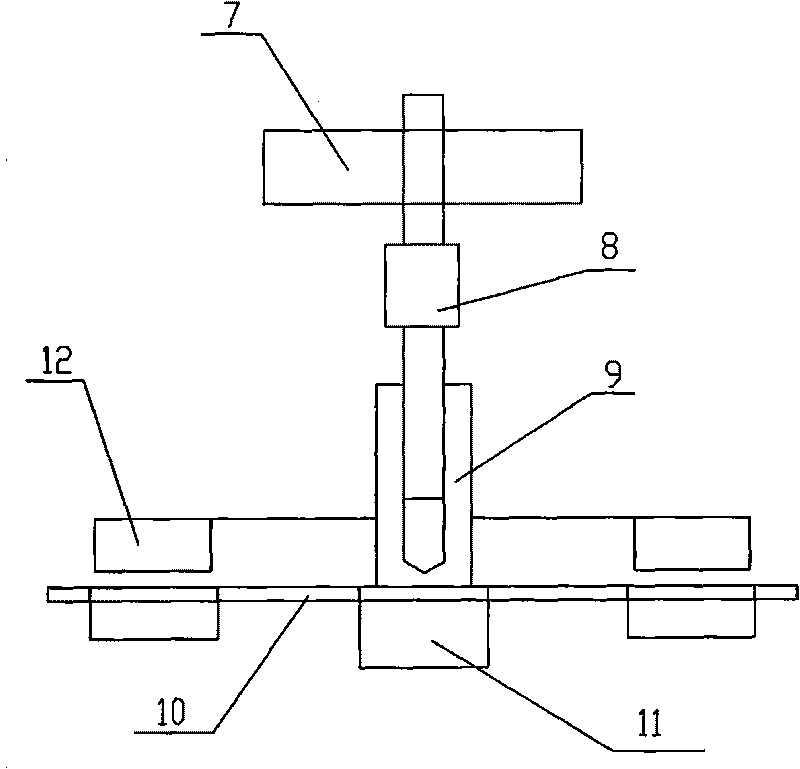

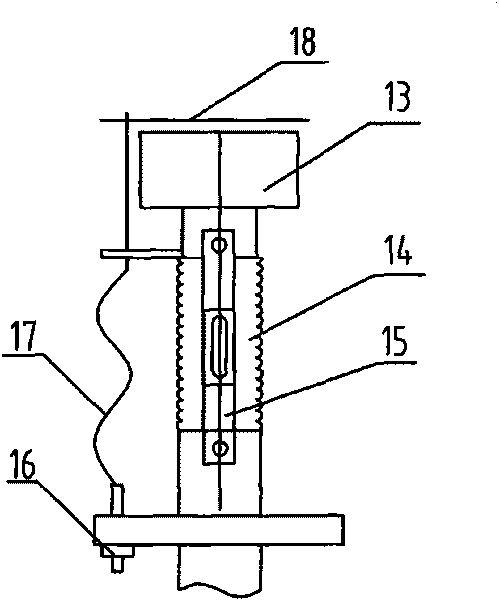

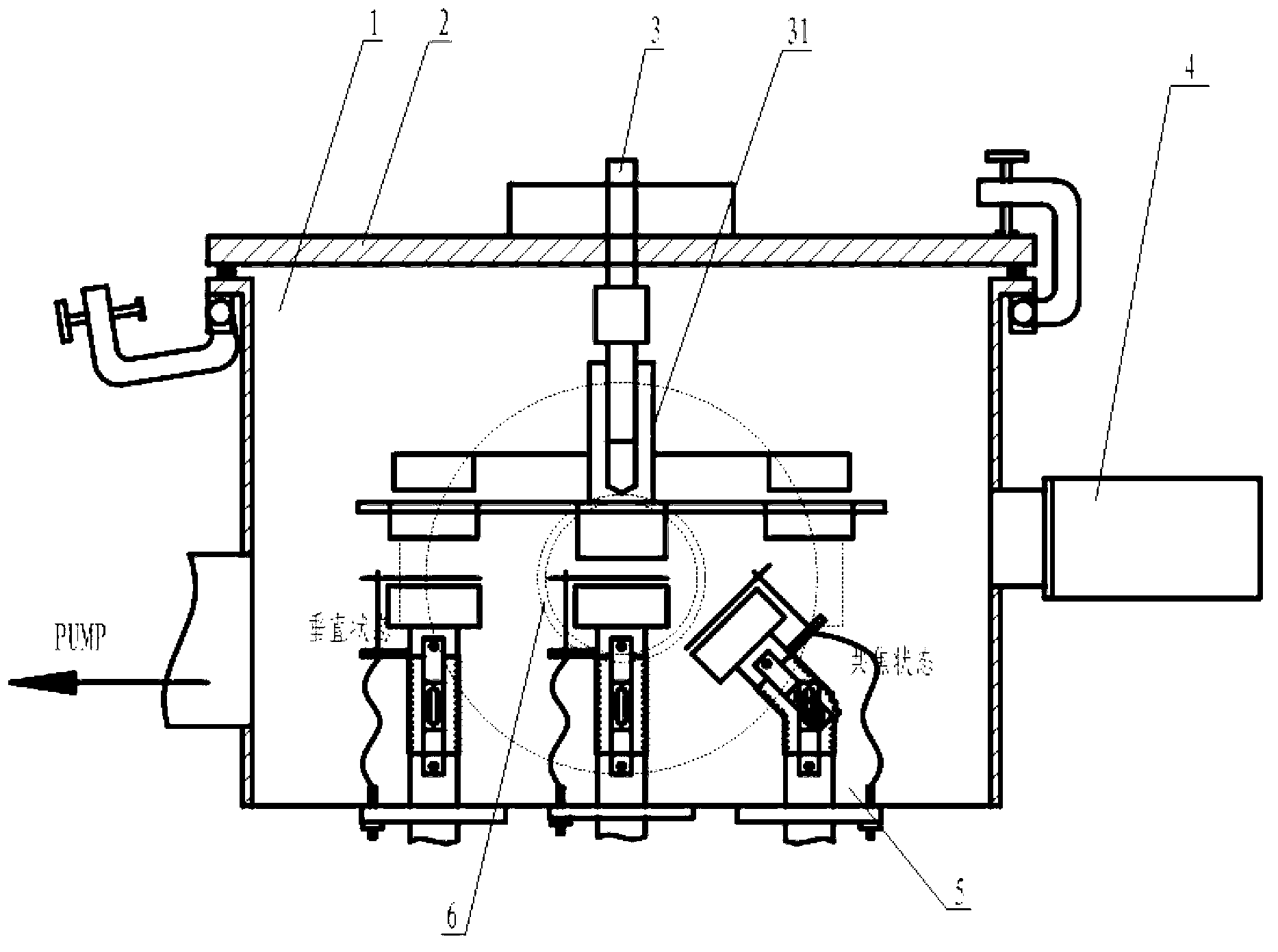

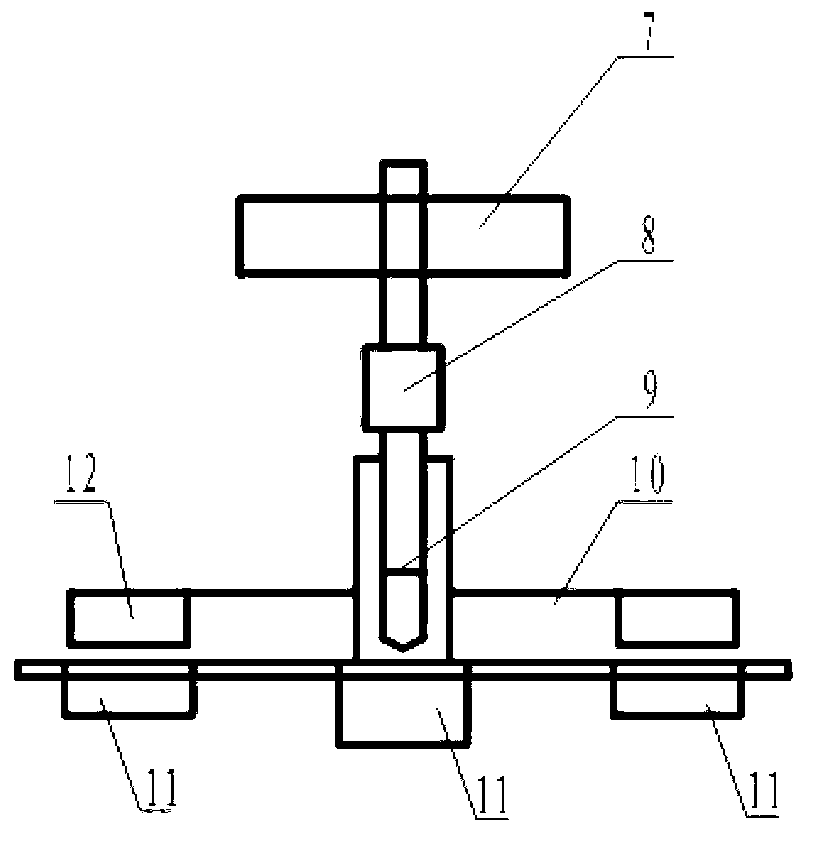

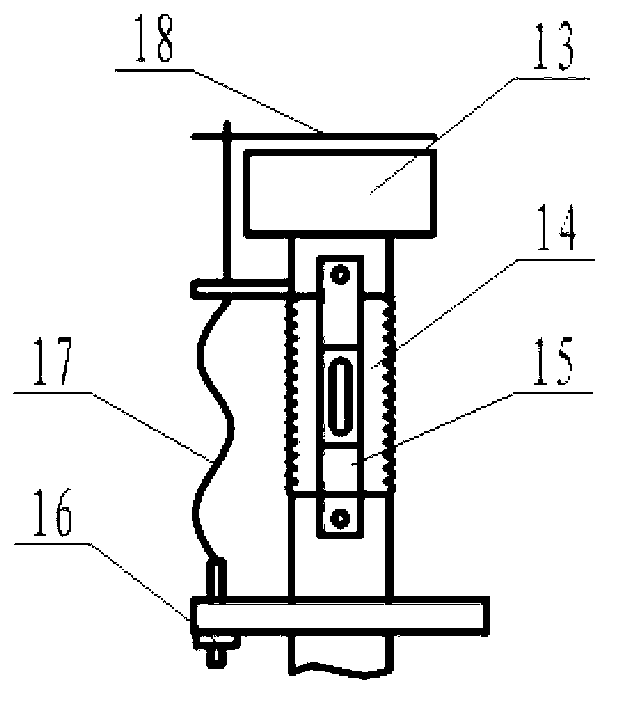

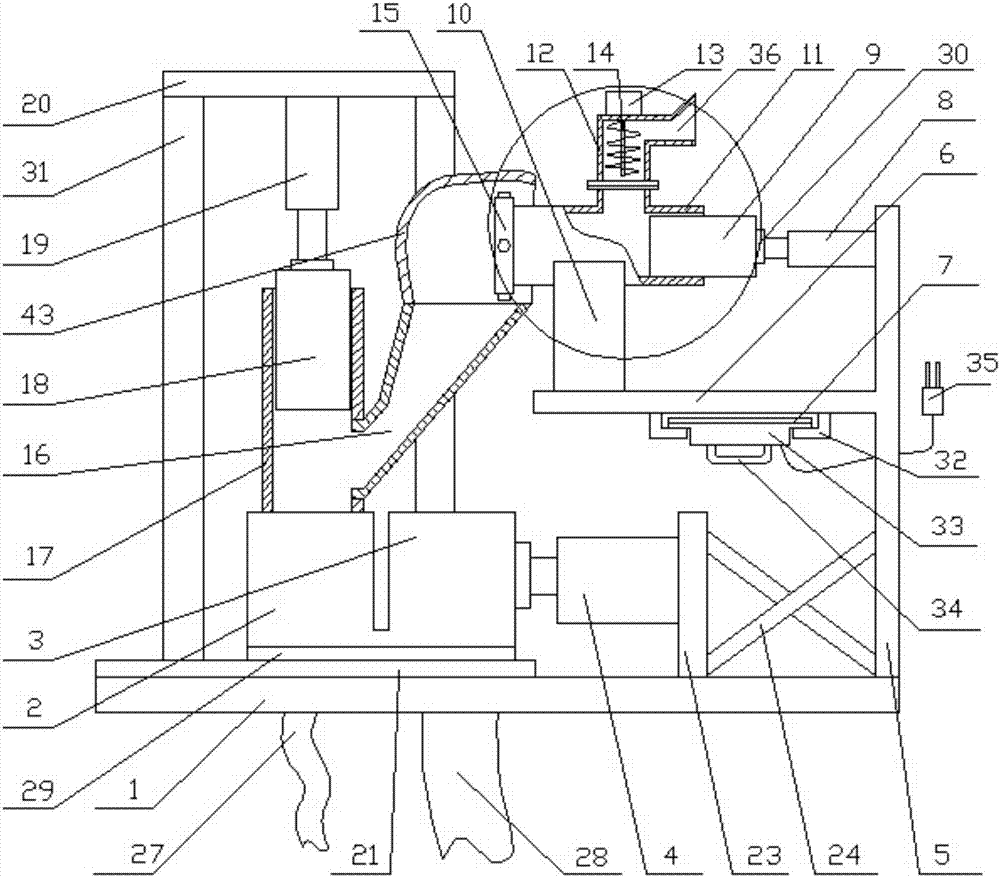

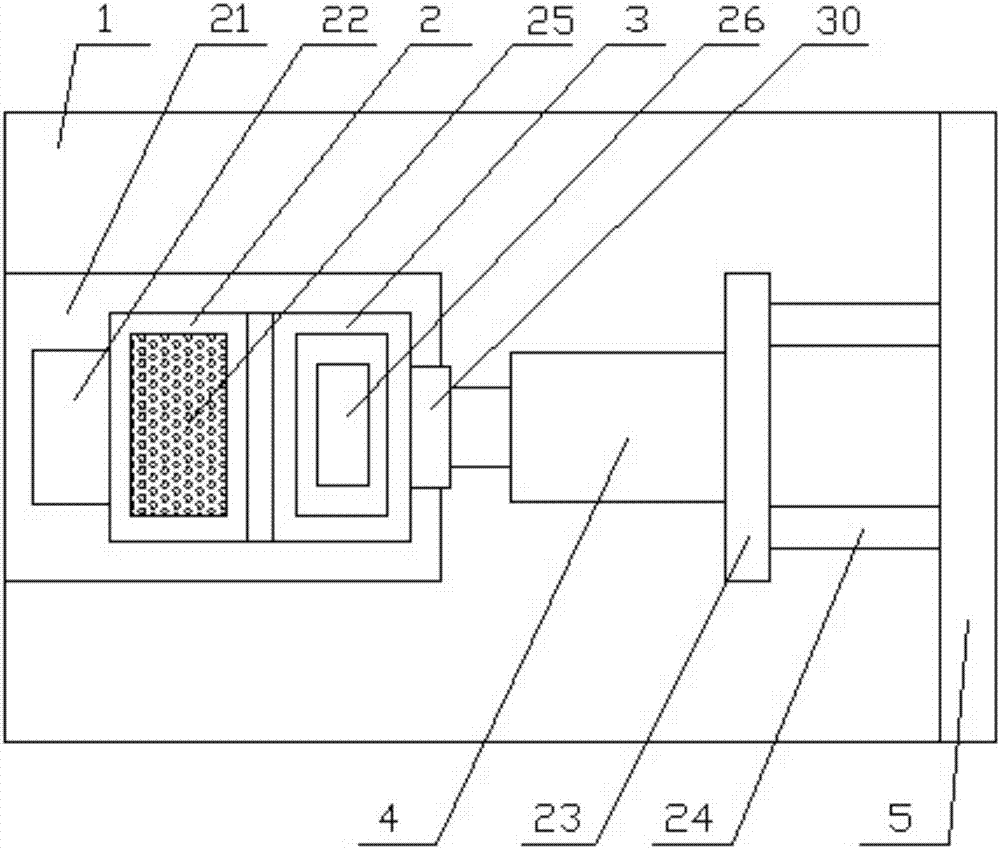

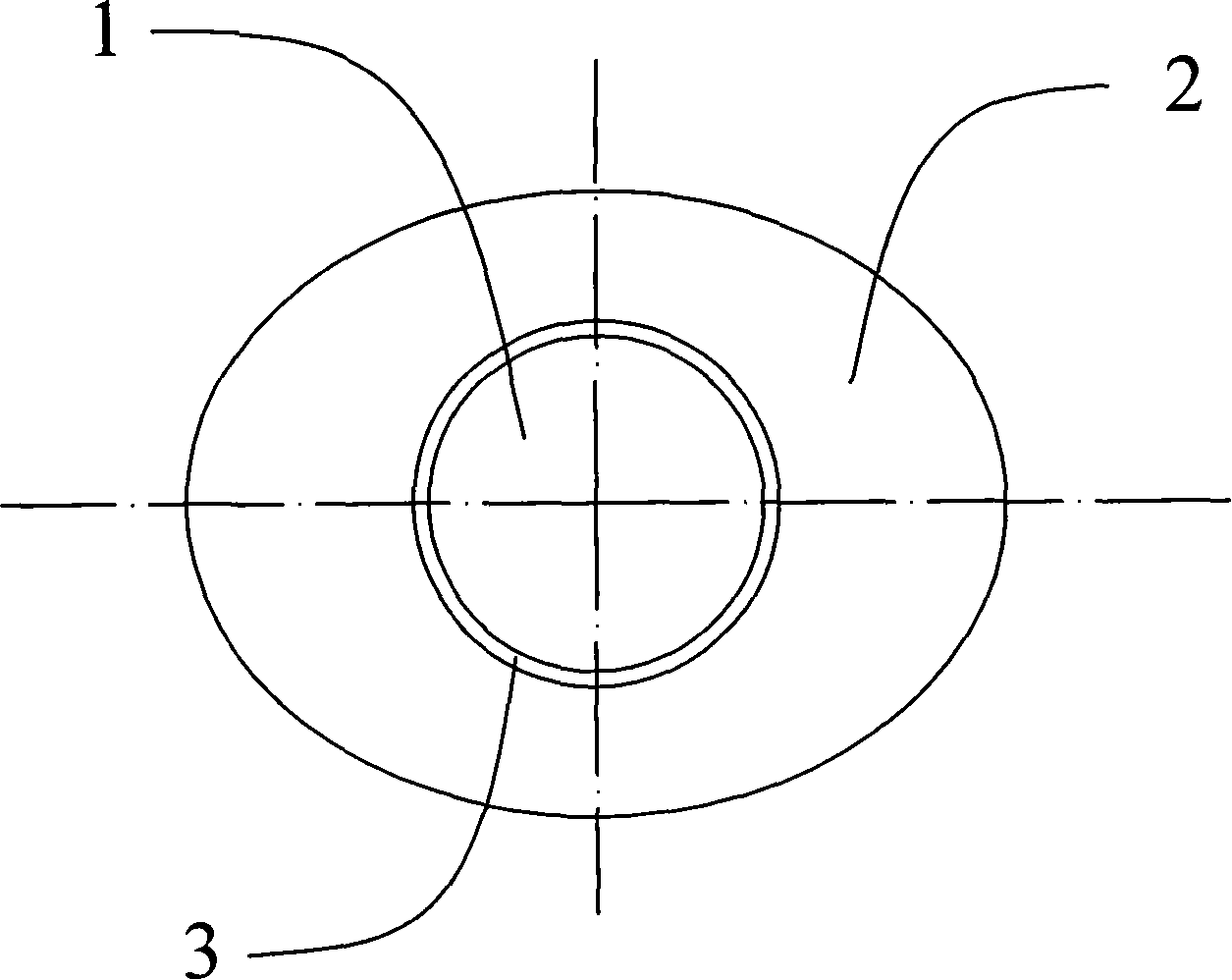

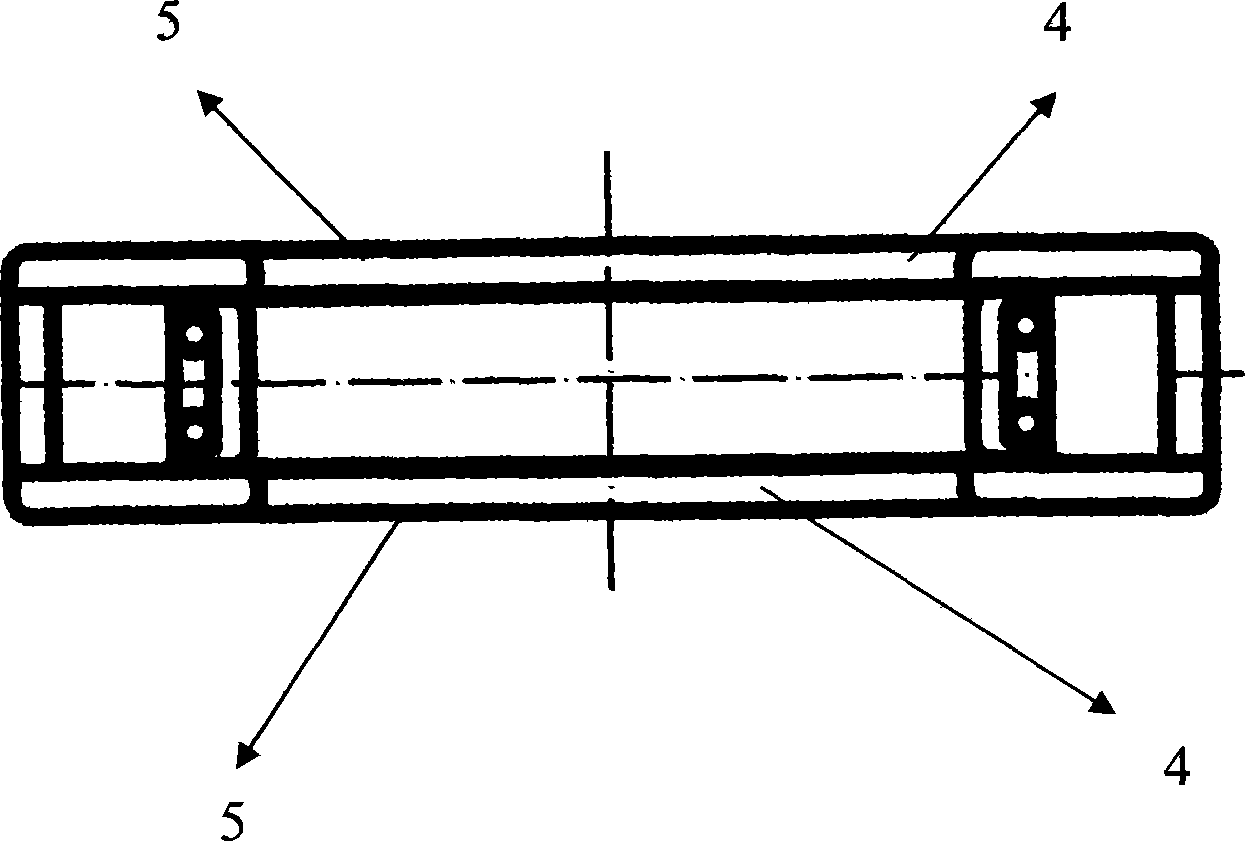

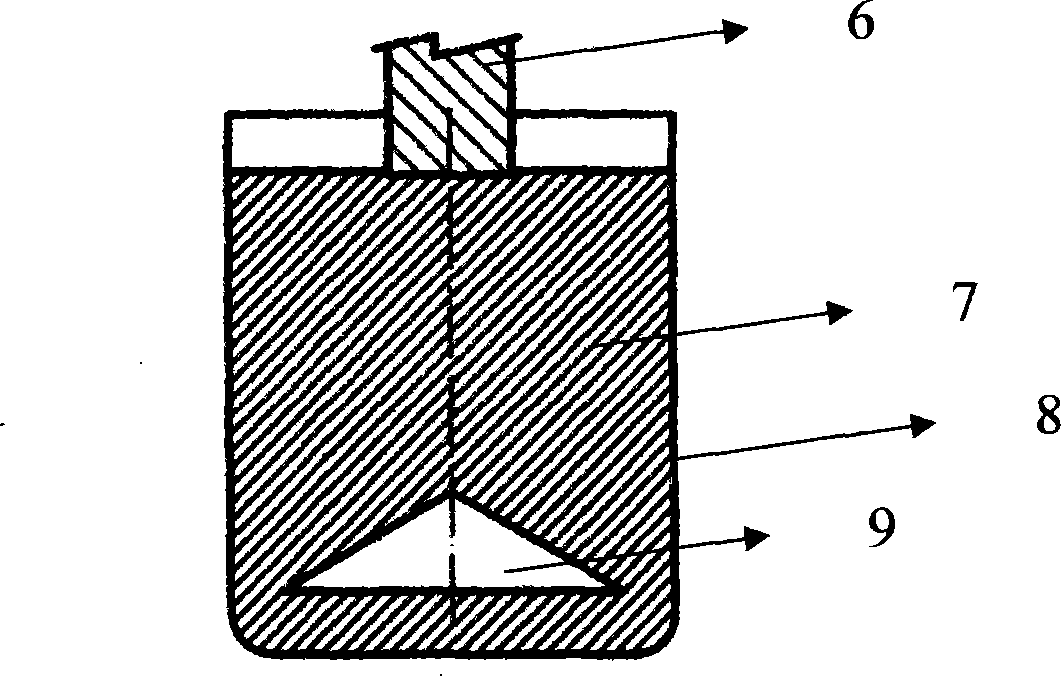

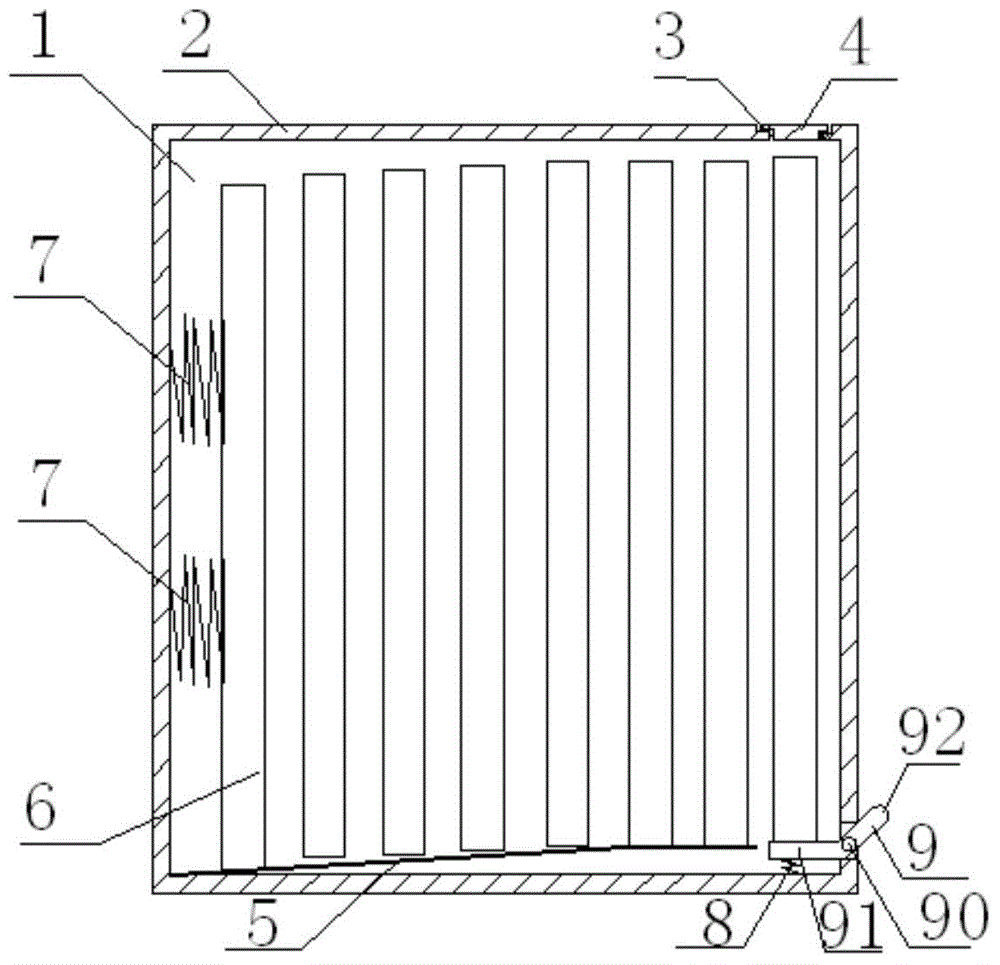

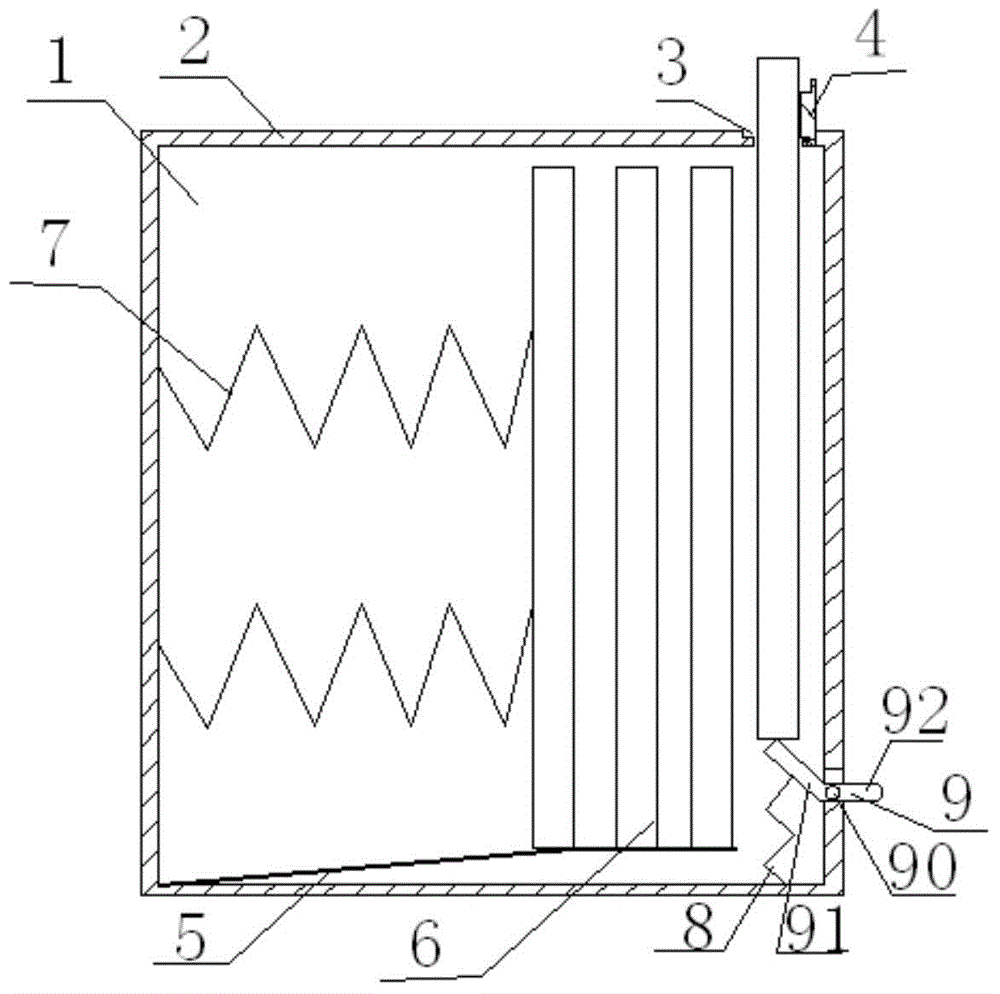

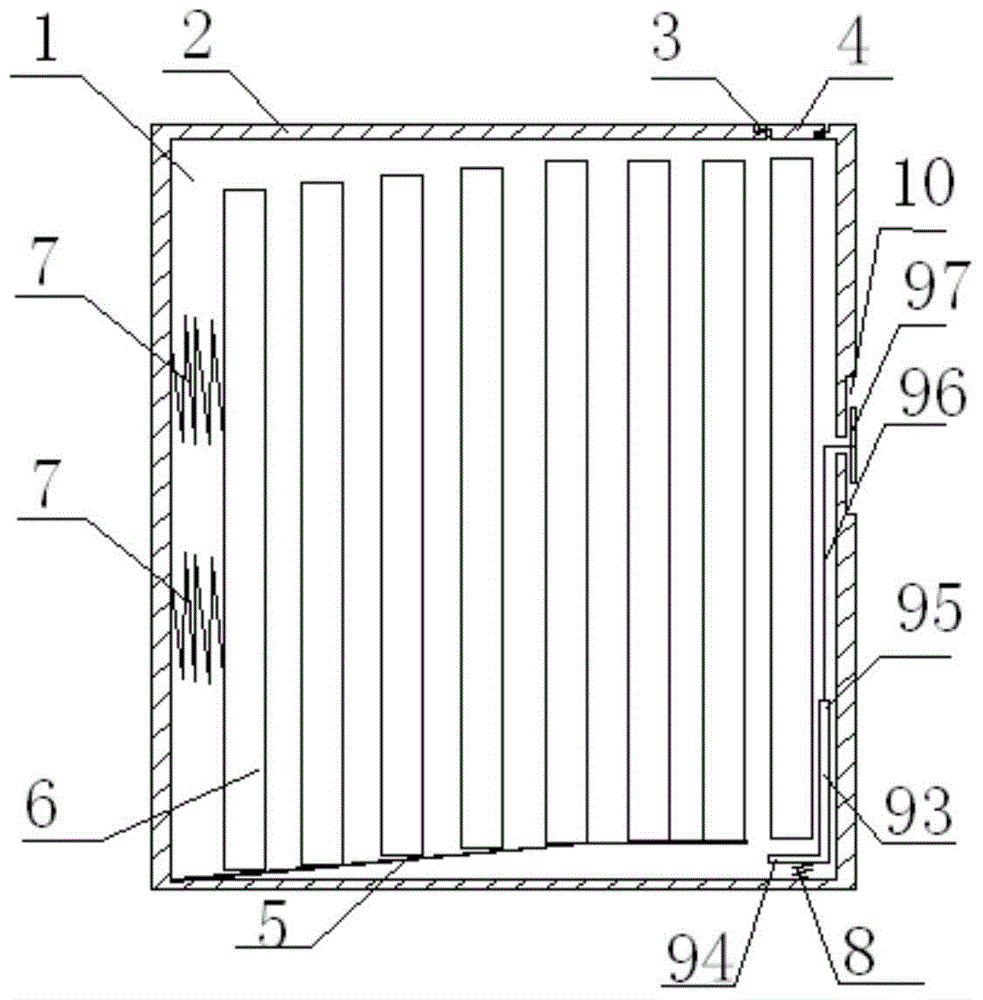

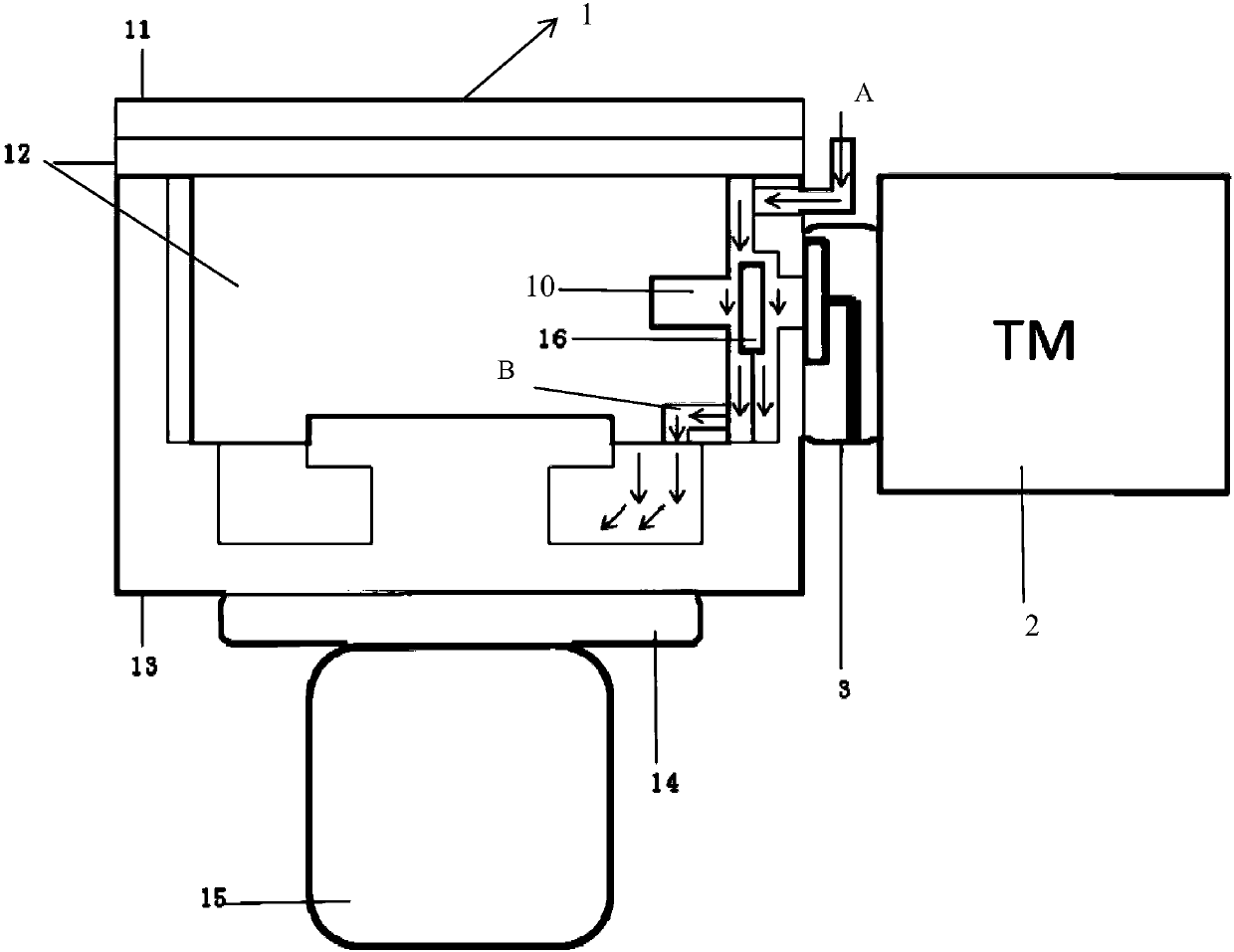

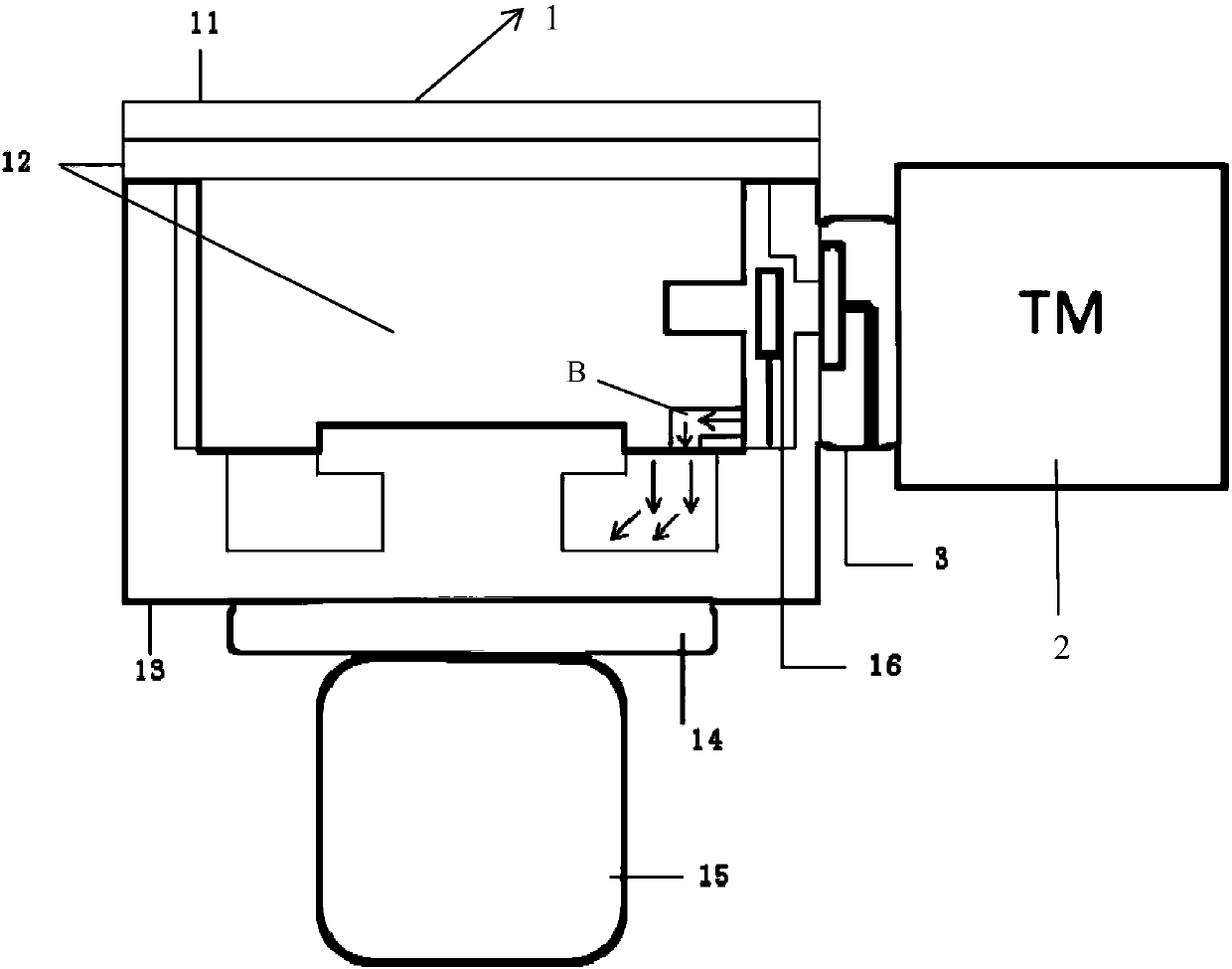

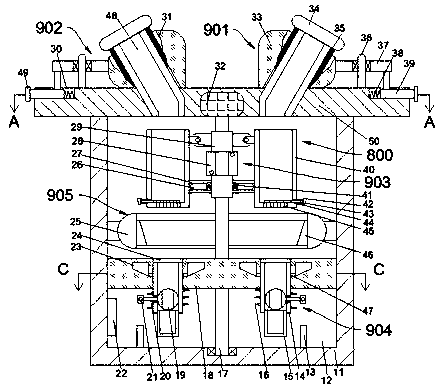

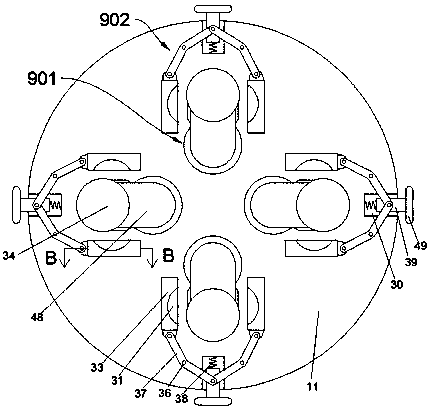

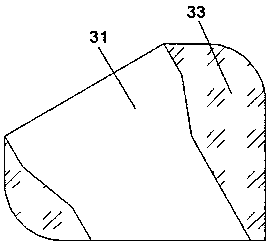

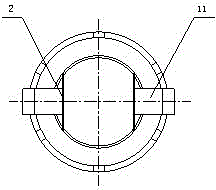

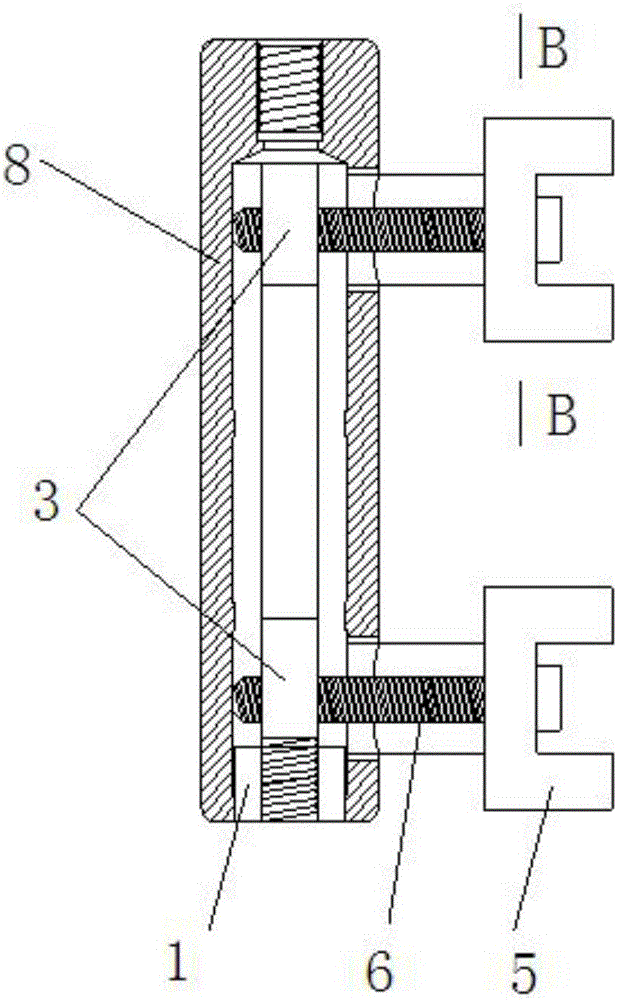

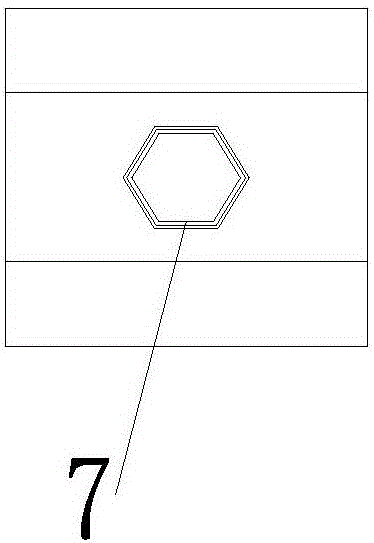

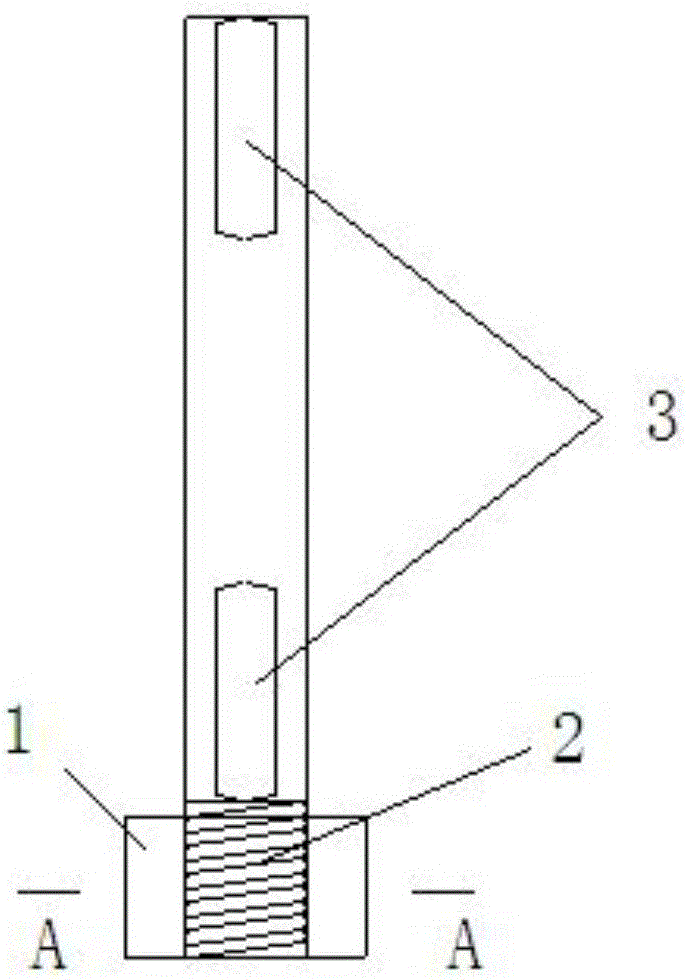

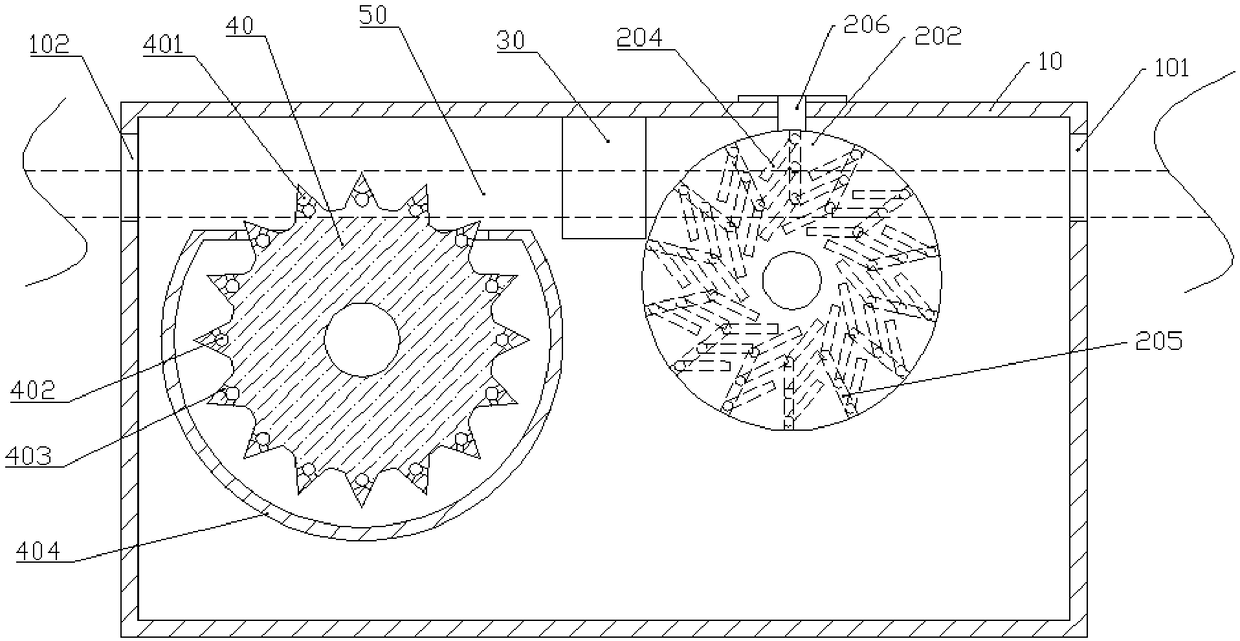

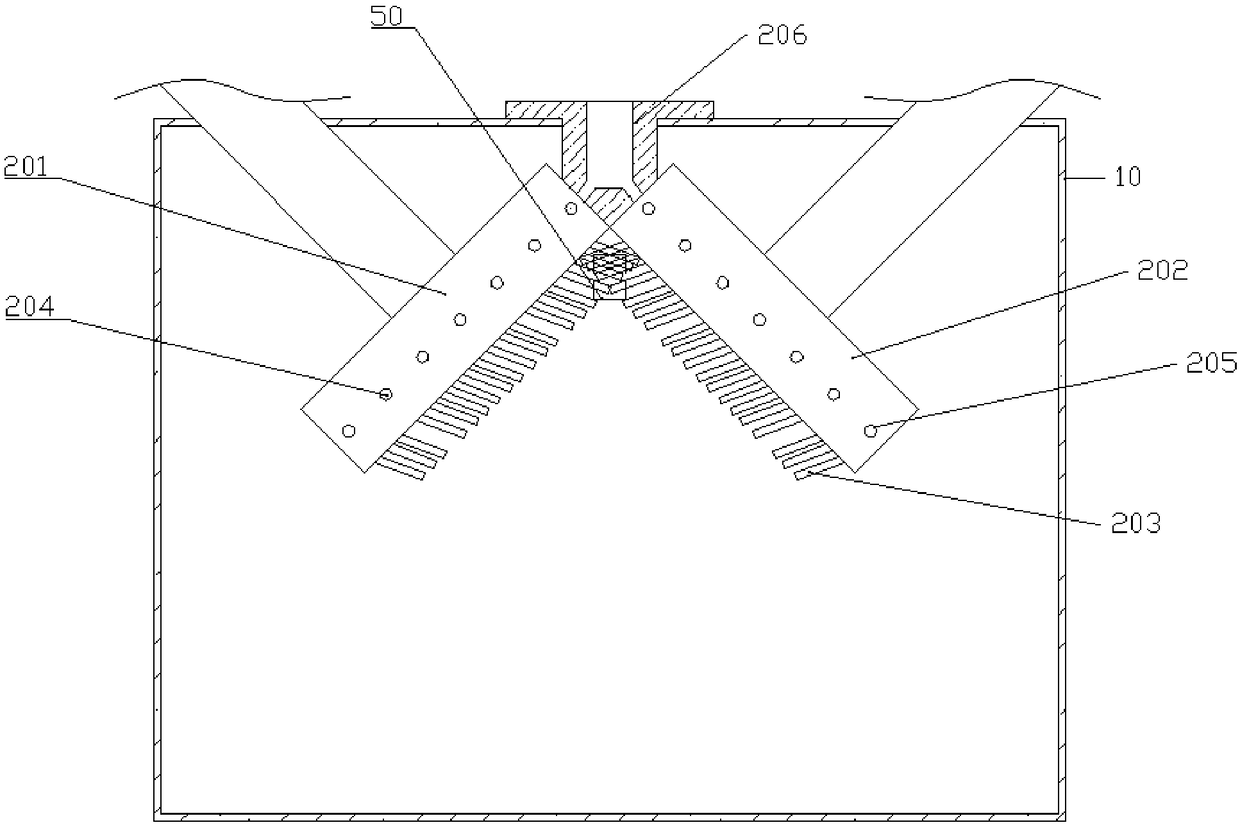

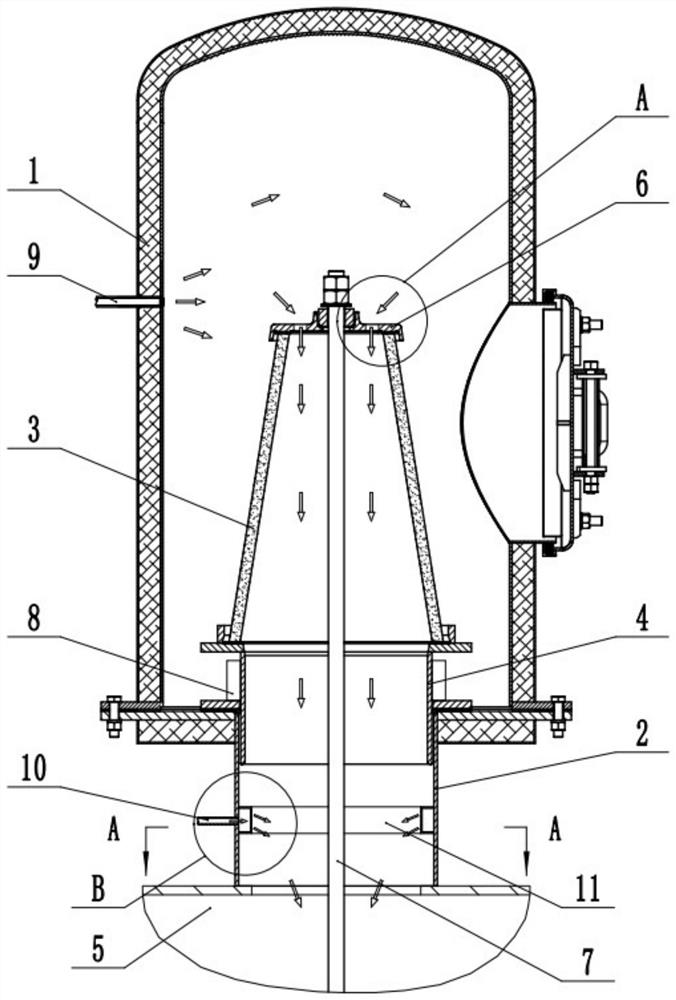

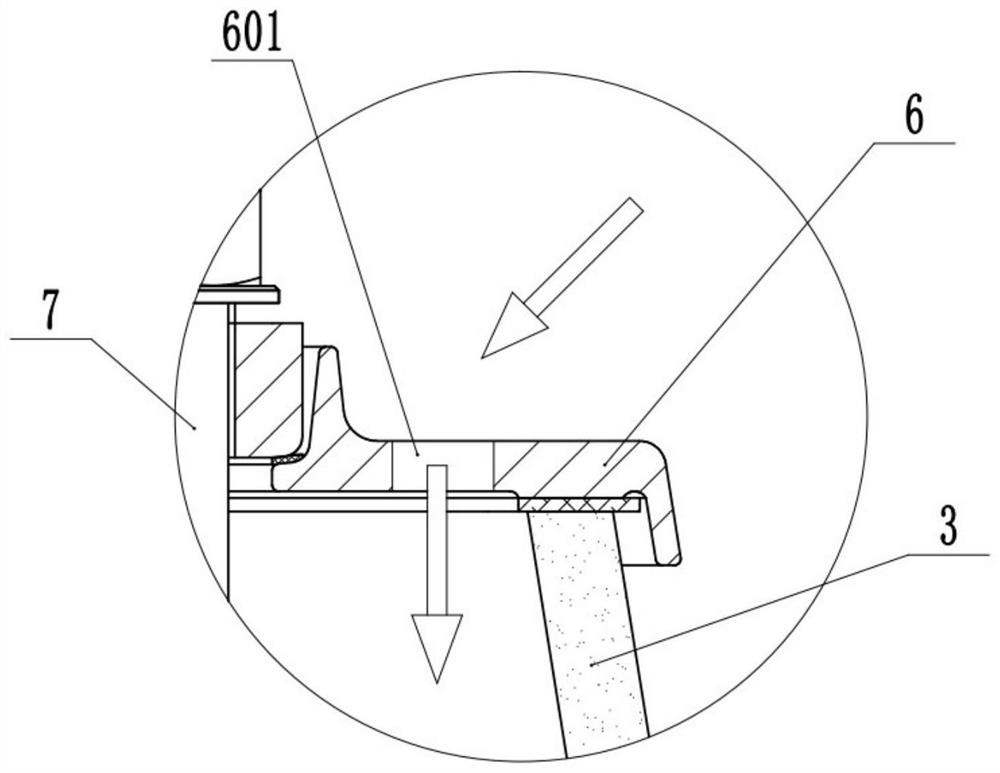

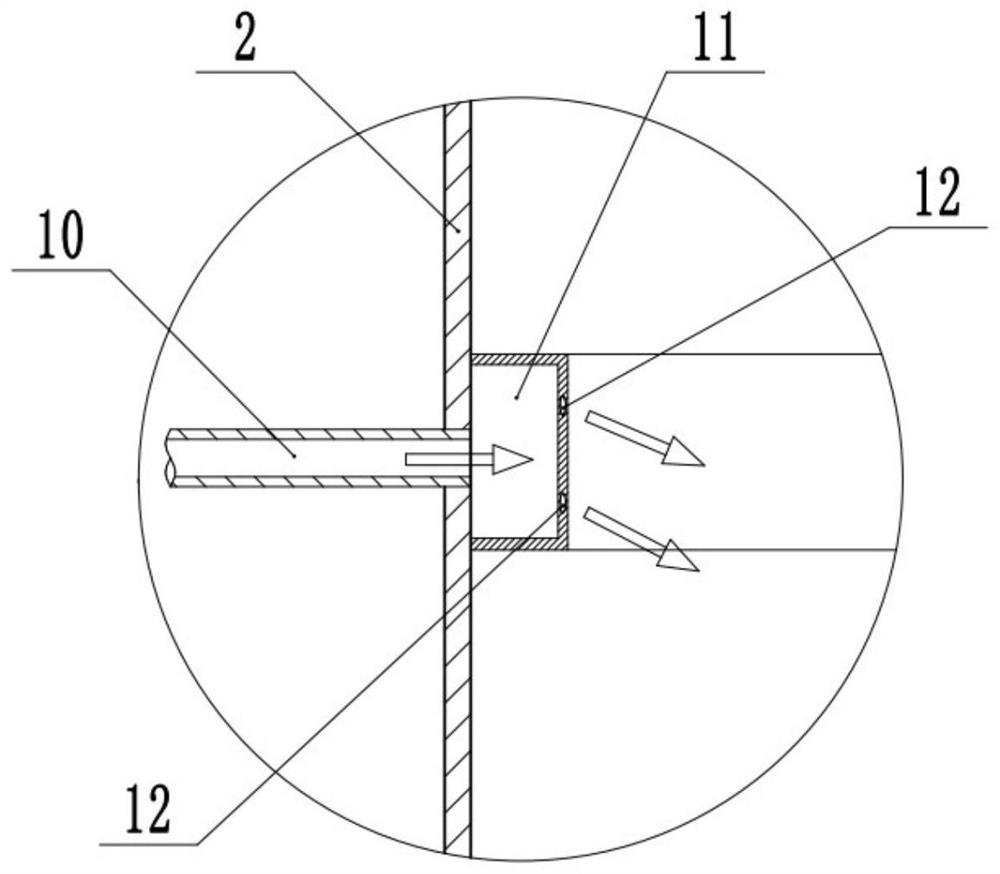

The invention discloses a multifunctional magnetic control sputtering film plating device which is characterized in that a substrate frame is fixedly connected to a top cover of a vacuum chamber and suspended in the vacuum chamber, and the substrate frame is arranged to a structural form capable of rotating and lifting; a substrate carrier is arranged on the bottom surface of a disk arranged at the bottom of the substrate frame, and a heating device is arranged at a position corresponding to the substrate carrier and positioned above the disk; magnetic control sputtering targets are uniformly arranged in the body of the vacuum chamber at positions relative to the substrate carrier on the same circumference of a bottom plate of the vacuum chamber; the inclined angles of the target heads of the magnetic control sputtering targets facing towards the spindle direction of the vacuum chamber are 0-45 degrees and can be adjusted; and sputtering baffles capable of turning over are arranged on the target heads. The multifunctional magnetic control sputtering film plating device has compact structure, miniaturization arrangement and multiple functions of depositing a single film, multiple films and a compound film meanwhile.

Owner:王君

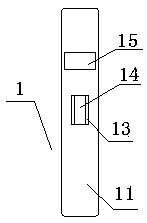

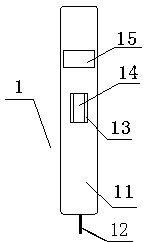

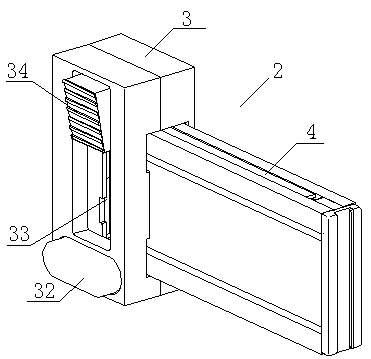

Multifunctional magnetron sputtering film coating device

InactiveCN103290379AEasy to disassemble and maintainAchieve cleaningVacuum evaporation coatingSputtering coatingSputteringEngineering

The invention discloses a multifunctional magnetron sputtering film coating device. The device comprises a vacuum chamber, a top cover, a connecting rod and a substrate frame, wherein the top cover is detachably connected onto the top of the vacuum chamber; the connecting rod is fixedly connected onto the top cover and arranged within the vacuum chamber in a suspension way, the substrate frame is in cup joint with the lower end of the connecting rod in a rotating and lifting way, a plurality of substrate carriers are arranged on the bottom surface of a disc at the bottom of the substrate frame, and heating devices are arranged above the disc and on the positions which correspond to the substrate carriers; a plurality of magnetron sputtering targets arranged on the same periphery are arranged on the position where the bottom of the inner cavity of the vacuum chamber corresponds to the substrate carriers, an inclined angle which is available between the target head arranged at the upper part of each magnetron sputtering target and the main shaft of the vacuum chamber can be adjusted from 0-45 degrees, and a turnover sputtering baffle plate is arranged under the target heads on the magnetron sputtering targets. The device has the characteristics of being compact in structure, high in practicability, and diversified in function, and the requirement for the research of a thin-film technology and a component test by a magnetron sputtering method in the colleges and universities and the scientific research institutions can be met.

Owner:HEFEI LIHENG HYDRAULIC SYST

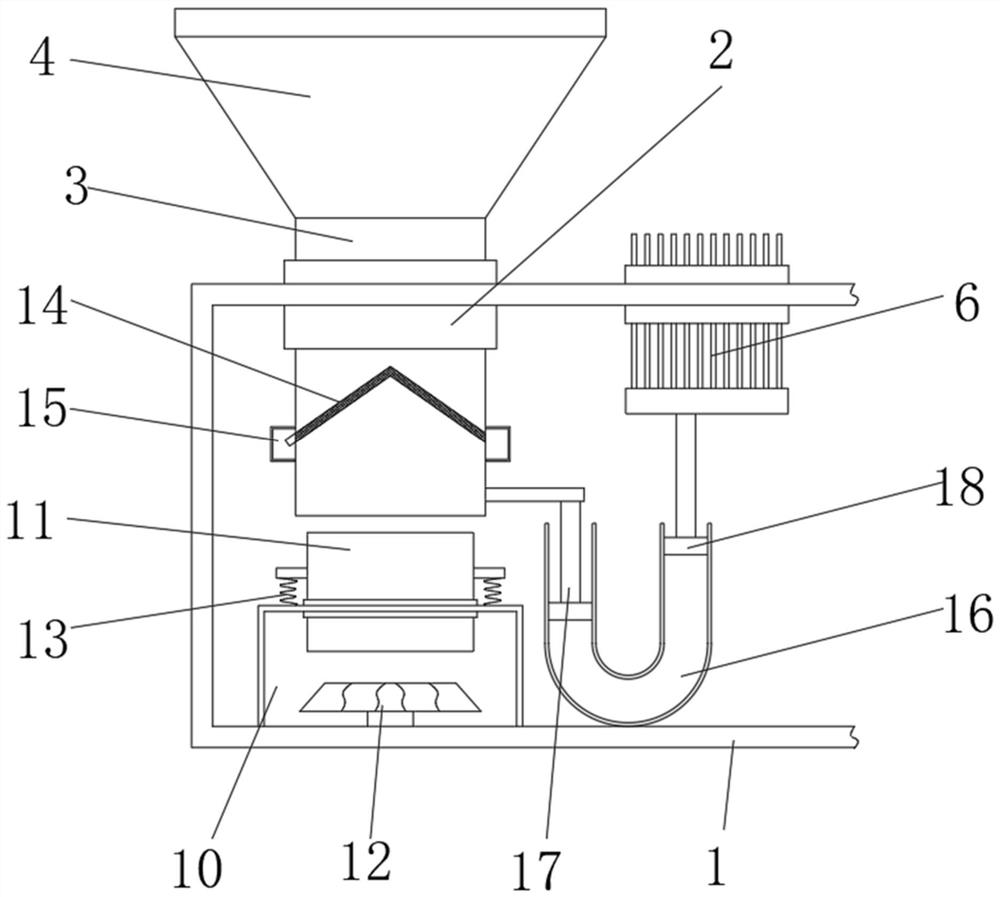

Vegetable drug juice extracting device for biological pharmacy

The invention discloses a vegetable drug juice extracting device for biological pharmacy. The vegetable drug juice extracting device for the biological pharmacy comprises a device base. The device base is provided with a juice collection box and a residue collection box in a sliding manner. One end of the device base is provided with a vertical plate. The middle portion of the vertical plate is provided with a controller. The upper portion of the vertical plate is provided with a feeding oil cylinder. The feeding oil cylinder coordinates with a feeding push head. The feeding push head is in sliding fit with a feeding square cylinder. The upper portion of the feeding square cylinder is connected with a feeding cylinder. The upper portion of the feeding cylinder is provided with a charging motor. The end portion of the feeding square cylinder is provided with a dividing device. The end portion of the feeding square cylinder coordinates with a conveying channel. The conveying channel is connected with a juice pressing cylinder. The juice pressing cylinder is internally provided with a juice pressing push head in a sliding manner. The vegetable drug juice extracting device for the biological pharmacy is easy to operate, convenient to control, capable of rapidly extracting vegetal juice and conveying the juice to the position of the next treating working procedure and high in automation degree and has a vegetal residue recovering function.

Owner:袁兴文

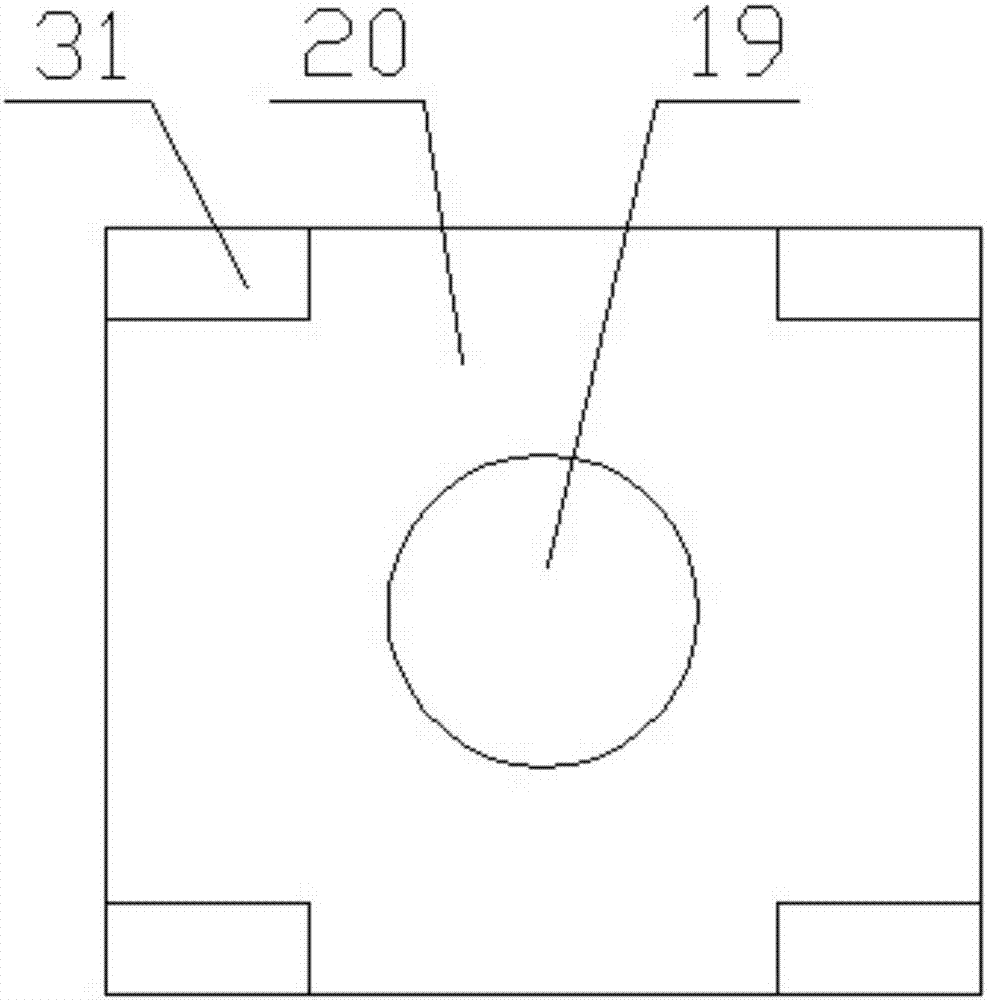

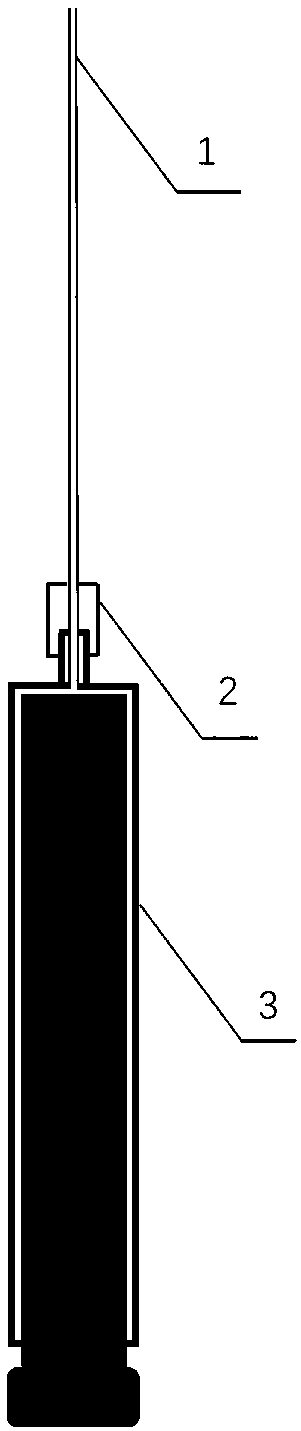

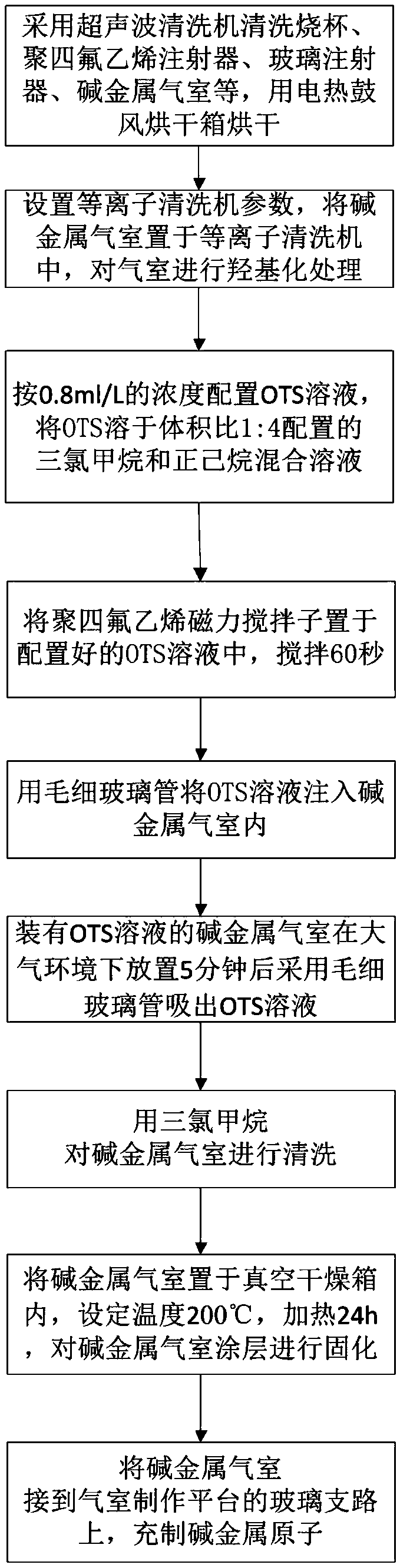

Alkali metal air chamber manufacturing method for improving relaxation resistance of coating based on Plasma hydroxylation

ActiveCN109518177AReduce pollutionImproved anti-relaxation propertiesMetallic material coating processesProblem of timeEngineering

The invention relates to an alkali metal air chamber manufacturing method for improving the relaxation resistance of a coating based on Plasma hydroxylation. According to the method, a plasma cleaningmachine is adopted for hydroxylating the inner surface of an air chamber; since a tail pipe of the alkali metal air chamber is thin, the operation that a thick cleaning solution needs to be extractedby adopting a capillary glass tube after cleaning through a traditional hydroxylation method is omitted, so that the air chamber is prevented from being pricked during a cleaning solution extractionprocess, and the problems of time waste, effort waste, nonideal consistency and nonideal relaxation resistance during the current air chamber manufacturing process are solved; and meanwhile, more hydroxide radicals can be formed on the glass surface, and no cleaning solution removal and follow-up drying is needed, so that the contact time of the hydroxide radicals and the outside environment is shortened, the hydroxide radical pollution is reduced, more hydroxide radical number can be maintained, a smooth and uniform covering surface is realized during the organochlorosilane reaction process,the surface covering rate on paramagnetic impurities is increased, and the relaxation resistance of the coating is improved. In addition, multiple air chambers can be processed at the same time, so that the consistency and the repeatability in manufacturing the coating are improved.

Owner:杭州诺驰生命科学有限公司

Medical ultrasound water pad

InactiveCN101224326ANot stimulatingWon't hurtUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyUltrasonographyPaperboard

A medical ultrasonic water-cushion is characterized in that the center of the water-cushion is provided with a water bag which is internally filled with steam removing water, and the periphery of the water bag is provided with a self-adhered patch, and a silica gel ring is arranged between the water bag and the self-adhered patch, and the upper side and the lower side of the water bag are provided with medical ultrasonic couplant layers. By adopting the self-adhered patch, the water-cushion can locate the treatment body surface touched by the doctor accurately; displacement of the water-cushion cannot occur in the therapeutic process; ultrasonic energy can be transmitted to the treated area of patients; stimulation or damage to the skin surface of patients cannot occur; an elastic latex film of the water-cushion can eliminate ultrasonic low frequency clutter, thus easing unconformable of patients; the ultrasonic water-cushion with the self-adhered location can be single-used, and owning to ex-factory disinfection treatment, routine disinfection is not needed before using, thus simplifying the operation procedure, avoiding cross infection of hospital source; the couplant is sealed by a light pressure paperboard to avoid the pollution to the couplant.

Owner:吴晓歌

Peritoneal dialysis solution product packaged by non-PVC soft bag and production method of peritoneal dialysis solution product

ActiveCN107554877ASmooth and stable feedingGuaranteed not to be pollutedBagsSacksPeritoneal dialysis fluidCatheter

The invention discloses a peritoneal dialysis solution product packaged by a non-PVC soft bag and a production method of the peritoneal dialysis solution product, and belongs to the technical field ofperitoneal dialysis. The peritoneal dialysis solution product packaged by the non-PVC soft bag comprises a packaging system which comprises a peritoneal dialysis solution bag, a medicine liquid guiding pipe and a waste liquid guiding pipe; a peritoneal dialysis solution is contained in the peritoneal dialysis solution bag; a sterile outer packaging bag is arranged outside the packaging system; the peritoneal dialysis solution bag is the non-PVC plastic infusion bag produced by a co-extruded film in a manner of dual films; a medicine adding pipe is connected to the infusion bag in a welded manner; an infusion pipe is further connected to the infusion bag in a welded manner; and the medicine liquid guiding pipe and the waste liquid guiding pipe can each be coiled into a circle with the diameter being 10-15 cm, and are each provided with a clamping device. According to the peritoneal dialysis solution product packaged by the non-PVC soft bag and the production method of the peritoneal dialysis solution product, the non-PVC plastic infusion bag is adopted for containing the peritoneal dialysis solution, and harm of a PVC packaging bag to a patient is avoided; and the infusion bag is connected with the medicine adding pipe and the infusion pipe both in the welded manner, and the phenomenon that when a soft bag made from a non-PVC film material is used for containing large-capacitypreparations, solution leakage happens easily is avoided.

Owner:HUAREN PHARMA (RIZHAO) CO LTD

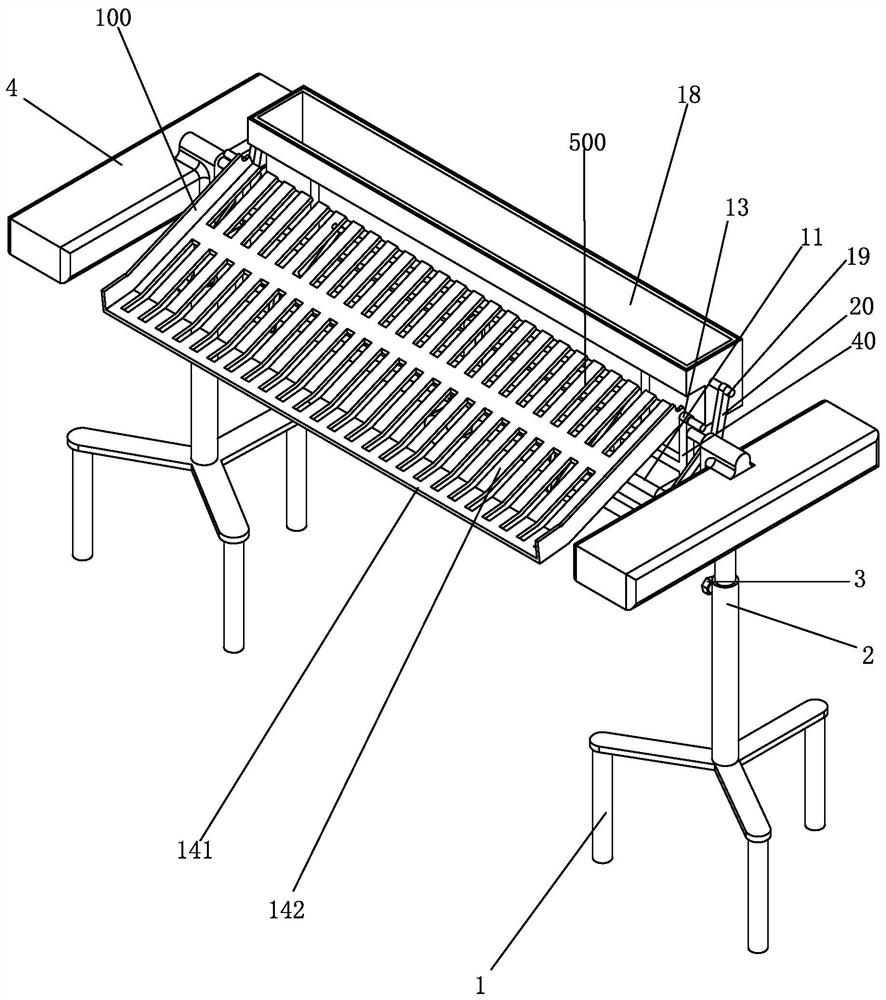

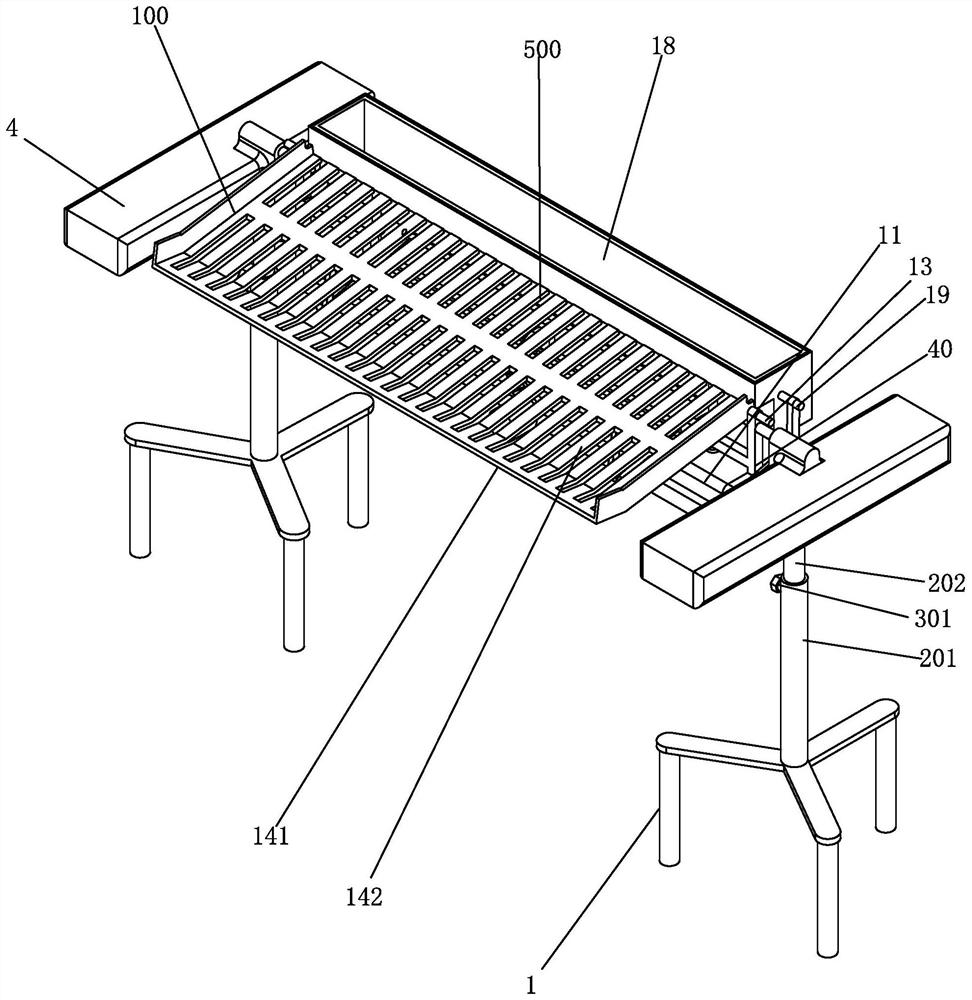

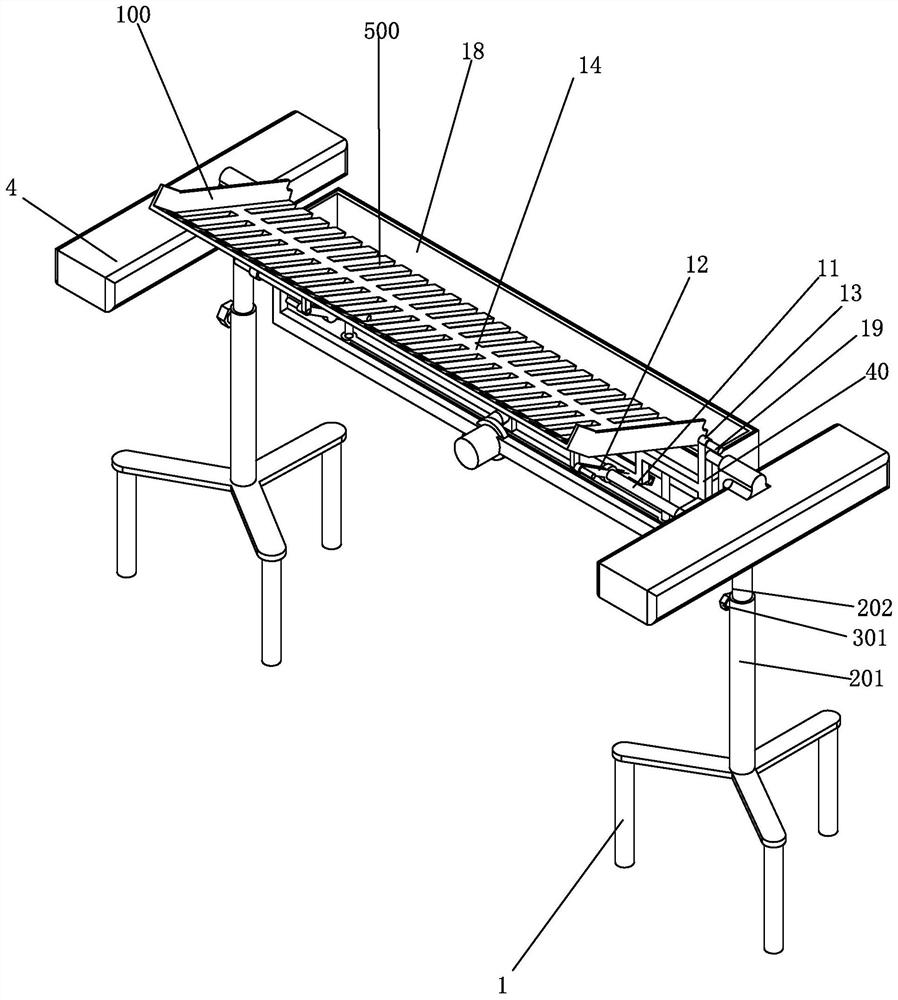

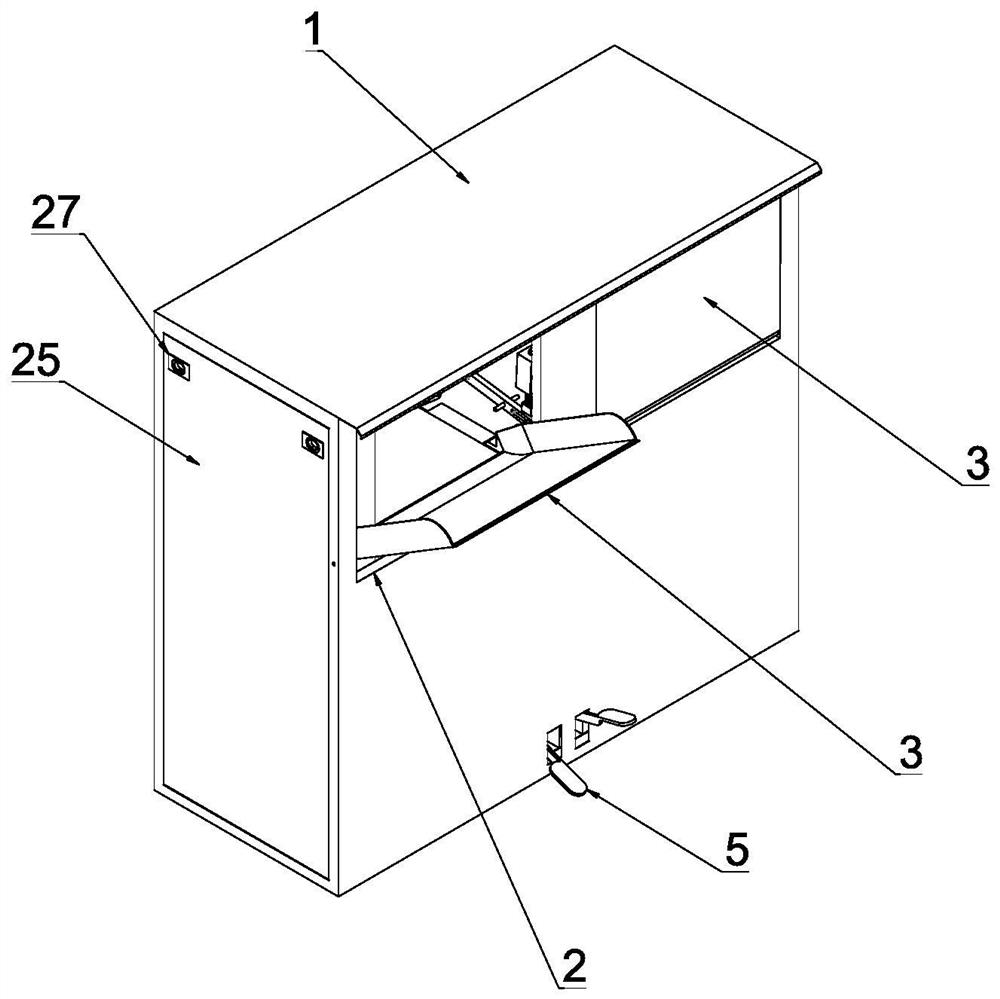

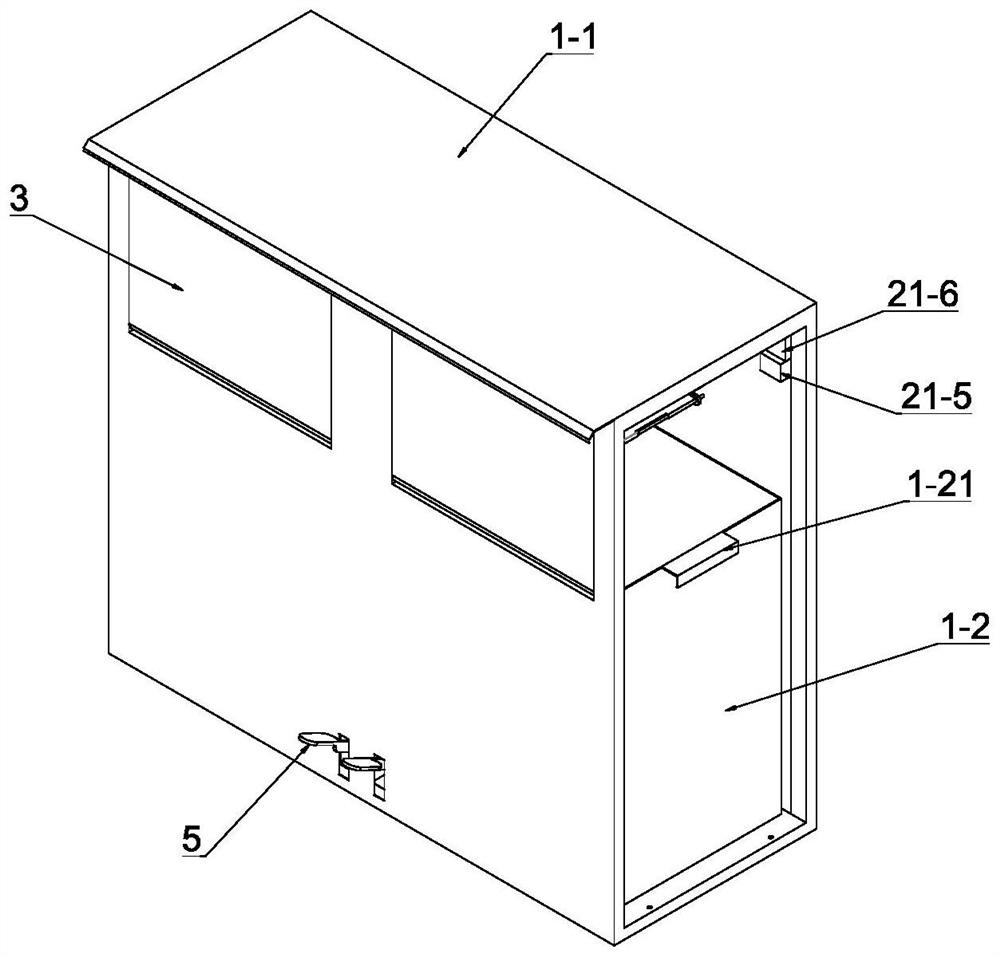

Usage box capable of automatically fetching and using absorption products

ActiveCN105584736AGuaranteed not to be pollutedDispensing apparatusEngineeringMechanical engineering

Owner:GOLD HONG YE PAPER

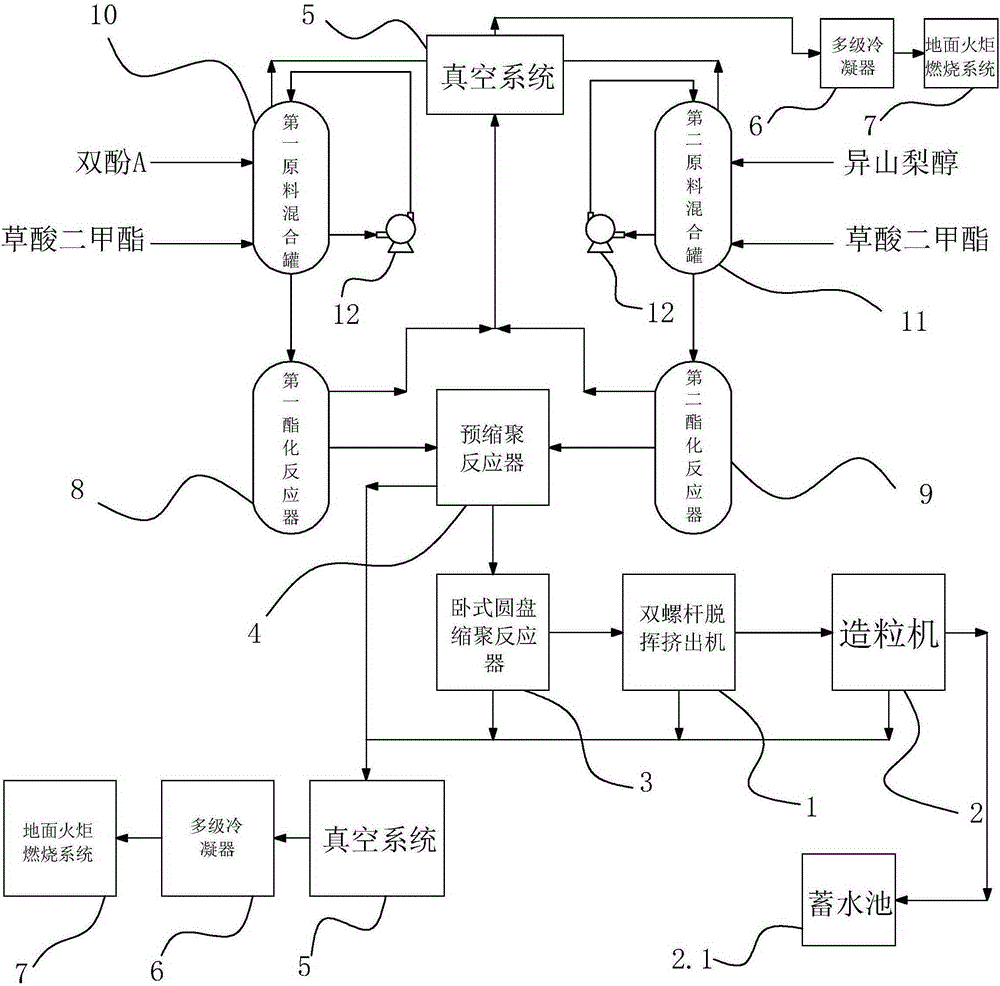

Polycarbonate production system

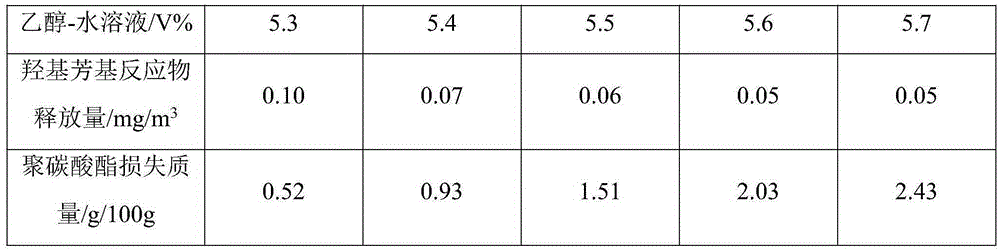

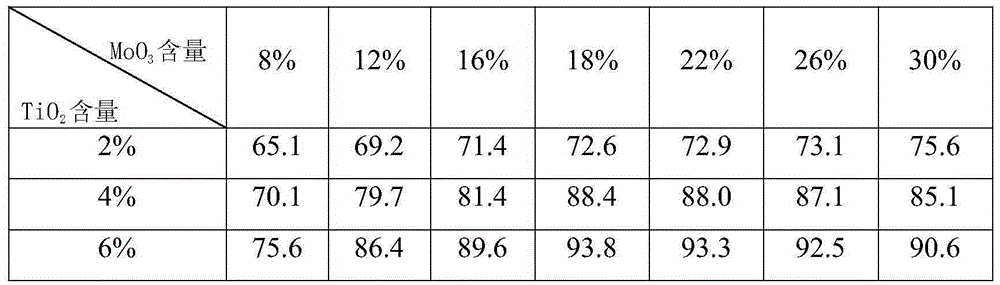

A polycarbonate production system comprises a devolatilization and granulation system. The devolatilization and granulation system comprises a double-screw devolatilization extruder, a granulation machine and a water storage pool. The double-screw devolatilizaiton extruder is communicated with the granulation machine. A particle output opening of the granulation machine is soaked below the liquid level in the water storage pool. In the polycarbonate granulation process, due to the fact that output polycarbonate particles are high in temperature at this moment, a great amount of hydroxyl aryl group reaction products are still volatilized, the volatilized hydroxyl aryl group reaction products can be absorbed while polycarbonate is extruded out by the double-screw devolatilizaiton extruder. The particle output opening of the granulation machine is located below the water surface in the water storage pool, the particles can be shaped quickly under the action of the cooling function of cooling water after being output, meanwhile, ester bond combination in the particles is firmer under the rapid cooling condition, and thus the rigidity of the particles is enhanced; and besides, the cooling water can absorb the hydroxyl aryl group reaction products to prevent the hydroxyl aryl group reaction products from entering the atmosphere.

Owner:NINGBO ZHETIE DAPHOON CHEM

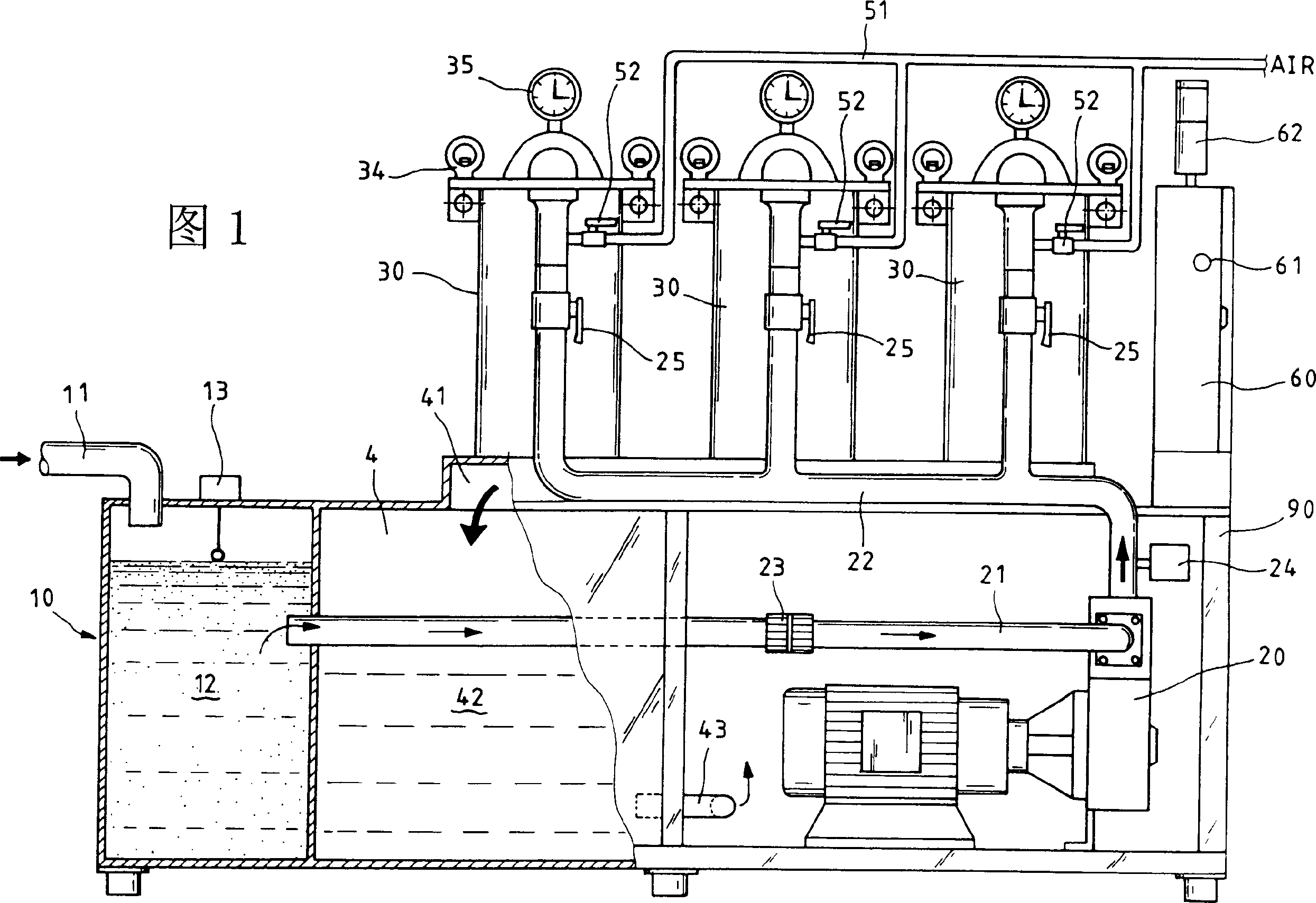

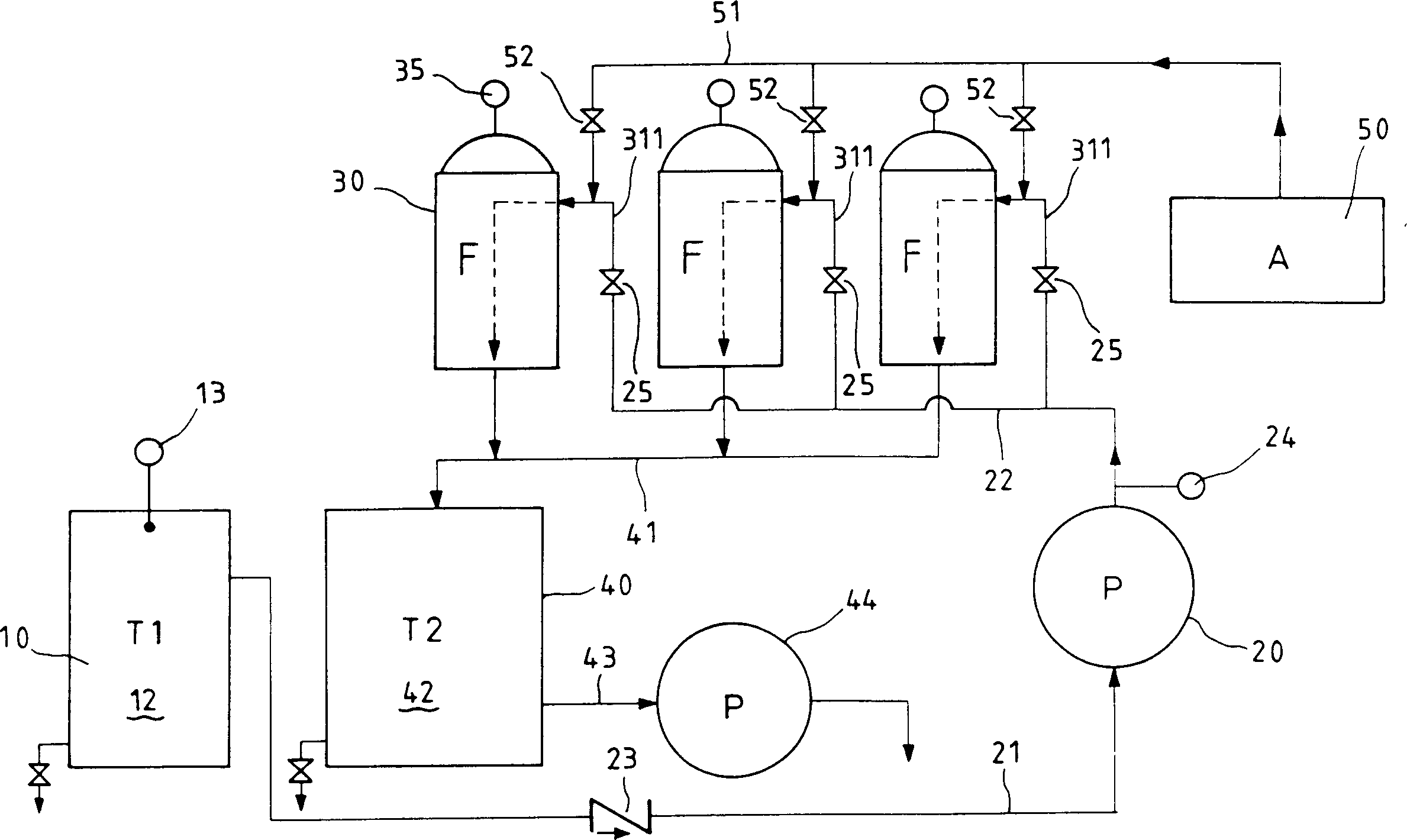

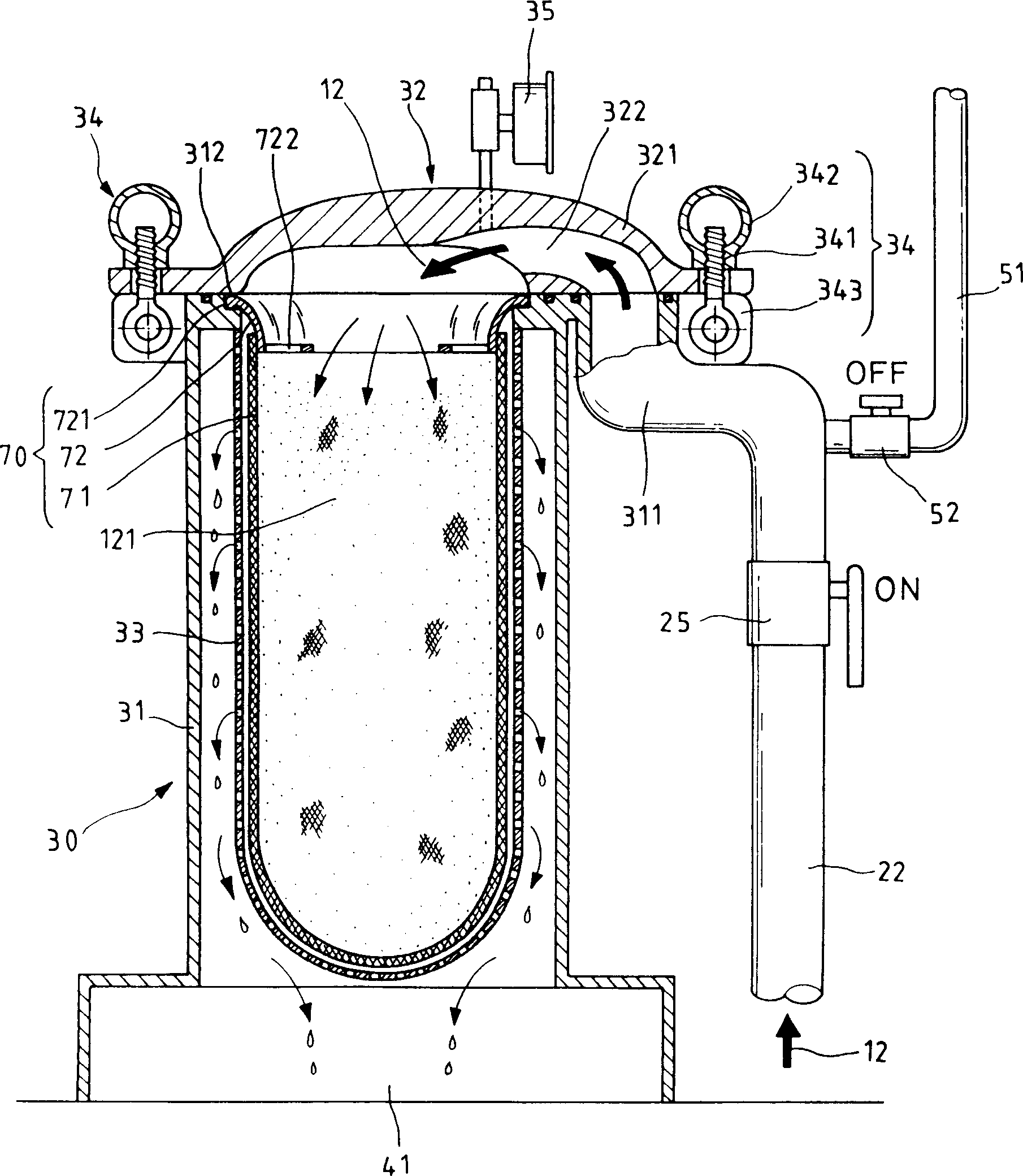

Precise water resource reclaiming machine

InactiveCN1704341AAchieve securityImprove filtration efficiencyWater/sewage treatmentFiltrationSpray nozzle

The invention relates to a water resource precise reclaiming machine, which comprises an exhausted liquid receiving tank, a pump exhausting end connected with the exhausted liquid receiving tank through a pumping pipe, an upper meshed groove is arranged in the filtration tube, the meshed groove is provided with a supporting surface for positioning a filtering bag consisting a bag body and a positioning frame, a tube cover is mounted on the upper portion of the tube through a locking piece, the tube cover is provided with an extension section on one side, the extension section is provided with a spray nozzle, the filtration water reclamation tank is arranged below the filtration cartridge reclamation tube.

Owner:邱 鸿芳

Plasma processing device capable of reducing pollution particles and method thereof

ActiveCN109962000AGuaranteed not to be pollutedImprove pollutionElectric discharge tubesChemical vapor deposition coatingVacuum pumpingVacuum pump

The invention discloses a plasma processing device capable of reducing pollution particles and a method thereof. The plasma processing device comprises a cavity and a lining. A dielectric window is arranged above the lining. The cavity, the lining and the dielectric window are enclosed to form a reaction cavity. The inner bottom of the reaction cavity comprises a base for placing a wafer. A vacuumpumping device for pumping gas in the reaction cavity to maintain low pressure in the reaction cavity is arranged on the lower part of the base. A baffle plate shielding between the opening on the side wall of the cavity and the opening on the side wall of the lining is arranged in the cavity to block the pollution particles in the gas flowing from the transmission cavity to the reaction cavity.A hole groove is arranged on the lower part of the lining. The flow space formed by enclosing of the outer wall of the lining and the inner wall of the cavity under the baffle plate is communicated with the inner space of the lining through the hole groove so that the pollution particles are evacuated by the vacuum pumping device. The current wafer is ensured not to be contaminated, the contamination of the next transmission wafer can be improved and the cleaning gas can be piped in so that the effect of taking out the contaminated particles of the reaction cavity can be more remarkable and the efficiency is higher.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

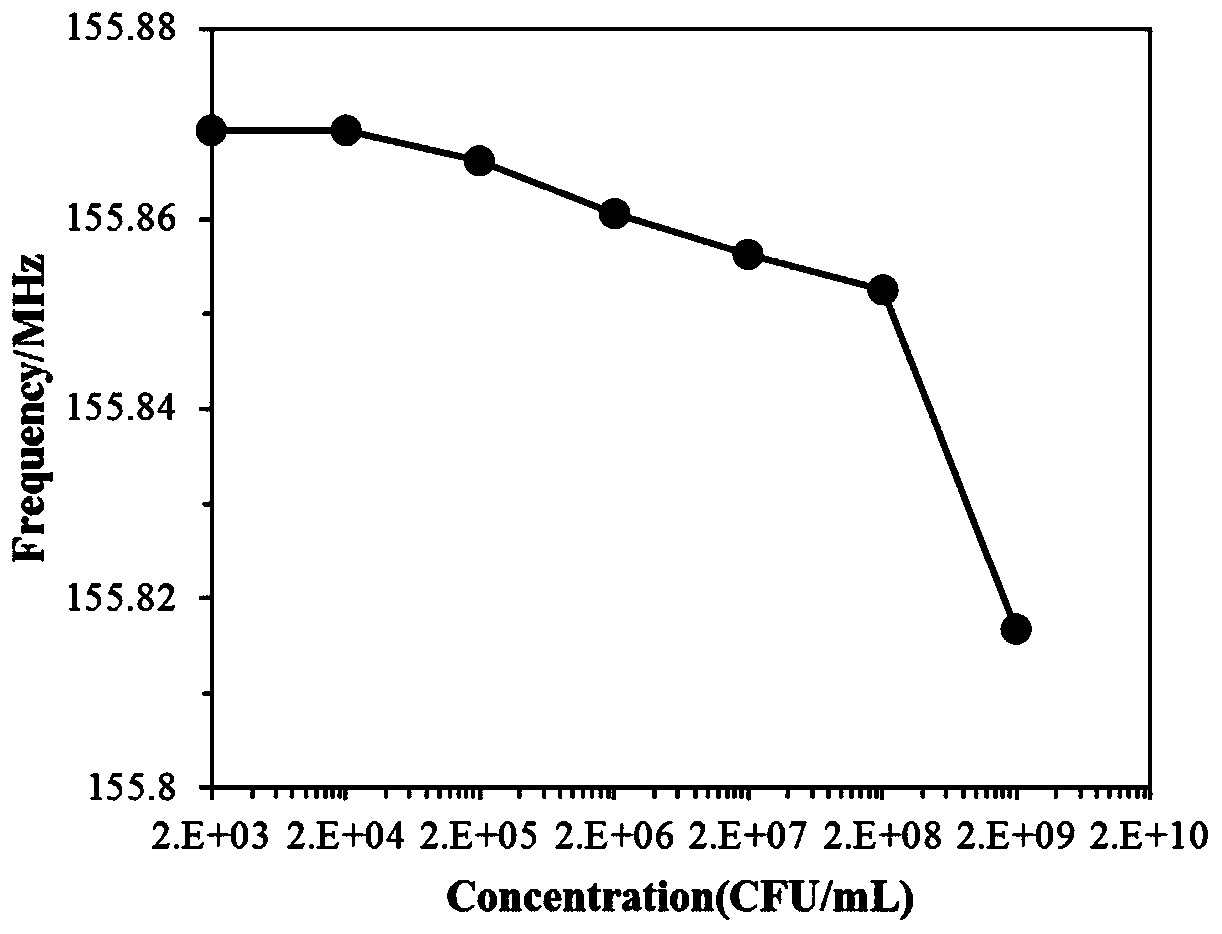

Multifunctional acoustic surface wave sensor and preparation method and application thereof

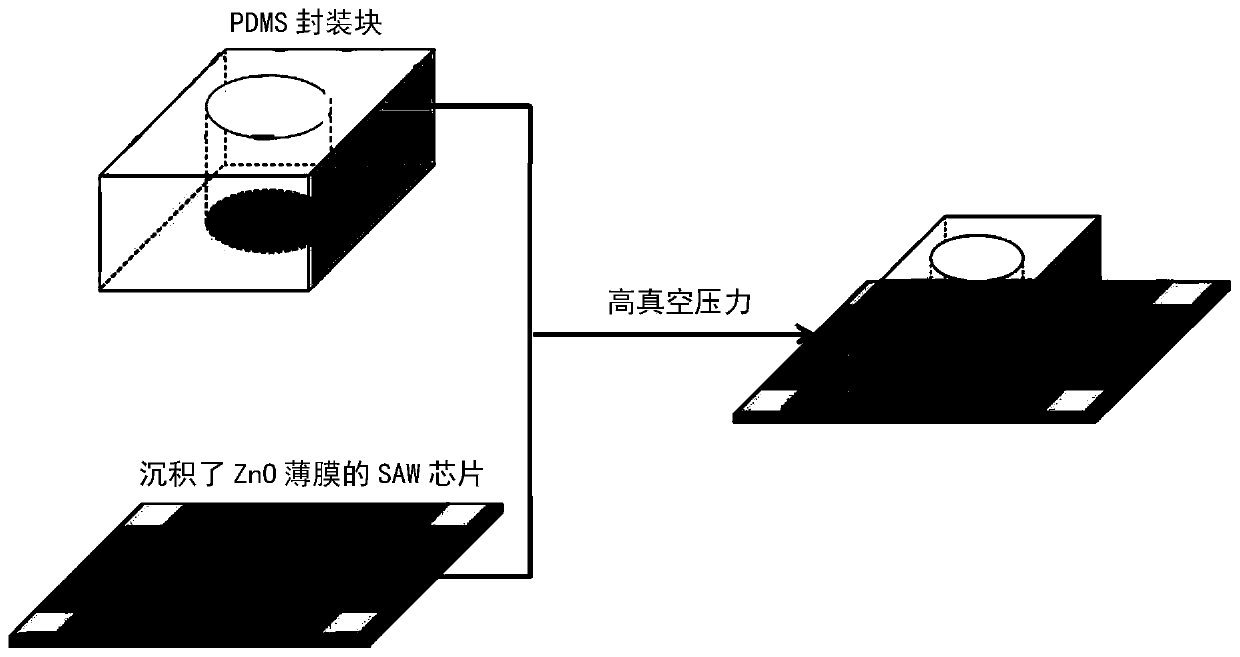

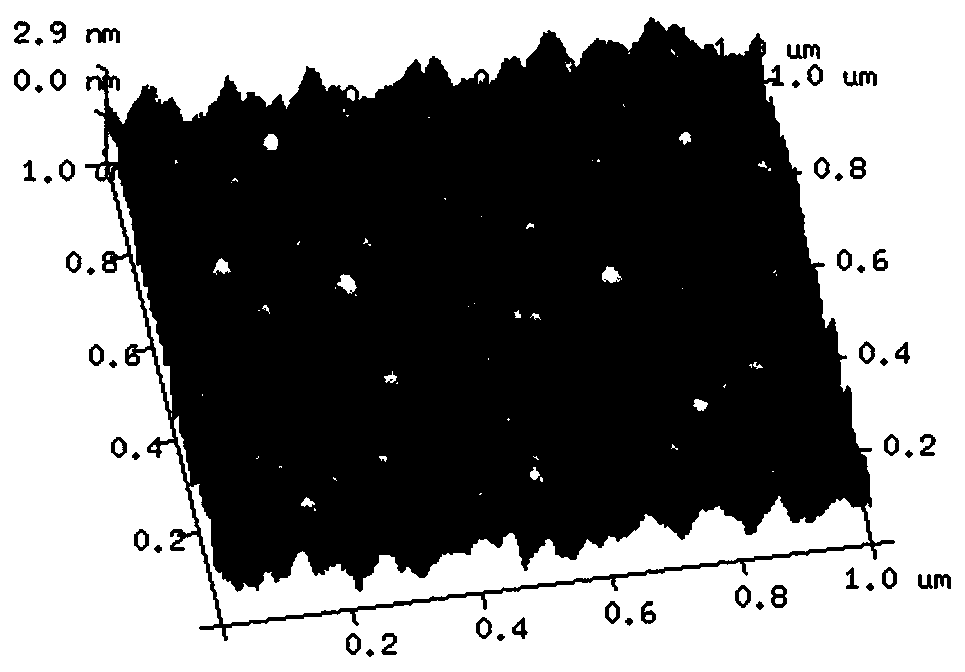

ActiveCN110208369AImplement encapsulationReal-time monitoringAnalysing fluids using sonic/ultrasonic/infrasonic wavesVacuum pressureNanoparticle

Provided in the invention is a method for preparing a multifunctional acoustic surface wave sensor. The method comprises steps: S1, preparing an SAW chip; S2, depositing a ZnO thin film; to be specific, depositing a nano-particle-shaped ZnO thin film with the size of 25 to 45 nm on the surface of the SAW chip by means of magnetron sputtering; and S3, carrying out PDMS packaging; to be specific, preparing a PDMS package block, opening a through hole in the center of the PDMS package block by using a drilling tool, enabling the PDMS package block to be in contact with the ZnO thin film, aligningthe through hole of the PDMS package block at a delay line area of the SAW chip, and realizing bonding of the PDMS package block and the ZnO film under the high vacuum pressure to obtain a multifunctional acoustic surface wave sensor. The preparation method is simple; the sensitive layer and the waveguide layer are protected from being polluted in the preparation process; and the prepared acoustic surface wave sensor is capable of carrying out real-time on-site high-precision monitoring on various various living microorganisms in a liquid phase environment.

Owner:SOUTHWEST JIAOTONG UNIV

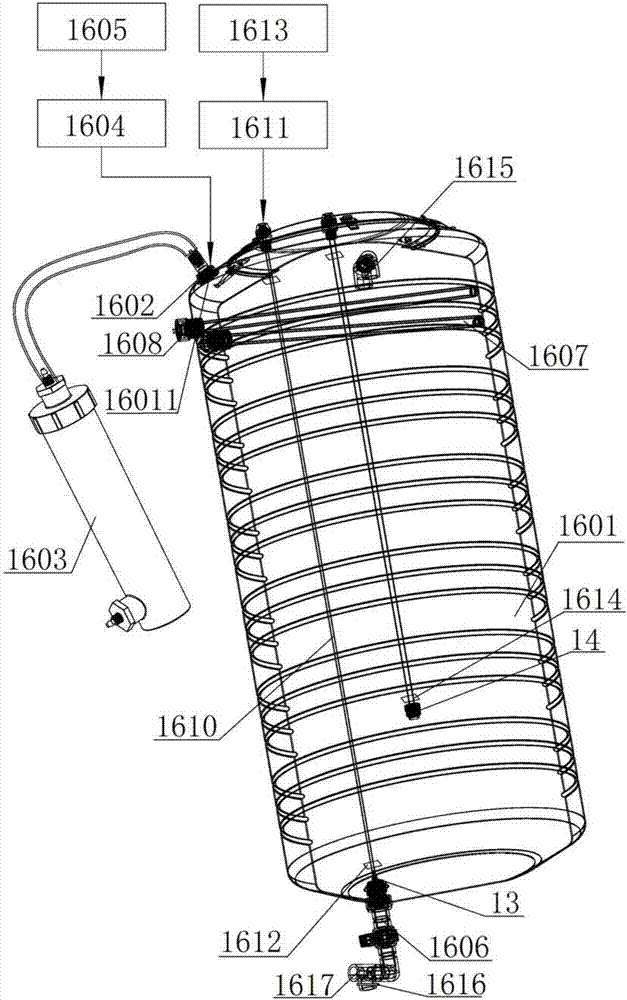

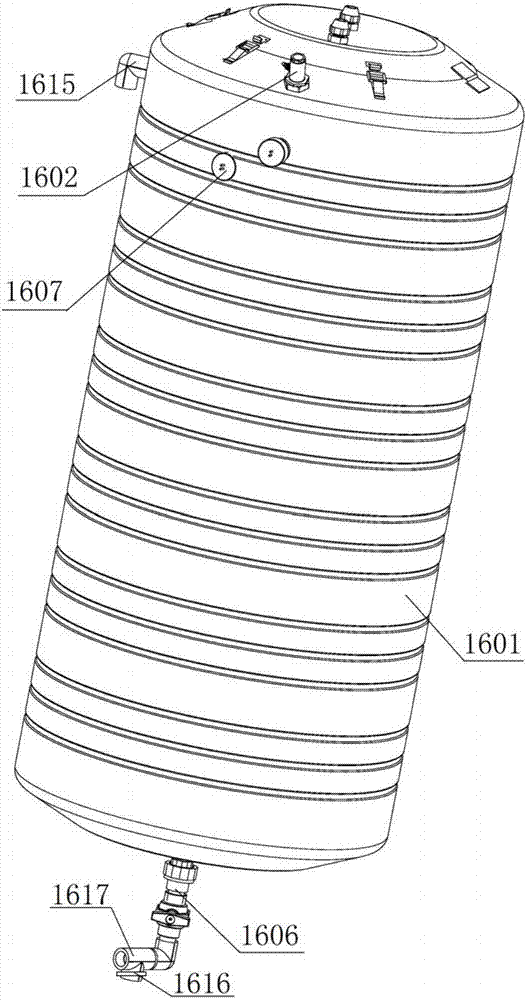

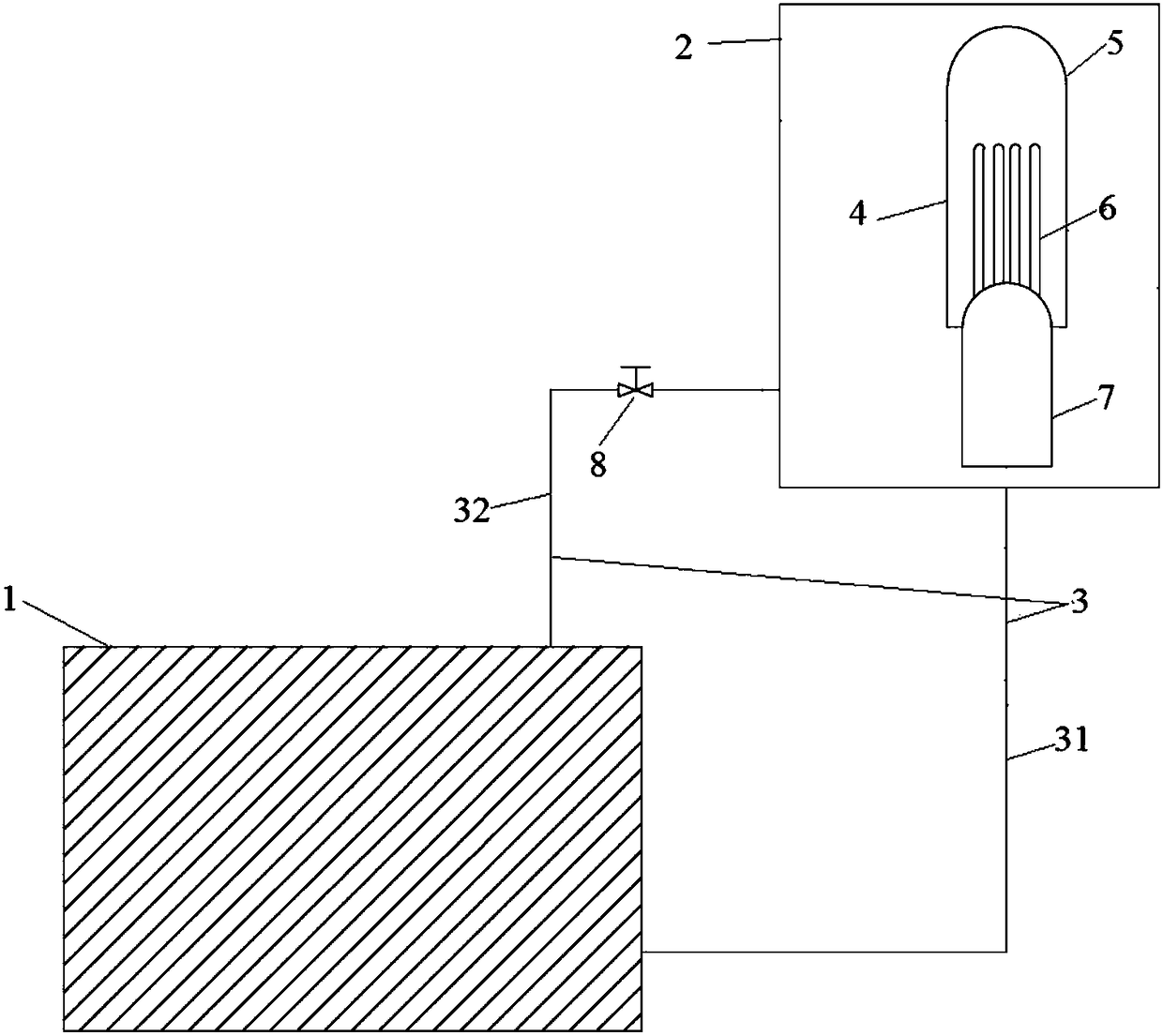

Water purifying and quality guaranteeing system

ActiveCN107352687AGuaranteed not to be pollutedAvoid breedingWater treatment parameter controlSpecific water treatment objectivesSiphonSolenoid valve

The invention discloses a water purifying and quality guaranteeing system. The system comprises a raw water supplying unit, a raw water purifying unit, a water-gas mixer, a booster pump, a water purifying tower, a first ozone generator and an air pump, wherein the water purifying tower comprises a water purifying tower body; a siphon port is formed in the water purifying tower body; the raw water supplying unit is connected with a water inlet end of the water-gas mixer through the raw water purifying unit; the air pump is connected with a gas inlet end of the first ozone generator; an output end of the first ozone generator is connected with a gas inlet end of the water-gas mixer; a water outlet end of the water-gas mixer is connected with a water inlet of the water purifying tower through the booster pump. The system further comprises a first three-way connector, a second three-way connector, a return flow solenoid valve and at least one direct drinking water submachine, and the direct drinking water submachine is connected in series between a third end of the second three-way connector and the water inlet end of the water-gas mixer. The system is not required to be washed, water in the water purifying tower and pipelines can be totally circulated, purified water is not prone to age or pollute, the quality of the purified water is high, the use and maintenance costs are low, and body heath is guaranteed.

Owner:HUNAN CHANGXIANG IND CO LTD

Material growth and test integrated system

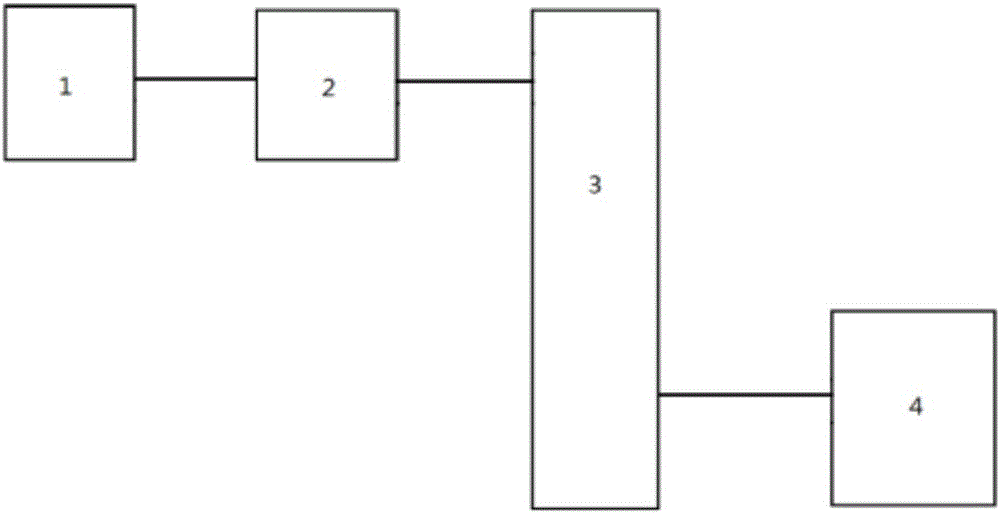

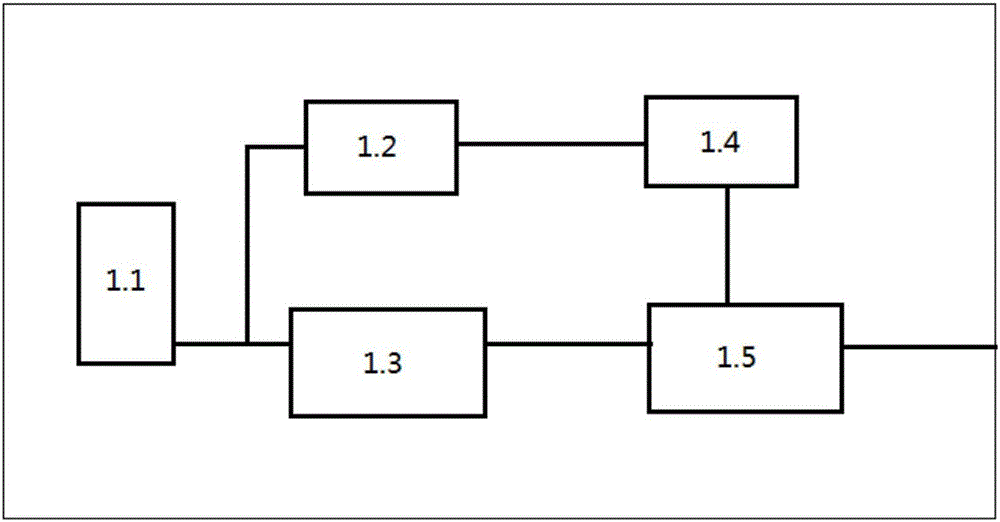

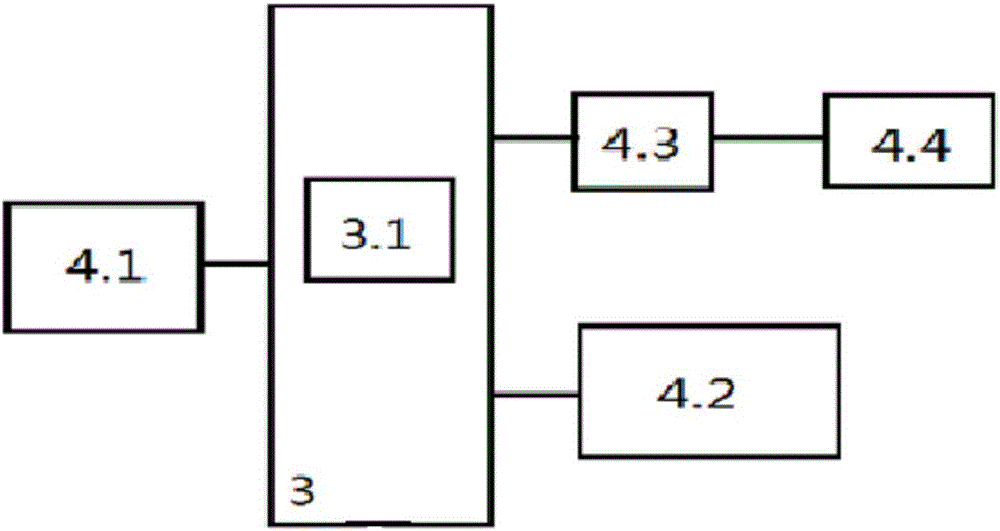

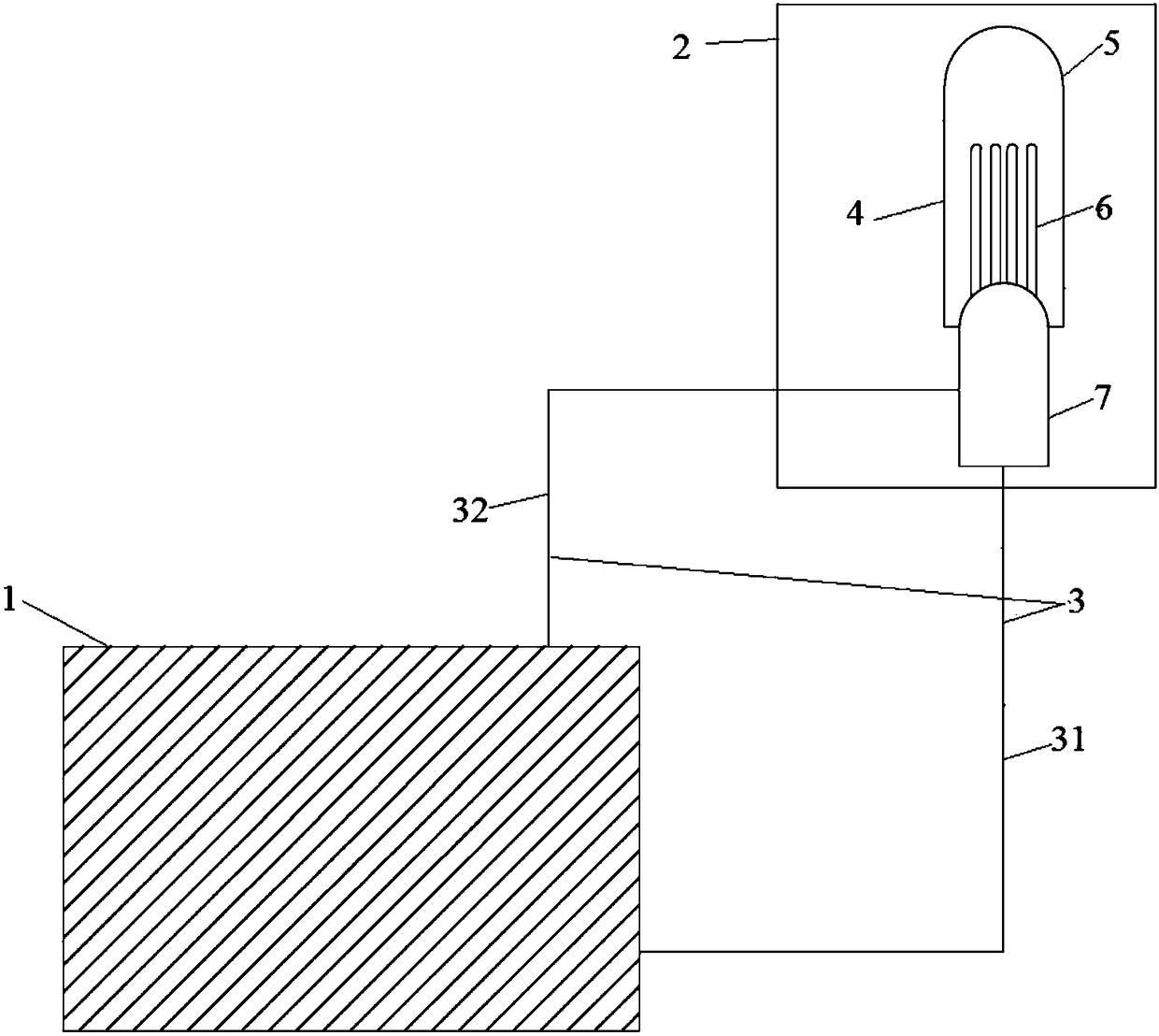

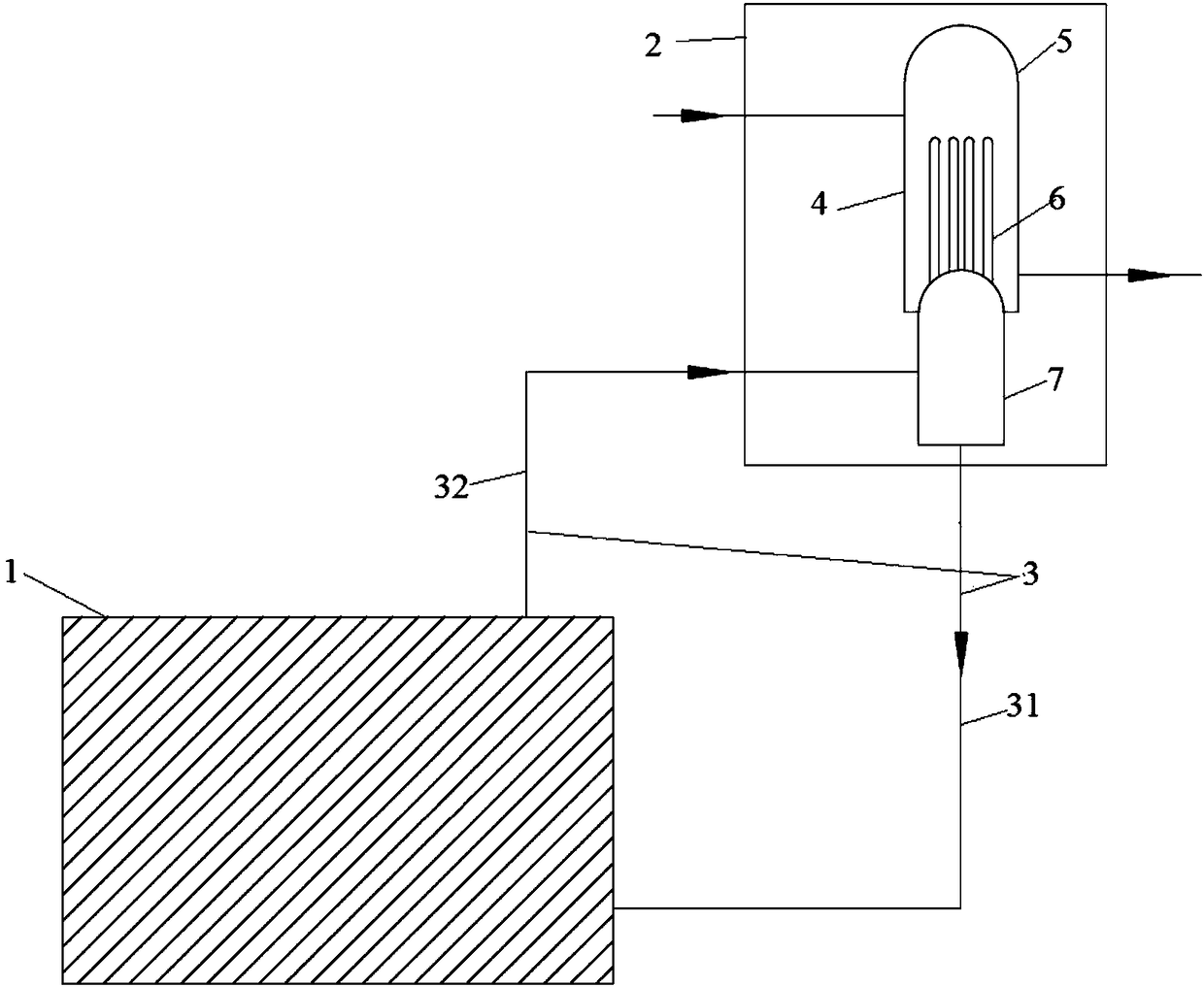

ActiveCN106756810AReduced measurement timeImprove signal-to-noise ratioMaterial analysis using wave/particle radiationVacuum evaporation coatingSpectrum analyzerScanning electron microscope

The invention relates to an advanced material growth and test integrated system. The advanced material growth and test integrated system comprises a light source generating system, a vacuum transmission system, a material growth system and a time and spinning-resolution electron spectrum test system, wherein the light source generating system comprises an extreme ultraviolet ultrashort pulse laser system, an optical parameter conversion system, an extreme ultraviolet ultrashort pulse laser conversion system, a time synchronization device and a pump light and probe laser beam combiner; the time and spinning-resolution electron spectrum test system comprises a combined beam input window, a vacuum test chamber, a sample fixed frame, a hemisphere electron spectrum analyzer and a scanning electron microscope; the material growth system comprises first and second molecular beam epitaxy growth systems and first and second pulse laser deposition systems; and the vacuum transmission system comprises an ultrahigh vacuum sample transmission trolley and an ultrahigh vacuum pipeline which is connected in series, and back-and-forth transmission between a growth chamber and a spectrum detection chamber is carried out through the ultrahigh vacuum pipeline. The advanced material growth and test integrated system is used for realizing the growth and preparation of different advanced materials.

Owner:NANJING UNIV

Immune cell cryopreservation liquid and cryopreservation method

InactiveCN110250161AAvoid direct contactGuaranteed not to be pollutedDead animal preservationTemperature controlCentrifugation

The invention discloses an immune cell cryopreservation liquid and a cryopreservation method. A cryopreservation device comprises a heat preservation box, a temperature control cavity with an upward opening is arranged in the heat preservation box, a sealing plate is fixedly connected to the upper end of the temperature control cavity; and four injection devices are arranged in an annular array on the sealing plate. A mechanical claw type clamping switch structure is used to avoid direct contact between an operator and a cell test tube, and ensures that cells are not polluted, and an integrated sealed sterile temperature control barrel structure is simultaneously adopted to avoid contact of the cells with the outside air in the treatment process before cell freezing, ensure that the cells may not denature, complete the processes of centrifugation and addition of a freezing liquid in the natural falling process of a cell liquid from top to bottom, and reduce the time required for freezing, and regionalization temperature drops from top to bottom, so that water in the cells may not generate ice crystals first due to the temperature to affect the own activity of the cells.

Owner:新昌县韵母电子有限公司

Electric hot water system

PendingCN108731265AGuaranteed not to be pollutedIncrease the heat exchange areaStorage heatersElectricityPlate heat exchanger

The invention provides an electric hot water system which comprises an electric heating unit, a heat exchange unit and a pipeline, wherein the electric heating unit is connected to the heat exchange unit through the pipeline, and the heat exchange unit comprises a condensing heat exchanger.

Owner:刘勇

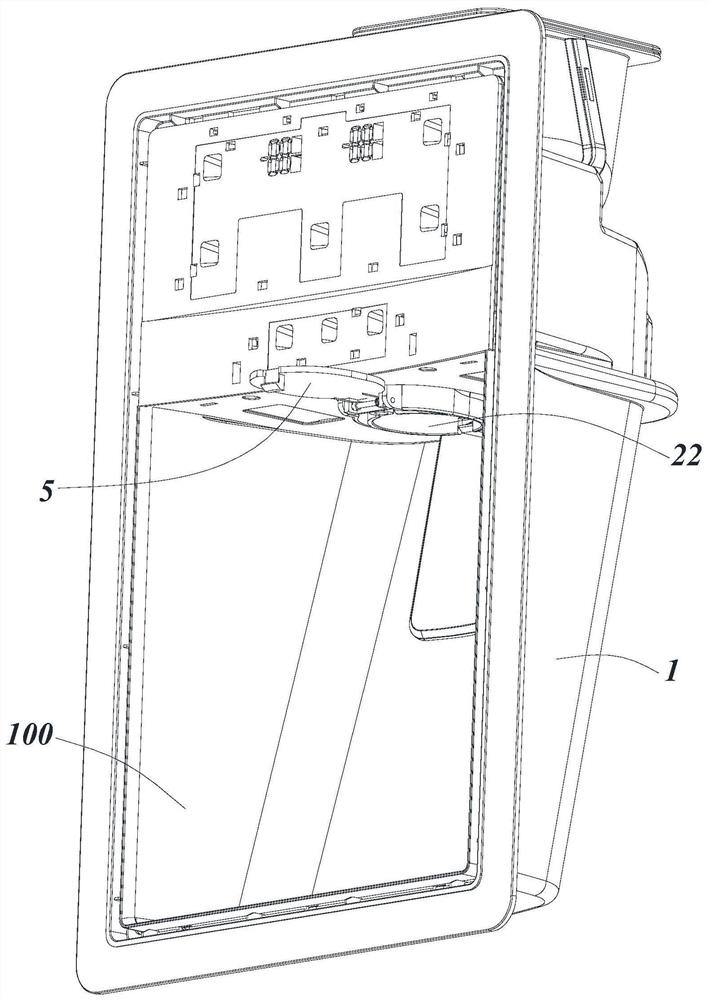

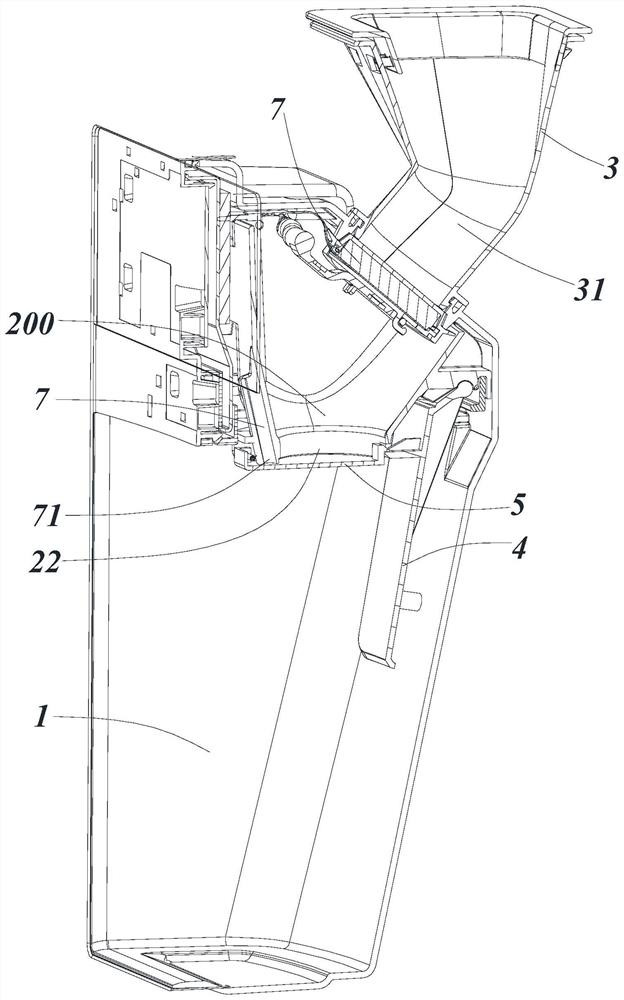

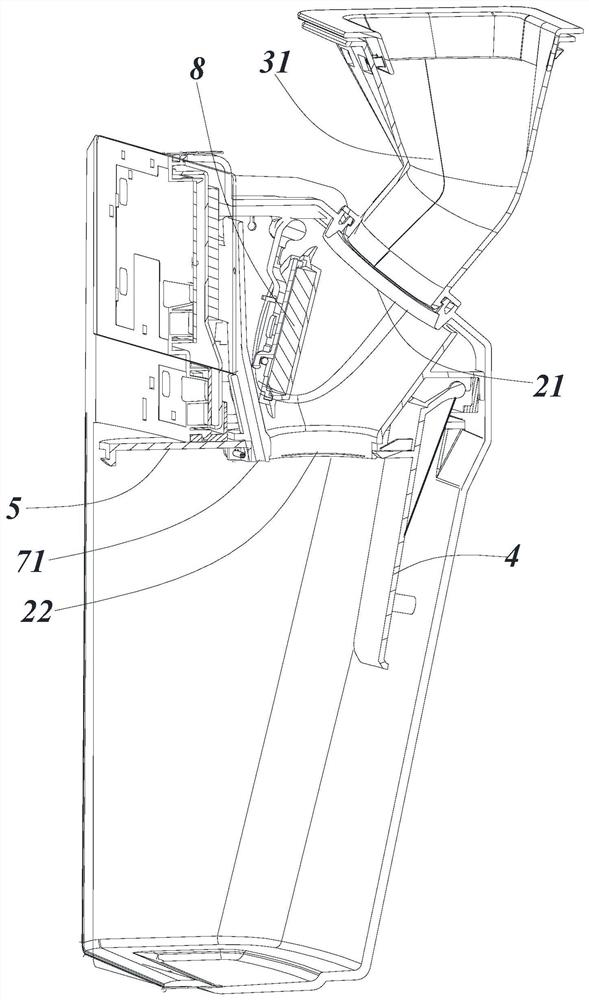

Distributor and refrigerator with distributor

ActiveCN111854260AWill not affect normal useGuaranteed not to be pollutedLighting and heating apparatusDomestic refrigeratorsElectrical and Electronics engineeringIcebox

The invention discloses a distributor and a refrigerator with the distributor. The distributor comprises a distributor barrel, an ice outlet pipeline, an ice outlet, a triggering piece and a cover plate, and when the triggering piece is switched to the triggering position from the standing position, ice blocks are controllably discharged from the ice outlet; the cover plate comprises a limiting part matched with the locking part of the triggering piece, and when the limiting part is connected with the locking part in a matched mode, the cover plate shields the ice outlet; and when the triggering piece is switched to the triggering position, the cover plate opens the ice outlet. According to the distributor, the cover plate opens or shields the ice outlet by operating the trigger piece andutilizing a mechanical structure, when the trigger piece is operated, the cover plate is converted into an open state, the ice outlet is controlled to discharge the ice blocks, and after the ice discharging action is completed, the cover plate can shield the ice outlet to ensure that the space in the ice outlet is not polluted; and the normal use of the distributor is not influenced by the shielding of the cover plate on the ice outlet.

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

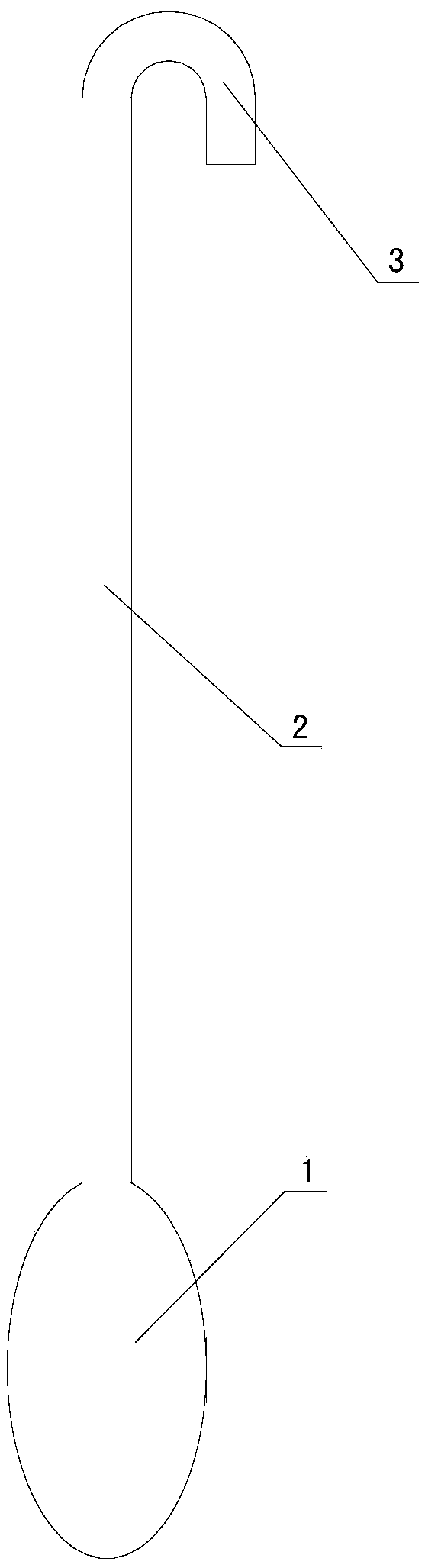

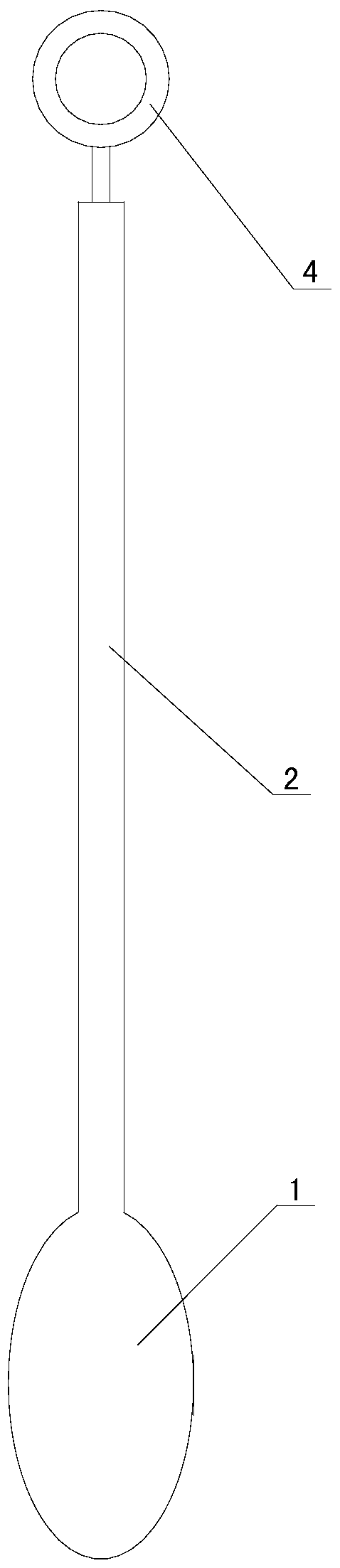

Hangable medicine spoon

A hangable medicine spoon comprises a spoon head and a spoon handle, wherein the spoon head is connected with the front end of the spoon handle; a hangable body is connected to the tail end of the spoon handle. According to the invention, a tester can hang the hangable medicine spoon provided by the invention on a prearranged hook or hanging bar vertically after use of the hangable medicine spoon, so that the spoon head is prevented from being in direct contact with other objects. Therefore, not only is the spoon head prevented from being contaminated to ensure the safety of raw medical materials and the accuracy of test results, but also residual chemicals on the spoon head are prevented from corroding and contaminating the other objects. The hangable medicine spoon is simple and reasonable in structure, and can be placed fast, conveniently and reasonably.

Owner:ANHUI SCI & TECH UNIV

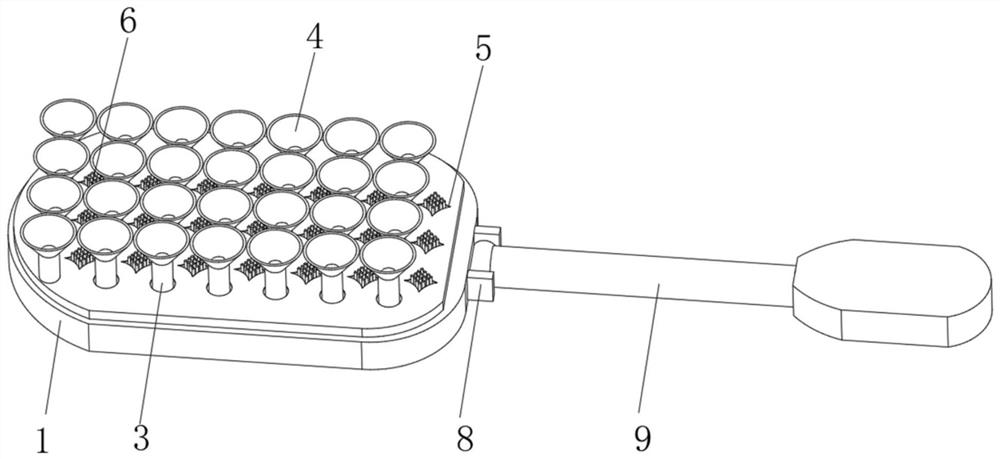

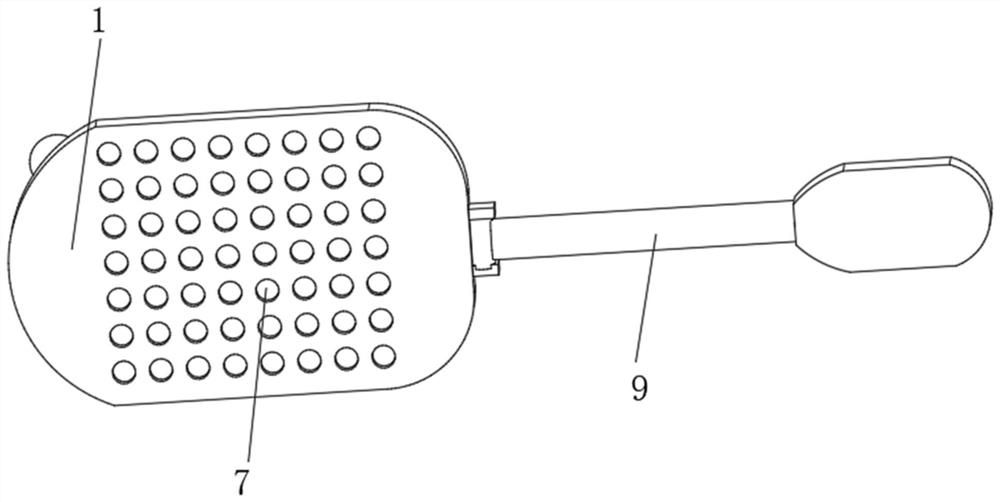

Air-based self-suction type dirty-free flyswatter facilitating collection

ActiveCN112273350AEasy to collectReduce exposureDirt cleaningCleaning using gasesStructural engineeringMechanical engineering

The invention discloses an air-based self-suction type dirty-free flyswatter facilitating collection. The flyswatter comprises a flapping bottom plate, movable inserting grooves are evenly formed at the top end of the interior of the flapping bottom plate, catching inserting pipes penetrate through and are slidably connected with the interiors of the movable inserting grooves, and the top ends, located outside the flapping bottom plate, of the catching inserting pipes fixedly communicate with outer cover grooves; supplementing guide grooves are evenly formed in the surface of the top of the flapping bottom plate, the position between the two outer cover grooves corresponds to the supplementing guide grooves, supplementing insertion pins penetrate through the interiors of the supplementingguide grooves and are slidably connected with the interiors of the supplementing guide grooves, ventilation guide holes are evenly formed in the surface of the bottom of the flapping bottom plate, anda buffer limiting mechanism is fixedly connected to the right side of the flapping bottom plate; and the right side of the buffer limiting mechanism is fixedly connected with a handheld rod. The invention relates to the technical field of flyswatters. According to the air-based self-suction type dirty-free flyswatter facilitating collection, flies are flapped without dead angles through the covergrooves and the insertion pins, meanwhile, the contact between the flies and the wall surface during flapping is greatly reduced, and the wall surface and the flyswatter are prevented from being contaminated.

Owner:淮北联联信息科技有限公司

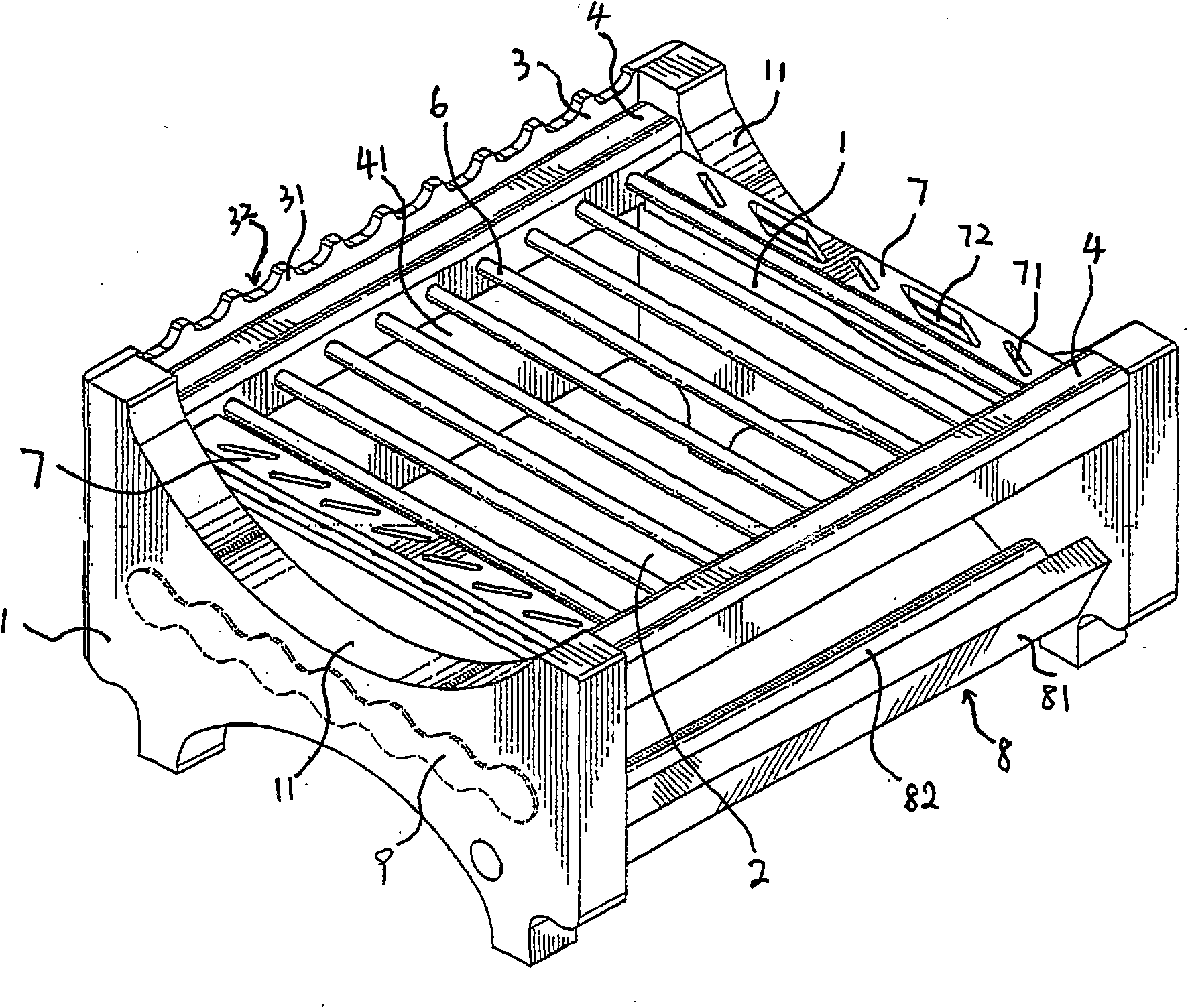

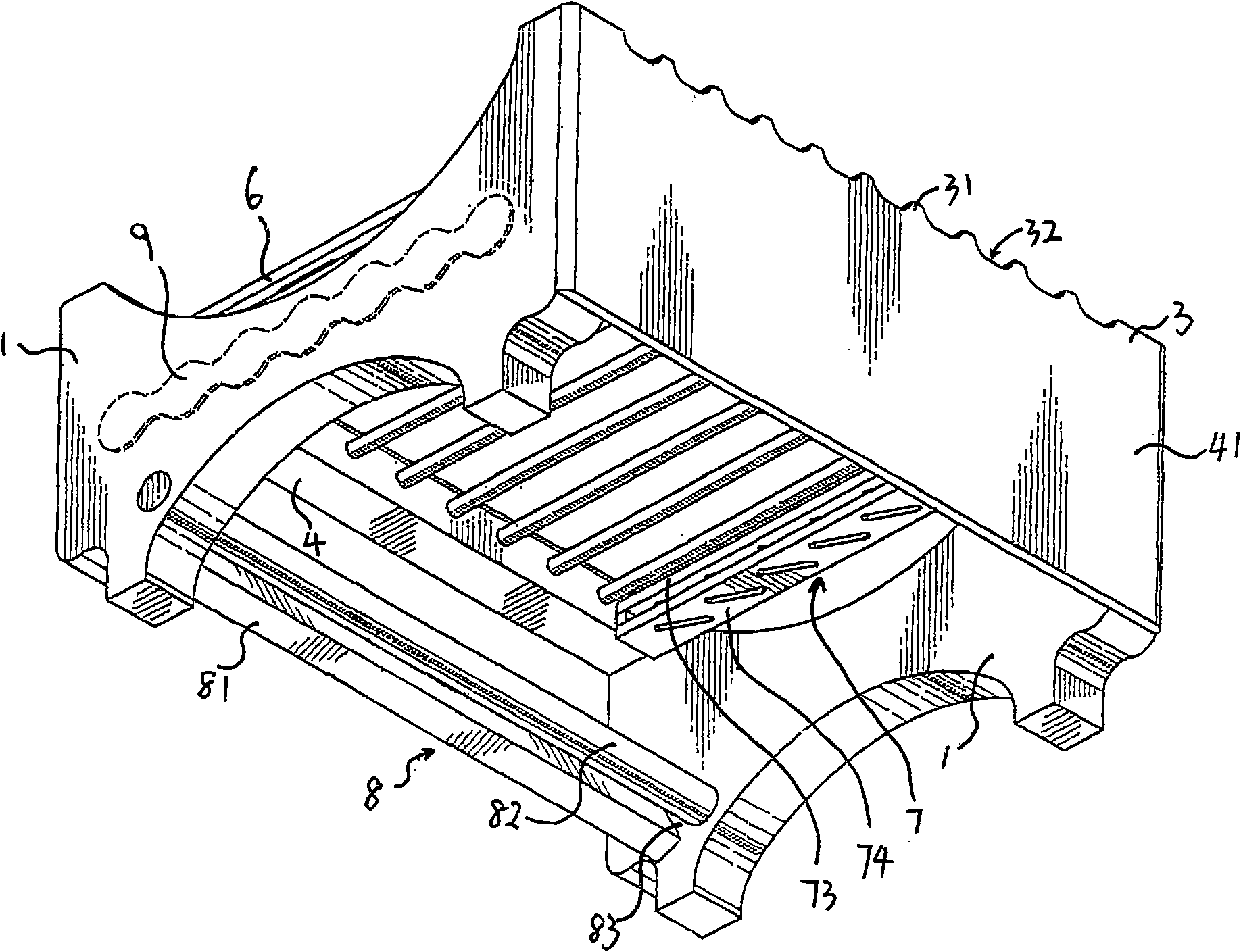

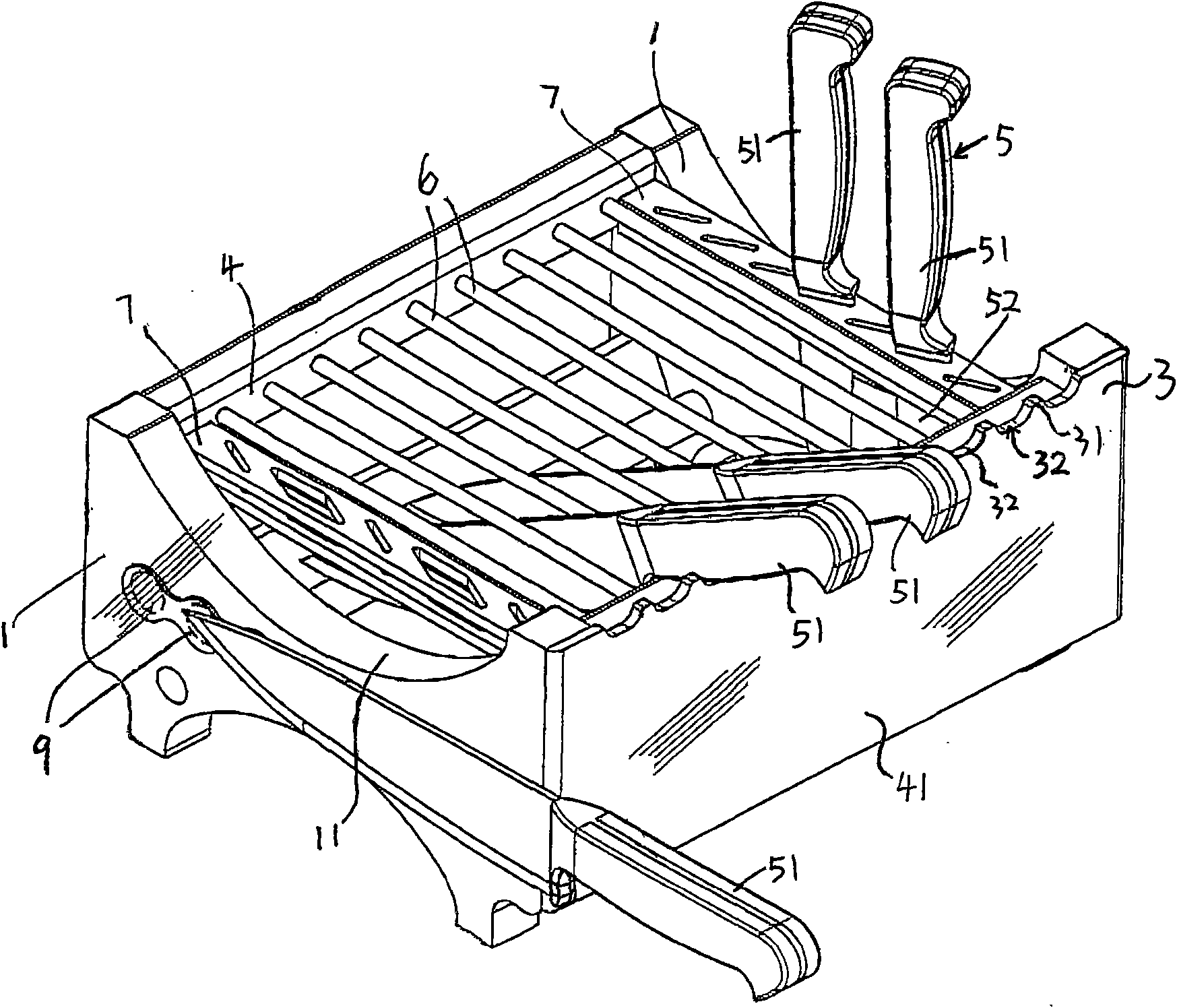

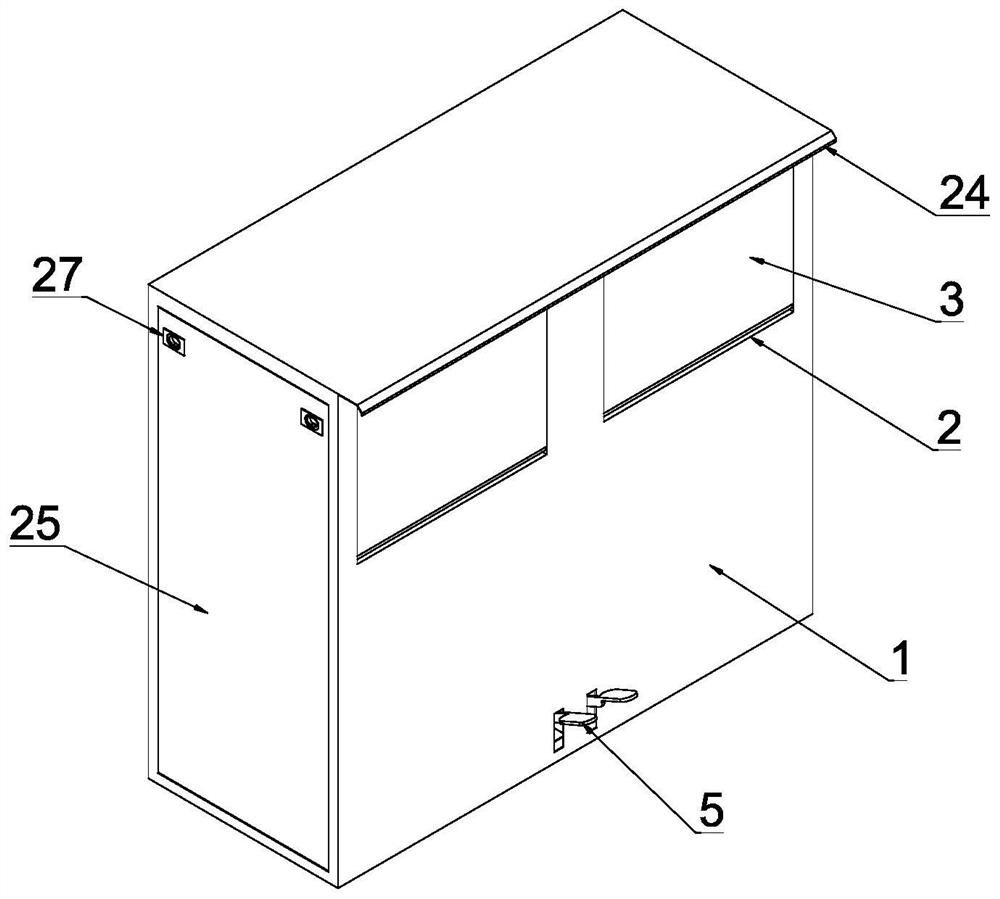

Kitchenware support appliance

InactiveCN101623177AGuaranteed not to be pollutedImprove efficiencyKitchen equipmentEngineeringSupport surface

The invention discloses a kitchenware support appliance, which comprises a pair of vertical frames, a handle support spanned between the pair of vertical frames in a strip shape, and a group of blade part supports, wherein a plurality of grooves are arrayed at the top end of the handle support along a length direction; the blade part supports are parallel to the handle support and are arranged at intervals; each blade part support comprises a blade tip baffle facing the support surface of the handle support and a blade support arranged between the blade tip baffle and the handle support; and the blade support is provided with a ridge extending along the length direction and protruding upwards. When kitchenware is supported by the support appliance, handles is arranged on the grooves, a blade is arranged on the ridge, and a blade tip is against the blade tip baffle. The kitchenware support appliance can protect kitchenware against cross contamination among the kitchenware caused by the support appliance, has the advantages of sanitation, beautiful appearance and convenient use, and can simultaneously accommodate multiple kitchenware.

Owner:阮英钢

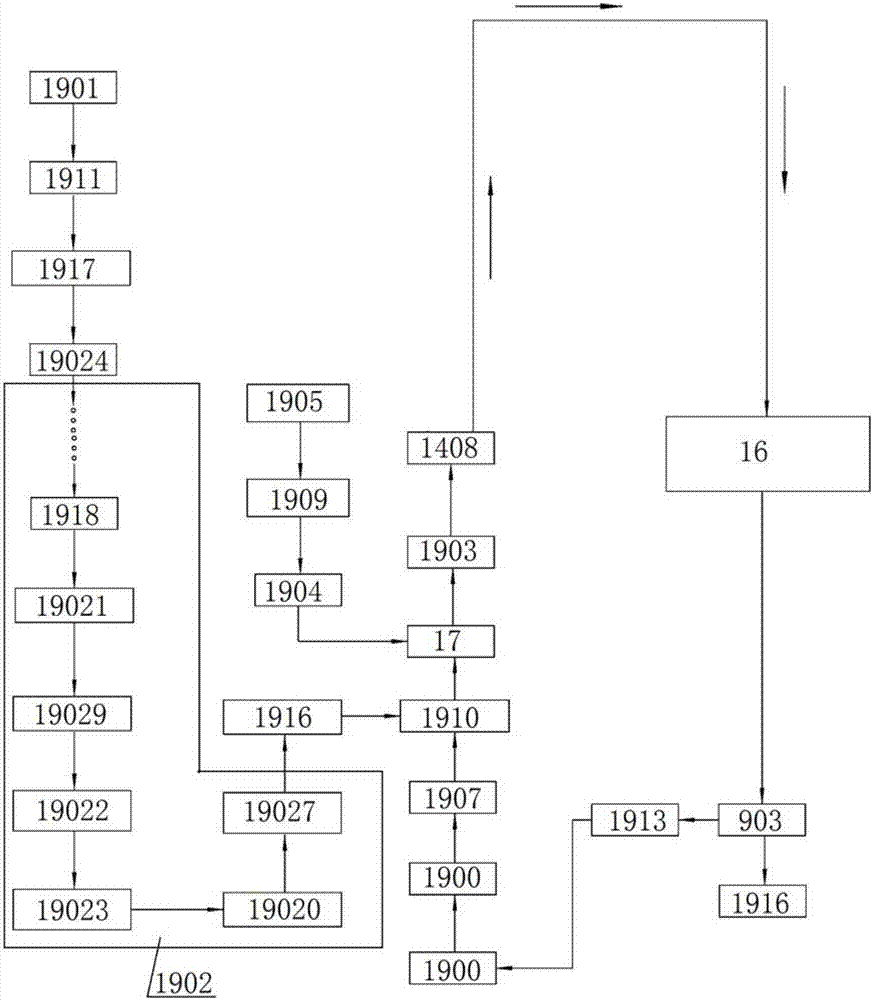

Protoperidinuim culture medium and method

ActiveCN106635815AShort doubling timeExtended growth timeUnicellular algaeMicroorganism based processesMicrobiologyCHITOSAN OLIGOSACCHARIDE

The invention discloses a protoperidinuim culture medium and method. The protoperidinuim culture medium is composed of, by weight, 20-100 mg of NH4NO3, 20-60 mg of CO(NH2)2, 1-10 mg of KH2PO4, 100-800 mg of NaHCO3, 15-50 g of MnCl2 4H2O, 10-30 mg of FeC6H5O7 5H2O, 1*10-5-1*10-3 mg of VB12, 50-200 mg of VB1, 0.5-5 mg of KCl, 10-15 mg of Na2EDTA, 0.2-5 g of chitosan oligosaccharide with a molecular weight of 1500-2000 Da, and 1000 mL of seawater. The protoperidinuim culture method comprises the steps of phase one, conical flask culture and phase two, mineral water barrel culture. The protoperidinuim culture medium and method provides the optimal nutritive salt formula for protoperidinuim culture, thereby improving the yield of protoperidinuim poison and reducing the culture cost; compared with traditional outdoor open cement ponds expanded culture manners, culturing protoperidinuim in mineral water barrels is lower in cost, less prone to pollution and easier to operate and can greatly reduce workload, increase the growth speed of the protoperidinuim and shorten the culture period.

Owner:QINGDAO UNIV OF SCI & TECH +1

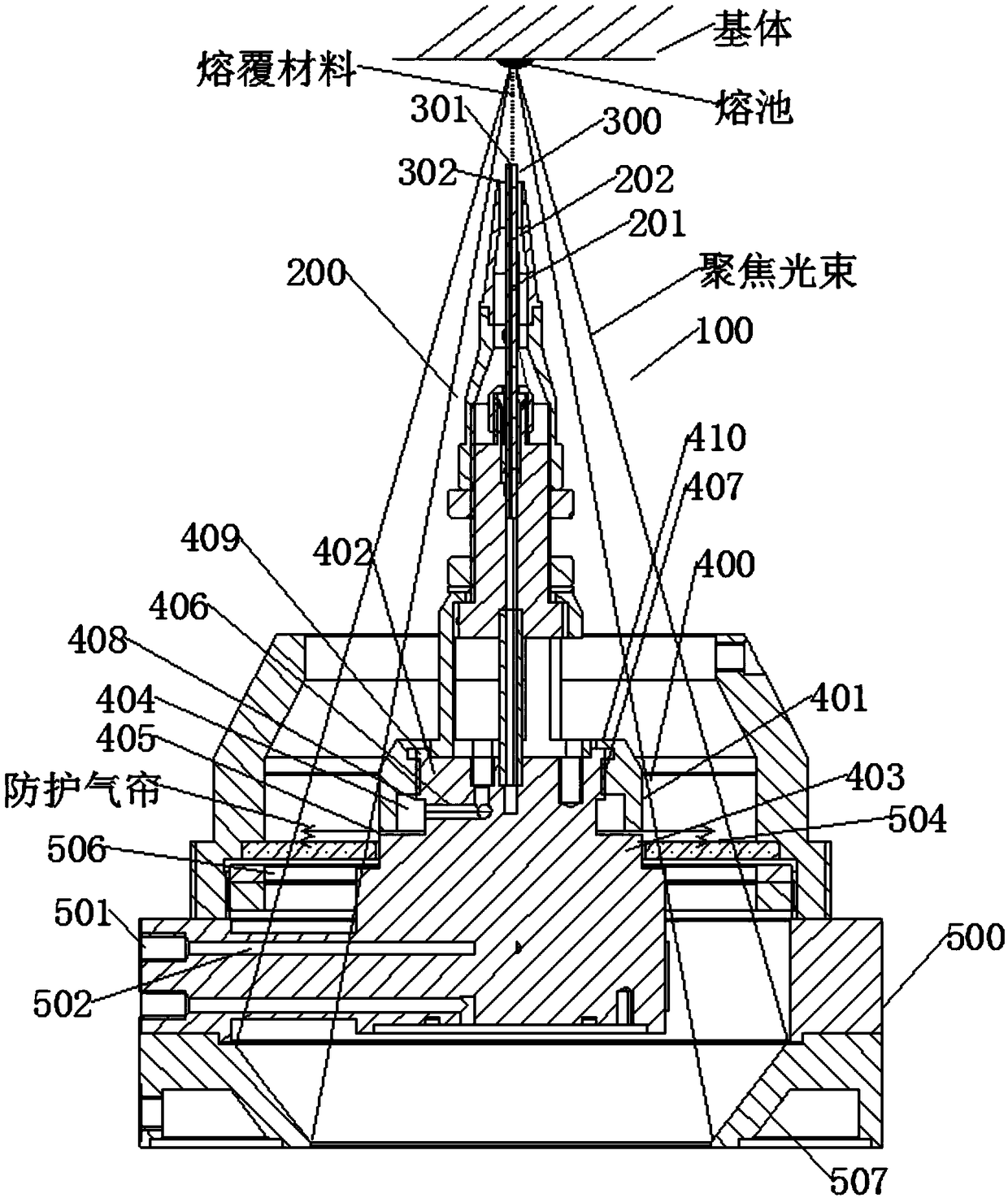

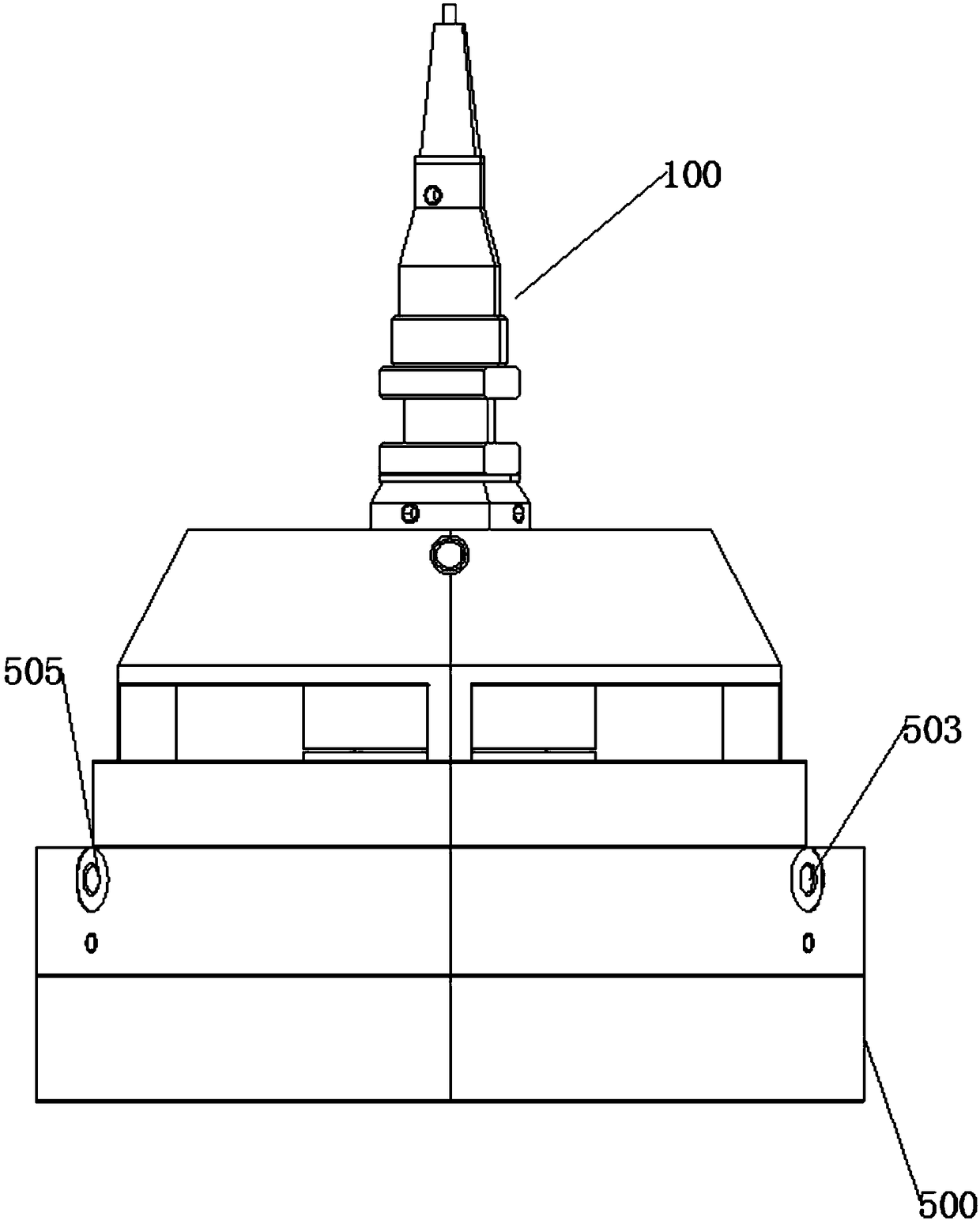

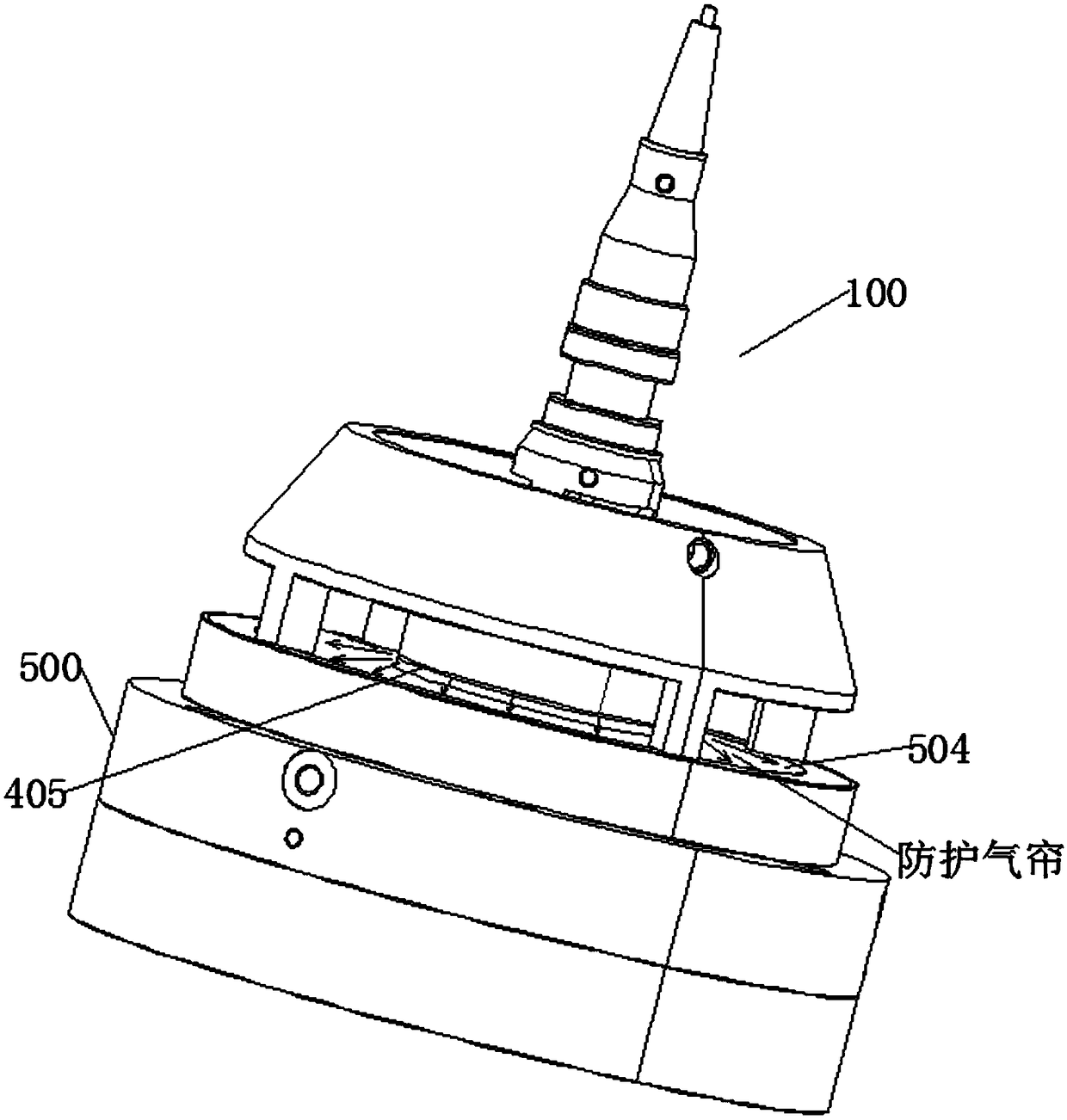

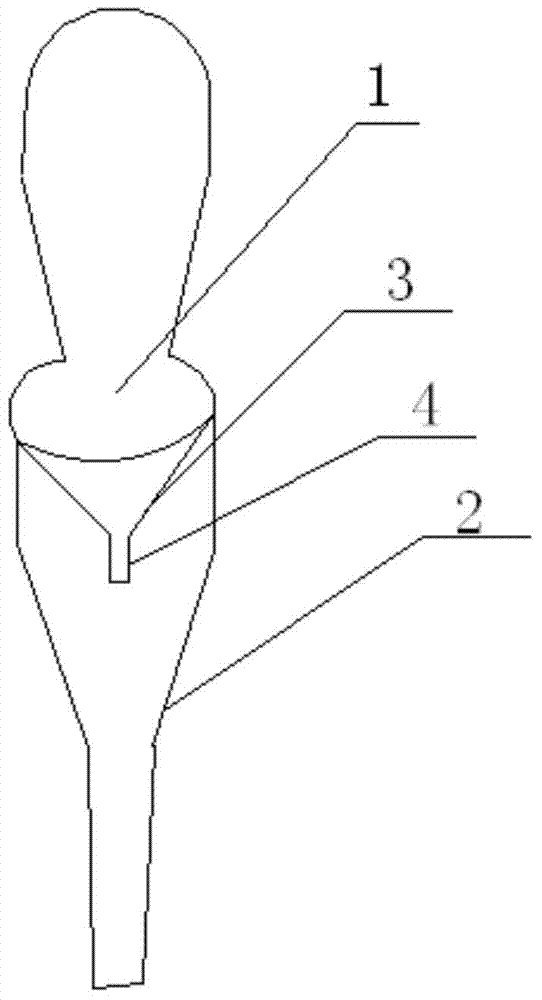

Three-dimensional space random-direction fusion-covering forming method

InactiveCN109351973AGuaranteed not to be pollutedCladding achievedAdditive manufacturing apparatusIncreasing energy efficiencySpray nozzleEngineering

The invention relates to a three-dimensional space random-direction fusion-covering forming method. The three-dimensional space random-direction fusion-covering forming method comprises the followingsteps of: providing a base body which is provided with surface needing fusion-covering accumulation or being repaired by fusion-covering, spraying a fusion-covering material to the surface of the basebody from a spray nozzle through a fusion-covering channel of a spray head main body, and focusing laser to the surface of the base body through a focusing lens to fusion-cover the fusion-covering material onto the surface of the base body; and forming a protective gas curtain for blowing away / isolating the fusion-covering material, which is not fusion-covered between the focusing lens and the spray nozzle, between the spray nozzle and the focusing lens. According to the three-dimensional space random-direction fusion-covering forming method provided by the invention, when a laser fusion-covering device is in large-angle inclination and vertical face-up fusion-covering or space continuous direction change, fusion-covering material fed out from the spray nozzle does not splash down on thefocusing lens to damage the focusing lens, so that stability and reliability of fusion-covering are guaranteed, and + / -180-degree three-dimensional space all-around random-direction fusion-covering isrealized.

Owner:SUZHOU UNIV

Anti-pollution rubber-head burette

The invention belongs to the technical field of chemical apparatuses, and particularly relates to an anti-pollution rubber-head burette, mainly solving the problems of high operation requirement, pollution caused by easy backflow, and the like of an existing rubber-head burette. According to the technical scheme adopted by the invention, the anti-pollution rubber-head burette comprises a rubber-head burette body and is characterized in that a funnel-shaped glass tube is arranged at the top of the inner side of a glass tube of the rubber-head burette body, the top of the funnel-shaped glass tube is connected with the top of the glass tube in a sealing manner, the bottom of a lower tube of the funnel-shaped glass tube is of an open structure, the radius of the lower tube is less than the minimum radius of the rubber-head burette body, and the length of the funnel-shaped glass tube is less than 1 / 3 that of the rubber-head burette body. The anti-pollution rubber-head burette has the advantages of simple structure, and less possibility of backflow and pollution.

Owner:文密

Environment-friendly treatment device for river pollutant cleaning

ActiveCN112813943AReduce cleanup costsSave manpower and material resourcesWater cleaningRiver routingEnvironmental engineering

The invention discloses an environment-friendly treatment device for river pollutant cleaning. The environment-friendly treatment device comprises a mounting base capable of being inserted into a river channel, wherein a lifting mechanism is arranged on the mounting base; a locking mechanism for locking the lifting height of the lifting mechanism is arranged on the lifting mechanism; a floating plate is arranged on the lifting mechanism; and a frame body is arranged on the floating plate, so that floating pollutants in the river channel are automatically fished. The environment-friendly treatment device replaces workers to clean the river channel, so that the river channel cleaning cost is reduced; after fishing is completed, the pollutants are automatically fed into a storage box, and manual treatment and storage are not needed, so that manpower and material resources are saved; and according to the structure of the environment-friendly treatment device, a driving element is adopted to complete the circulating action of fishing and pollutant storage, continuous fishing can be carried out for multiple times, the working efficiency is high, the river channel is prevented from being polluted, the manufacturing cost is reduced, and the cleaning strength of the river channel is guaranteed.

Owner:陕西智丽环保科技有限公司

Side opening type material loading device capable of compressing materials and improving loading capacity

ActiveCN113501231ATake advantage ofImprove abilitiesWaste collection and transferRefuse receptaclesStructural engineeringMechanical engineering

The invention discloses a side opening type material loading device capable of compressing materials and improving the loading capacity. The device comprises a container body, wherein a feeding opening is formed in the side face of the container body, a cover body is arranged at the position, corresponding to the feeding opening, of the container body, the cover body is hinged to the container body through hinge shafts arranged at the two ends of the cover body, and a cover turning driving mechanism is arranged on the container body; when the feeding opening is opened, the upper end of the cover body is turned downwards towards the outside of the container body, and the lower end of the cover body is turned upwards towards the inside of the container body; and the container body is further provided with a material compression mechanism, and the material compression mechanism comprises a compaction piece and a compression driving mechanism which are arranged in the container body. According to the device, loaded materials can be compressed, so that the space in the container body is fully utilized, the material loading capacity is improved, resource waste is reduced, and energy conservation and consumption reduction are achieved; and in addition, when the device is used for feeding materials, the operation process is simple and convenient, meanwhile, the good isolation effect on the outside is achieved, and the sealing performance is good.

Owner:李正辉

Secondary extrusion-outlet forming device for miscellaneous-grain instant noodle cakes

ActiveCN102860464AMaintain a constant temperature environmentGuaranteed not to be pollutedFood shapingFood preparationInstant noodleWater jacket

The invention discloses a secondary extrusion-outlet forming device for miscellaneous-grain instant noodle cakes, which comprises a circulating water jacket (4), an extrusion sleeve (5), an extrusion screw (6), an extrusion template (3), a fixing sleeve (1), blocking plates (2) and a feed hopper (8), wherein the extrusion sleeve (5) is provided with a feed inlet (9), the extrusion sleeve (5) on the outer side of the feed inlet (9) is provided with the feed hopper (8), two blocking plates (2) are arranged on the outer side of the fixing sleeve (1), and a liner of the extrusion sleeve (5) is made of stainless steel materials. The device disclosed by the invention has the beneficial effects that the temperature is controllable and in the cleanness is high in the extrusion sleeve, so that the quality and the sanitation of products are ensured; the ripening degree of products reaches over 90%, the edge of a noodle belt is tidy, and a noodle cake is high in beautiful degree; and the addition of lubricating oil is convenient, so that the downtime in the process of maintenance is shortened, and the service life of equipment is prolonged.

Owner:SICHUAN JIUJIUAI FOOD

Blockage preventer for grouting sleeves of prefabricated parts

InactiveCN106639161AAvoid cloggingGuaranteed tightnessWallsBuilding reinforcementsArchitectural engineeringGrout

The invention relates to the field of building construction, and in particular to a blockage preventer for grouting sleeves of prefabricated parts. The blockage preventer for the grouting sleeves of the prefabricated parts relates to a grouting section-sealing assembly which blocks a grouting section of a grouting sleeve, the grouting section-sealing assembly comprises a rubber base and a rod, the rod is connected with the base, the rod is located in the grouting section, the base is embedded in an opening of the grouting section, the rod is provided with two through holes, and the two through holes respectively correspond to the positions of a grouting hole and a grout discharge hole; two sets of hole-sealing assemblies are respectively plugged in the grouting hole and the grout discharge hole, each hole-sealing assembly comprises a rubber sealing base and a sealing rod, the sealing rods in the grouting hole and the grout discharge hole are respectively correspondingly inserted in the two through holes, and the sealing bases connected to the sealing rods are respectively plugged in the openings of the grouting hole and the grout discharge hole. The blockage preventer for the grouting sleeves of the prefabricated parts is simple in structure and easy to operate, prevents problems, such as the trouble of later cleaning due to grout leakage caused by the conventional process, can increase working efficiency, and ensures that the grouting sleeve cannot be stained.

Owner:DALIAN SANCHUAN BUILDING TECH CO LTD

Lubricating equipment for chain teeth

ActiveCN108443479AEasy to cleanIncrease contactCleaning using toolsCleaning using liquidsLubricationMechanical engineering

The invention relates to the field of mechanical lubrication, and in particular, discloses lubricating equipment for chain teeth. The lubricating equipment comprises a cleaning mechanism and a conveying mechanism; the cleaning mechanism is positioned in an inlet of a shell; the conveying mechanism is positioned in an outlet of the shell; the cleaning mechanism comprises a first cleaning disc capable of rotating, a second cleaning disc capable of rotating, and multiple cleaning brushes; the first cleaning disc and the second cleaning disc are vertically inclined; an included angle between a plane of the first cleaning disc and a plane of the second cleaning disc is 15-45 degrees; the first cleaning disc and the second cleaning disc are in point contact; the cleaning brushes are aslant fixedon two opposite sides of the first cleaning disc and the second cleaning disc; the conveying mechanism is a rotating chain disc; multiple chain teeth are arranged on the chain disc; oil outlet pipesare arranged in the chain teeth; and multiple oil outlet holes communicating with the oil outlet holes are formed in the side surfaces of the chain teeth. The lubricating equipment can brush rollers and sleeves between chains.

Owner:TIANJIN JINYA ELECTRONICS

A material growth test integrated system

ActiveCN106756810BReduced measurement timeImprove signal-to-noise ratioMaterial analysis using wave/particle radiationVacuum evaporation coatingSpectrum analyzerUltra-high vacuum

Owner:NANJING UNIV

Nitrogen rotational flow sealing heat preservation barrel for wet-type electric dust remover

PendingCN114534920AGuaranteed insulation performanceAvoid backtrackingIncreasing energy efficiencyExternal electric electrostatic seperatorEngineeringNitrogen gas

The invention belongs to the field of metallurgical and chemical equipment, and particularly discloses a nitrogen rotational flow sealing heat preservation barrel for a wet-type electric precipitator, which comprises a barrel body, an insulator communicated with the wet-type electric precipitator is arranged in the barrel body, and a nitrogen rotational flow sealing structure is arranged on the barrel body. The nitrogen rotational flow sealing structure comprises a nitrogen supplementing pipe, a nitrogen drainage pipe and a nitrogen storage cavity communicated with the nitrogen drainage pipe, the barrel body comprises a barrel body upper portion and a barrel body base, and a plurality of drainage holes allowing nitrogen to flow into the barrel body base and forming rotational flow in the barrel body base are formed in the side wall of the nitrogen storage cavity. And the rotational flow flows towards the wet-type electric dust remover. The part where nitrogen is introduced into the barrel body is improved, the nitrogen flowing state is optimized, a nitrogen curtain wall is formed in the barrel body, an insulator is isolated from the wet-type electric dust remover, and smoke in the wet-type electric dust remover is prevented from reversely flowing into the insulator, so that it is guaranteed that the insulator is not polluted, the insulation performance of the insulator is guaranteed, and safety accidents are avoided; potential safety hazards are eliminated.

Owner:CISDI INFORMATION TECH CO LTD

A blood collection needle and a continuous blood collection device

ActiveCN105596015BGuaranteed not to be pollutedAvoid cross infectionDiagnostic recording/measuringSensorsBlood collectionCross infection

The invention provides a blood taking needle. The blood taking needle comprises a shell body, a needle body and an ejection mechanism, wherein a hole-slot is formed in the shell body; the needle body and the ejection mechanism are arranged inside the shell body; the ejection mechanism comprises a trigger part; the trigger part corresponds to the position of the hole-slot, and is not protruded to the surface of the shell body. The invention further provides a continuous blood collection device. The device comprises a main body, a needle box and the blood taking needle, wherein the main body comprises a main body shell, a button, a slide block and a slide way; the slide block and the slide way are arranged inside the main body shell; an opening through which the blood taking needle passes is formed in the lower half part of the slide way; a push block extends out from the top of the slide block, and the slide block can slide along the slide way; a needle box insert hole is formed in the side surface of the main body shell; a first needle outlet and a second needle outlet are formed in the bottom of the main body shell, and are communicated with each other; a contact is arranged on the back of the button; when the blood taking needle reaches a working position, the contact is opposite to the trigger part. The blood taking needle and the continuous blood collection device can be used for effectively avoiding cross infection among different patients, are convenient for user operation, have few operation steps and are compact in structure.

Owner:ANDON HEALTH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com