Multifunctional magnetic control sputtering film plating device

A magnetron sputtering coating, multi-functional technology, used in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, to achieve the effect of expanding the scope of use, avoiding pollution, and facilitating maintenance and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

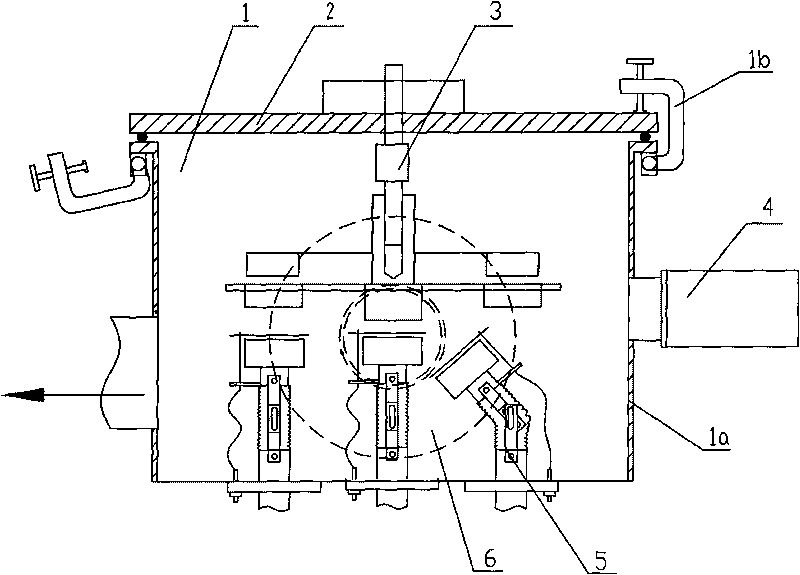

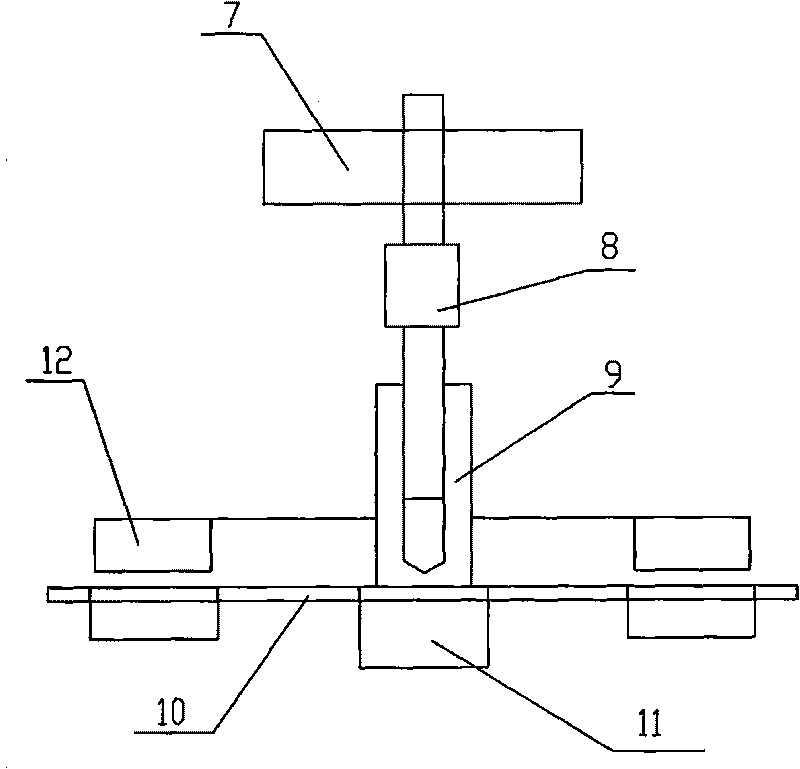

[0025] see figure 1 , figure 2 , in this embodiment, the substrate frame 3 is fixedly connected to the vacuum chamber top cover 2, and is suspended in the vacuum chamber. On the bottom surface of the disc 10 at the bottom of the rack 3, at a position corresponding to the substrate carrier 11, on the upper part of the disc 10, a heating device 12 is provided;

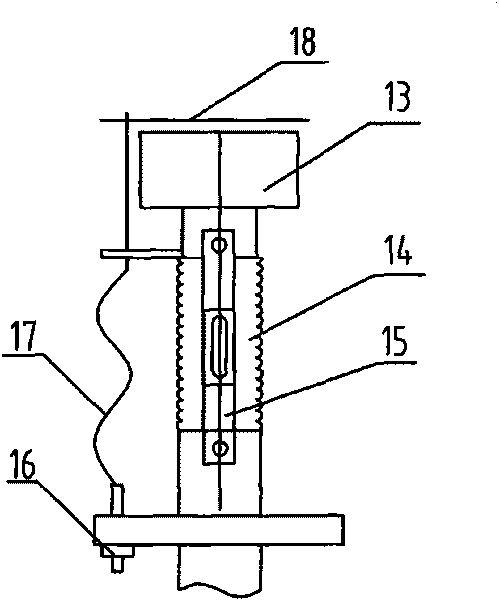

[0026] figure 1 , image 3 As shown, in this embodiment, in the vacuum chamber body 1a, on the position opposite to the substrate carrier 11, on the same circumferential position of the vacuum chamber body bottom plate, each magnetron sputtering target 5 is uniformly arranged; in order to meet the vertical According to the requirements of sputtering and confocal sputtering, the included angle of the target head of each magnetron sputtering target 5 in the direction toward the main axis of the vacuum chamber is adjustable from 0 to 45°; Baffle 18.

[0027] image 3 The shown magnetron sputtering target 5 with adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com