Multifunctional magnetron sputtering film coating device

A magnetron sputtering coating, multi-functional technology, applied in the direction of sputtering coating, ion implantation coating, vacuum evaporation coating, etc., to achieve the effect of improving film base adhesion, improving functional diversity, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

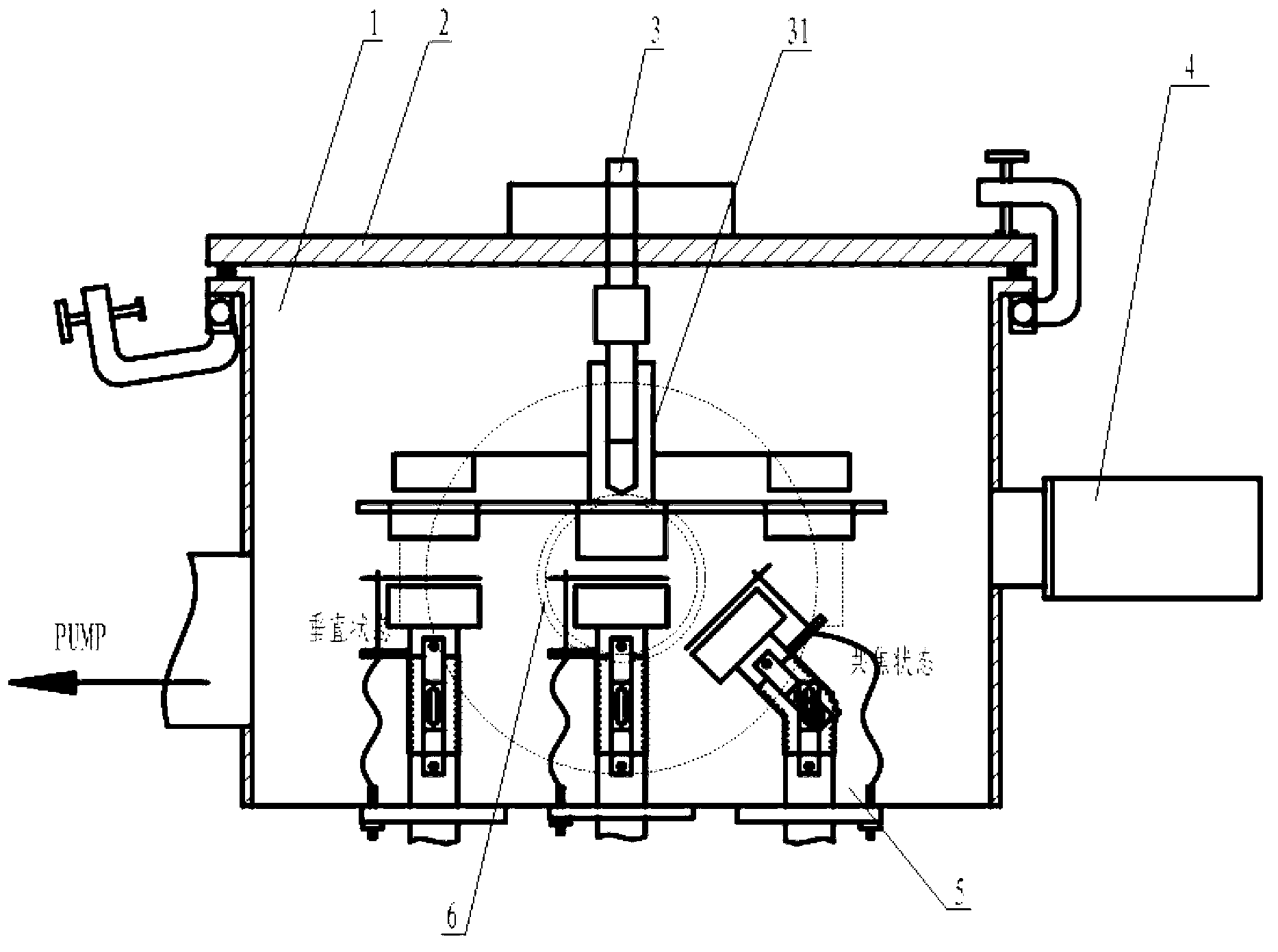

[0024] Example: see Figure 1-4 , the multifunctional magnetron sputtering coating device of the present embodiment, it comprises:

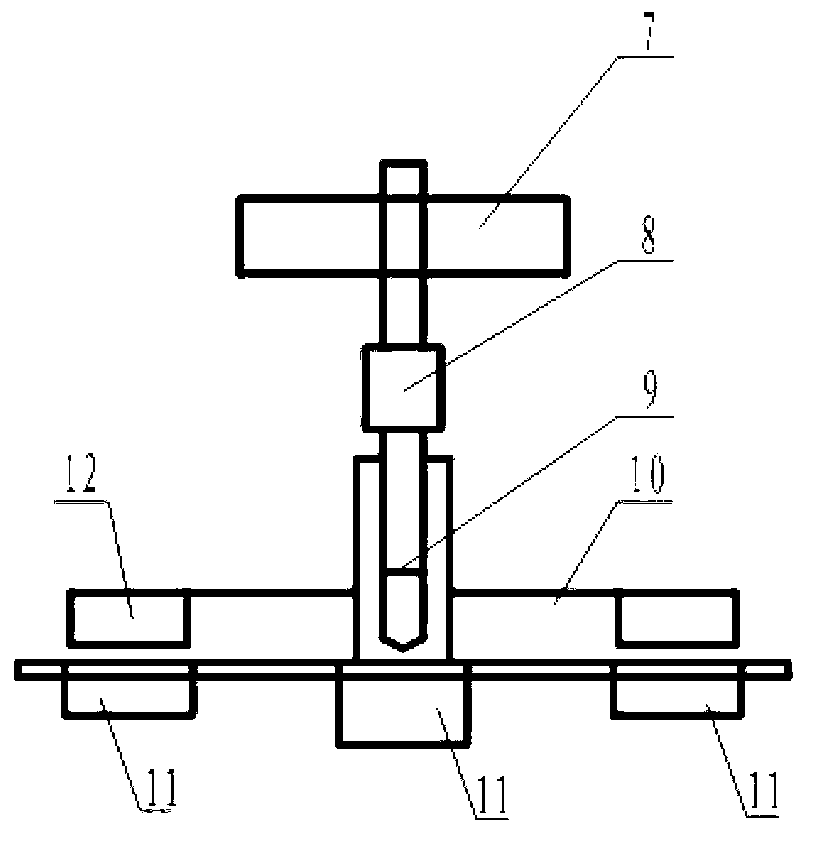

[0025] The vacuum chamber 1 and the top cover 2 detachably connected to the top of the vacuum chamber 1; the top cover 2 is fixedly connected with a connecting rod 3, which is suspended in the vacuum chamber and is rotatably and liftably socketed at the lower end of the connecting rod There is a substrate frame 31, a plurality of substrate carriers 11 are arranged on the bottom surface of the disk 10 positioned at the bottom of the substrate frame 3, and a plurality of substrate carriers are on the same circumference, above the disk 10 and connected to the substrate carrier At the corresponding position, a heating device 12 is provided.

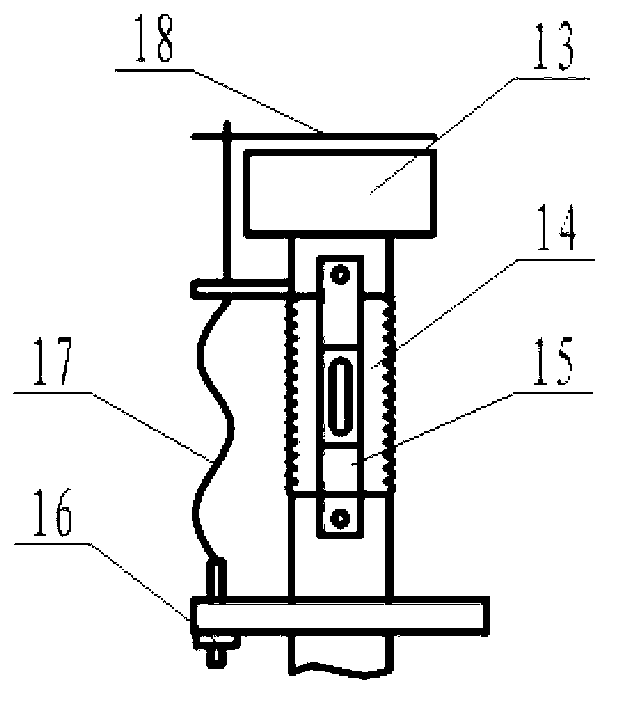

[0026] At the position corresponding to the substrate carrier 11 at the bottom of the vacuum chamber cavity, a plurality of magnetron sputtering targets 5 on the same circumference are arranged, and the upper t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com