Plasma processing device capable of reducing pollution particles and method thereof

A processing device and plasma technology, applied in the direction of discharge tube, metal material coating process, coating, etc., can solve the problems of wafer hidden dangers, wafer pollution, etc., and achieve the goal of improving pollution, significant effect and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

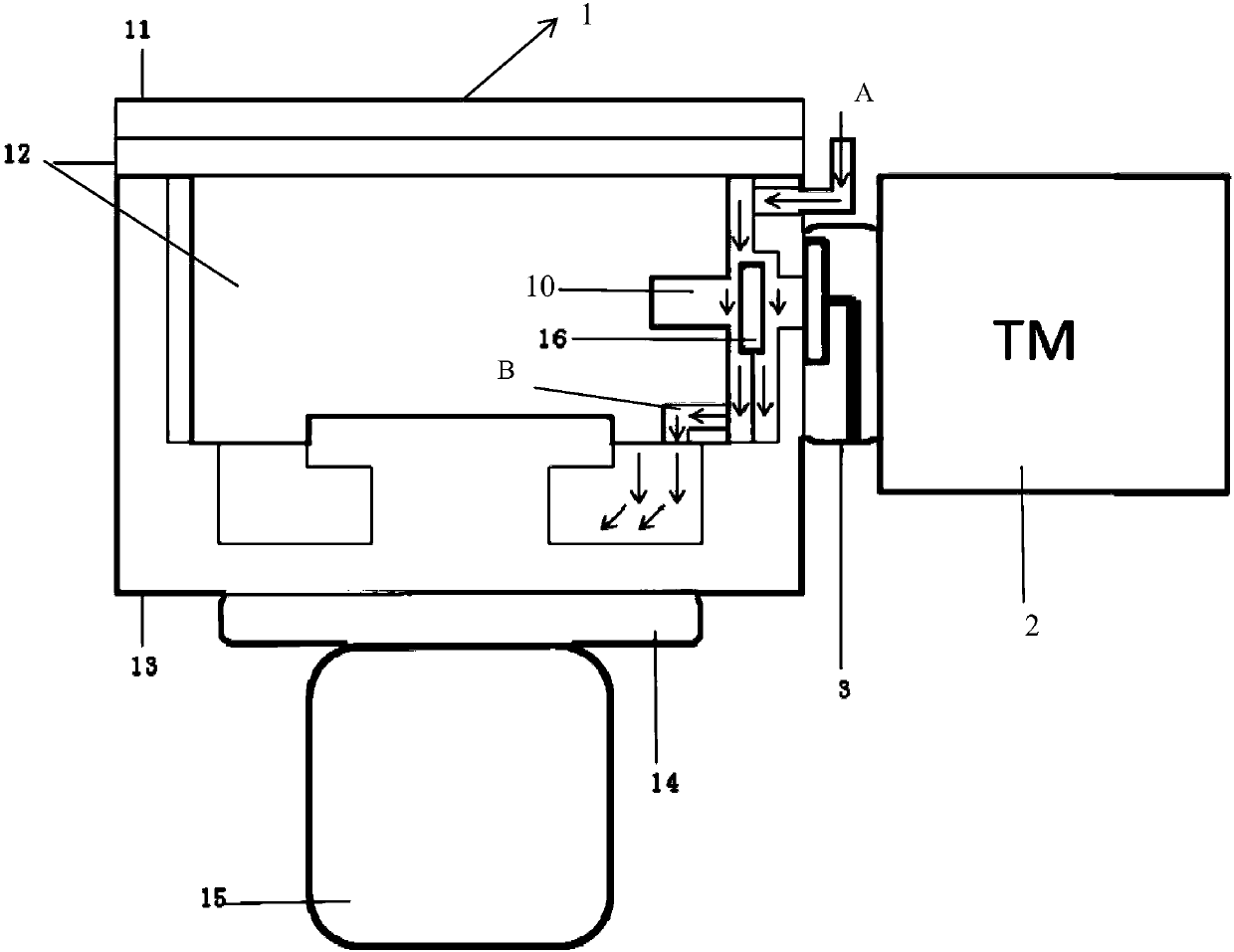

[0040] Such as figure 2 As shown, in the first embodiment, the lower part of the bushing 12 is provided with a hole B, and the flow space formed by the outer wall of the bushing and the inner wall of the cavity under the baffle plate 16 communicates with the inner space of the bushing 12 through the hole B, Create an efficient gas flow path.

[0041] After finishing the first wafer transfer and before the second wafer transfer, the cavity 13 is provided with a gas pipeline connected to the cleaning gas source supplying the cleaning gas A, the cleaning gas A (such as argon Ar etc.) After entering the cavity 13, the air curtain will be formed by flowing vertically downward along the baffle plate 16, that is, it will flow from top to bottom along the gap between the inner wall of the cavity and the outer wall of the bushing, and will pass through the outer wall of the bushing and the outer wall of the bushing under the baffle plate 16. The flow space formed around the cavity pa...

Embodiment 2

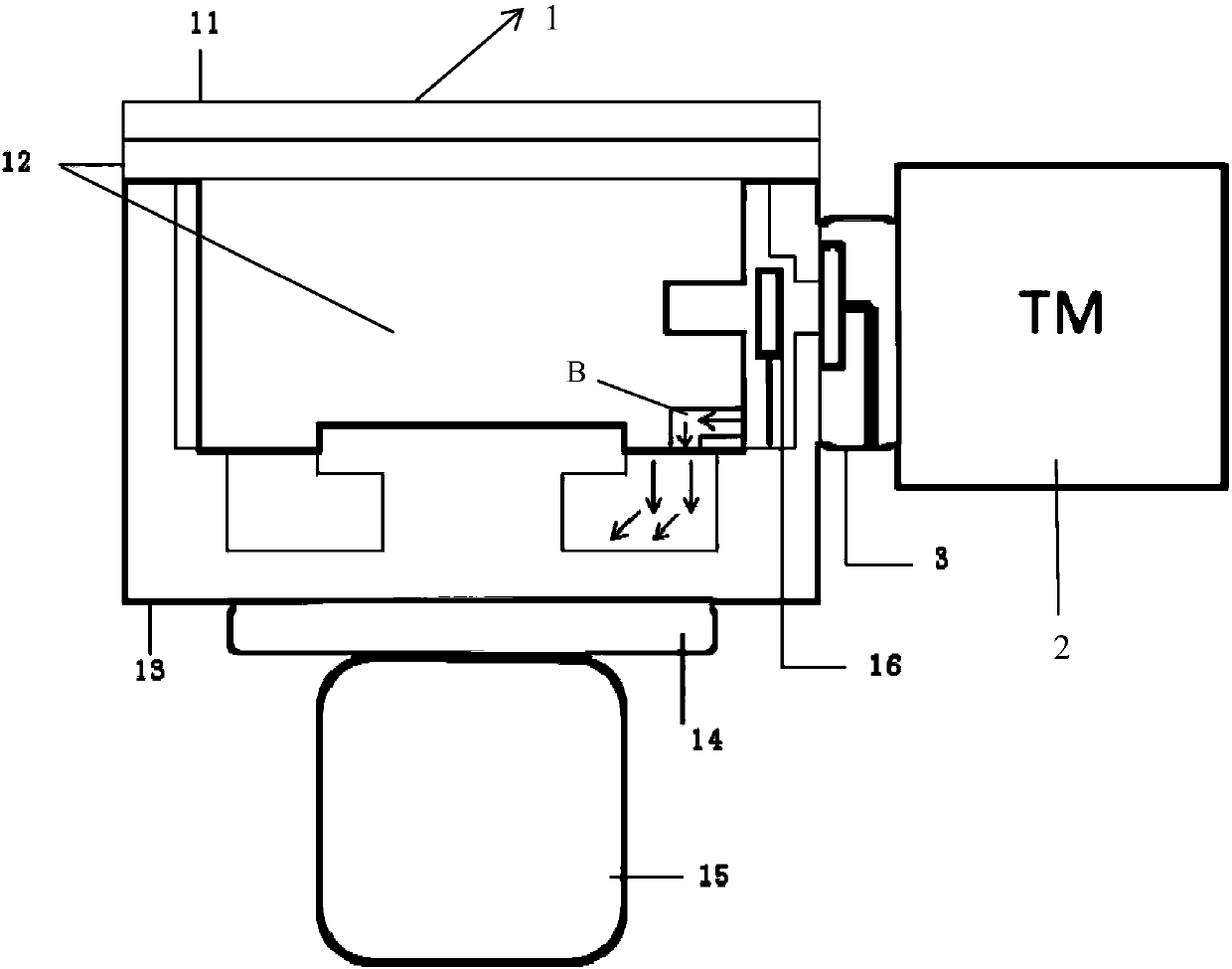

[0044] Such as image 3 As shown, in the second embodiment, the lower part of the bushing 12 is provided with a hole B, and the flow space formed around the outer wall of the bushing and the inner wall of the cavity under the baffle plate 16 communicates with the inner space of the bushing 12 through the hole B, Create an efficient gas flow path.

[0045] In the second embodiment, no gas pipeline is provided on the cavity 13 to communicate with the clean gas source for supplying the clean gas, that is, the upper end of the cavity 13 is not filled with clean gas, and only the gas flow path is communicated with the vortex pump 15 .

[0046] After finishing the first wafer transfer and before the second wafer transfer, when the vortex pump 15 is turned on, the last transfer process falls on the outer wall of the bushing and the cavity 13 formed around the shielding plate 16. After the pollution particles in the space are pulled by the vortex pump 15, the space formed by the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com