Polycarbonate production system

A production system, polycarbonate technology, applied in the chemical field, can solve problems such as physical hazards for workers, low thermal stability, environmental pollution, etc., and achieve the effects of avoiding pollution, strong degradation ability, and strong ester bond bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

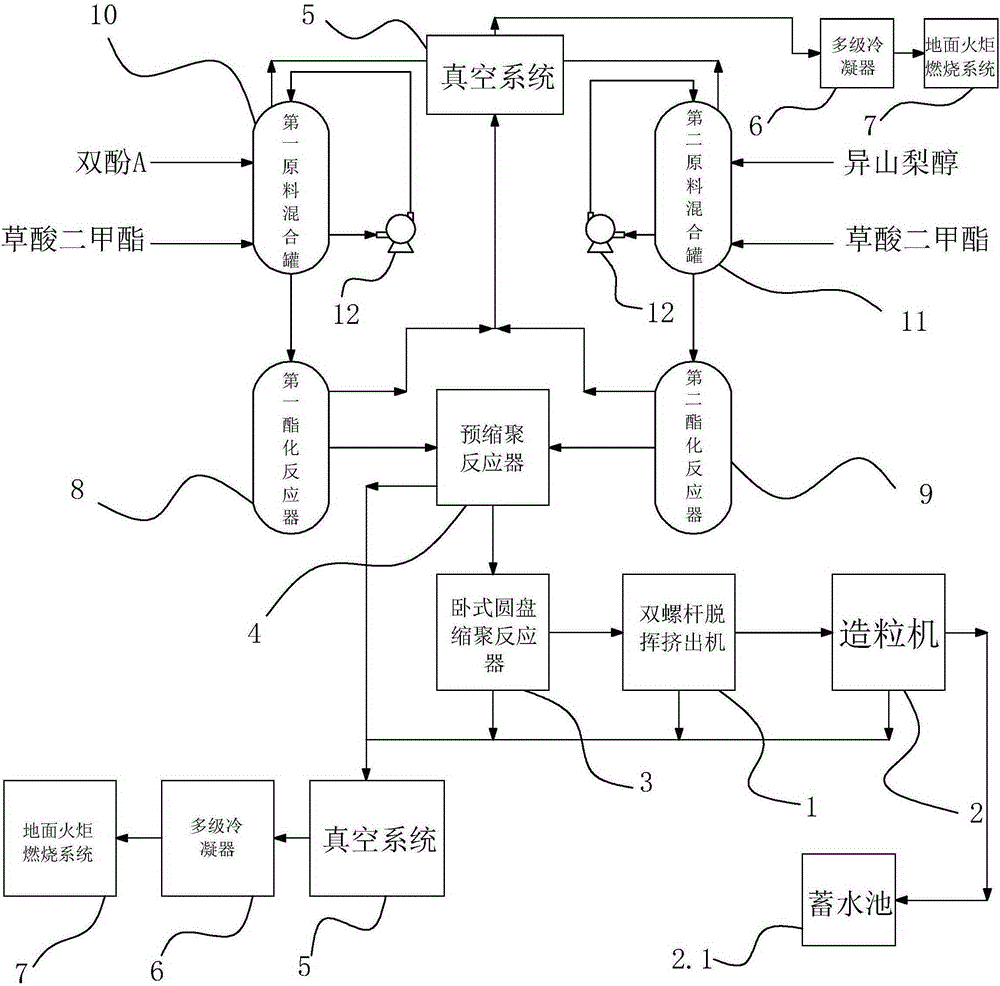

[0024] refer to figure 1 Embodiments of the present invention will be further described.

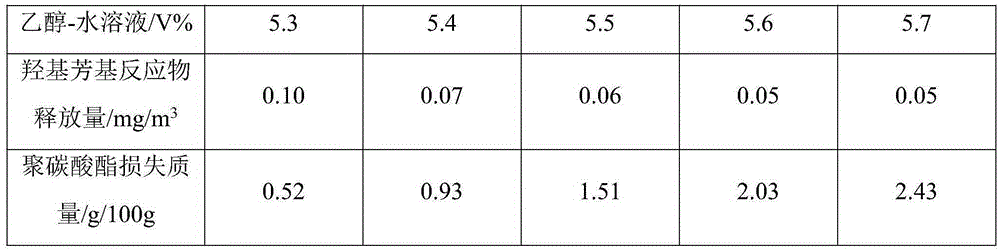

[0025] A polycarbonate production system, including a devolatilization granulation system, the devolatilization granulation system includes a twin-screw devolatilization extruder 1, a granulator 2 and a reservoir 2.1, the output of the twin-screw devolatilization extruder 1 The port is connected with the input port of the granulator 2, and the output port of the granulator 2 is submerged under the liquid level of the reservoir 2.1. Since the polycarbonate is extruded from the twin-screw devolatilization extruder 1, the temperature at this time is between 265°C and 305°C, so a large amount of hydroxyaryl reaction products will be taken out at this time, while the twin-screw devolatilization extruder The volatilization extruder 1 is communicated with a vacuum system 5, and the vacuum system 5 can extract the air in the twin-screw devolatilization extruder 1, thereby ensuring that the vola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com