Side opening type material loading device capable of compressing materials and improving loading capacity

A technology of loading capacity and material loading, applied in waste collection and transfer, household utensils, garbage collection, etc., can solve the problems of inconvenient operation of garbage disposal, low utilization rate of trash can space, waste of resources, etc., and achieve simple operation of feeding materials Convenience, improve material loading capacity, reduce waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

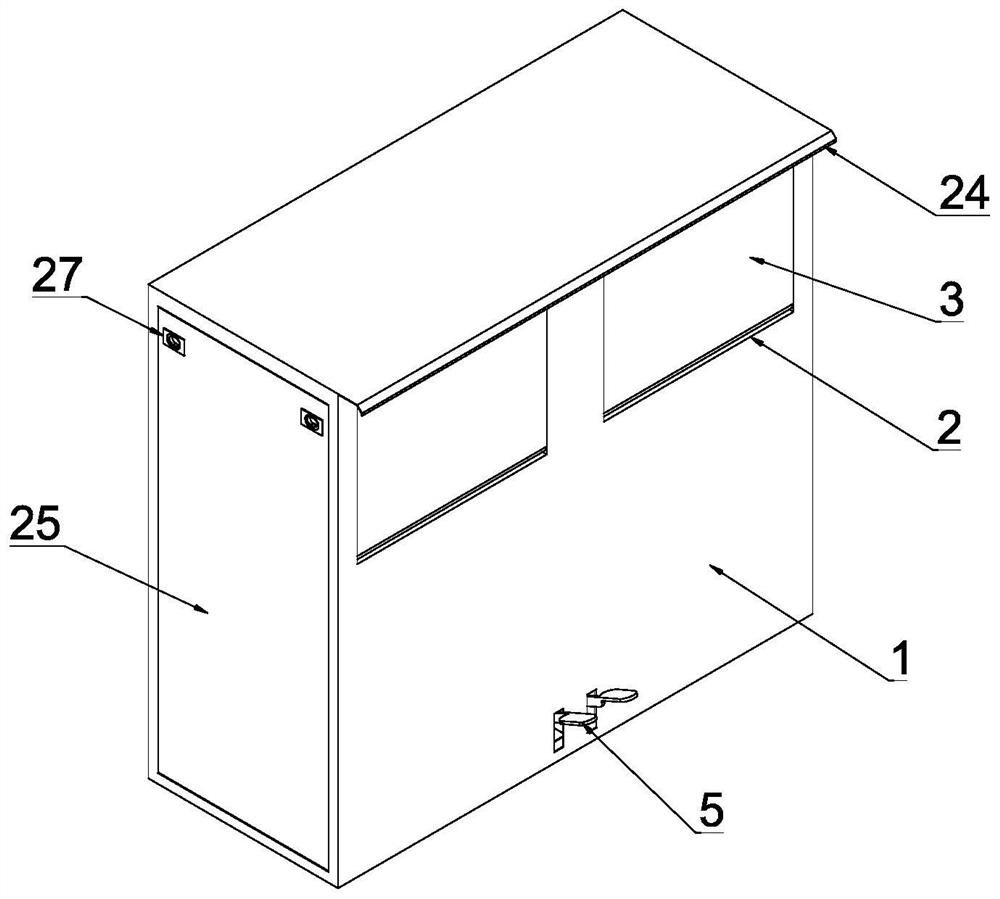

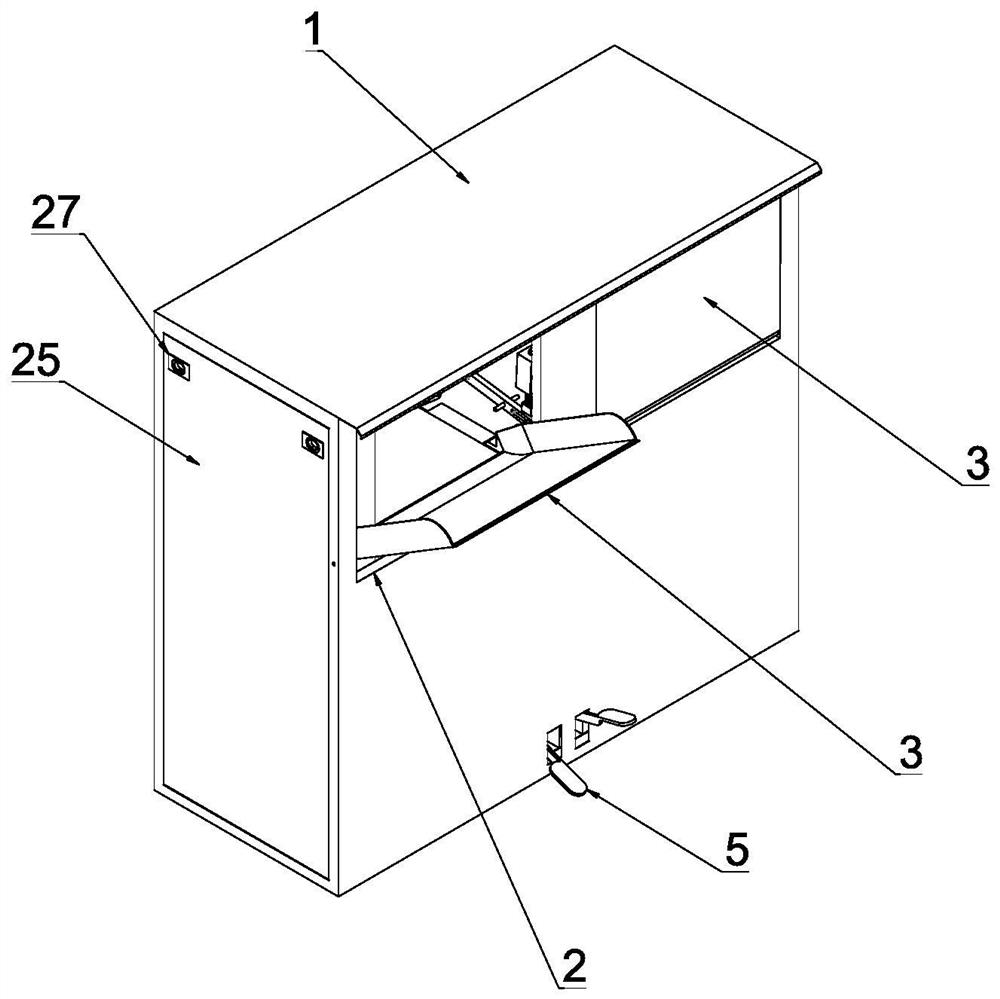

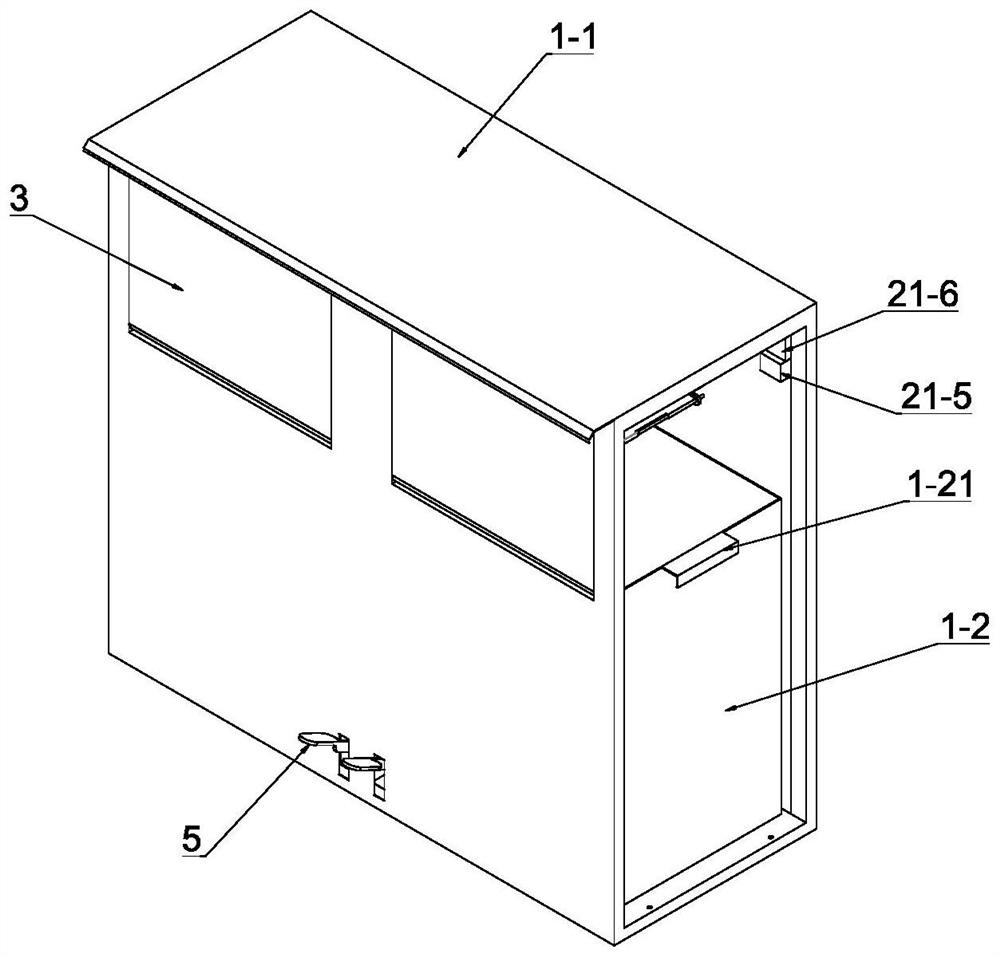

[0058] see Figure 1-Figure 7 and Figure 15 , this embodiment discloses a side-opening material loading device for compressible materials to improve loading capacity, including a container body 1, a side of the container body 1 is provided with a feeding port 2 for feeding materials, and the container body 1 is used for feeding A cover body 3 is provided at a position corresponding to the mouth 2, and the cover body 3 is hinged on the container body 1 through hinge shafts 4 arranged at both ends of the cover body 3, wherein the container body 1 is provided with a The cover body 3 rotates around the hinge shaft 4 so as to open the feed opening 2 and impel the cover body to keep closed under normal conditions; when the feed opening 2 is opened, the upper end of the cover body 3 faces the container body 1. The outside is turned downwards, and the lower end is turned upwards toward the inside of the container body 1 to form a material guiding posture that guides the material to ...

Embodiment 2

[0099] Other structures in this embodiment are the same as in Embodiment 1, the difference is that the hinge shaft 4 is arranged on the upper end of the cover body 3. At the upper end of the cover body 3, when the pedal lever 5-1 is released, under the action of the self gravity of the cover body 3, the lower end of the cover body swings downward and drives the pedal lever 5-1 to reset until the cover body 3 is in the In the vertical state, close the feeding port 2. By arranging the above structure, the third return driving spring 5-4 can be replaced to realize the automatic closing of the feeding port 2 and the automatic reset of the pedal rod 5-1.

Embodiment 3

[0101] see Figure 20 , other structures in this embodiment are the same as in Embodiment 2, the difference is that a counterweight 28 is provided at the lower end of the cover body 3, and by setting the counterweight 28, the counterweight 28 is driven by gravity. The lower end of the cover body 3 swings downwards, so that the feeding port is closed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com