Three-dimensional space random-direction fusion-covering forming method

A technology of any direction and molding method, applied in the direction of process efficiency improvement, energy efficiency improvement, additive manufacturing, etc., can solve the problems of easy flow of molten pool, polluted mirror surface, damage of focusing mirror, etc., to ensure the effect of not being polluted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

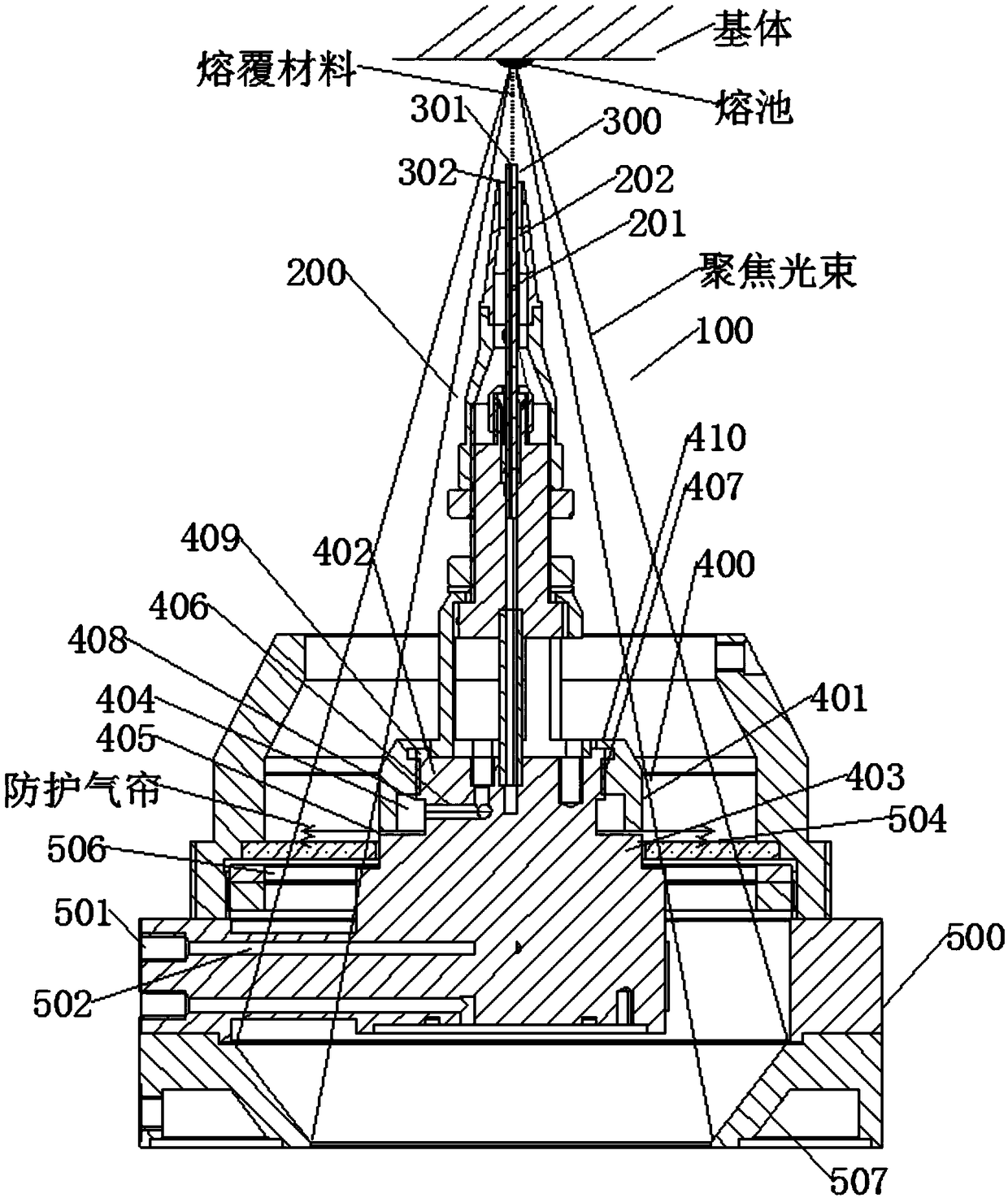

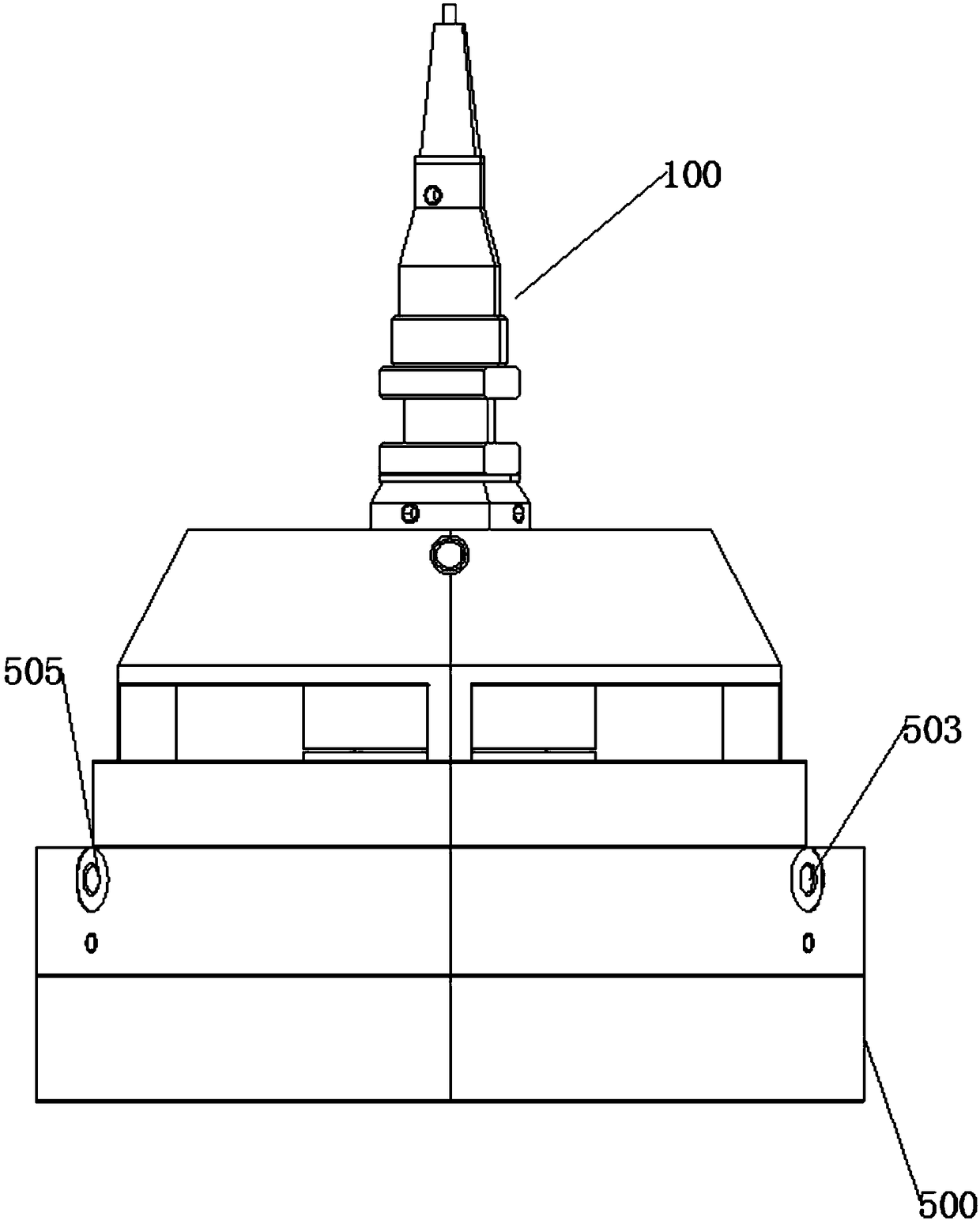

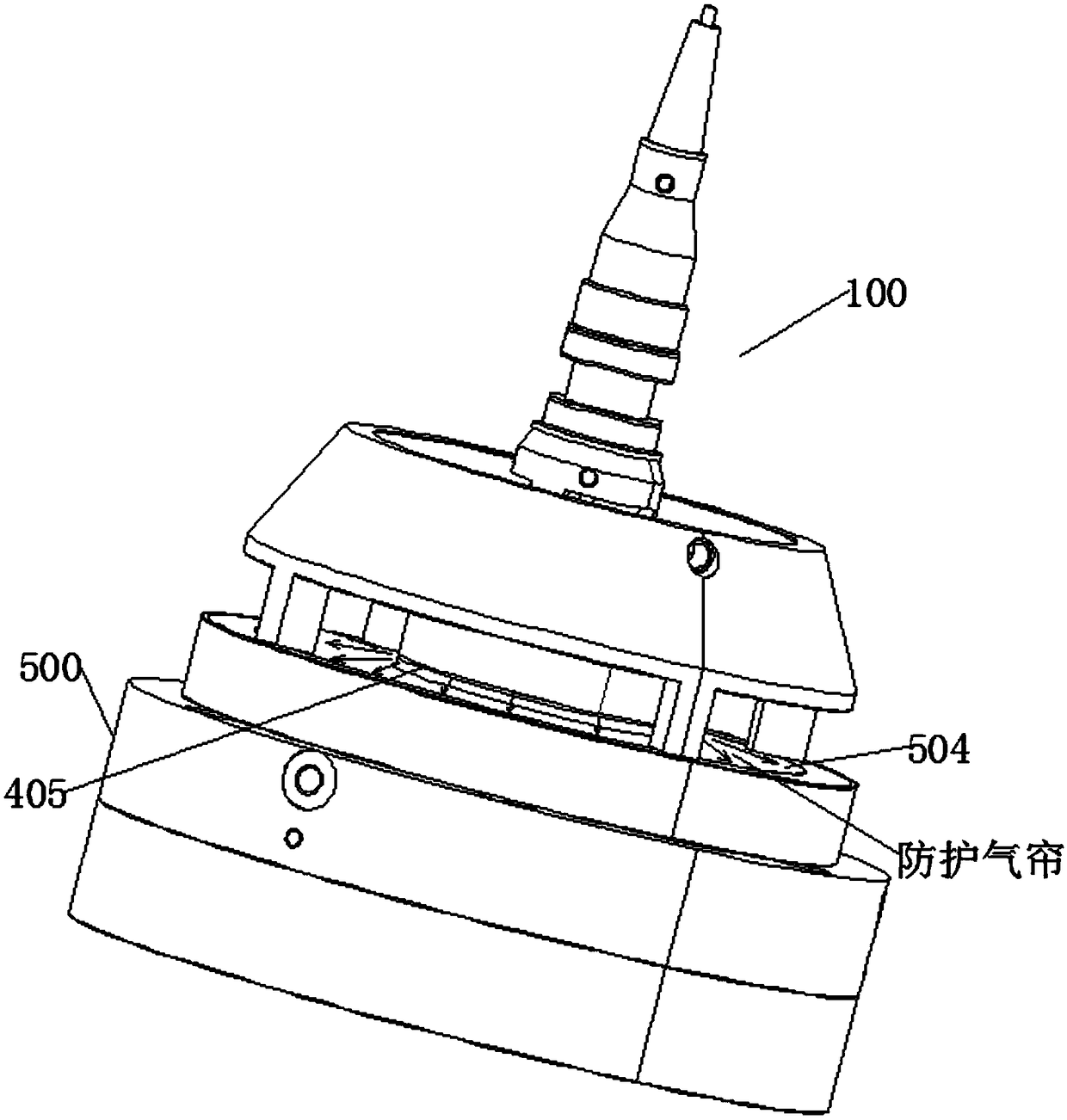

[0029] See Figure 1-3 , a cladding molding method in any direction in three-dimensional space according to Embodiment 1 of the present invention is mainly used to prevent the cladding material from splashing and adhering to the focusing mirror 507 when the laser cladding device continuously changes its orientation, so as to prevent the focusing mirror 507 from being damaged due to For the problem of damage caused by cladding materials, the cladding molding method in any direction in three-dimensional space includes the following steps: providing a substrate with a surface that needs cladding accumulation or cladding repair, and the cladding material passes through the cla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com