Setting machine applied to tie production and processing

A technology of setting machine and tie, which is applied in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of short service life of the setting machine, prone to safety accidents, poor operation safety performance, etc., to improve quality, Easy to operate and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

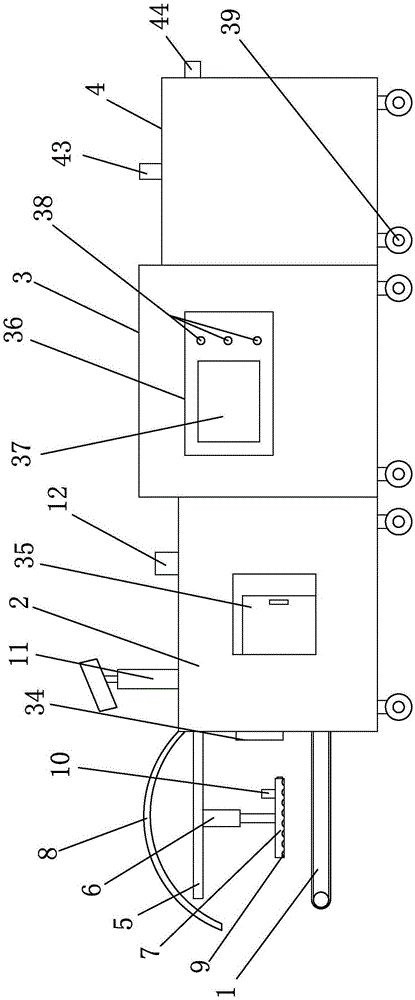

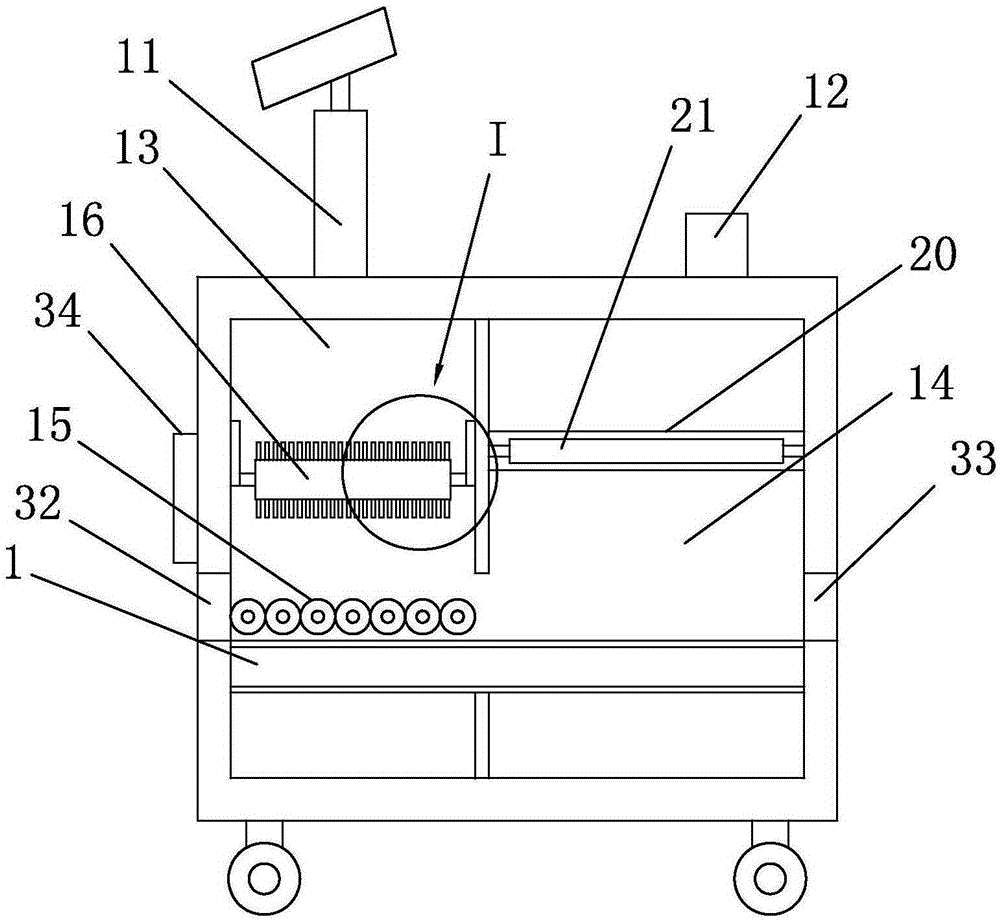

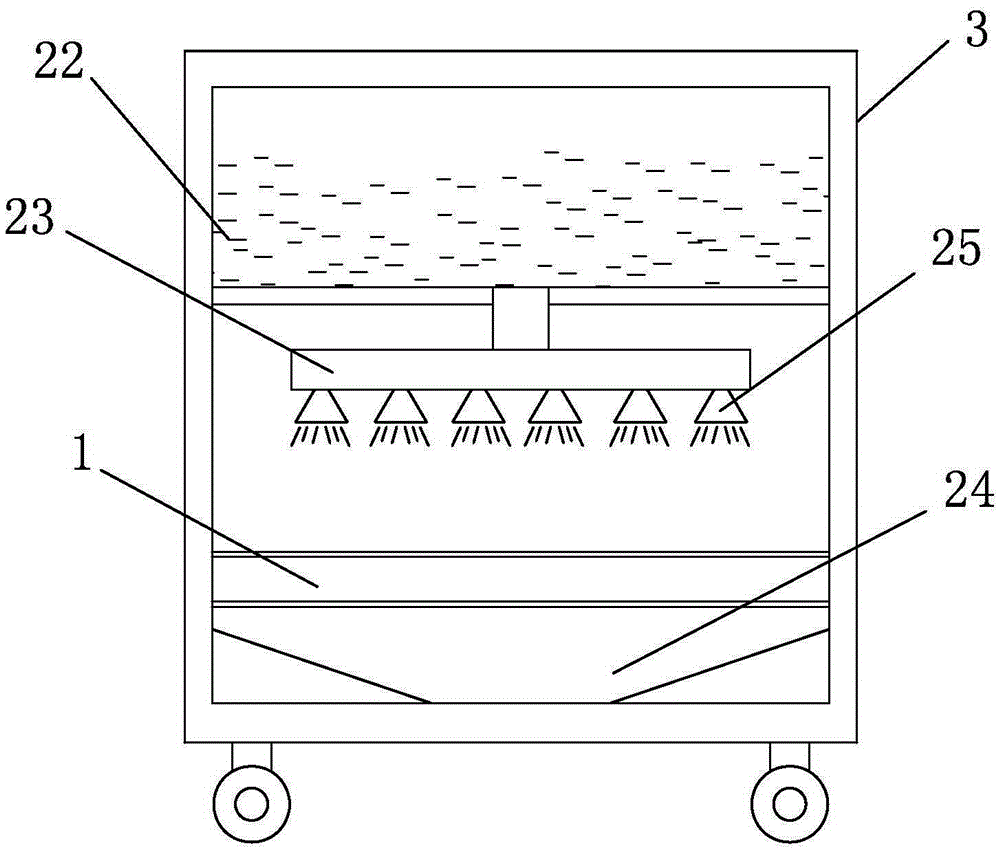

[0032] Such as Figure 1 to Figure 7 As shown, it is a sizing machine applied to the production and processing of neckties according to the present invention, which includes a transfer table 1, a sizing box 2, a spray box 3 and a drying box 4, and a pressing device is arranged above the transfer table 1, and the pressing device includes Horizontal guide rail 5, telescopic rod 6 and jet disc 7, the right end of horizontal guide rail 5 is connected with the outer wall of shaping box 2, and the bottom surface of horizontal guide rail 5 is provided with slideway, and telescopic rod 6 is limited in the slideway, along the slideway left and right Move, the telescopic rod 6 is connected with the top surface of the air jet disc 7, the design of the horizontal guide rail 5 can facilitate the fixing and installation of the pressing device, and the design of the slideway can facilitate the movement of the air jet disc 7, so that the air jet disc 7 is facing the feeding The cloth on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com