Detaching device

A dismantling device and position-limiting technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as easy scraping of fixtures, low efficiency, and high labor intensity, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

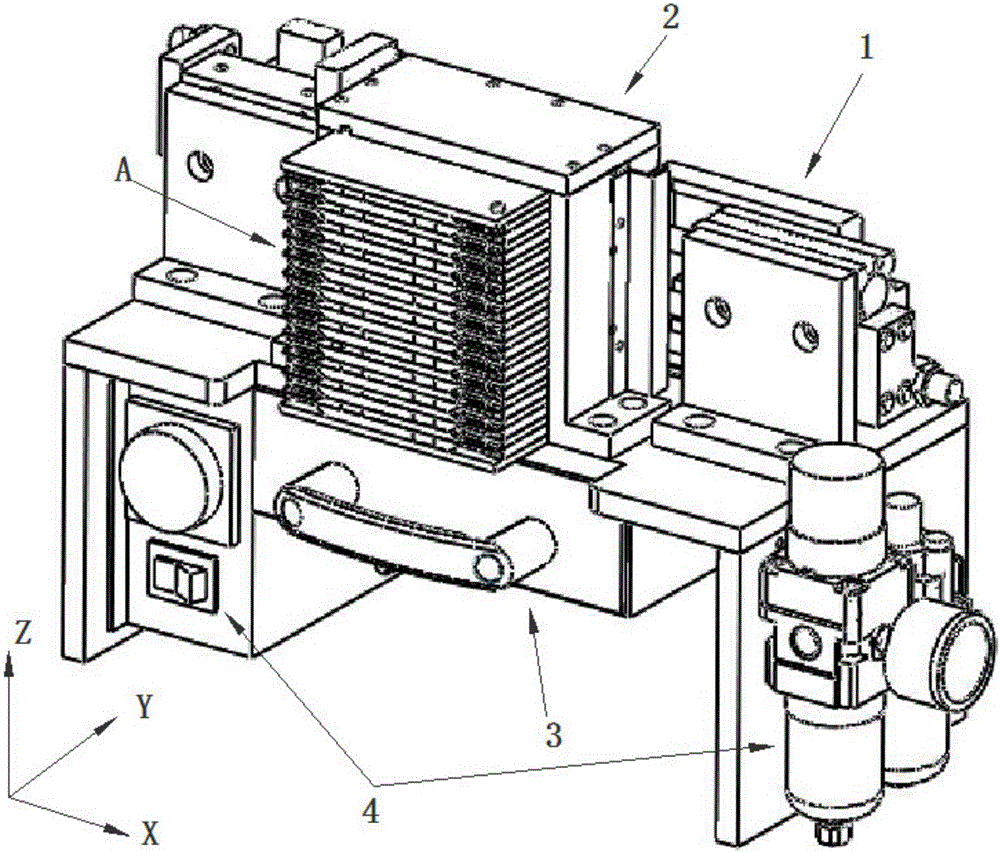

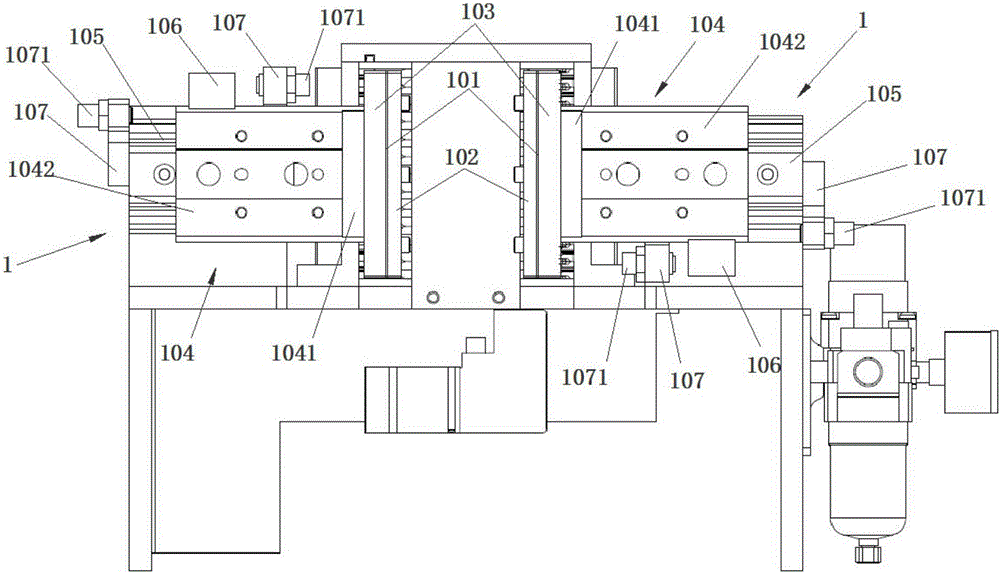

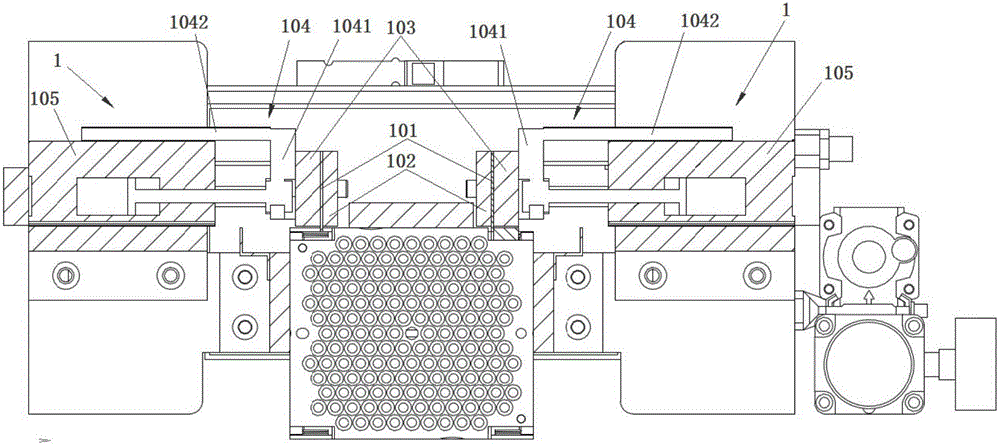

[0043] The description of this illustrative embodiment should be taken in conjunction with the accompanying drawings, which should be considered a part of this complete specification. In the drawings, the shapes or thicknesses of the embodiments may be exaggerated and marked for simplification or convenience. Furthermore, parts of each structure in the drawings will be described separately. It should be noted that elements not shown in the drawings or described in words are forms known to those of ordinary skill in the art.

[0044] figure 1 Shown in A is the jig loaded with the lens of the mobile phone lens, which is used to carry and transport the lens of the mobile phone. The jig itself is rectangular as shown (see also image 3 ), many lens modules are distributed or loaded in the fixture. The fixture consists of upper and lower parts, namely the upper cover and the lower base. At the four corners of the fixture, buckles are provided for fastening and fixing the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com