Natural gas cylinder production line

A technology of natural gas and wire body, which is applied in the field of wire body for conveniently putting gas cylinders into the frame, which can solve the problems of gas cylinder collision damage, labor consumption, and low work efficiency, so as to improve work efficiency, save manpower and material resources, and shorten assembly the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

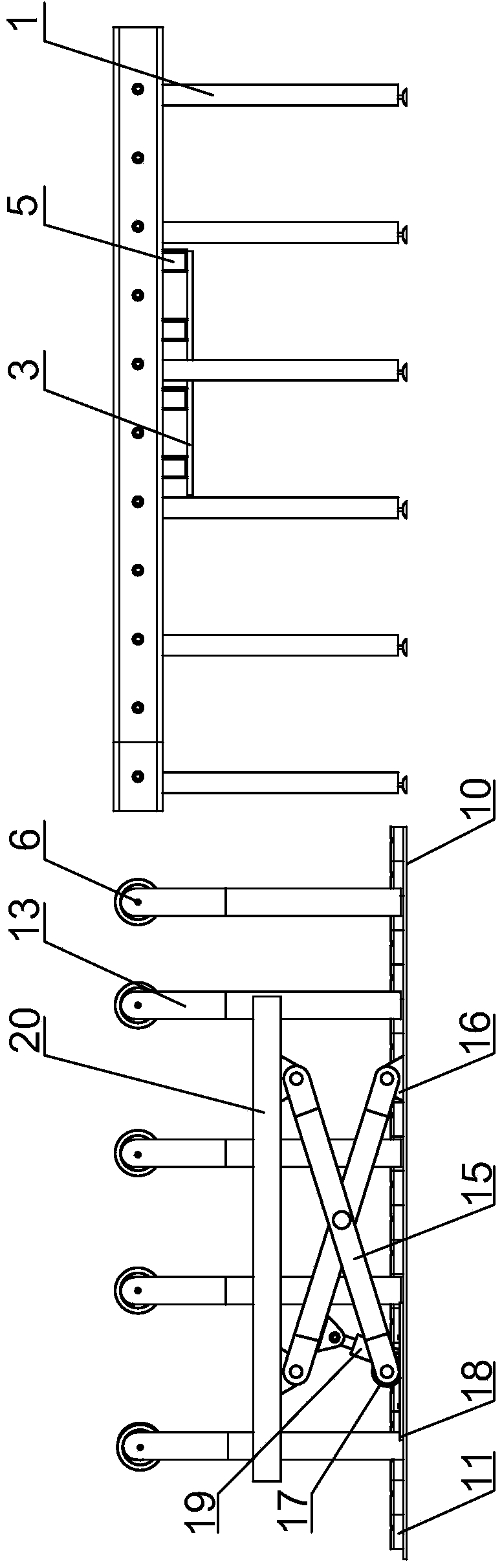

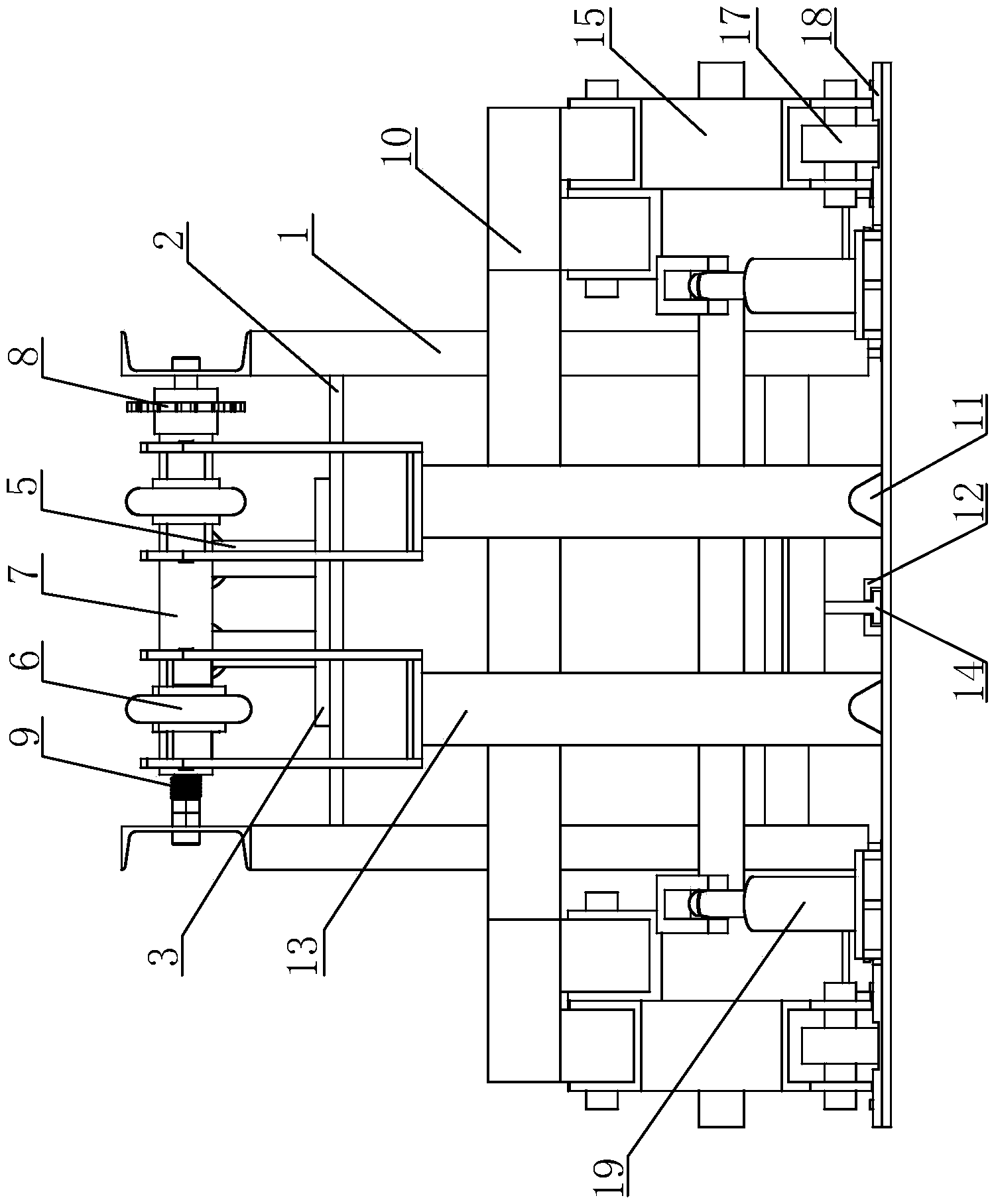

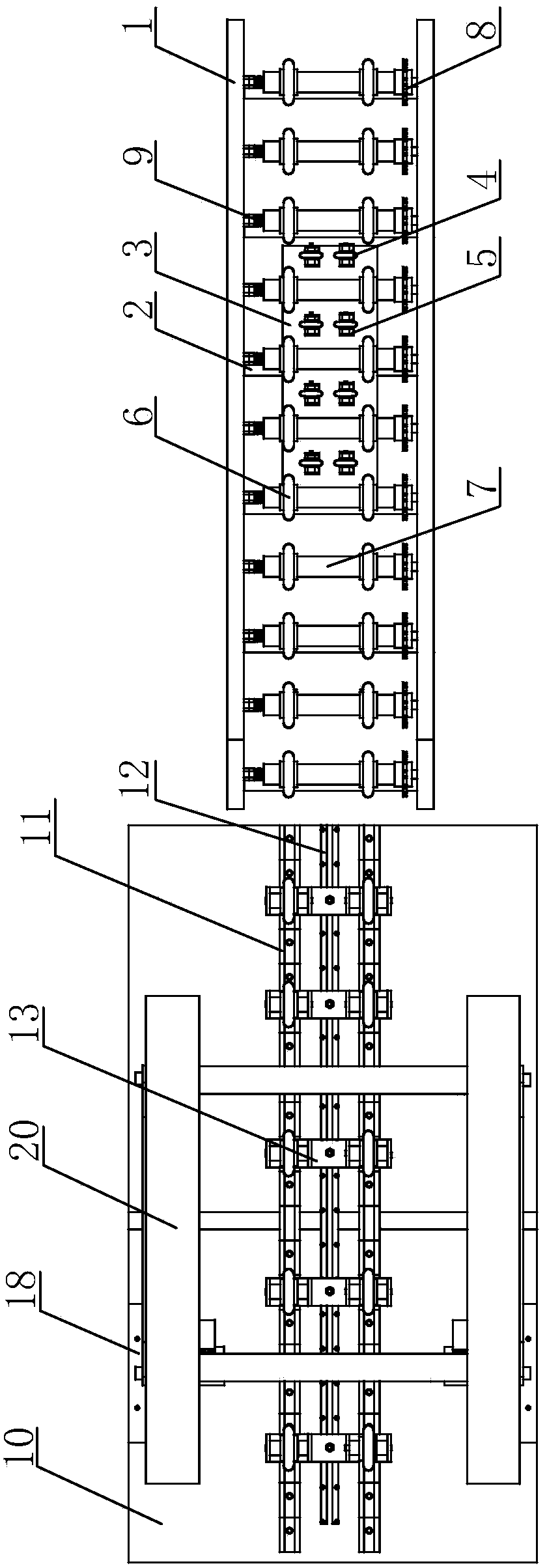

[0012] Such as figure 1 , 2 , 3, and 4, the present invention installs the steering wheel plate 3 by welding the support plate 2 under the line body support 1, the steering wheel 4 is installed on the steering wheel base 5 of the steering wheel plate 3 through the rotating shaft, and the guide wheel 6 is fixed. On the guide wheel shaft 7, the two ends of the guide wheel shaft 7 are respectively inserted into the fixing holes of the line body support 1, so that the guide wheel 6 can rotate with the guide wheel shaft 7 through the fixing holes, and are set at one end of the guide wheel shaft 7 The gear 8 is fitted with a spring 9 at the other end, and two parallel raised slideways 11 are installed on the lifting platform base 10 through bolts, and a strip-shaped opening is welded at the middle position of the two raised slideways 11. Cuboid slideway 12, one end of the pull rod 14 at the bottom of the guide wheel frame 13 is stuck in the elongated opening of the cuboid slideway ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com