Commutator bearing mechanism for automatic rotor commutator press-in machine

A technology of bearing mechanism and commutator, which is applied in the manufacture of motor generators, electromechanical devices, electric components, etc. It can solve the problems that affect the production capacity and output value, the pressing is not in place, and the motor casing cannot be installed, so as to achieve a simple design structure Practical and prevents misplacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0008] see figure 1 , the embodiment of the present invention includes:

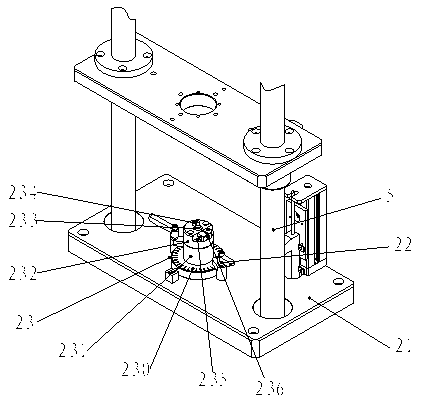

[0009] A commutator carrying mechanism of a rotor commutator automatic press-in machine, the commutator support mechanism of the rotor commutator automatic press-in machine includes a bottom plate 21 with a commutator jig 23 fixed in the middle through a quick handle 22, the bottom plate The two sides of 21 are provided with guide bar 5; Described commutator jig 23 is that the cylindrical seat 231 upper end of band lower fixed side 230 is provided with commutator inserting disc 232, and commutator inserting disc 232 middle is provided with inserting hole 233 The commutator insert ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com