A rock drilling device that can perform a variety of work methods

A rock drilling device and technology outside the device, applied in earthwork drilling, drilling equipment and methods, construction, etc., can solve problems such as difficult operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

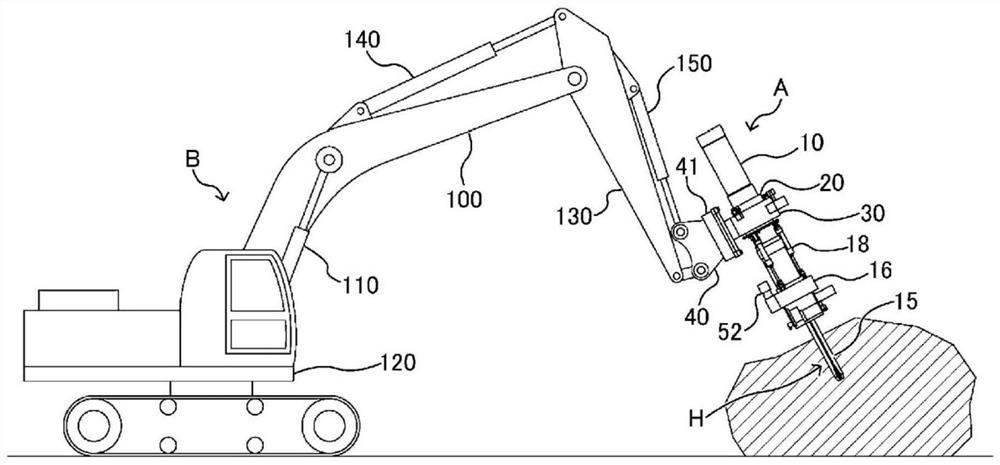

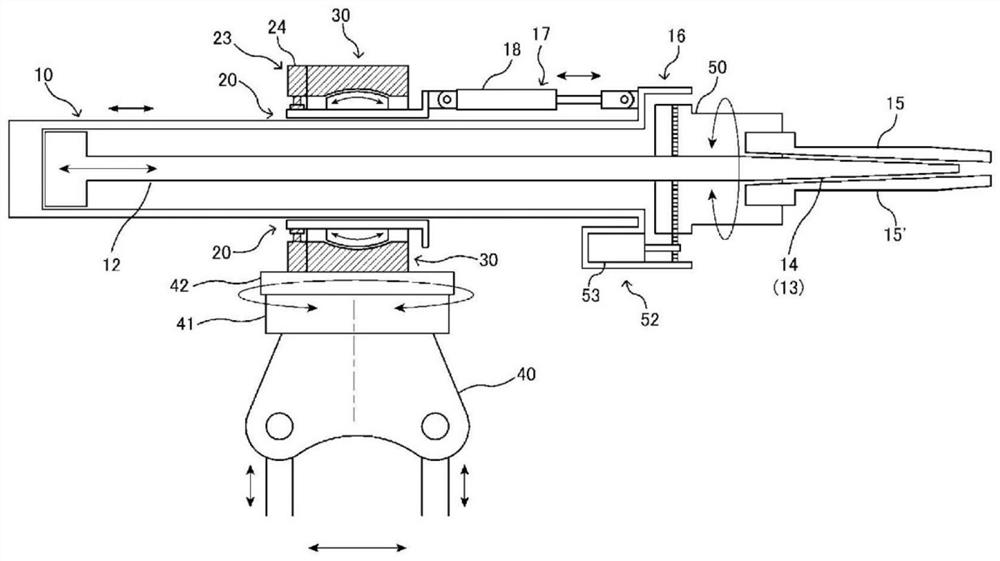

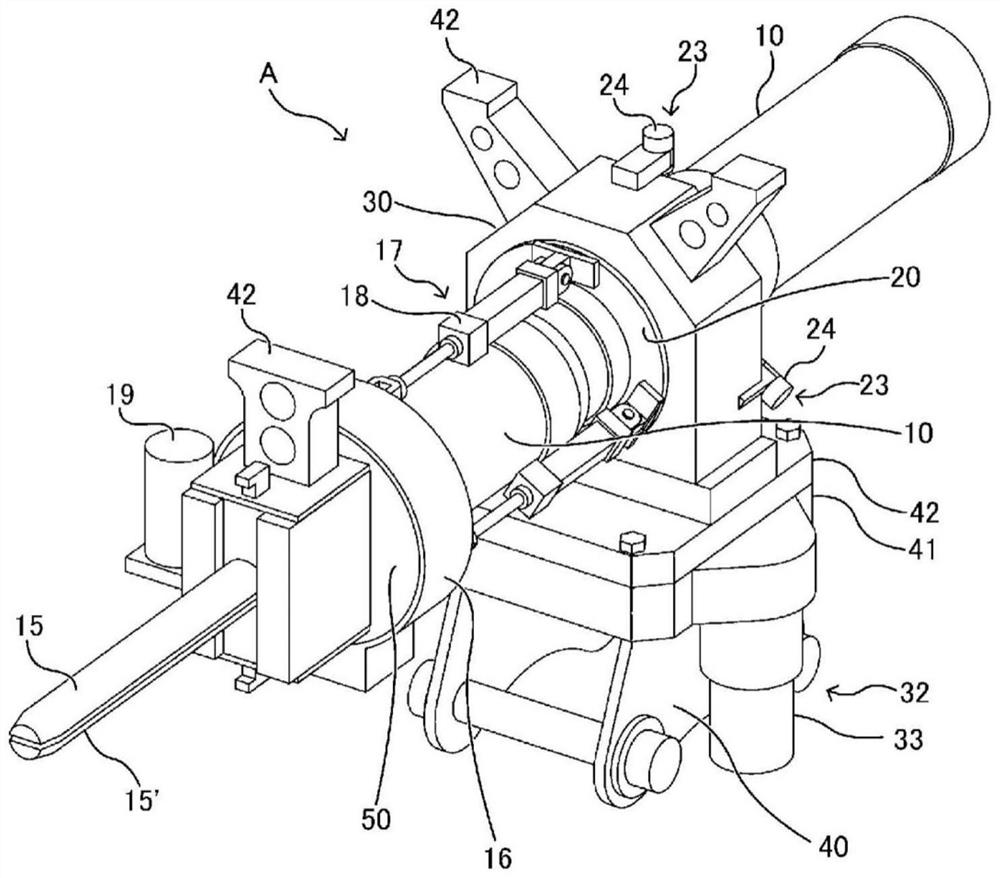

[0047] The gist of the present invention is a rock drilling device capable of performing various operation modes, characterized in that, in the rock drilling device constituted by combining the device main body and the device outer body, the device main body consists of a main cylinder block and is provided in the main cylinder block. The wedge body on the extension part of the piston rod and a pair of expandable rock drilling blade bodies abutting on the outer side surface at the top end of the wedge body are formed. The main body is loosely fitted with an outer body shell, and a device mounting board is provided at the top end of the bracket of the arm of the backhoe for work separately prepared. The outer body is mounted and supported on the bracket body through the ball joint so as to be able to swing in all directions,

[0048] Further, the device main body is composed of a cylindrical main body case and a rock drilling blade body support case in which a master cylinder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com