Full-automatic vulcanizing machine for bearing sealing ring

A bearing sealing and vulcanizing machine technology, which is applied in the field of vulcanizing machines, can solve the problems of low automation and low production efficiency, and achieve the effect of improving production efficiency and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

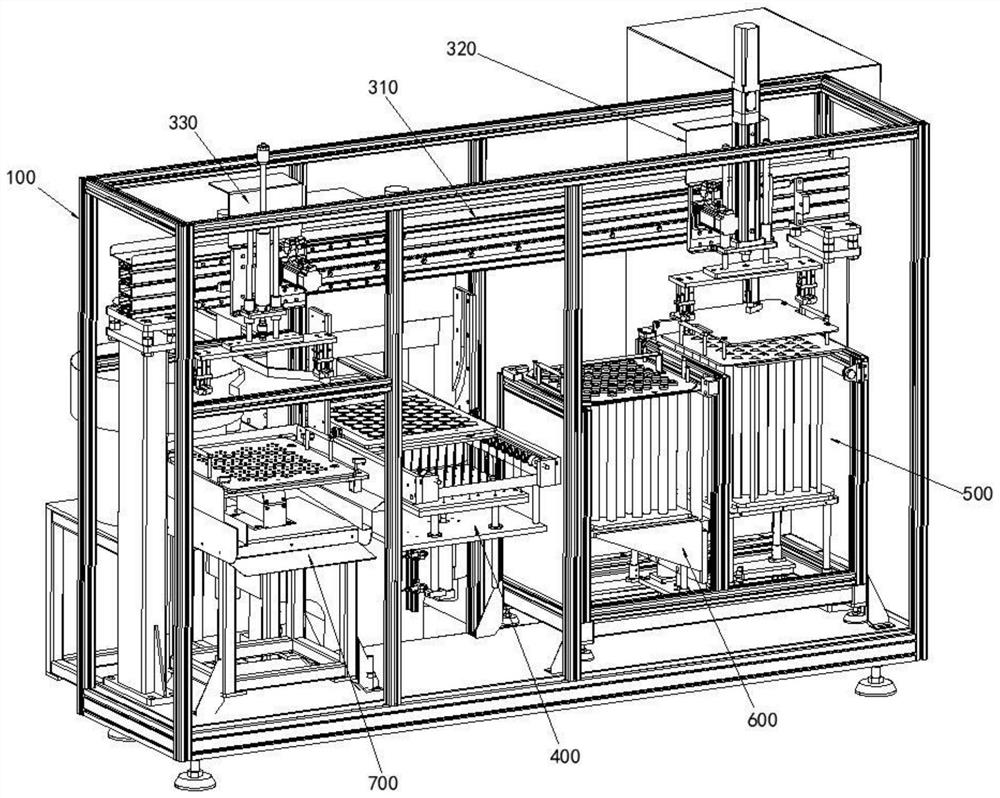

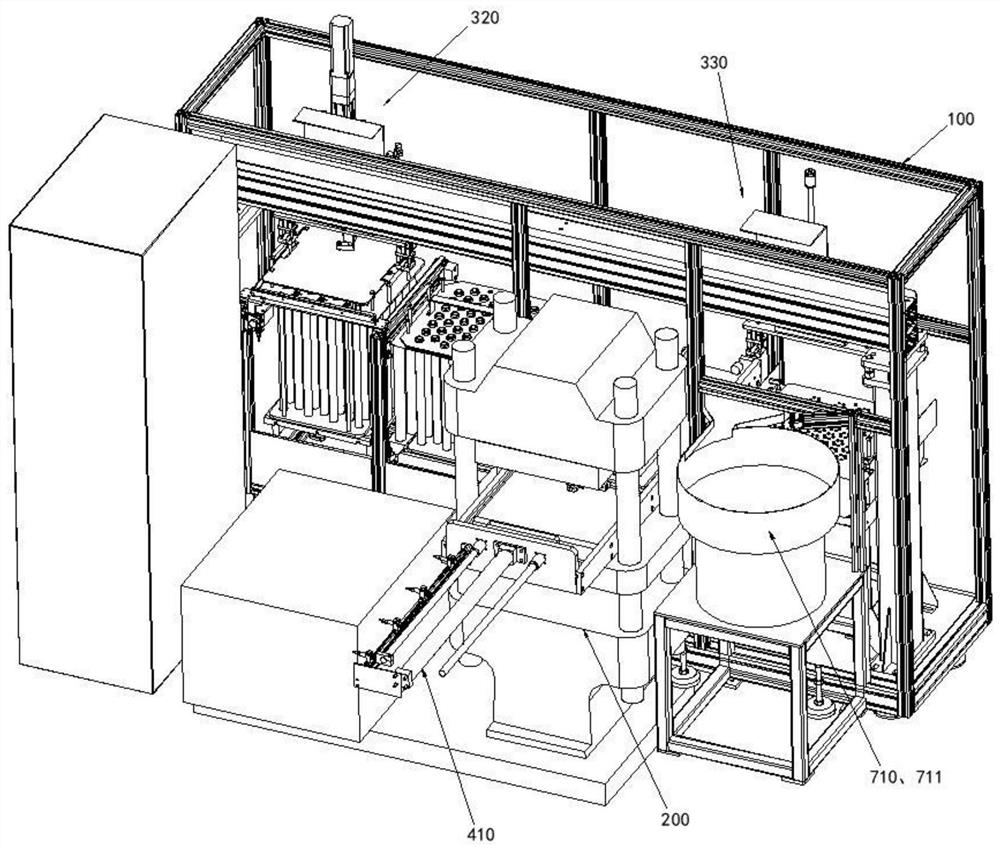

[0045] Such as figure 1 with figure 2 As shown, the fully automatic vulcanizer for bearing sealing rings in this embodiment includes a frame 100, a vulcanizer body 200, a truss assembly 300, a mold assembly 400, a blanking assembly 500, a skeleton feeding assembly 600, and a particle feeding assembly 700;

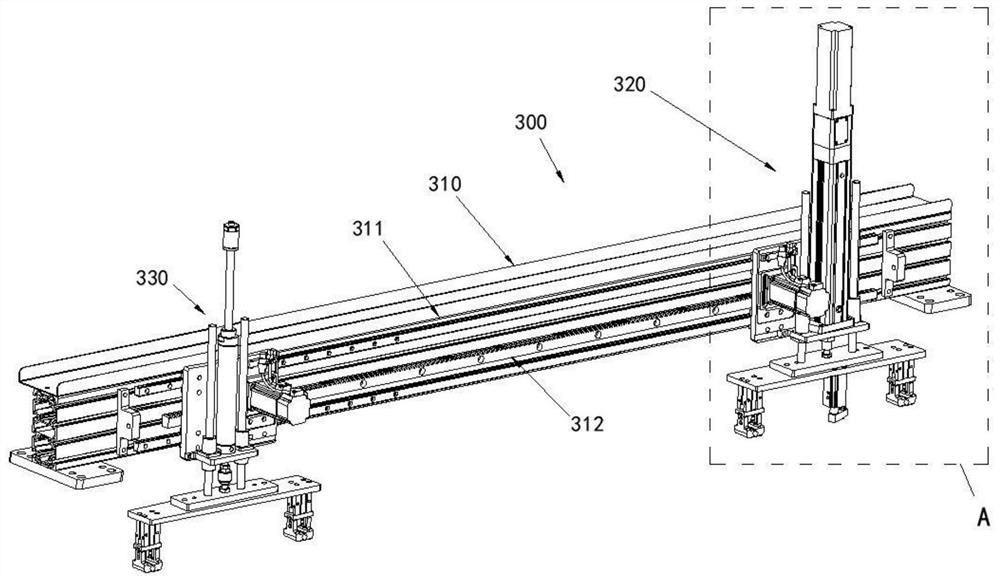

[0046] Such as Figure 3 to Figure 5 As shown, the truss assembly 300 includes a horizontal truss 310, a first clamp assembly 320 and a second clamp assembly 330, the horizontal truss 310 is fixed on the frame 100, the horizontal truss 310 is provided with a horizontal track 311 and a horizontal rack 312, the first clamp The assembly 320 includes a moving plate 321, a first motor 322, a gear, a base plate 323, a first cylinder 324, a chuck 325, a second cylinder 326, a second motor 327 and a cross bar 328, and the moving plate 321 is installed on the horizontal track 311, The first motor 322 is installed on the moving plate 321, the rotating shaft of the first motor 322 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com