Rose scented cigarette paper and preparation method thereof

A technology of cigarette paper and rose fragrance, which is applied in the fields of tobacco, papermaking, paper coating, etc., and can solve problems such as destruction of raw materials of fragrance sources, waste of raw materials of fragrance sources, and reduction of product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention provides the preparation method of rose-flavored cigarette paper described in the above-mentioned technical solution, comprising the following steps:

[0043] Disintegrating and beating the fibers in sequence to obtain a fiber slurry;

[0044] After mixing the fiber slurry and the filler, papermaking is carried out to obtain a mixed slurry;

[0045] The mixed slurry is sequentially subjected to wire forming, press dehydration, embossing and first drying to obtain a first dry paper web;

[0046] mixing the aqueous solution of the combustion enhancer with the microcapsule powder of rose essential oil to obtain a mixed solution;

[0047] The mixed solution is used as a sizing agent to carry out surface sizing on the first dried paper web, and then carry out second drying to obtain rose-flavored cigarette paper.

[0048] In the invention, the fibers are crushed and beaten in sequence to obtain fiber slurry. The present invention has no special limit...

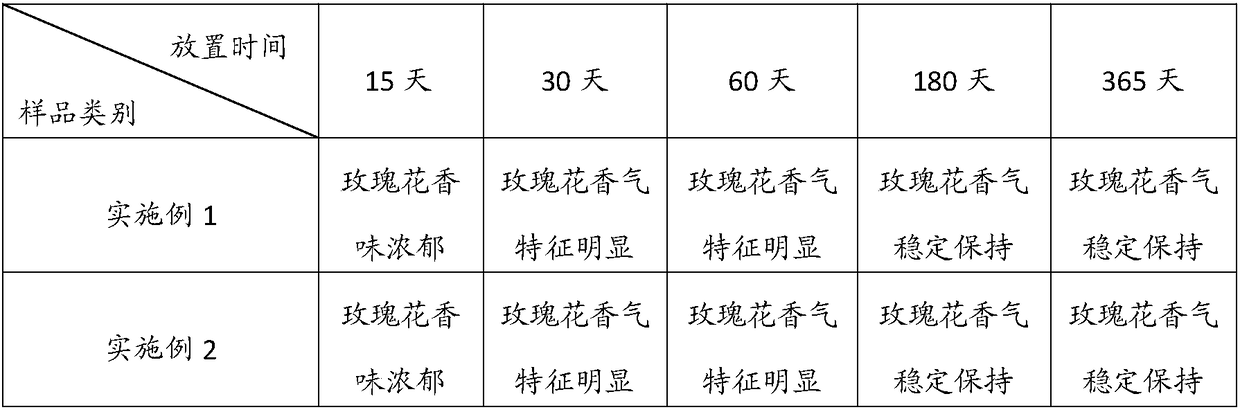

Embodiment 1

[0072] The preparation of rose essential oil comprises the following steps:

[0073] Cut edible roses into rose fragments with a length of 2-4cm and a width of 1-2cm, put the rose fragments and water in an extraction tank at a mass ratio of 1:4, and steam the extraction tank heating to extract the rose fragments to obtain an oil-water mixture;

[0074] Concentrating the oil-water mixture, adding solid sodium chloride to the obtained residue until the solid sodium chloride is no longer dissolved, standing for 4 hours to separate oil and water, the upper layer of the obtained system is an oil phase, and the lower layer is an aqueous phase;

[0075] Using a motor pump to pump out the water phase from below, adding anhydrous sodium sulfate to the oil phase to absorb the remaining water in the oil phase, filtering to remove the sodium sulfate, and obtaining the oil phase as rose essential oil.

[0076] Prepare rose essential oil microcapsule powder, comprise the following steps:

...

Embodiment 2

[0087] Rose-flavored cigarette paper is prepared according to the method of Example 1, the difference is that the fibers include 650kg wood pulp fiber and 150kg hemp pulp fiber, calcium carbonate is 450kg, and the combustion enhancer includes 25kg potassium malate and 25kg sodium malate, rose The essential oil microcapsule powder is 5kg; the quantitative index of controlling the described rose-flavored cigarette paper is 28g / m 2 , with an air permeability of 60 Coresta.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com