Novel automatic lamination device and method of automobile laminated glass

A laminated glass, automatic technology, applied in windshields, vehicle parts, transportation and packaging, etc., can solve problems such as raw material waste, manual trimming, etc., to improve quality, facilitate changeover production, and ensure lamination accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to describe the technical content, achieved goals and effects of the invention in detail, the following description will be made in conjunction with the embodiments and accompanying drawings.

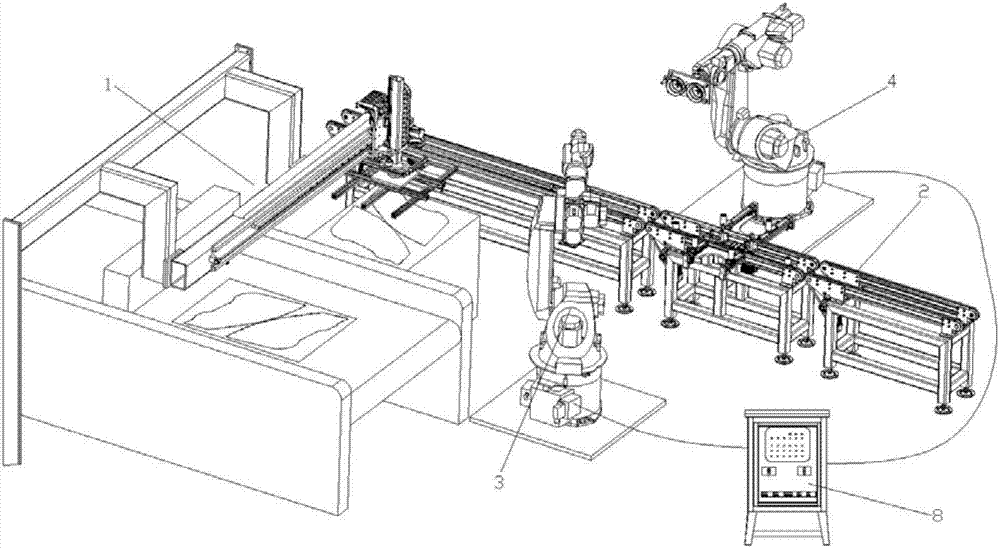

[0048] The overall layout of the new automatic lamination device for laminated glass for automobiles provided by the invention is as follows: figure 1 As shown, it includes a PVB film cutting transmission system 1, which is arranged on the side of the belt conveyor 2, and the two sides of the belt conveyor 2 are respectively equipped with a film manipulator 3 and a film combining manipulator 4, and the belt conveyor 2 is provided with a positioning platform 5. The lamination supporting mechanism 6 and the ferrule station 7 are also provided with a control cabinet 8 with a control system.

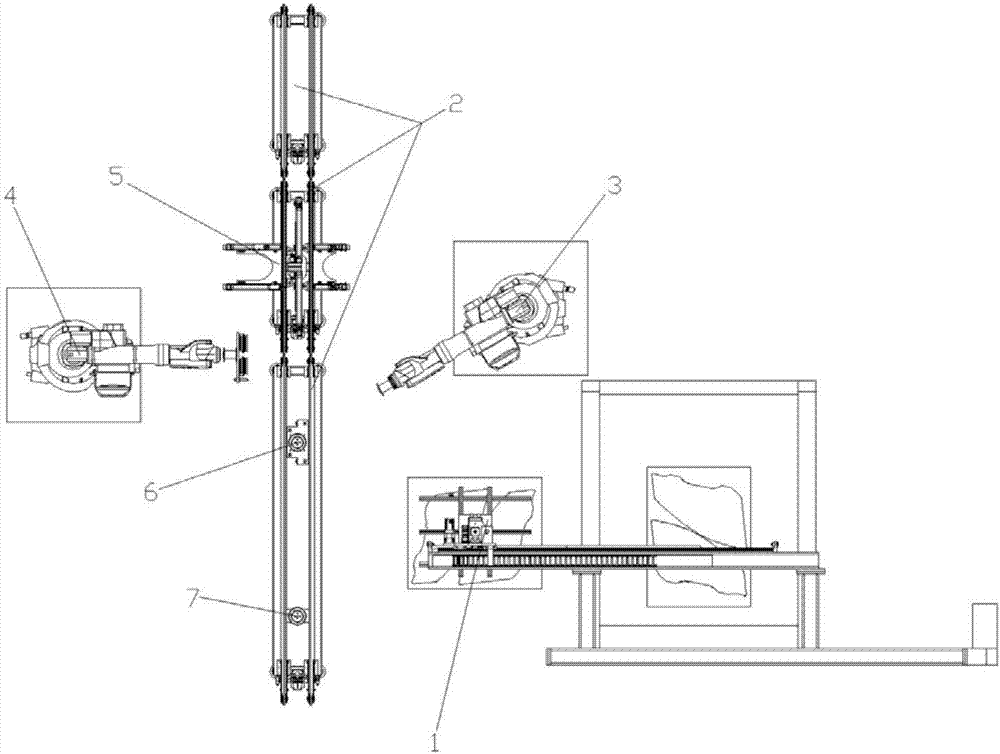

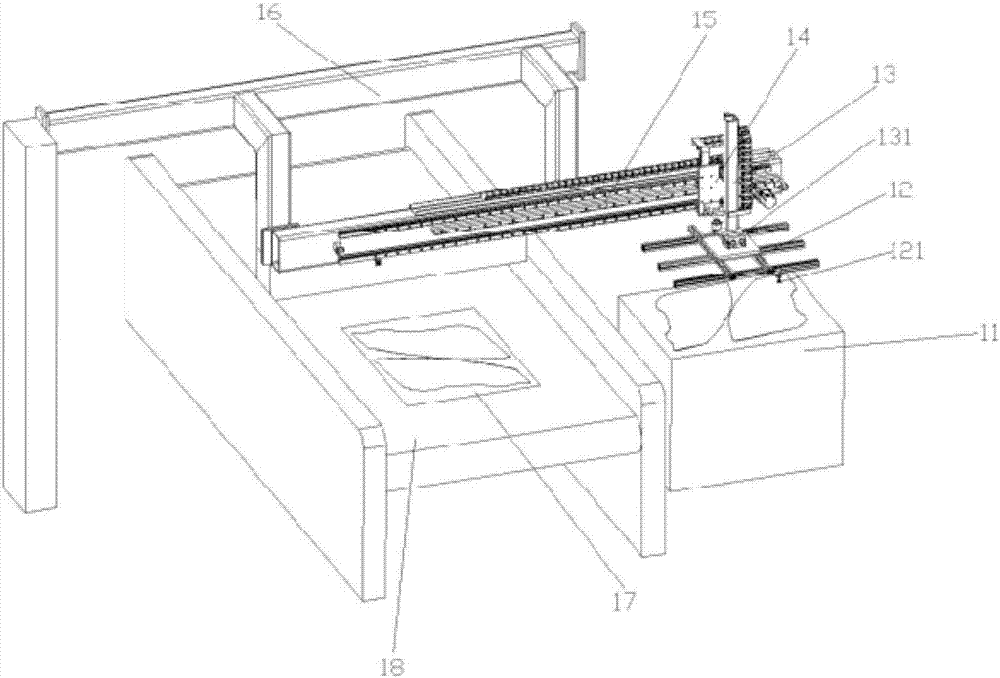

[0049] Such as Figure 1 to Figure 6 As shown, the novel automobile laminated glass automatic sheet closing device provided by the present invention includes

[0050] PVB diaphragm c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com