Current collecting piece welding device, lower current collecting piece welding device and fixture of lower current collecting piece welding device

A current collector and fixture technology, applied in the field of supercapacitor current collector welding fixtures, can solve problems such as poor positioning accuracy, eccentricity between winding core and current collector, and unstable assembly quality, saving man-hours and costs, improving Work efficiency, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

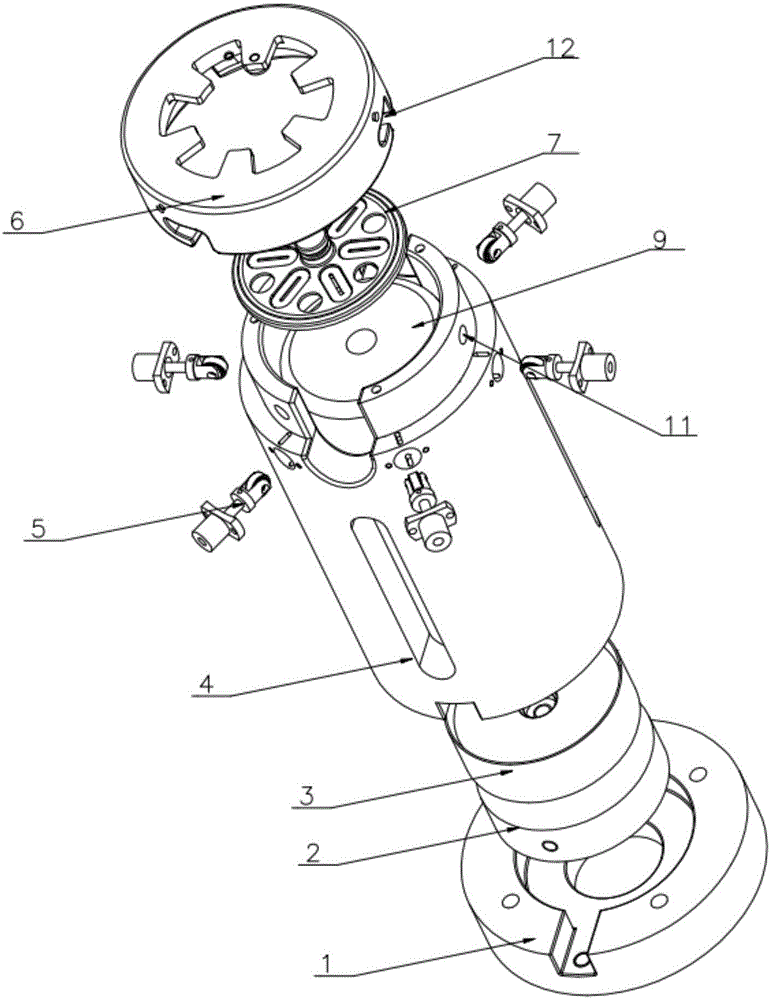

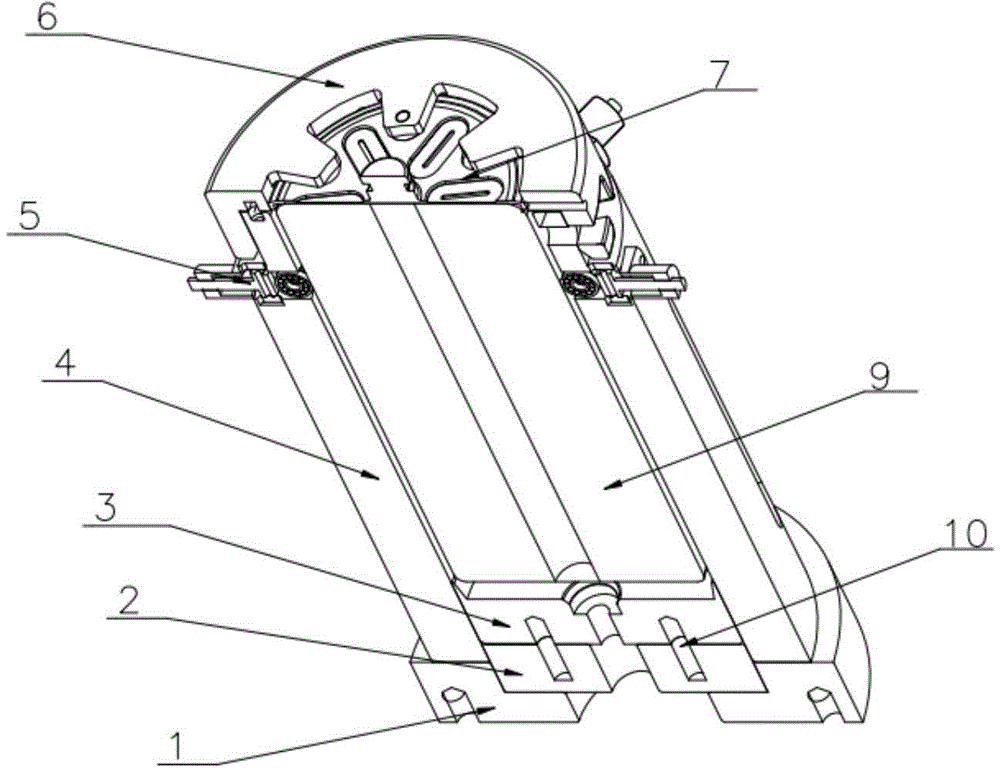

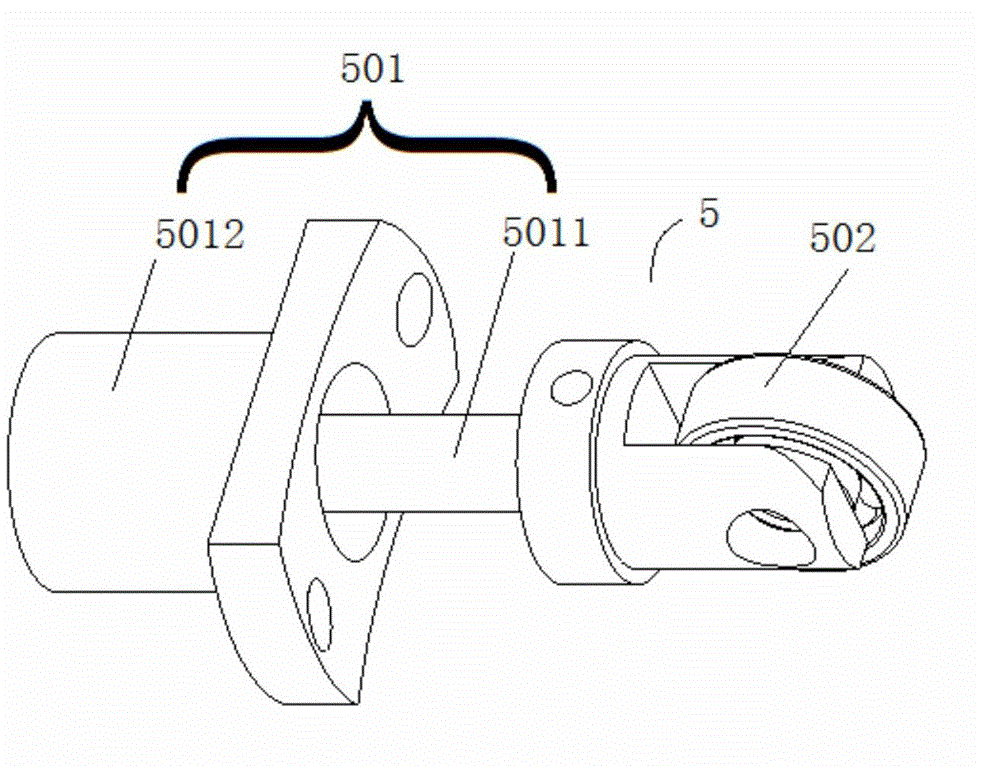

[0031] Such as figure 1 , figure 2 As shown, the lower current collector welding jig of this embodiment includes a base 1, a guide block 2, a winding core support block 3, a jig body 4 and an upper cover 6; the base 1, the guide block 2 and the winding core The supporting blocks 3 are arranged sequentially from bottom to top, and the center of the winding core supporting block 3 is provided with a centering groove 301, and the centering groove 301 is used to center one end of the winding core 9 of the supercapacitor to be processed. position; the clamp cylinder 4 is connected to the base 1, and is covered outside the guide block 2 and the winding core support block 3; the clamp cylinder 4 is set at a certain height from the base 1 The centering part 5 is used to apply pressure to the winding core 9 of the supercapacitor to be processed so that it is in the center position; the bottom wall of the upper cover 6 has a working window required for laser welding, and the side wall...

Embodiment 2

[0040] The lower current collector welding device of this embodiment includes a power component, a rotating support platform, two or more jigs for welding the lower current collector as described in Embodiment 1, and two or more laser welding parts correspondingly arranged, each The lower current collector welding jig is evenly arranged on the rotating support platform along the circumferential direction, and the guide block can drive the core support block to move under the action of the power component, so that the lower current collector It is close to the winding core of the supercapacitor to be processed. This design can have multiple welding stations, which can simultaneously weld the lower current collectors of multiple products, thereby improving efficiency.

[0041] The above-mentioned rotating support platform can also be a mobile support platform, as long as the conversion between the two stations of product loading and unloading and product welding can be realized....

Embodiment 3

[0043] The current collector piece welding device of this embodiment includes a rotating support platform, a jig for upper current collector piece welding, the lower current collector piece welding device described in Embodiment 2, and correspondingly arranged laser welding components. The jig for welding the upper current collector and the jig for welding the lower current collector are symmetrically arranged on the rotating support platform.

[0044] Such as Figure 4 and Figure 5 As shown, the clamp for welding the upper current collector includes a second base 1′, a second guide block 2′, a second winding core support block 3′, a second clamp cylinder 4′ and a second upper cover 6′, the second The clamp cylinder 4' is set on the second base 1', the second guide block 2' and the second winding core support block 3' are inside the second clamp cylinder 4'; the bottom of the second upper cover 6' The wall is provided with a second working window required for laser welding,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com