Parts loading device and demonstration method for position adjustment

A technology of installation location and parts, applied in the direction of electrical components, electrical components, control/regulation systems, etc., can solve problems such as defects, achieve the effect of improving operating efficiency and shortening the time for production change operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

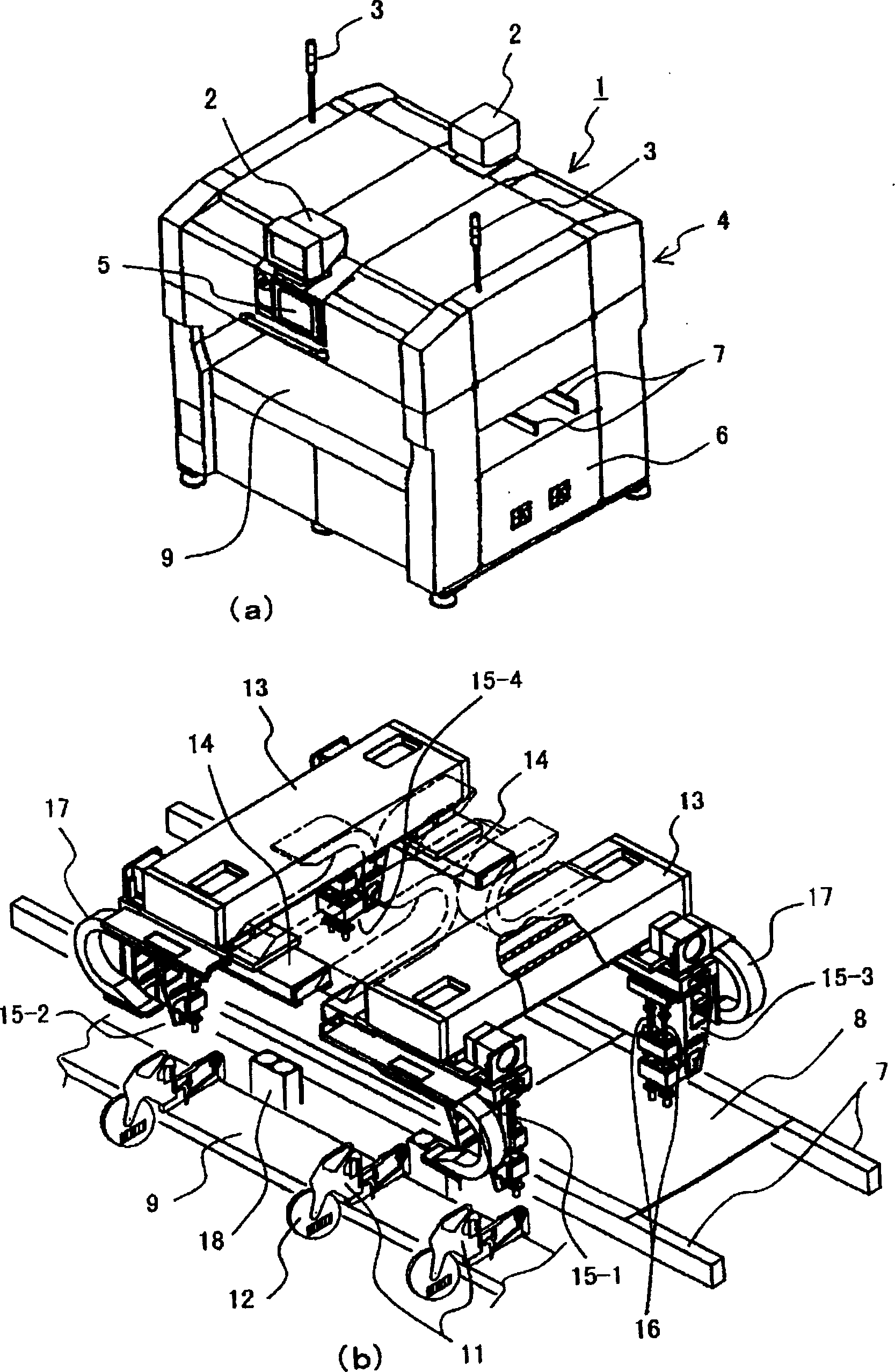

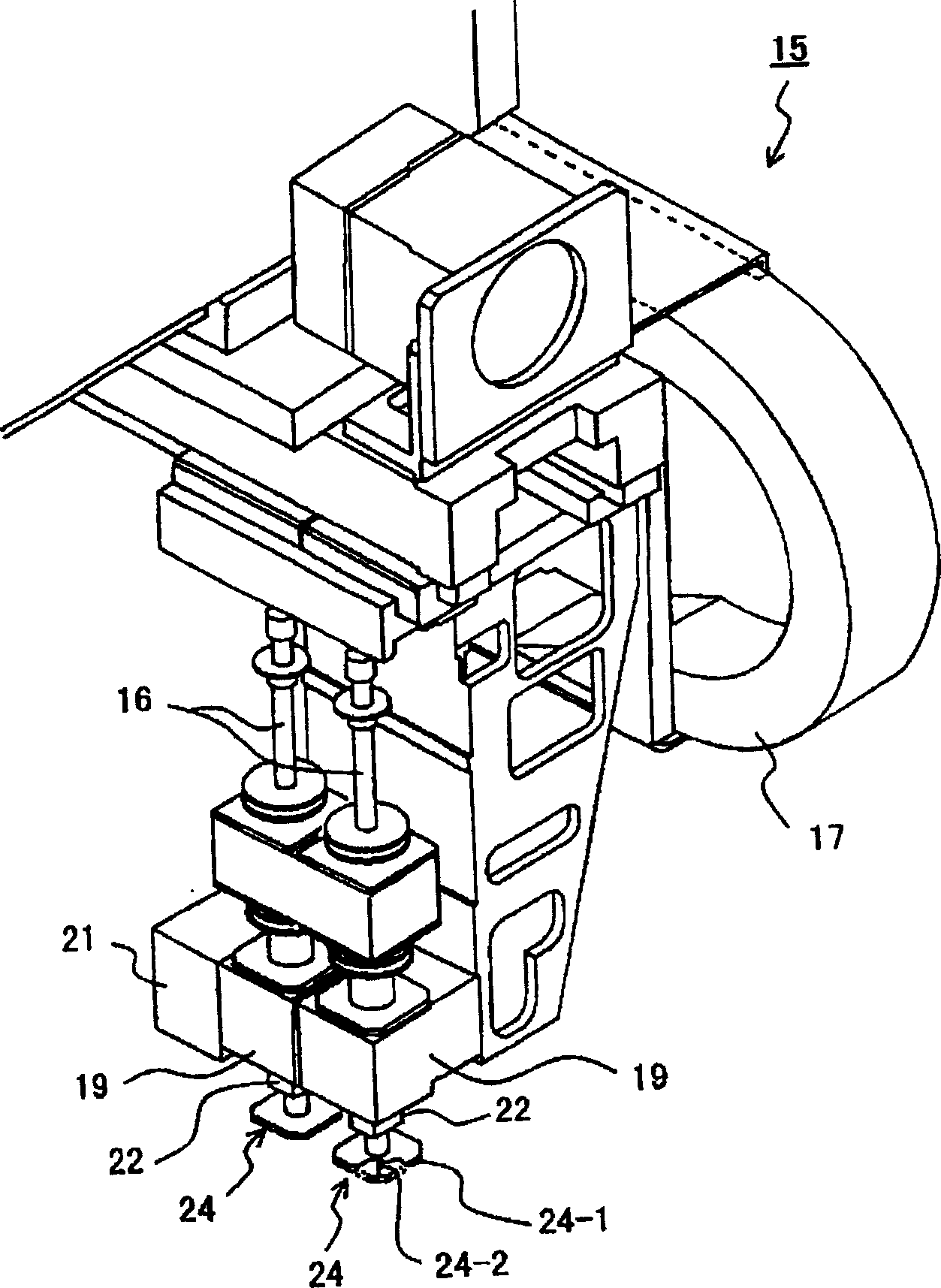

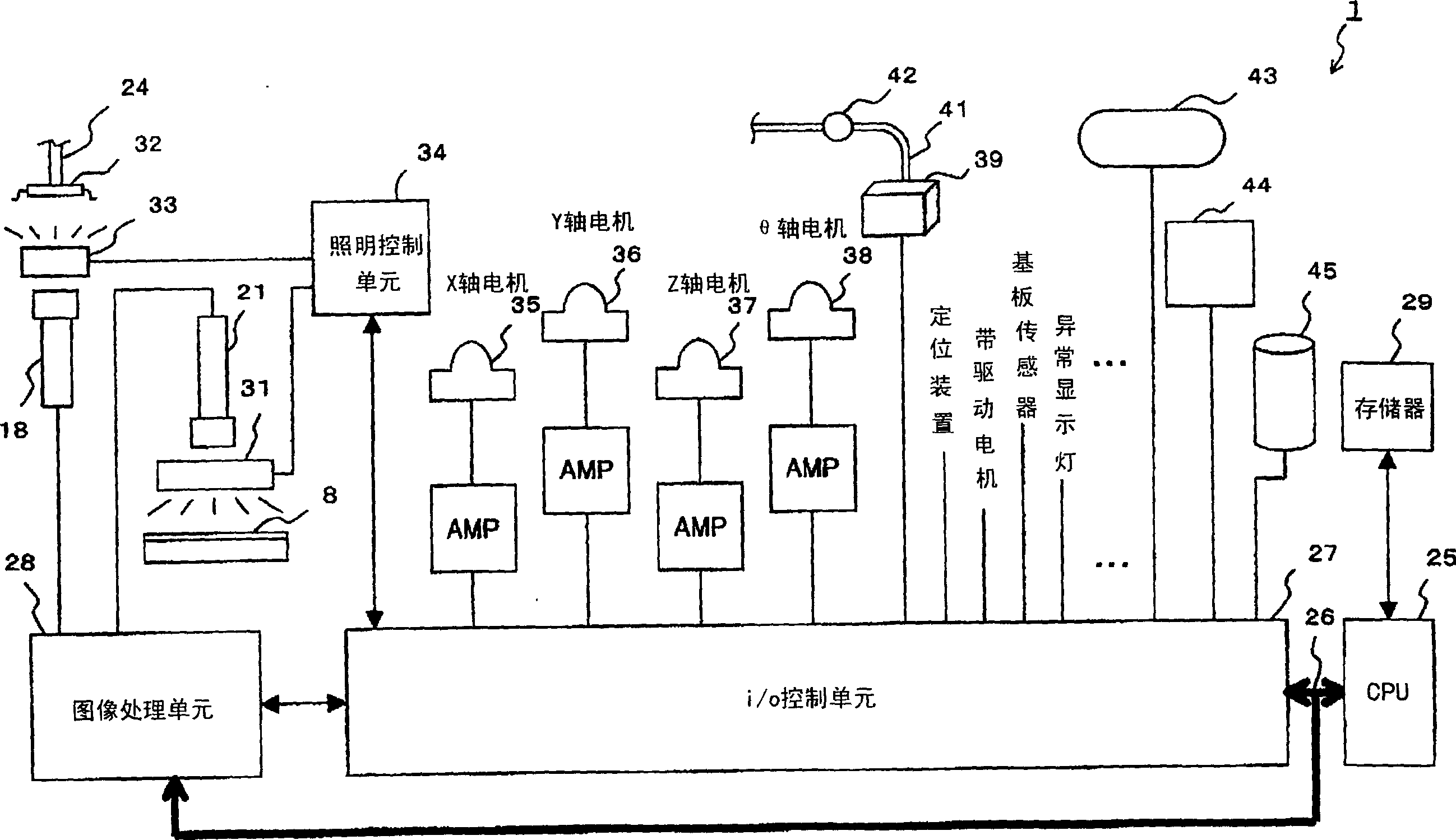

[0032] figure 1 (a) is an external perspective view showing an example of such a parts loading device, figure 1 (b) is a perspective view schematically showing the internal structure with the upper and lower protective covers removed.

[0033] like figure 1 As shown in (a), the parts loading device 1 includes: a monitoring device 2 constituted by a CRT display at the front and rear of the top cover; In addition, on the front and rear surfaces of the upper protective cover 4, an operation input display device 5 composed of a liquid crystal display and a touch input device and capable of inputting various instructions through an operation from the outside is arranged (referred to as an upper right diagonal in the figure). The operation input display device 5 at the rear of the direction is covered and cannot be seen).

[0034] Above the lower base 6, in the center, a fixed and movable pair of parallel substrate rails 7 figure 1 The conveyance direction of the substrate 8 sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com