A control method of a mobile tank feeding system without dead angle return cleaning

A control method and technology of feeding system, which are applied in pipeline system, tobacco preparation, tobacco, etc., can solve the problems of inability to clean the pipeline, no solution, and insufficient return of materials, so as to solve the problem of residual material and liquid and improve production efficiency. , Improve the effect of feeding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

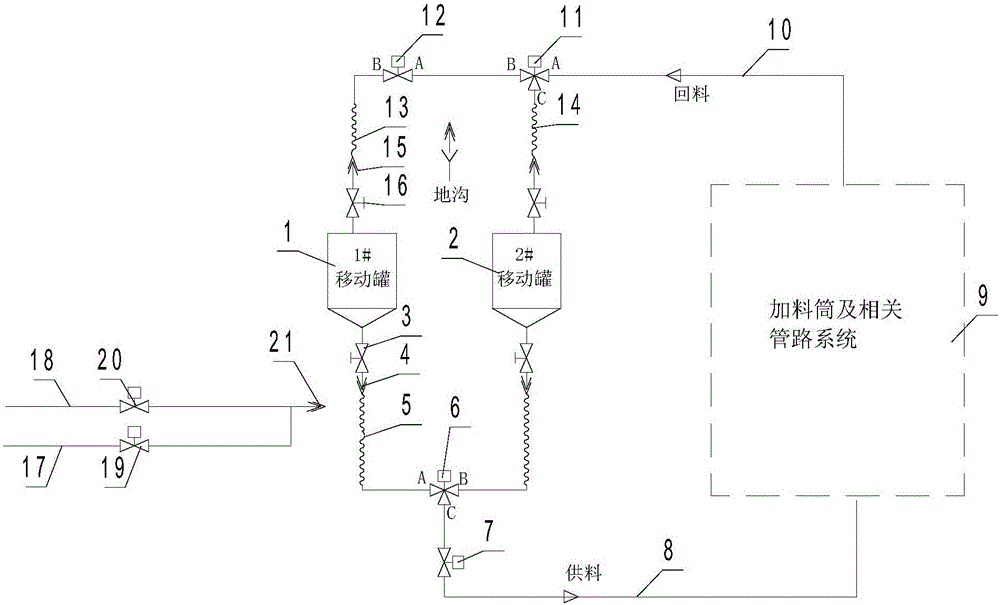

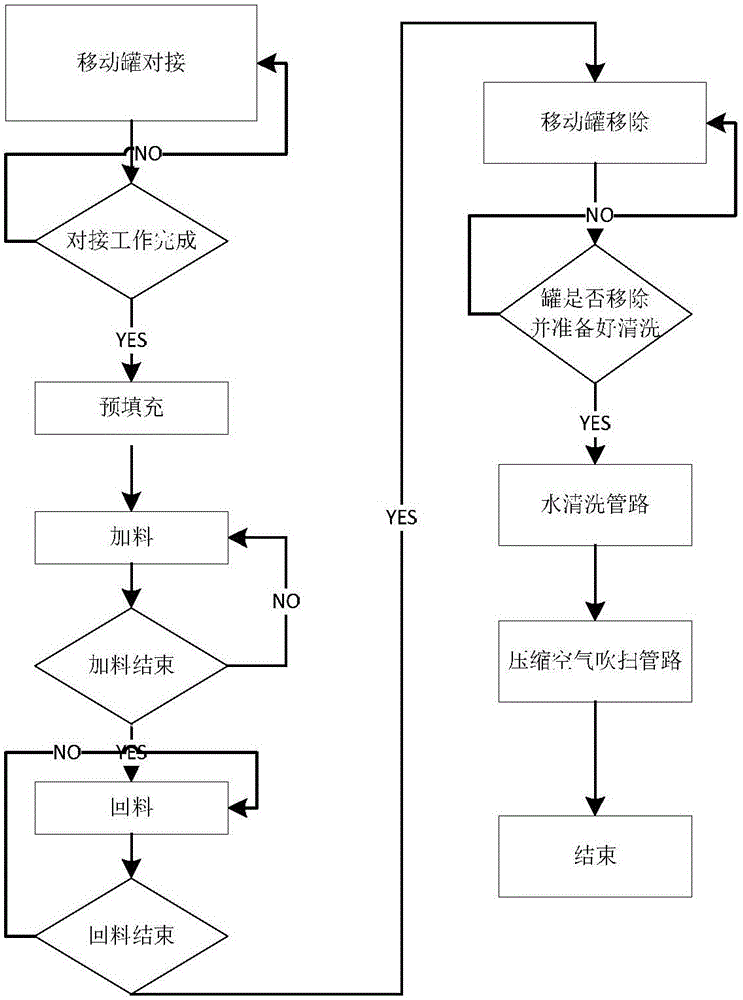

[0020] Such as figure 1 Shown is a mobile tank feeding system with no dead angle return cleaning, the system includes 1# mobile tank 1, 2# mobile tank 2, feeding cylinder and feeding cylinder pipeline system 9 and cleaning device, characterized in that: 1# The outlets of mobile tank 1 and 2# mobile tank 2 are respectively provided with manual discharge ball valves 3, and the outlet ends of the two manual discharge ball valves 3 are respectively provided with discharge quick joints 4, and the discharge quick joints 4 are respectively connected with Feeding hose 5, two feeding hoses 5 are connected to a discharge two-position three-way solenoid valve 6, the outlet end of the discharge two-position three-way solenoid valve 6 is connected with a feed solenoid valve 7, the feed solenoid valve 7 is connected to the feed cylinder and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com