A pipe jacking machine fixed buckle tile

A technology of fixing buckle and pipe jacking machine, which is applied in the direction of guiding/positioning/aligning device, etc., can solve the problems of difficult processing of fixing buckles, difficult replacement of fixing buckles, long processing cycle, etc., so as to shorten the production mold change time. , The effect of saving manpower and material resources and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

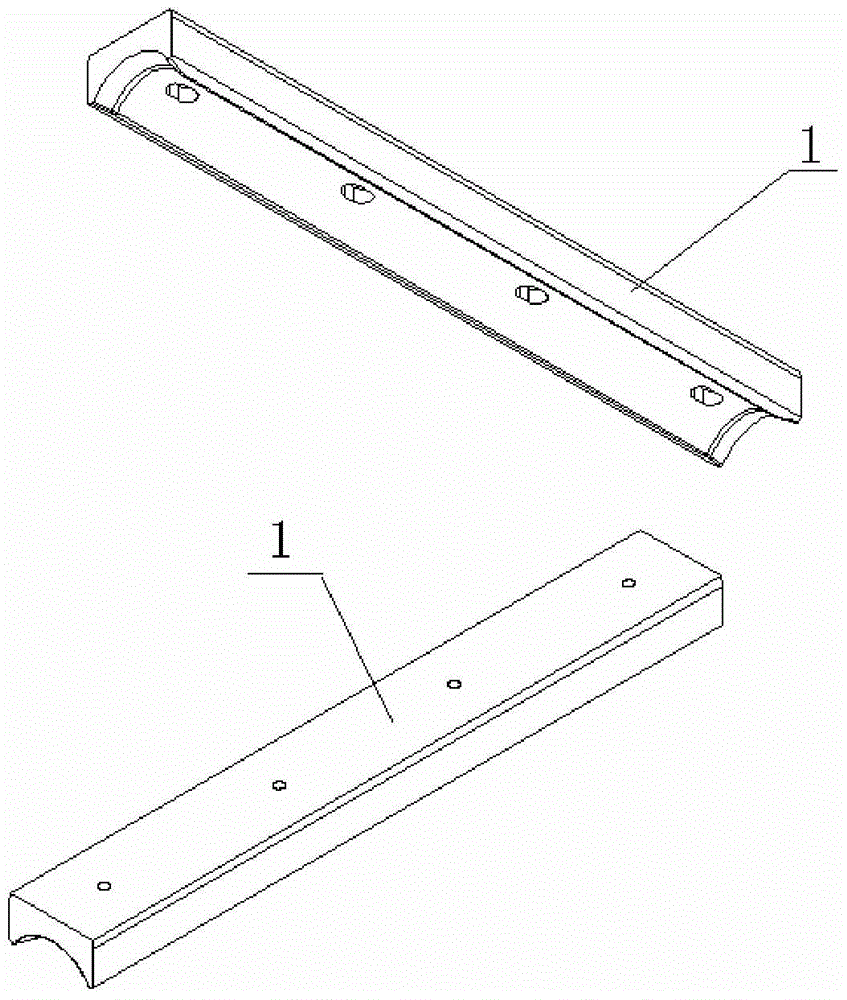

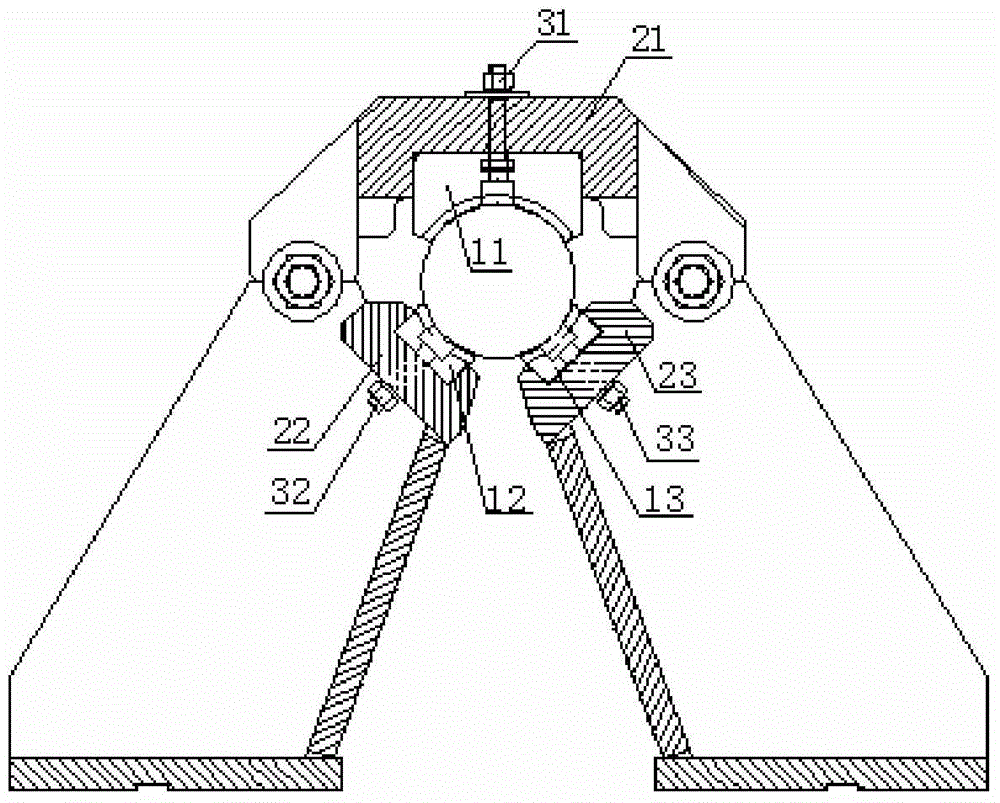

[0035] Such as Figure 4 , Figure 5 and Figure 6 As shown, the preferred embodiment of the fixed buckle tile of the pipe jacking machine of the present invention is an integral circular structure, and the fixed buckle tile 4 is installed on the tile buckle bracket.

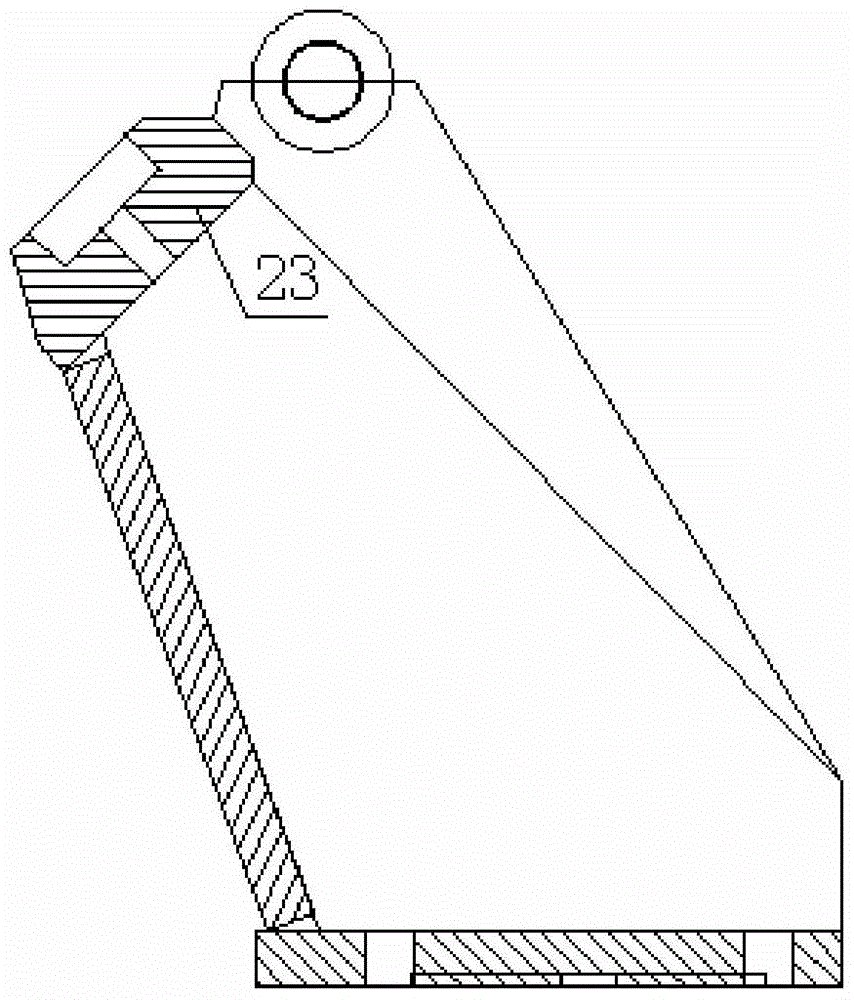

[0036] Specifically, the fixed button tile 4 is a cylindrical structure with a hollow inner cavity, and on the wall of the cylinder along the length direction of the fixed button tile 4, there is an opening from one end surface of the fixed button tile 4 to the other end surface. There is a straight groove connected with the hollow inner cavity of the cylindrical body. The fixed buckle 4 of the present invention adopts an integral design. The contact surface of the machining putter has made great progress.

[0037] In order to increase the contact surface between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com