Rotating type feeding and discharging machine

A rotary and feeder technology, applied in metal processing, etc., can solve problems such as difficulty in meeting production needs, low degree of automation, and low efficiency of production change, and achieve the effects of convenient production change, high degree of automation, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

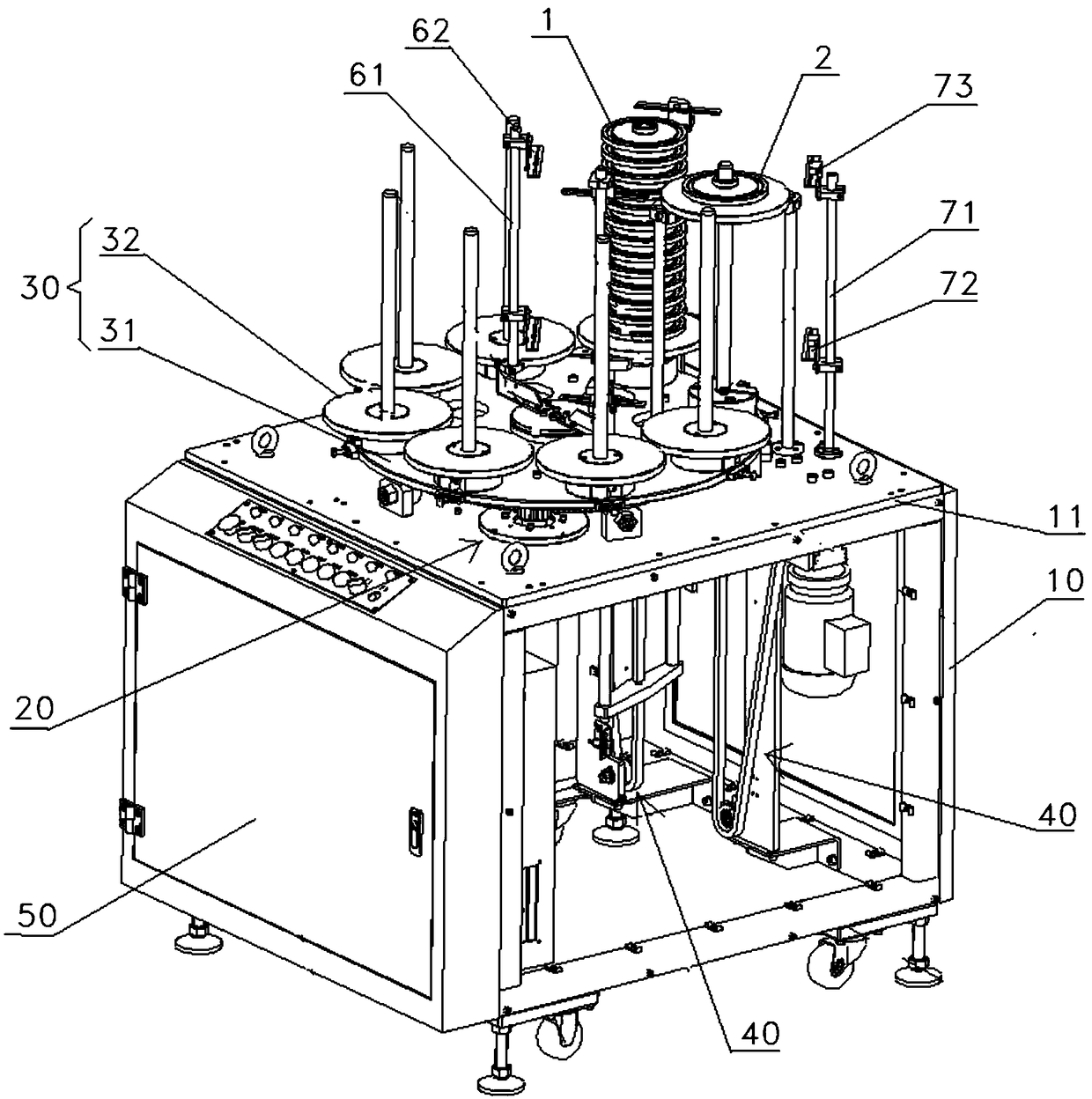

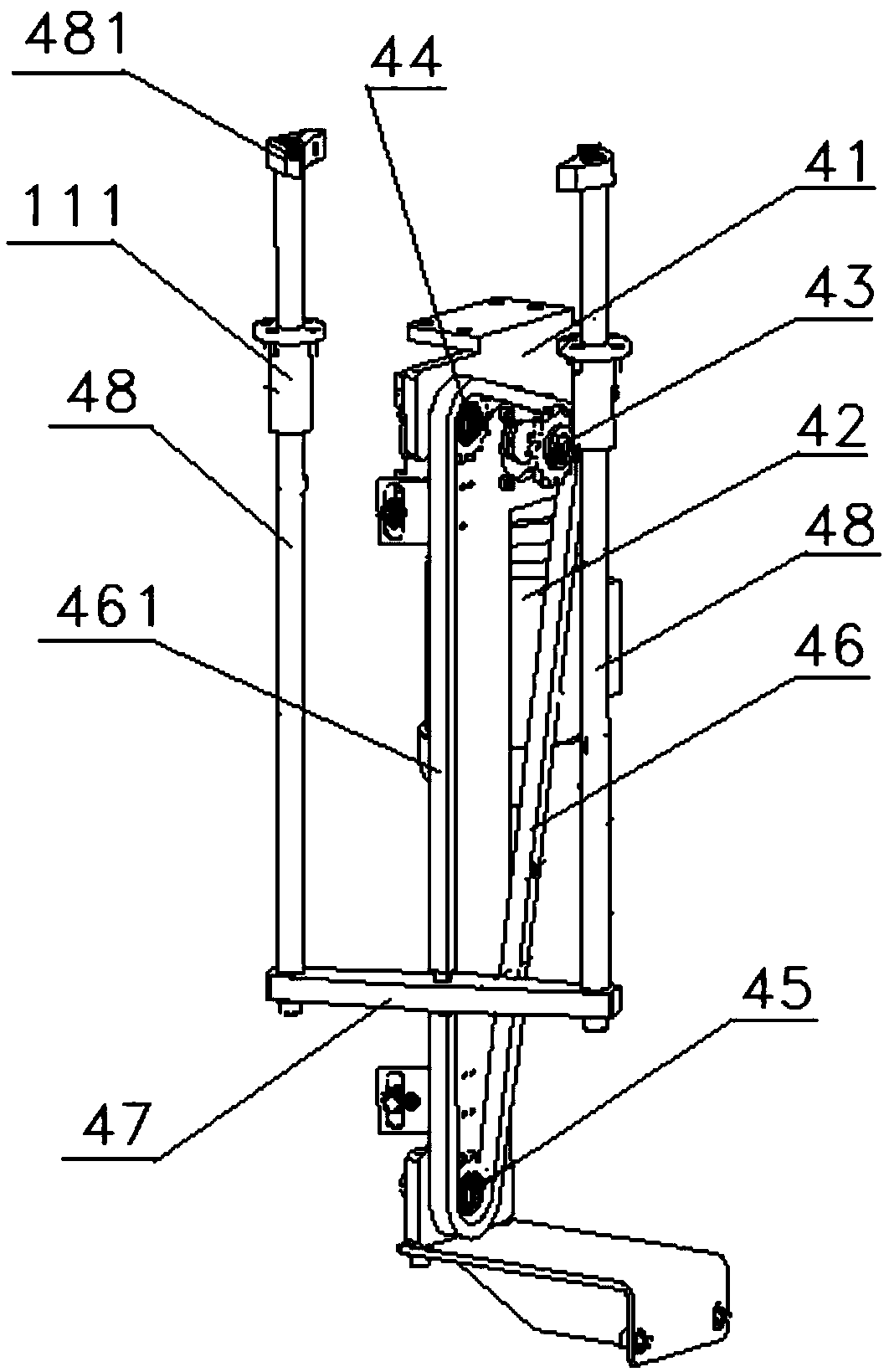

[0035] see figure 1 , the present invention provides a rotary loading and unloading machine, which includes a frame 10 and a driving mechanism 20 , a turning mechanism 30 and a lifting mechanism 40 all installed on the frame 10 .

[0036] The frame 10 is roughly a hollow box structure, and the top of the frame 10 forms a support platform 11 .

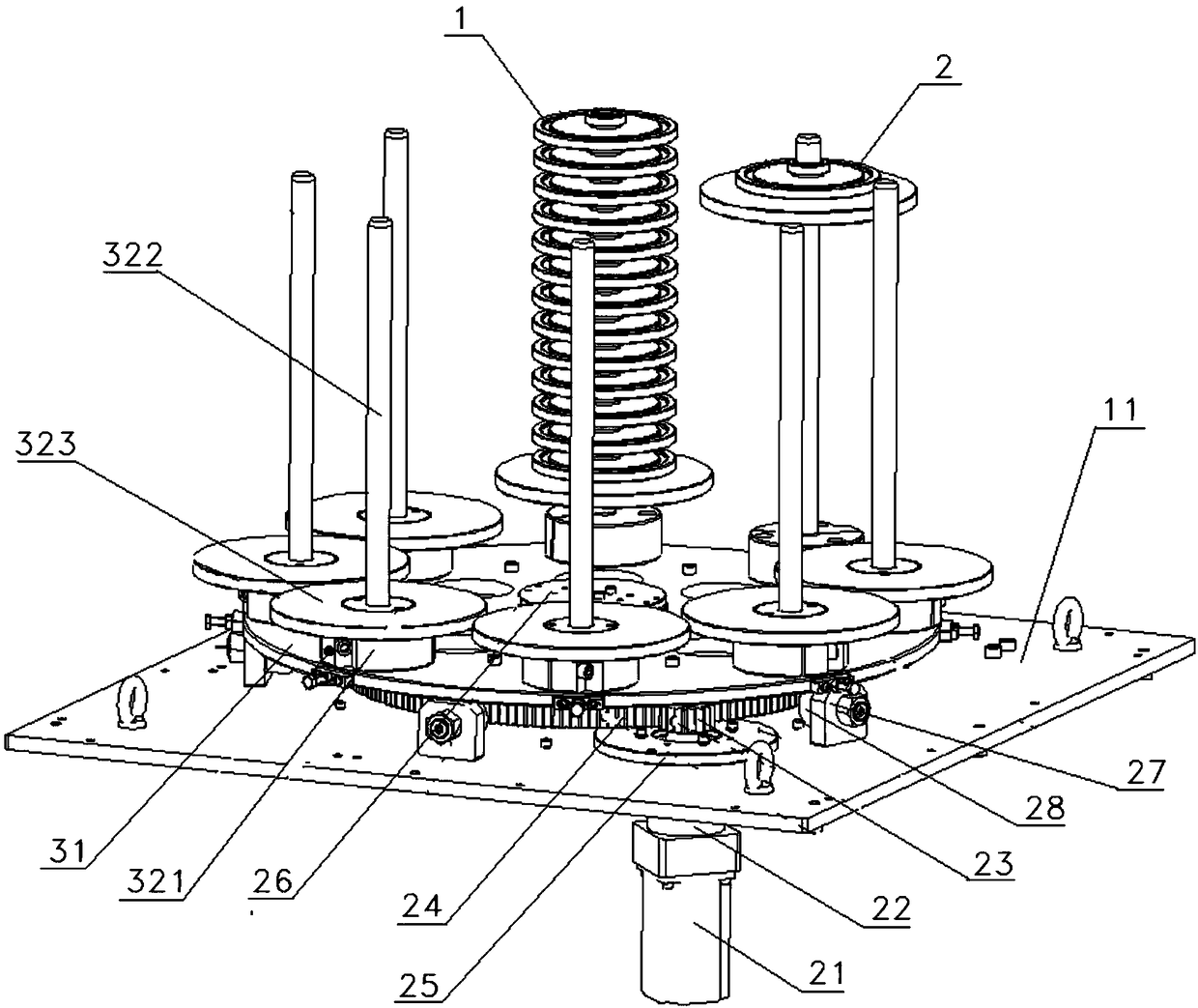

[0037] see figure 2 , the drive mechanism 20 includes a rotary motor 21 , a speed reducer 22 , a driving gear 23 and a driven gear 24 . The rotary motor 21 and the reducer 22 are all installed under the support platform 11, the output shaft of the rotary motor 21 is connected with the input shaft of the reducer 22, and the output shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com