Permeable emulsified asphalt concrete and preparation method thereof

A technology for emulsified asphalt and concrete, applied in the field of asphalt concrete, can solve problems such as plastic deformation of asphalt, achieve stable performance, improve bending deformation resistance, and solve the effects of settlement and rutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

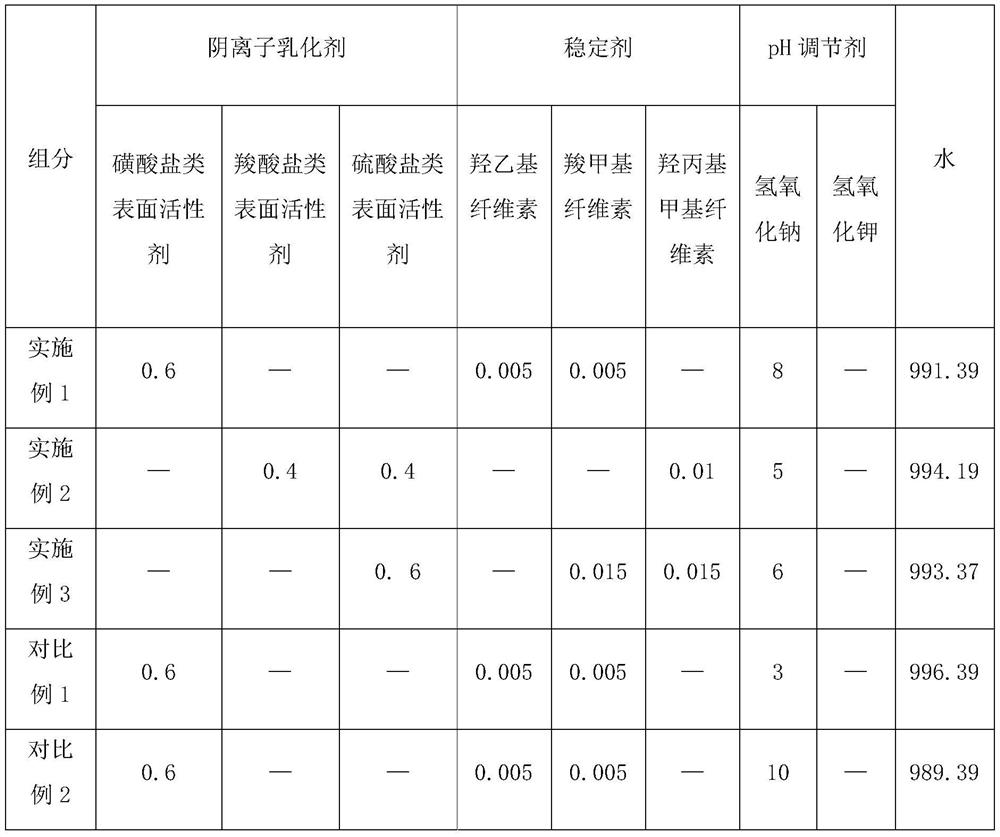

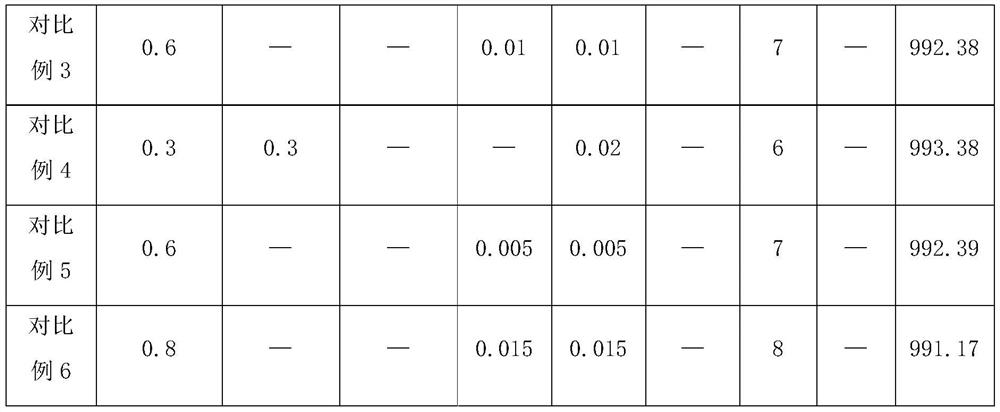

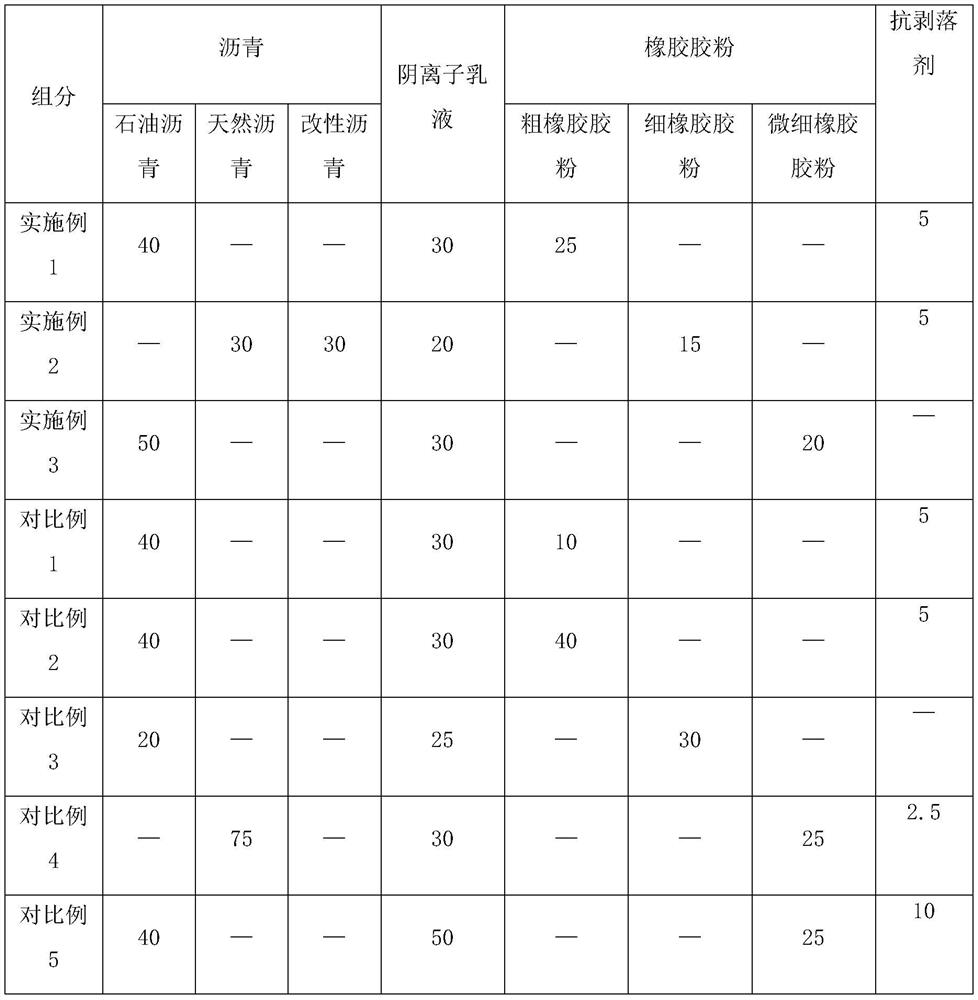

Examples

preparation example Construction

[0031] A preparation method of permeable emulsified asphalt concrete, specifically comprising the following steps:

[0032] (1), preparation of modified emulsified asphalt:

[0033] Weigh asphalt, anionic emulsion and anti-stripping agent in parts by mass, put them into a high-speed shear mixing mill, shear at high speed for 1-2min, and circulate for three times to obtain a uniform emulsion, and weigh the uniform emulsion at 40-60°C in parts by mass Stir and mix with rubber powder, the stirring speed is 20-30r / min, and the stirring time is 20min, so as to obtain modified emulsified asphalt;

[0034] (2) Mix and stir the coarse aggregate and half of the water for 30s according to the ratio of parts by mass, then add cement, cement, modified emulsified asphalt and the remaining half of water according to the ratio of parts by mass, and continue stirring for 120s to prepare permeable emulsified asphalt concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com