Heat-insulating refractory material and preparation method thereof

A technology for refractory materials and refractory raw materials, applied in the field of refractory materials, can solve the problems of high porosity and poor corrosion resistance, and achieve the effects of high porosity, improved thermal shock stability and low strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

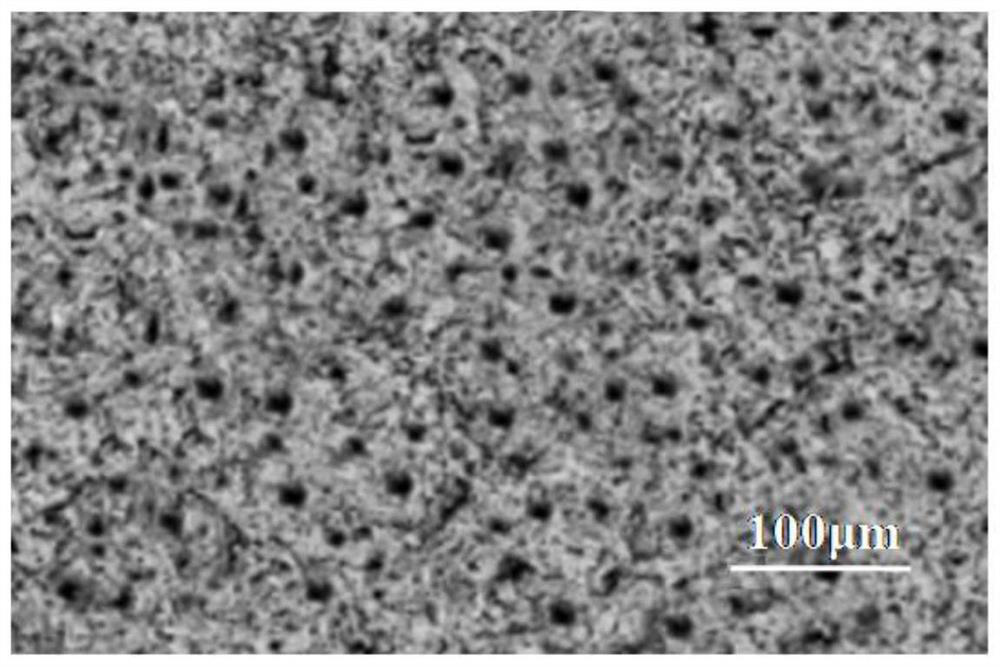

Image

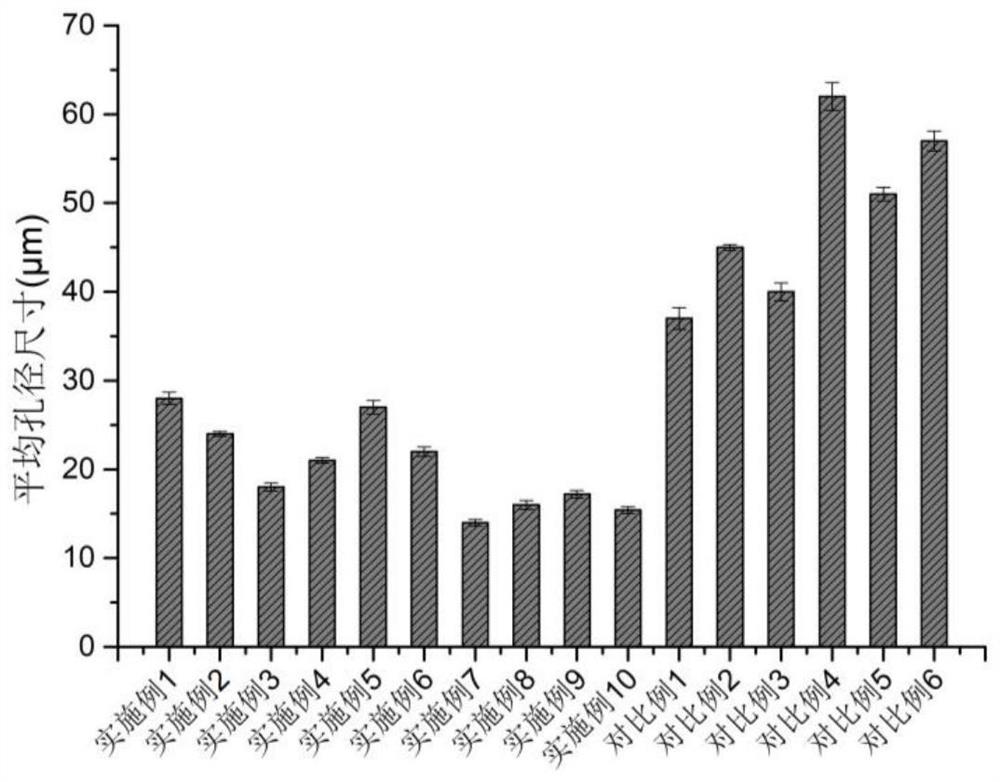

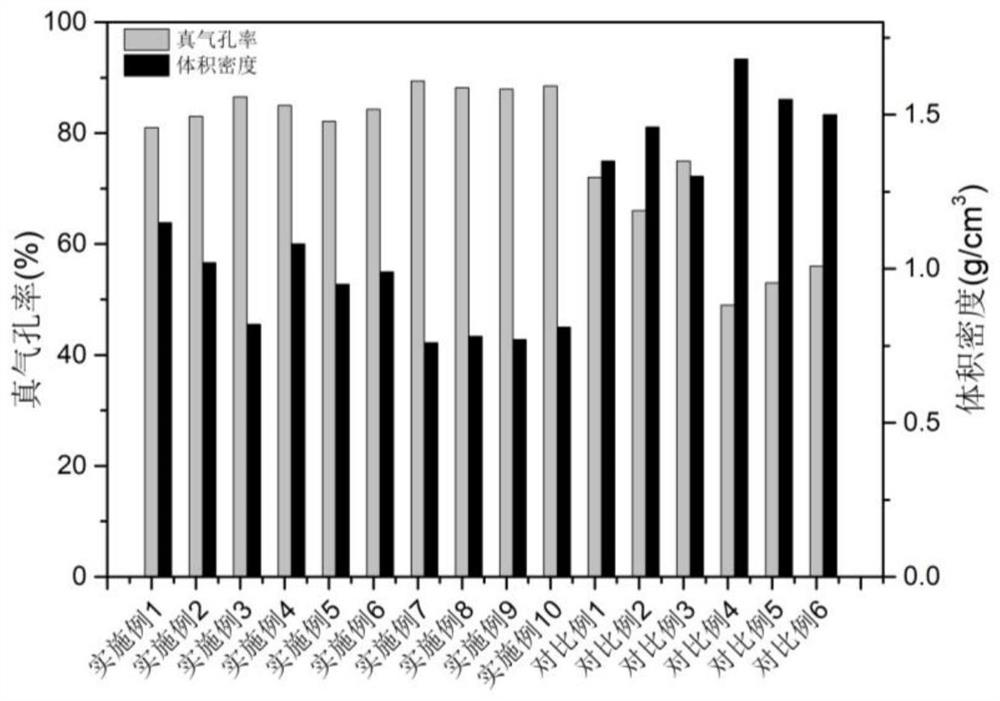

Examples

Embodiment 1

[0044] A kind of heat insulation refractory material, its preparation method comprises:

[0045] S1: 55 parts by weight of mullite and 13 parts by weight of yttrium aluminum garnet fiber are placed in a ball mill tank for wet mixing, water is used as the mixing medium, and zirconium balls are used as the ball milling medium; the mass ratio of raw materials, water and zirconium balls 1:1:1, ball milled for 2 hours; the ball-milled raw materials were dried in an oven at 75°C to obtain mixed dry materials;

[0046] S2: Put 45 parts by weight of mixed dry material with 4 parts by weight of aluminum chloride hexahydrate, 1 part by weight of 4-hydroxy-3-methoxybenzyl alcohol, and 15 parts by weight of modified starch in a wet mill, and mix the materials , the mixing time is 25min to obtain a billet;

[0047] S3: Form the above blank into a cylindrical sample of φ35mm×35mm under a molding pressure of 8MPa, and heat the sample at 120°C for 22h for drying treatment to obtain a green b...

Embodiment 2

[0050] A kind of heat insulation refractory material, its preparation method comprises:

[0051] S1: 60 parts by weight of mullite and 15 parts by weight of yttrium aluminum garnet fiber are placed in a ball mill tank for wet mixing, water is used as the mixing medium, and zirconium balls are used as the ball milling medium; the mass ratio of raw materials, water and zirconium balls 1:1:1, ball milled for 4 hours; the ball-milled raw materials were dried in an oven at 75°C to obtain mixed dry materials;

[0052] S2: 50 parts by weight of mixed dry material, 5 parts by weight of aluminum chloride hexahydrate, 3 parts by weight of 4-hydroxy-3-methoxybenzyl alcohol, and 10-15 parts by weight of modified starch are placed in a wet mill, and the The materials were mixed, and the mixing time was 28min to obtain a billet;

[0053] S3: Form the above-mentioned blank into a cylindrical sample of φ35mm×35mm under a molding pressure of 6-10MPa, and heat the sample at 125°C for 20h for d...

Embodiment 3

[0056] A kind of heat insulation refractory material, its preparation method comprises:

[0057] S1: 70 parts by weight of mullite and 10 parts by weight of yttrium aluminum garnet fiber are placed in a ball mill tank for wet mixing, water is used as the mixing medium, and zirconium balls are used as the ball milling medium; the mass ratio of raw materials, water and zirconium balls 1:1:1, ball milled for 3.5 hours; the ball-milled raw materials were dried in an oven at 72°C to obtain mixed dry materials;

[0058] S2: Put 56 parts by weight of mixed dry material with 2 parts by weight of aluminum chloride hexahydrate, 2 parts by weight of 4-hydroxy-3-methoxybenzyl alcohol, and 14 parts by weight of modified starch in a wet mill, and mix the materials , the mixing time is 30min to obtain a billet;

[0059] S3: Form the above-mentioned blank into a cylindrical sample of φ35mm×35mm under a molding pressure of 9MPa, and heat the sample at 135°C for 21h for drying treatment to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com