Automobile thin pipe fitting and cutting method thereof

A cutting method and thin technology, applied in the direction of pipe shearing device, shearing device, shearing machine attachment, etc., can solve the problems of affecting the processing quality of pipe fittings, cutting port deformation, low strength, etc., and achieve light weight and long service life , good aging resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

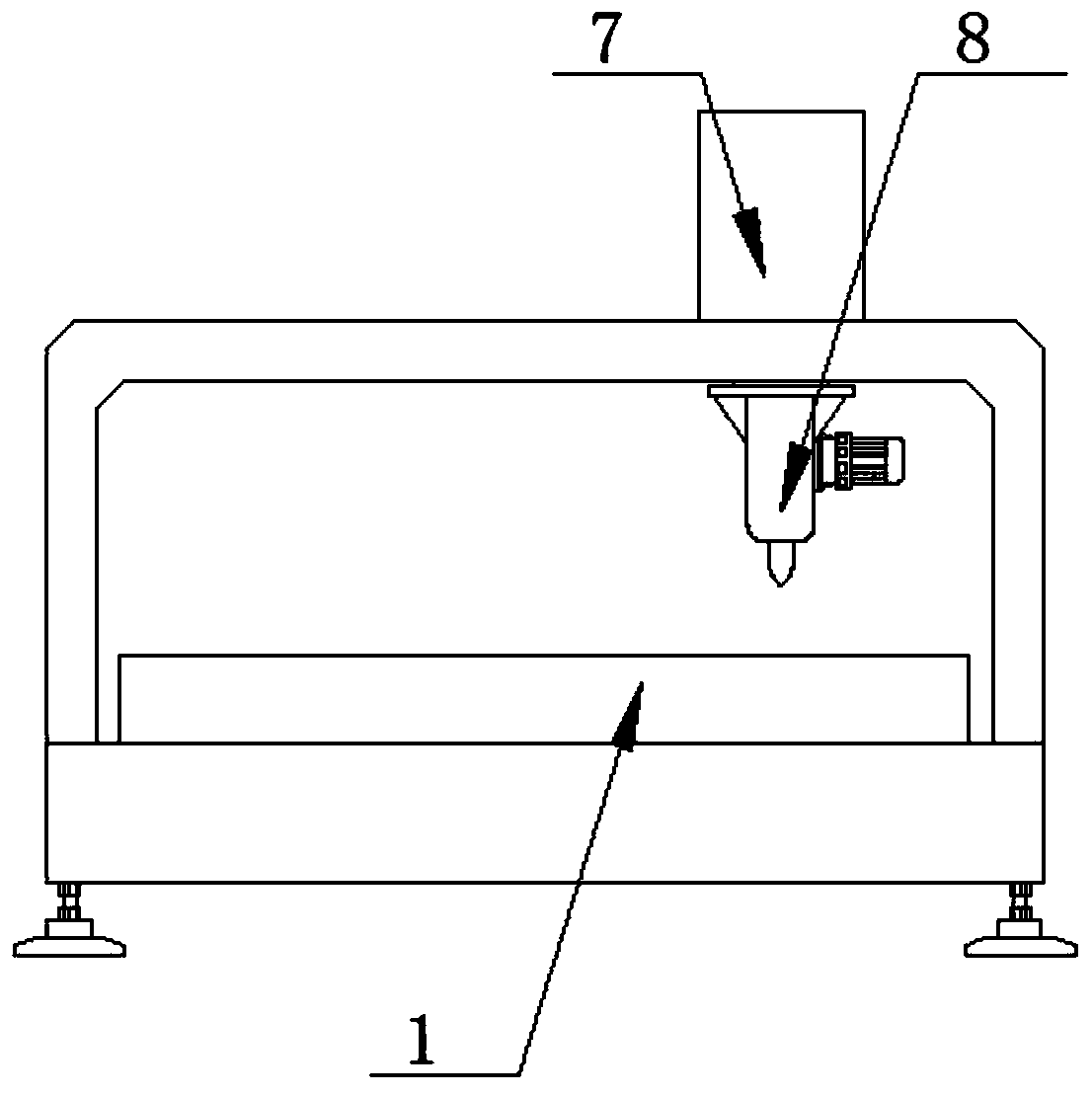

Examples

Embodiment 1

[0030] S1, select 30 parts of raw materials polyacrylic resin, 10 parts of polyvinyl chloride, 5 parts of butadiene rubber, 1 part of stearic acid, 2 parts of stabilizer, 2 parts of foaming agent and 1 part of antioxidant, mix and melt the raw materials, The molten raw material is extruded through the extruder, and the pipe fittings are formed through the forming die;

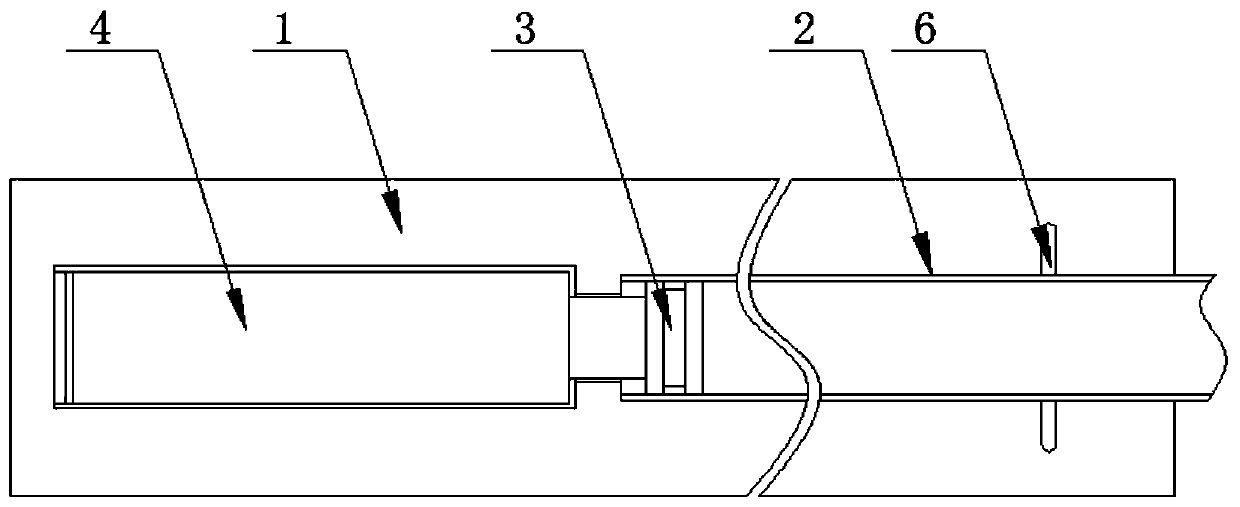

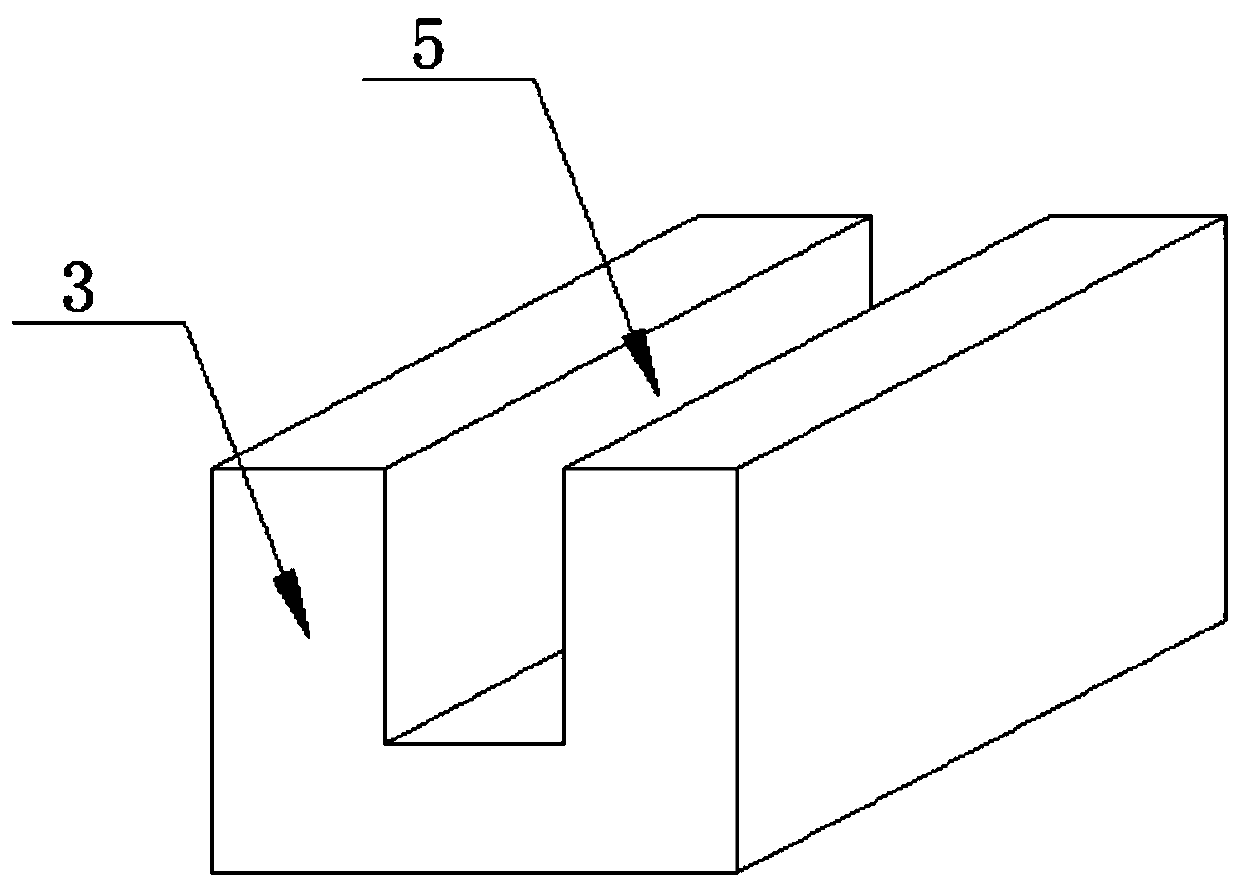

[0031] S2. Place the thin pipe fitting in the placement groove 2 inside the cutting table 1, and put one end of the thin pipe fitting in contact with one side of the inner wall of the placement groove 2. The inner wall of the thin pipe fitting is slidingly connected to the surface of the support block 3, and the support block 3 access to the interior of thin fittings;

[0032] S3, the operation controller turns on the working switch of the first electric cylinder 4, uses the output shaft of the first electric cylinder 4 to push the support block 3 to move to one side inside the thin pipe, and controls the outpu...

Embodiment 2

[0035] S1, select 50 parts of raw materials polyacrylic resin, 20 parts of polyvinyl chloride, 10 parts of butadiene rubber, 3 parts of stearic acid, 6 parts of stabilizer, 6 parts of foaming agent and 3 parts of anti-aging agent, mix and melt the raw materials, The molten raw material is extruded through the extruder, and the pipe fittings are formed through the forming die;

[0036] S2. Place the thin pipe fitting in the placement groove 2 inside the cutting table 1, and put one end of the thin pipe fitting in contact with one side of the inner wall of the placement groove 2. The inner wall of the thin pipe fitting is slidingly connected to the surface of the support block 3, and the support block 3 access to the interior of thin fittings;

[0037]S3, the operation controller turns on the working switch of the first electric cylinder 4, uses the output shaft of the first electric cylinder 4 to push the support block 3 to move to one side inside the thin pipe, and controls th...

Embodiment 3

[0040] S1, select 40 parts of raw material polyacrylic resin, 15 parts of polyvinyl chloride, 7 parts of butadiene rubber, 2 parts of stearic acid, 4 parts of stabilizer, 4 parts of foaming agent and 2 parts of anti-aging agent, mix and melt the raw materials, The molten raw material is extruded through the extruder, and the pipe fittings are formed through the forming die;

[0041] S2. Place the thin pipe fitting in the placement groove 2 inside the cutting table 1, and put one end of the thin pipe fitting in contact with one side of the inner wall of the placement groove 2. The inner wall of the thin pipe fitting is slidingly connected to the surface of the support block 3, and the support block 3 access to the interior of thin fittings;

[0042] S3, the operation controller turns on the working switch of the first electric cylinder 4, uses the output shaft of the first electric cylinder 4 to push the support block 3 to move to one side inside the thin pipe, and controls the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com