Asphalt-based material decolorizing high-viscosity curing emulsion and preparation method thereof

An asphalt-based, high-viscosity technology, used in asphalt coatings, anti-corrosion coatings, solid waste management, etc., can solve the problems of easy peeling, freezing, aging and brittle cracking of the emulsified asphalt layer, and achieves a simple and low-temperature construction process. The effect of crack resistance and good high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

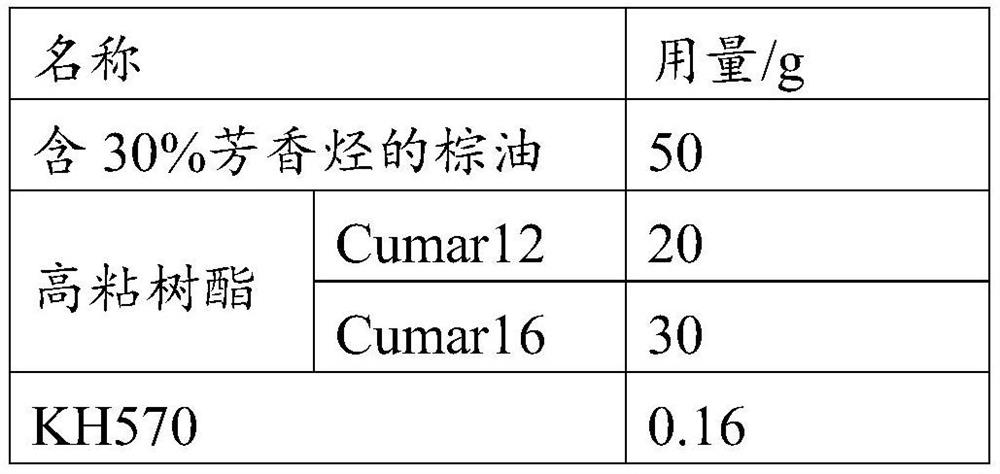

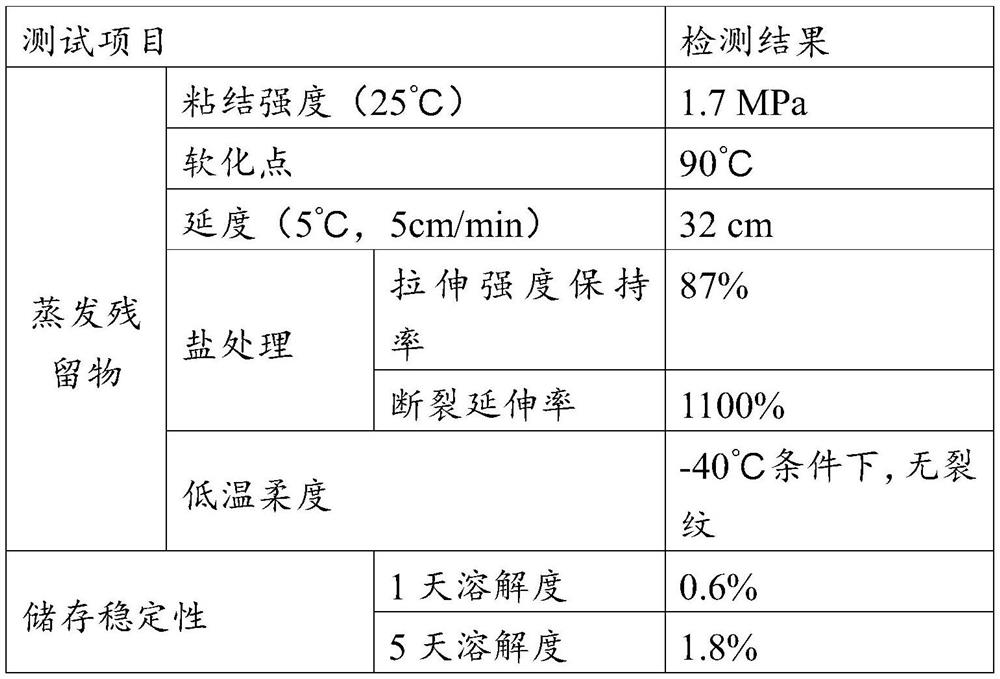

[0055] Composition and dosage of decolorized asphalt material

[0056]

[0057] Preparation of decolorized bitumen:

[0058] Add palm oil rich in 30% aromatic hydrocarbons into the reactor and heat it to 170°C, then start stirring and slowly and evenly add Cumar12 and Cumar16 high-viscosity resins. During the process of adding high-viscosity resins, keep the heating device of the stirring tank open , maintain this temperature and stir evenly until no particulate matter exists. The state of uniform stirring can be judged by taking a small sample and observing it with the naked eye. After palm oil and high-viscosity resin are stirred evenly, a small amount of second stabilizer KH570 is added to form decolorized asphalt. From the beginning of adding high-viscosity resin to the end of stirring, the whole process should be controlled within 0.7h.

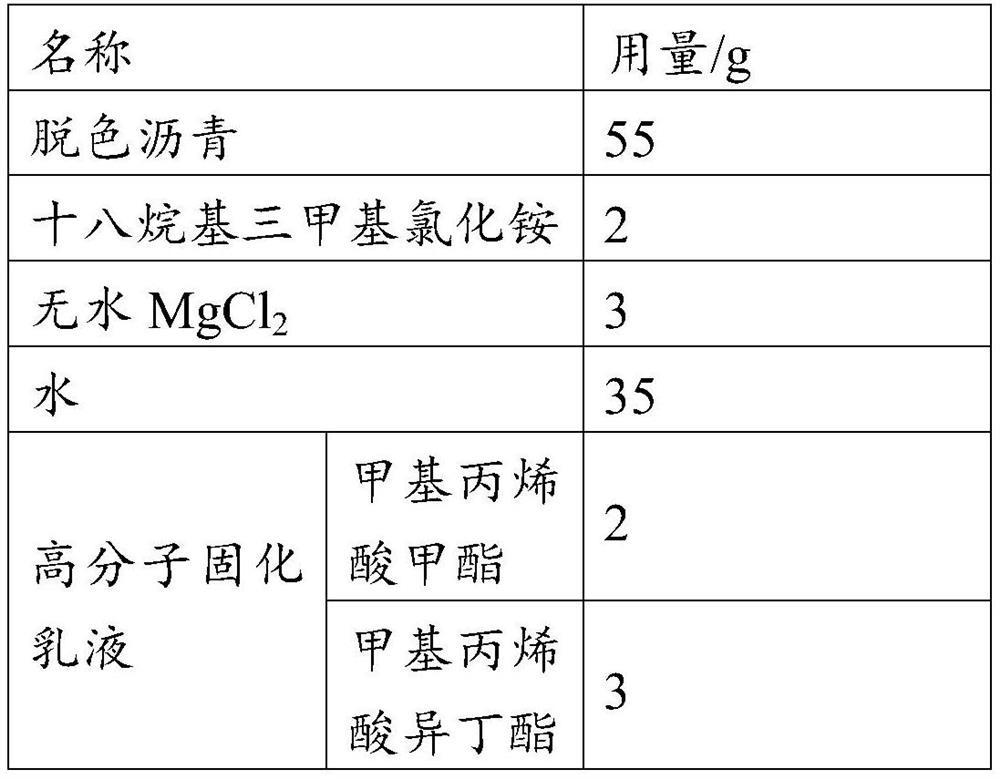

[0059] Components and dosage of 100g decolorized high-viscosity solidified emulsion

[0060]

[0061] The specific preparation...

Embodiment 2

[0069] Composition and dosage of decolorized asphalt material

[0070]

[0071] Preparation of decolorized bitumen:

[0072] Add palm oil rich in 30% aromatic hydrocarbons into the reactor and heat it to 170°C, then start stirring and slowly and evenly add Cumar12 and Cumar16 high-viscosity resins. During the process of adding high-viscosity resins, keep the heating device of the stirring tank open , maintain this temperature and stir evenly until no particulate matter exists. The state of uniform stirring can be judged by taking a small sample and observing it with the naked eye. After palm oil and high-viscosity resin are stirred evenly, a small amount of second stabilizer KH570 is added to form decolorized asphalt. From the beginning of adding high-viscosity resin to the end of stirring, the whole process should be controlled within 0.7h.

[0073] Components and dosage of 100g decolorized high-viscosity solidified emulsion

[0074]

[0075] The specific preparation...

Embodiment 3

[0084] Composition and dosage of decolorized asphalt material

[0085]

[0086] Preparation of decolorized bitumen:

[0087] Add palm oil rich in 30% aromatic hydrocarbons into the reactor and heat it to 170°C, then start stirring and slowly and evenly add Cumar12 and Cumar16 high-viscosity resins. During the process of adding high-viscosity resins, keep the heating device of the stirring tank open , maintain this temperature and stir evenly until no particulate matter exists. The state of uniform stirring can be judged by taking a small sample and observing it with the naked eye. After palm oil and high-viscosity resin are stirred evenly, a small amount of second stabilizer KH570 is added to form decolorized asphalt. From the beginning of adding high-viscosity resin to the end of stirring, the whole process should be controlled within 0.7h.

[0088] Components and dosage of 100g decolorized high-viscosity solidified emulsion

[0089]

[0090]

[0091] The specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| storage stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com