Allulose-containing syrup composition and food containing same

A technique of psicose and composition, applied in the field of psicose-containing syrup compositions, can solve the problems of poor usability and cooking applicability, difficulty in adjusting the amount of psicose added, deterioration of palatability, etc. The effects of improving storage stability and low viscosity, improving cooking convenience, and improving palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1 to example 25

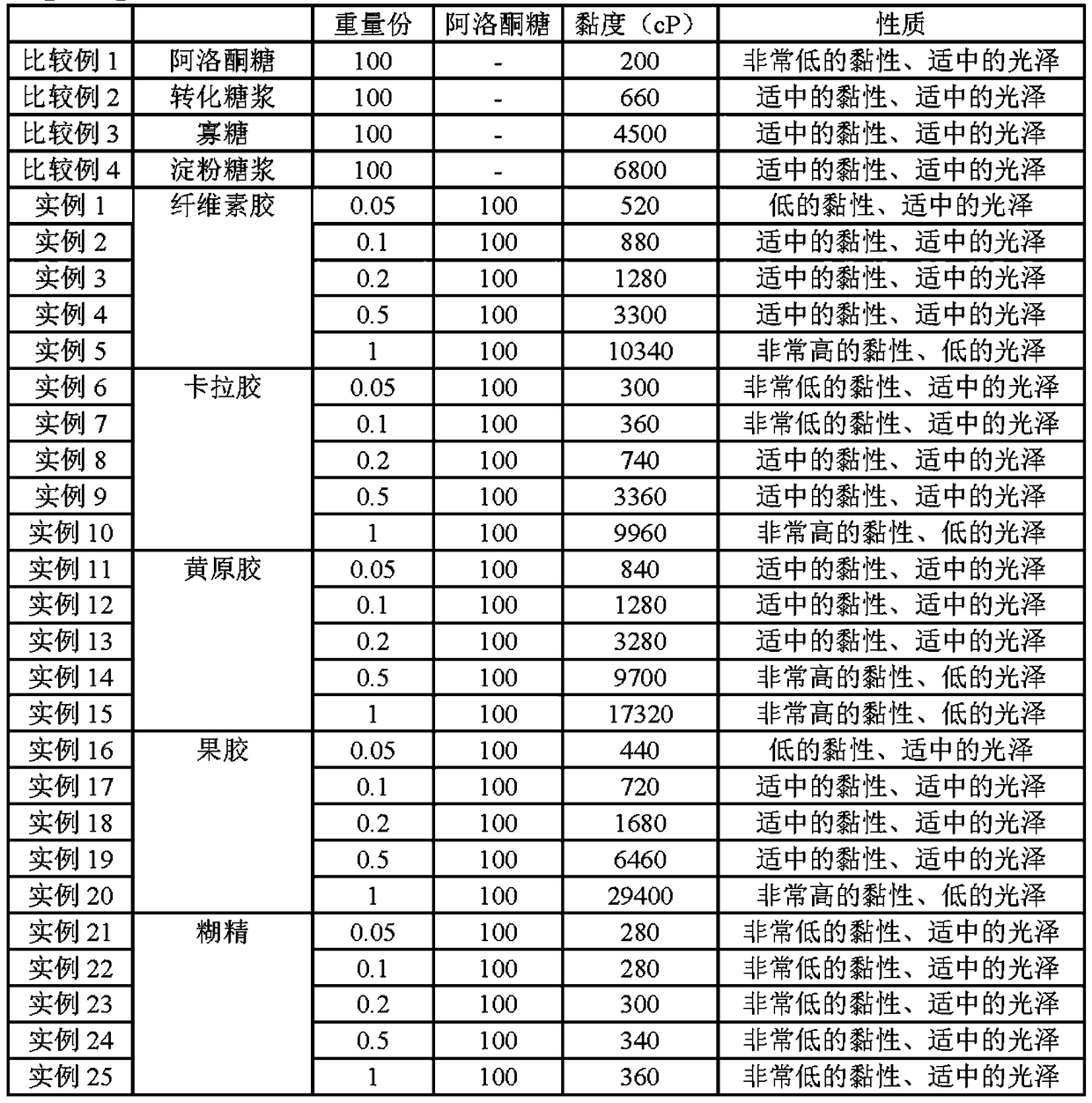

[0040] Examples 1 to 25: Preparation of allulose-containing syrup composition

[0041] In Examples 1 to 25, relative to 100 parts by weight of liquid psicose in terms of solid content (solid content of 70% to 76% by weight, relative to 100 parts by weight of liquid psicose in terms of solid content, 95 The allulose of weight part and the fructose of 5 weight parts), CJ CJ company], with the amount of 0.05 weight part, 0.10 weight part, 0.20 weight part, 0.50 weight part or 1.00 weight part to cellulose gum (Vallo Sai 100PA, Dayan Co., Ltd.), Carrageenan (Sacha Gum ABN 26, SKT Trading Company), Xanthan Gum (Dayan Co., Ltd.), Pectin (Jenu Explorer Pectin 65CS, (Share) JoVE International Co., Ltd.) or dextrin (CJ CJ Corporation) were mixed and then homogenized to prepare a syrup composition.

experiment example 1

[0052] Experimental example 1. Determination of the viscosity and properties of the allulose-containing syrup composition

[0053] Under the conditions of No. 5 mandrel, RPM20 and 25°C, a viscometer (Broadfield DV-II+Pro Viscometer, Broadfield Engineering Laboratories Co., Ltd., INC.) was used to measure the viscosity in Example 1 to Example 35. and the viscosity of each of the syrup compositions prepared in Comparative Example 1 to Comparative Example 4, and the properties of each of the syrup compositions were determined with the naked eye.

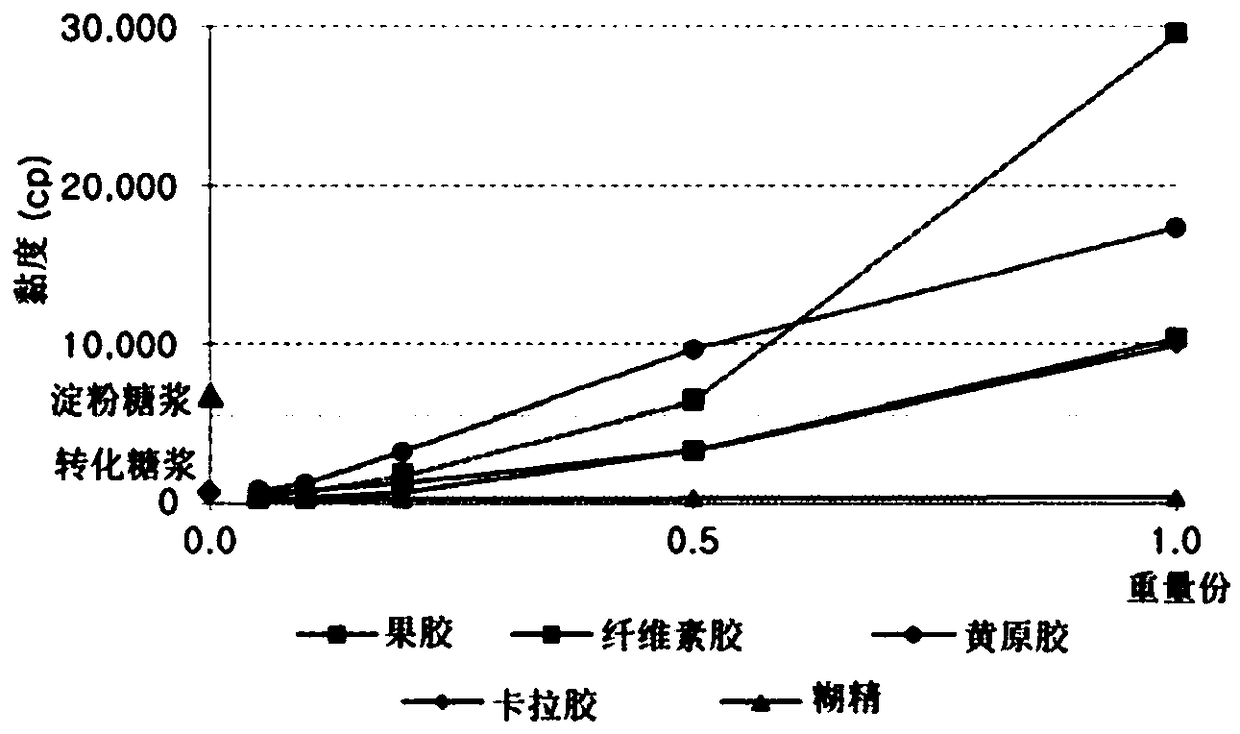

[0054] As in Table 1 and figure 1 As can be seen in the graph, it has been confirmed that compared with the viscosity and properties of the syrup composition of Comparative Example 1, the viscosity and properties of the syrup compositions of Examples 1 to 20 are significantly improved. Specifically, compared with the existing commercially available liquid sugar (Comparative Example 2 to Comparative Example 4, viscosity: 660cP to 6,800c...

experiment example 2

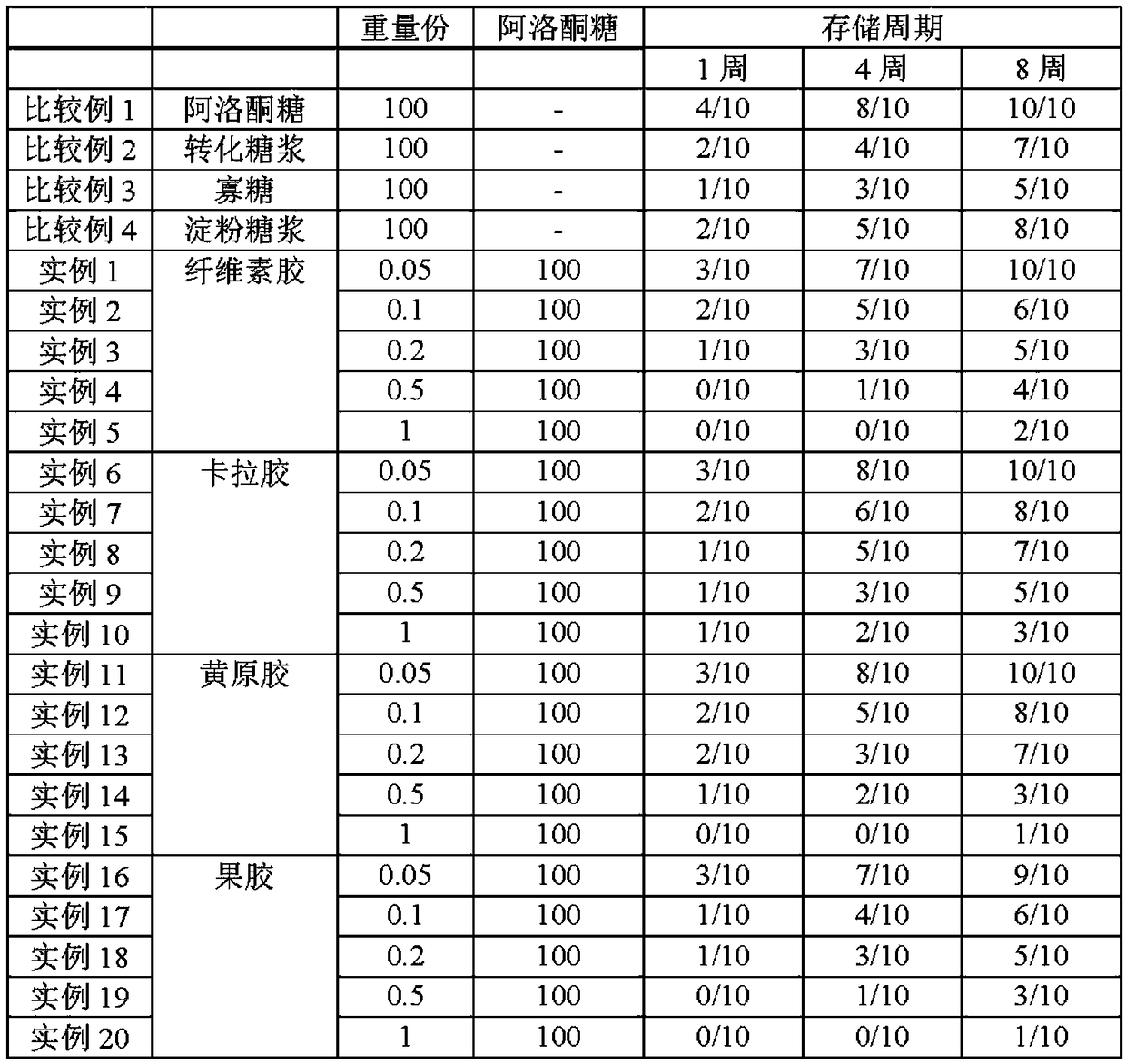

[0057] Experimental example 2. Determination of crystallization

[0058] In order to determine the crystallization and degree of crystallization of the allulose-containing syrup composition, each of the syrup compositions of Examples 1 to 20 and Comparative Examples 1 to 4 was sampled in an amount of 100 ml, and 0.5% by weight seed crystal was added to each sample to accelerate crystallization. For the syrup compositions of Examples 1 to 20 and Comparative Example 1 containing psicose, crystalline psicose (purity 99%, CJ CJ) was used as the seed crystal, while for the syrup compositions containing invert syrup, oligosaccharide In the syrup compositions of Comparative Example 2 to Comparative Example 4 of starch syrup, crystalline psicose (99%, CJ CJ Corporation) was used as a seed crystal. While storing 10 samples at 7° C. to accelerate crystallization under refrigeration conditions specified in the Korean Food Standards Code, crystallization of the samples was visually obser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com