Polymer, semiconductor composition comprising polymer, and method for manufacturing film using semiconductor composition

A polymer and bonding technology, applied in the field of polymers, can solve the problem of not recording the required characteristics of the underlying anti-reflection film, and achieve the effects of improving flatness, reducing sublimation, and reducing standing waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0269] The present invention will be described below by way of various examples. Aspects of the invention are not limited to these examples.

[0270] Synthesis of Polymer 1

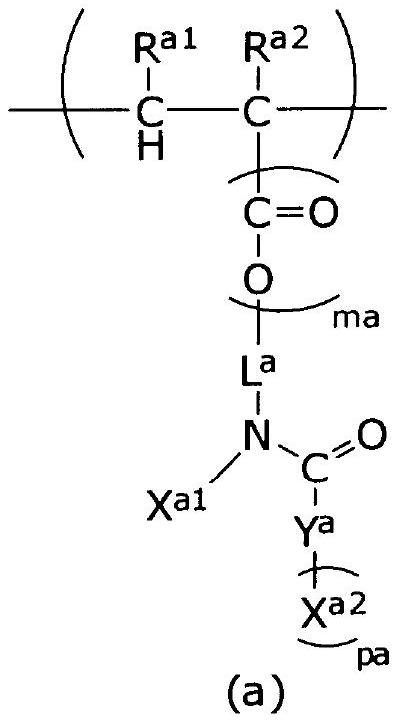

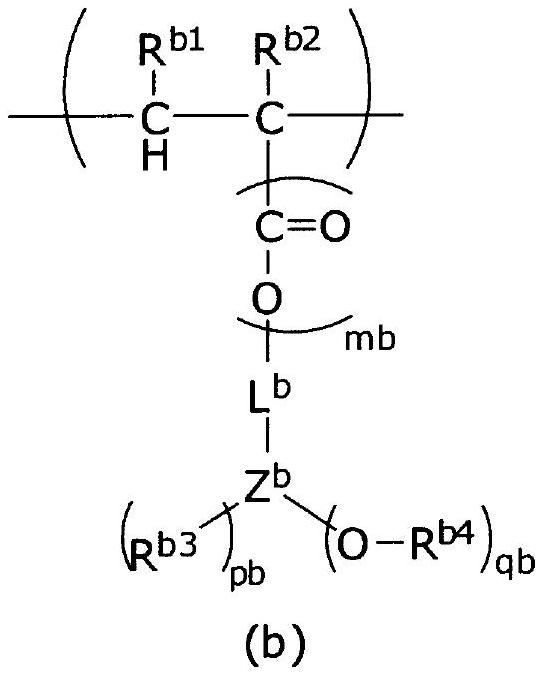

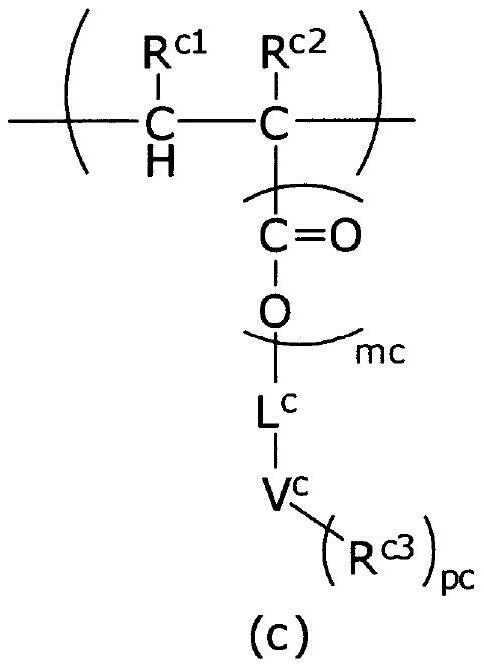

[0271] Add 350g PGMEA in the three-necked flask, then add the following MOI-BP (Karenzu MOI-BP, Showa Denko) 32.79g, McHN (Kawasaki Chemical Industry) 20g, DYE-M9A (Osaka Shinyaku) 6.422g, HPMA (Light Ester HOP, Kyoeisha Chemical) 8.16g. They correspond to unit (a), unit (b), unit (c) and unit (d), respectively.

[0272]

[0273] Furthermore, V-601 / oil-soluble azo polymerization initiator (Fujifilm Wako Pure Chemical Industries, Ltd.) was added. Charge nitrogen into the three-necked flask, cover the lid, heat while stirring, and react at 80° C. for 4 hours. Additionally, 3 g of PGME was added and stirred to complete the polymerization. The reaction solution was brought back to room temperature. The reaction solution was added dropwise to 1500 g of hexane to precipitate a polymer. It was filtered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com