Environment-friendly water-based acrylic acid modified alkyd protective paint used for spraying mechanical equipment, and preparation method of protective paint

A water-based acrylic, mechanical equipment technology, applied in coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems of organic compound residues, operator hazards, hazards, etc., and achieve high fullness, excellent anti-corrosion, and no paint film The effect of ills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

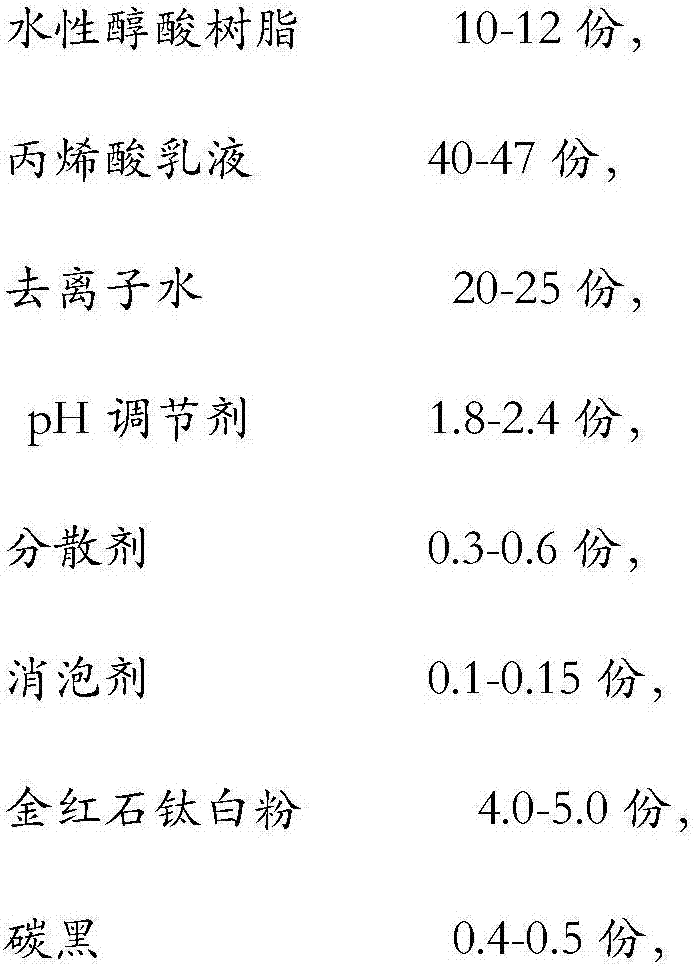

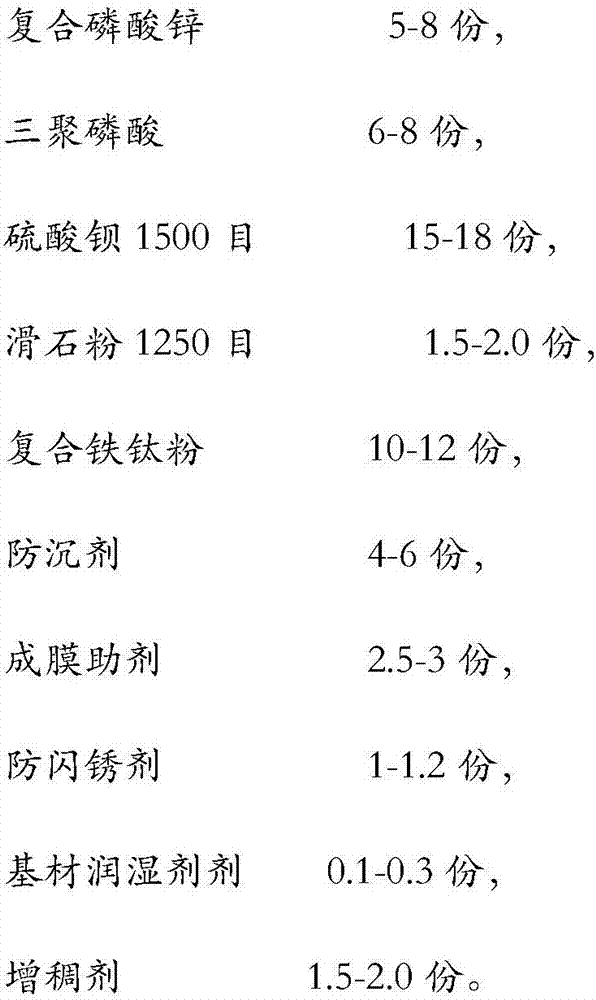

[0036] A kind of environment-friendly water-based acrylic acid modified alkyd protective paint for spraying mechanical equipment and equipment of the present invention, described environmental protection water-based acrylic modified alkyd protective paint for spraying mechanical equipment and equipment comprises the following components by weight:

[0037]

[0038]

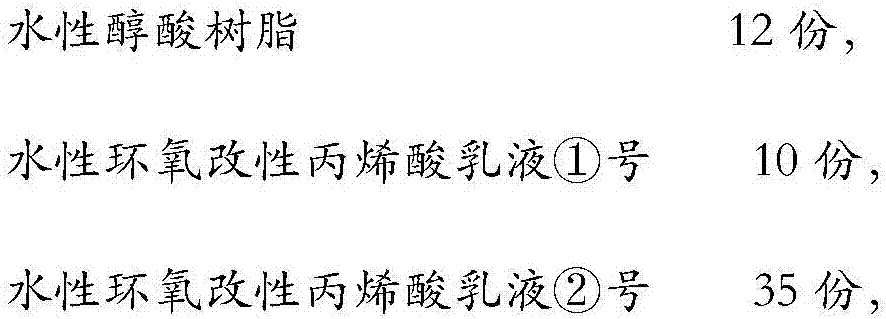

[0039] The water-based alkyd resin is independently developed by Hebei Chenyang Group, and the water-based epoxy-modified acrylic emulsion No. ① and water-based epoxy-modified acrylic emulsion No. ② are two emulsions cooperated with Shandong Wanhua Group.

[0040] The pH regulator is dimethylethanolamine; the dispersant is non-ionic acrylic polymer Tego760W.

[0041] Described defoamer is the composition of polyether siloxane copolymer and Tego902W defoamer, and the mass ratio of described polyether siloxane copolymer and Tego902W defoamer and deionized water is 1:1; The film-forming aid is DPNB; the anti-se...

Embodiment 2

[0050] The difference between embodiment 2 and embodiment 1 is:

[0051] A kind of environmental protection water-based acrylic acid modified alkyd protective paint for spraying mechanical equipment and equipment of the present invention, described environmental protection water-based acrylic modified alkyd protective paint for spraying mechanical equipment and equipment comprises the following components by weight:

[0052]

[0053] The preparation method of the environmental protection water-based acrylic acid modified alkyd protective paint for spraying mechanical equipment and equipment of the present invention comprises the following steps:

[0054] In step (1), stir at a low speed of 300r / min for 5 minutes until the water-based resin is neutralized into a uniform state; add defoamer and dispersant in turn, and stir at a medium speed for 8 minutes;

[0055] In step (4), add the ground qualified paint slurry into the paint mixing tank, and slowly add water-based epoxy-m...

Embodiment 3

[0058] The difference between embodiment 3 and embodiment 1 is:

[0059] A kind of environment-friendly water-based acrylic acid modified alkyd protective paint for spraying mechanical equipment and equipment of the present invention, described environmental protection water-based acrylic modified alkyd protective paint for spraying mechanical equipment and equipment comprises the following components by weight:

[0060]

[0061]

[0062] The preparation method of the environmental protection water-based acrylic acid modified alkyd protective paint for spraying mechanical equipment and equipment of the present invention comprises the following steps:

[0063] In step (1), stir at a low speed of 300r / min for 5 minutes until the water-based resin is neutralized into a uniform state; add defoamer and dispersant in turn, and stir at a medium speed for 9 minutes;

[0064] In step (4), add the ground qualified paint slurry into the paint mixing tank, and slowly add water-based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com