Modified asphalt emulsion and preparation method thereof

A technology for modifying asphalt and emulsion, applied in building components, building insulation materials, buildings, etc., can solve the problems of no disclosed emulsifier, low storage stability, and high residue on the emulsified asphalt sieve, and achieve good demulsification and coagulation. Good stability, good storage stability and low sieve residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

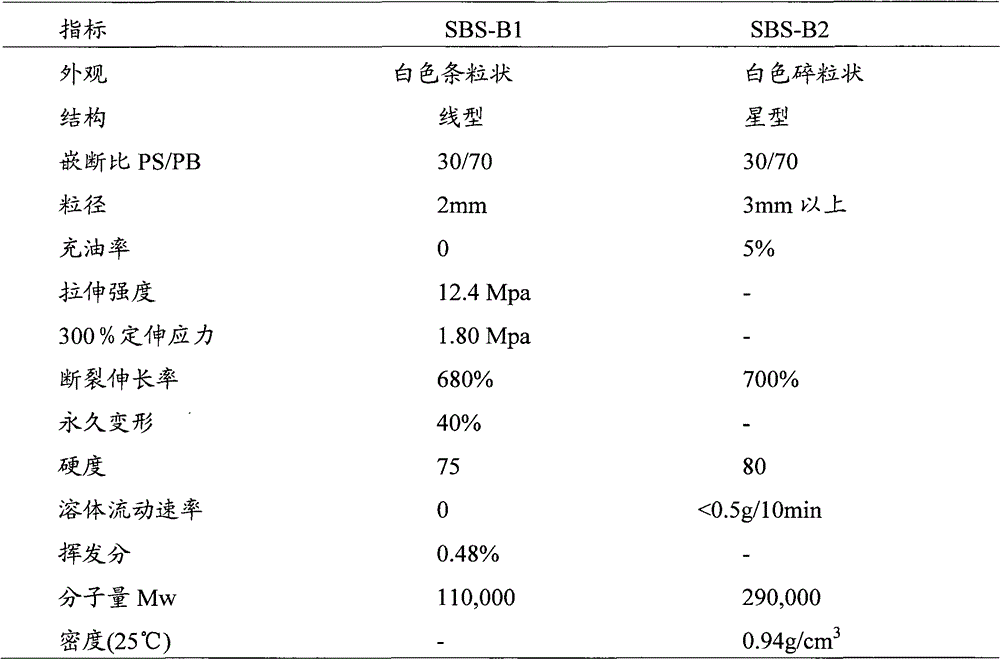

[0018] In the preparation method of the asphalt emulsion provided by the invention, the asphalt raw material is heated to 100-200°C, then the elastomer polymer is added, mixed evenly, and the temperature of the mixture is controlled to be 100-200°C. It can be mixed evenly by stirring, and the stirring time is usually 0.1-1 hour, then pass through a colloid mill, and then add a stabilizer. After adding the stabilizer, react for a period of time, preferably 1-8 hours, to obtain modified asphalt, and control the reaction temperature to 100-200°C, preferably 150-190°C.

[0019] In the preparation method of asphalt emulsion provided by the present invention, in step (3), the modified asphalt obtained in step (1) is mixed with the emulsifier solution obtained in step (2), and dispersed with an emulsifier, and then the dispersed The mixture is condensed to obtain a modified asphalt emulsion; the modified asphalt obtained in step (1) and the emulsifier solution obtained in step (2) ca...

specific Embodiment approach

[0022] According to the preparation method of asphalt emulsion provided by the present invention, a kind of preferred embodiment comprises the following steps:

[0023] (1) Raise the temperature of 48-67 parts by weight of the asphalt raw material to 100-200°C, add 1-6 parts by weight of the elastomeric polymer into the temperature-controlled asphalt, stir for 0.2-1h to disperse the elastomeric polymer evenly, Then pass colloid mill, then add the modified asphalt stabilizer of 0.01-1 weight part, make modified asphalt after reaction 1-8h; Wherein asphalt: elastomeric polymer: the weight ratio of modified asphalt stabilizer is 48-67 : 1-6: 0.01-1; the temperature of the resulting mixture is 100-200°C, preferably 150-190°C.

[0024] (2) Mix 0.05-5 parts by weight of emulsifier compound, 0.02-2 parts by weight of emulsification aid and 25-45 parts by weight of water to prepare an aqueous emulsifier solution, and heat the solution to 40-90°C ; Wherein the weight ratio of lignin e...

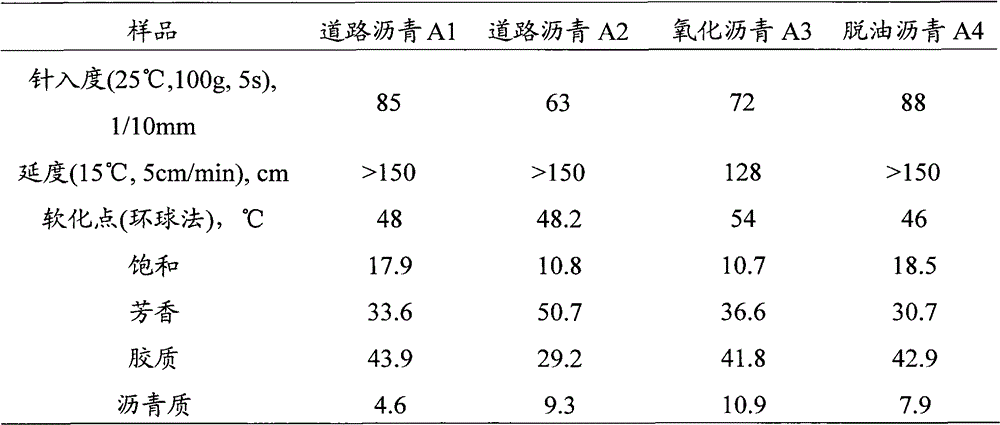

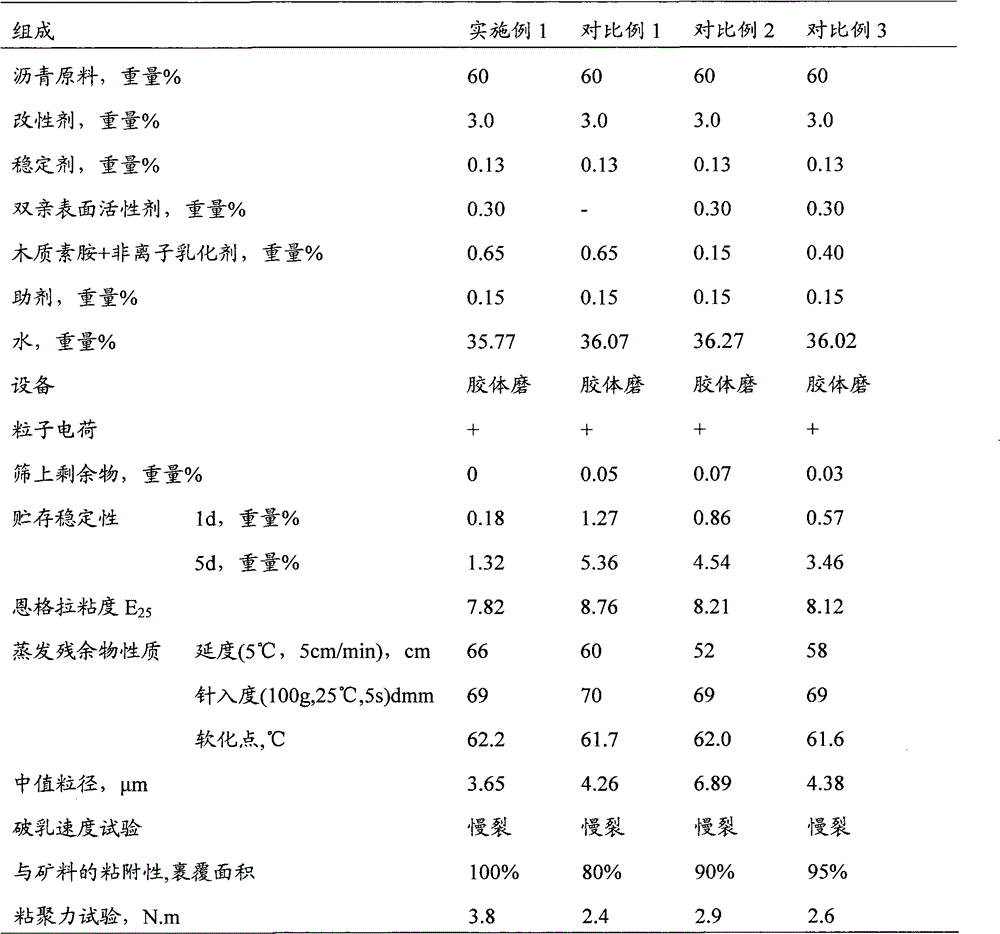

Embodiment 1

[0029] Heat 600g of road asphalt A1 to a temperature of 160°C, add 30g of polymer B1 and stir for 30 minutes, pass through a colloid mill, then add 1.3g of sulfur, stir and react for 4 hours, then heat to 170°C for later use, denoted as CW1; add 4.5g of lignin Polyamine, 0.3g tetradecyl polyoxyethylene dodecyl ammonium chloride, 2g octylphenol polyoxyethylene (10) ether and 1.5g calcium chloride are mixed with 357.7g water, stirred to dissolve the components , to obtain an emulsifier aqueous solution, and then heated to 65 °C; the prepared CW1 and emulsifier aqueous solution were sheared and dispersed through a colloid mill at the same time, and cooled to obtain a modified asphalt emulsion. "Technical Requirements for Modified Asphalt Emulsion", see Table 3 for properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com