Light diffusion sheet for a display device

A technology of light diffuser and display device, applied in optics, optical components, nonlinear optics, etc., can solve problems such as display performance distortion of LCD panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

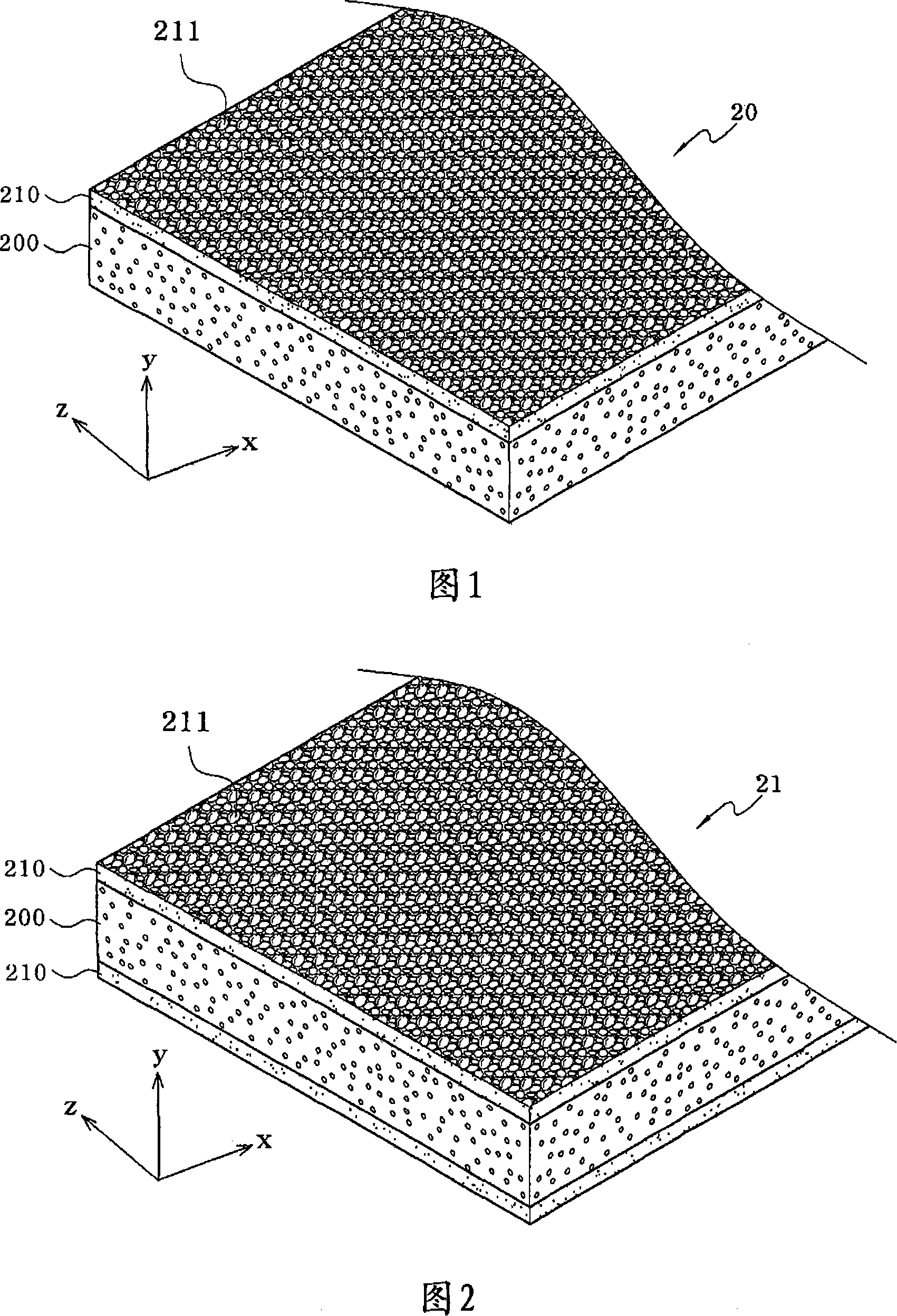

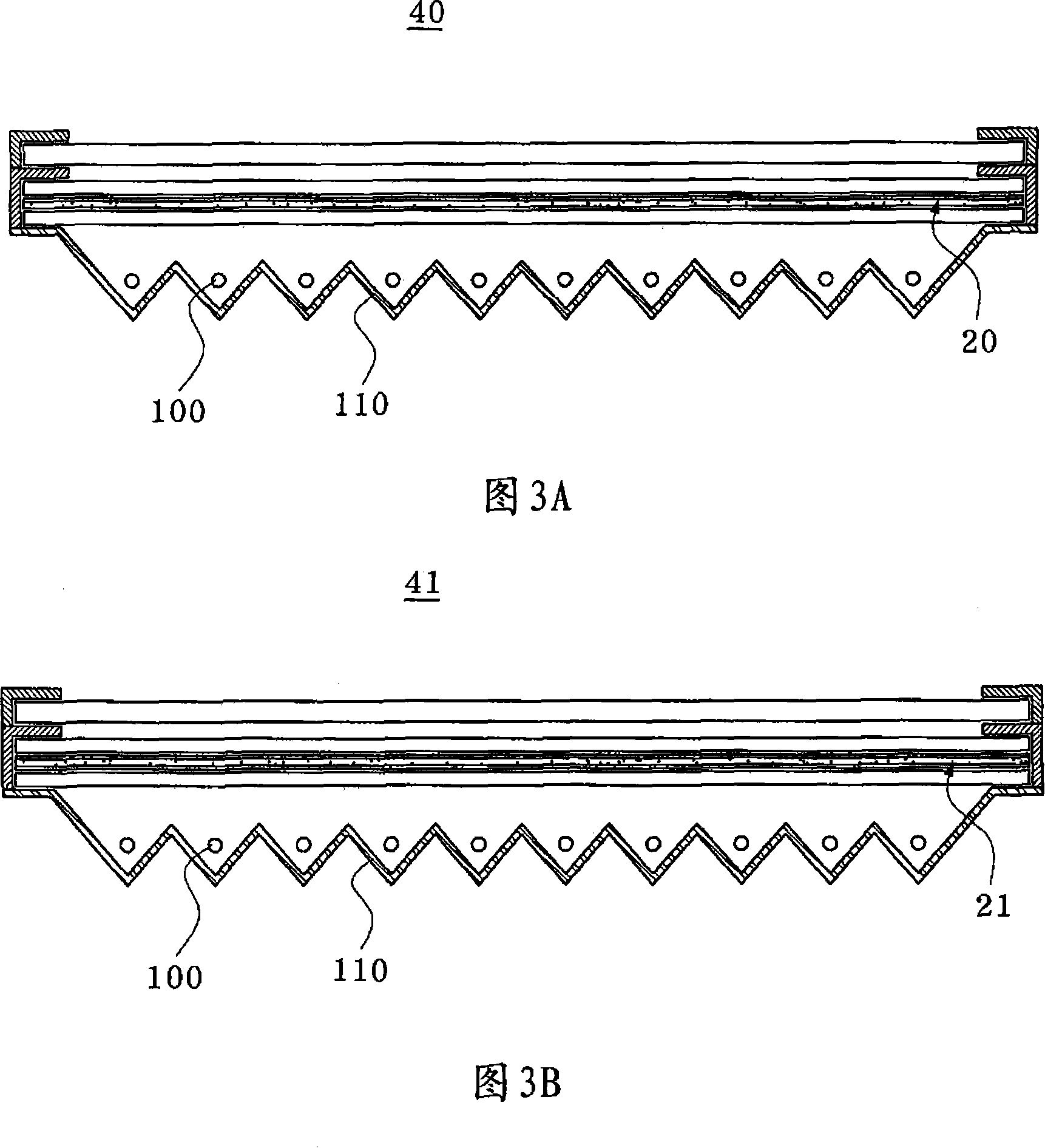

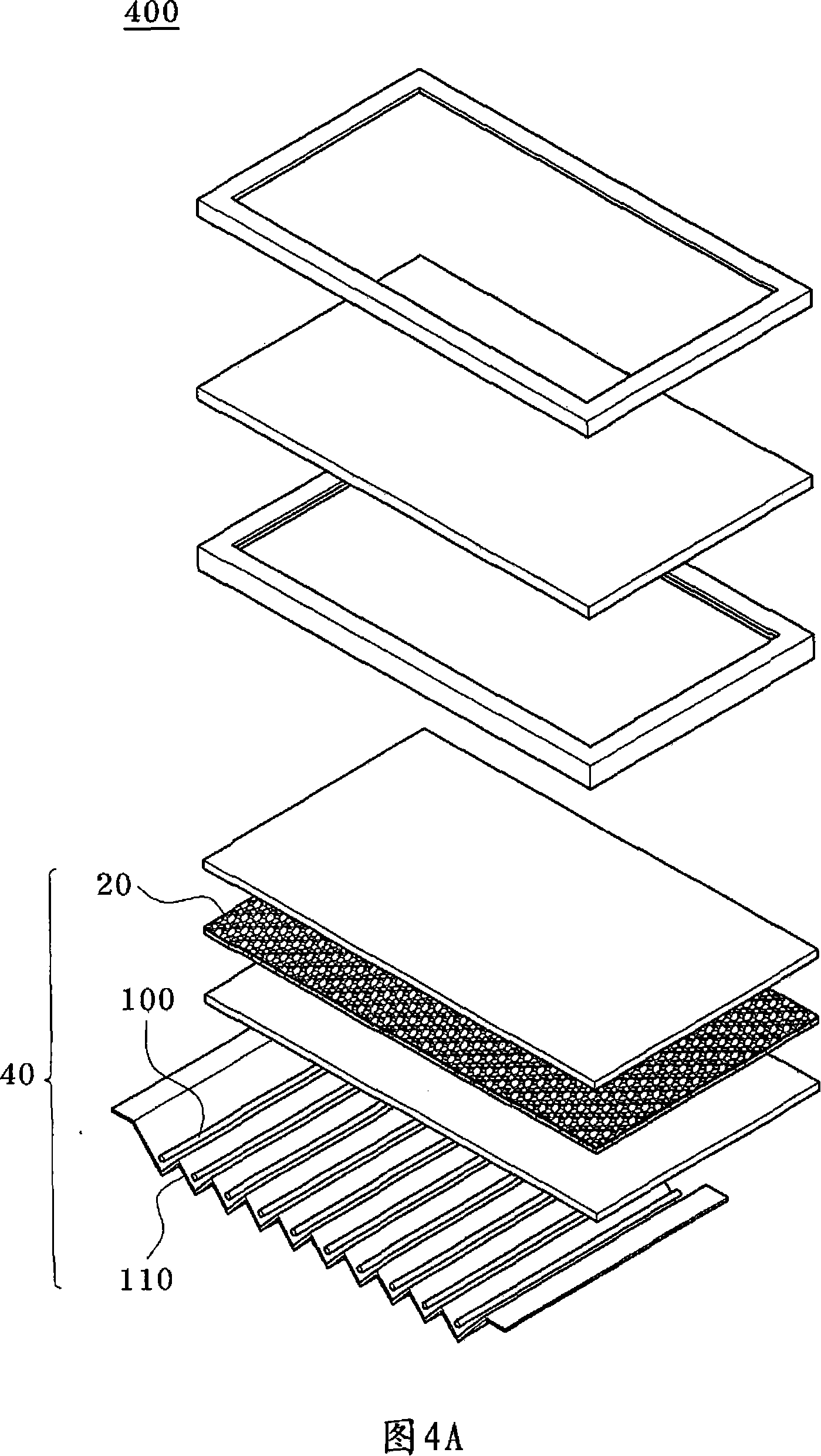

[0048] Production of base layer: A methacrylate-styrene (MS) copolymer and a methyl methacrylate-styrene (MMS) copolymer were mixed to form 100 parts by weight of a base resin mixture. Silicone resin particles having an average diameter of 2 μm in an amount of 2 ppwb (obtained from GE Toshiba Silicone Co., Ltd.) and acrylic crosslinked particles having an average diameter of 8 μm in an amount of 2 ppwb (obtained from Sekisui Chemical Co., Ltd.) were added into the base resin mixture to form the base layer composition.

[0049] Production of coating: MS copolymer was prepared to form 100 parts by weight of base coating resin. Acrylic acid crosslinked particles (obtained from Sekisui Chemical Co., Ltd) with an average diameter of 20 μm in an amount of 10 ppwb, an antistatic agent in an amount of 1 ppwb, and a light stabilizer in an amount of 1 ppwb were added to the base coat resin to form a coating combination.

[0050]Production of multi-layer light diffusion sheet: each bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com