Polyvinyl chloride toughening modifier

A kind of toughening modifier, polyvinyl chloride technology, applied in rigid pipes, mechanical equipment, pipes/pipe joints/fittings, etc., to achieve the effect of improving balance torque, reducing air bubbles and promoting plasticization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (embodiment 1, polyvinyl chloride toughening modifier)

[0025] This embodiment is a polyvinyl chloride toughening modifier, comprising:

[0026] Methyl methacrylate-butadiene-styrene copolymer is also called MBS: 1.1 parts; the specific choice is the MBS produced by Japan Zhongyuan Company with the brand name B564;

[0027] Acrylic ester impact modifier is also called ACR impact modifier: 10.5 parts; specifically select the ACR impact modifier of KM355P produced by Singapore Kureu Company; the acrylate impact modifier It is a core-shell copolymer formed by the copolymer of alkyl acrylate and methyl methacrylate or acrylate and methyl methacrylate as the shell, and the elastomer formed by crosslinking butyl acrylate as the core. The parts of the above-mentioned components are all parts by weight.

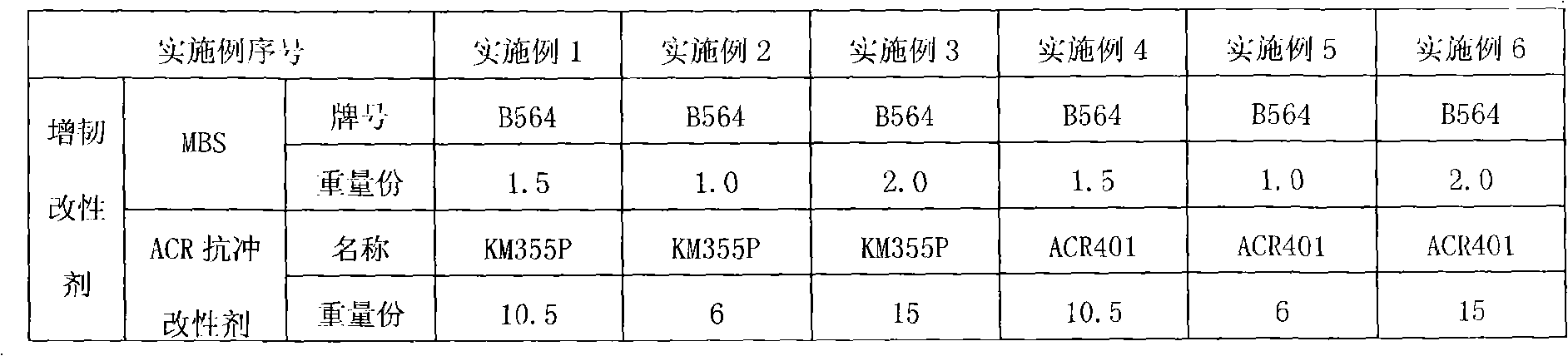

[0028] The composition and proportioning of this embodiment are shown in Table 1.

[0029] Table 1

[0030]

Embodiment 2 to Embodiment 3

[0032] Embodiment 2 to Embodiment 3 are basically the same as Embodiment 1, the difference is that: the ratio of raw materials used is different, and the specific ratio is shown in Table 1.

Embodiment 4 to Embodiment 6

[0034] Embodiment 4 to Embodiment 6 are basically the same as Embodiment 1, except that the ACR impact modifier is ACR401 produced by Taixing Linjiang Chemical Factory. See Table 1 for the specific proportioning of each embodiment in Embodiment 4 to Embodiment 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com