Patents

Literature

190results about "Adhesive processes using foamed adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

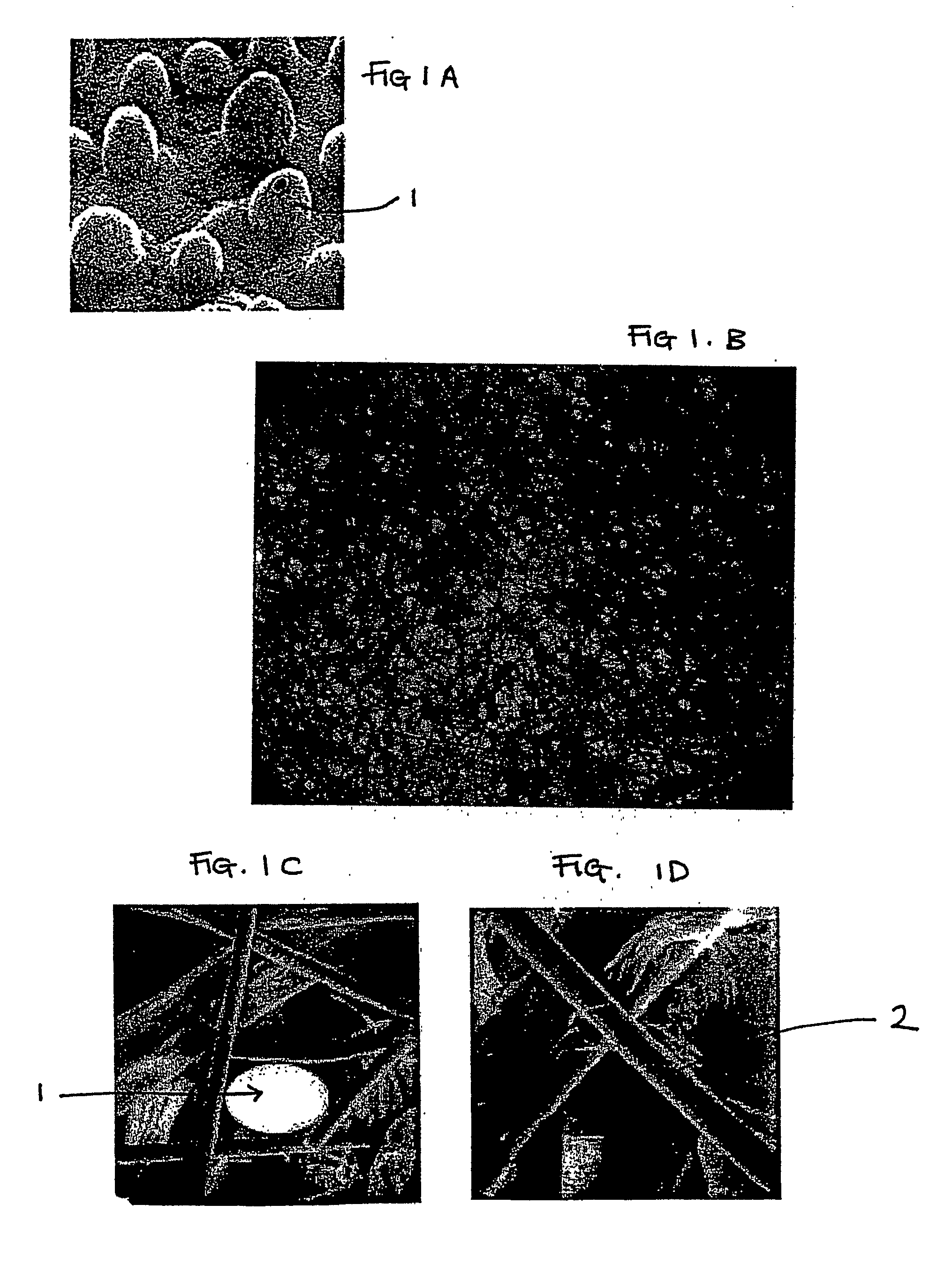

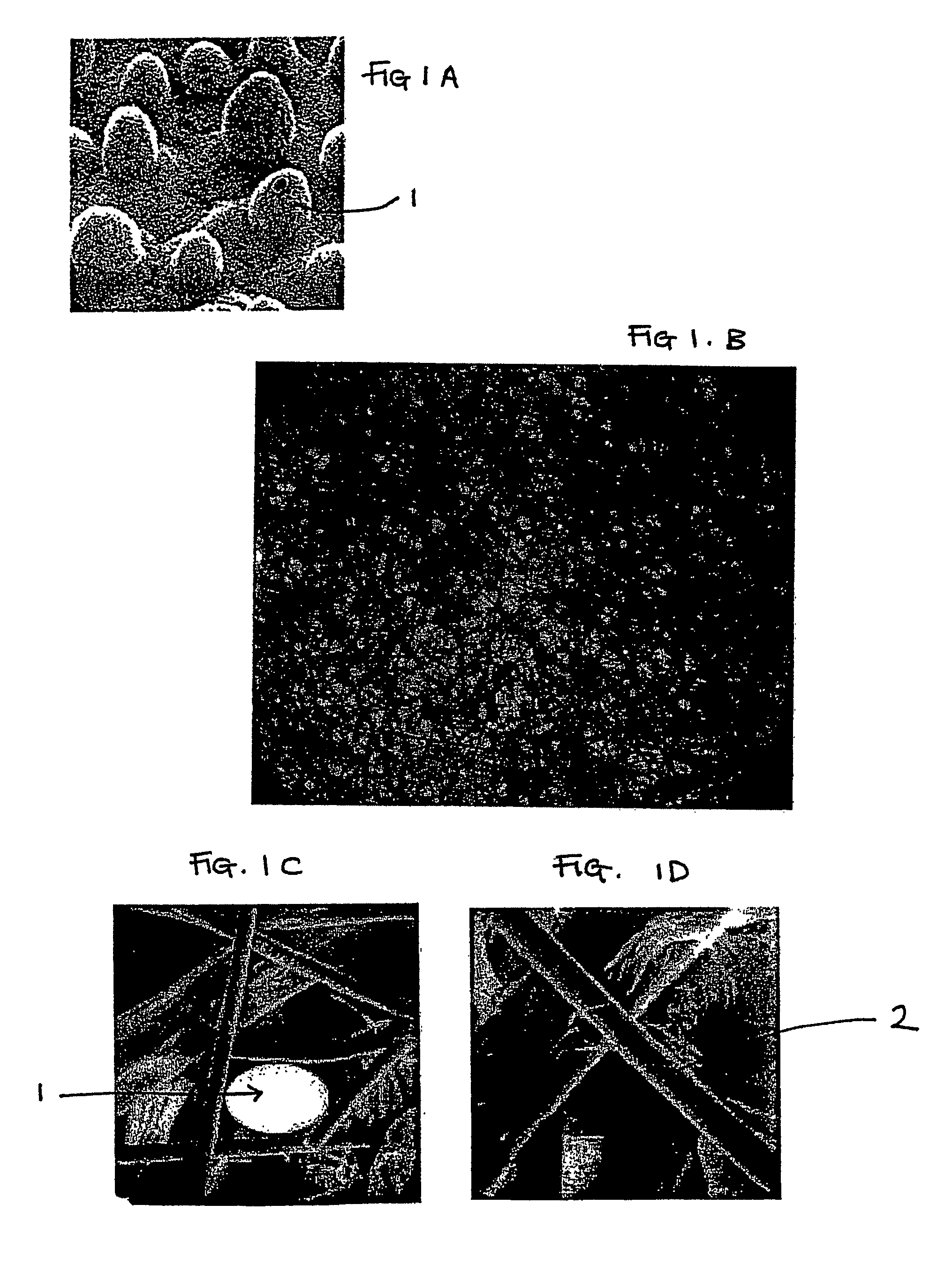

Adhesives having a microreplicated topography and methods of making and using same

InactiveUS6197397B1Easy to disassembleChange surface propertiesAdditive manufacturing apparatusLayered productsAdhesiveTopography

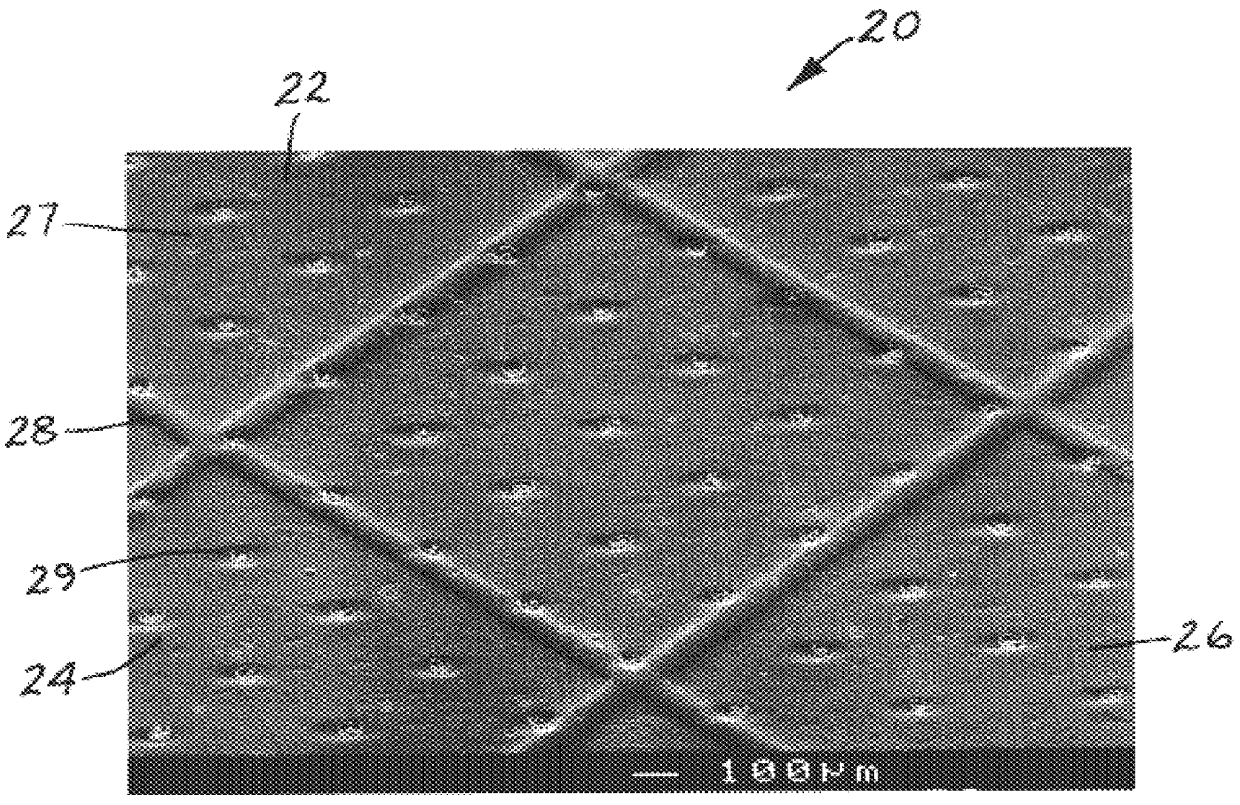

Adhesives having a microreplicated topography are prepared from contacting a microembossed pattern to a layer of adhesive. When an adhesion interface is established between the layer of adhesive and a supporting substrate, the topography of the adhesive surface controls the performance of the adhesion interface. Articles having microreplicated adhesive surfaces are also disclosed that have an advantage of providing microchannels for fluid egress for an effective period of time. Multiple microembossed patterns produce microreplicated adhesive surfaces having both microchannels for fluid egress and pegs for improved adhesive properties.

Owner:3M INNOVATIVE PROPERTIES CO

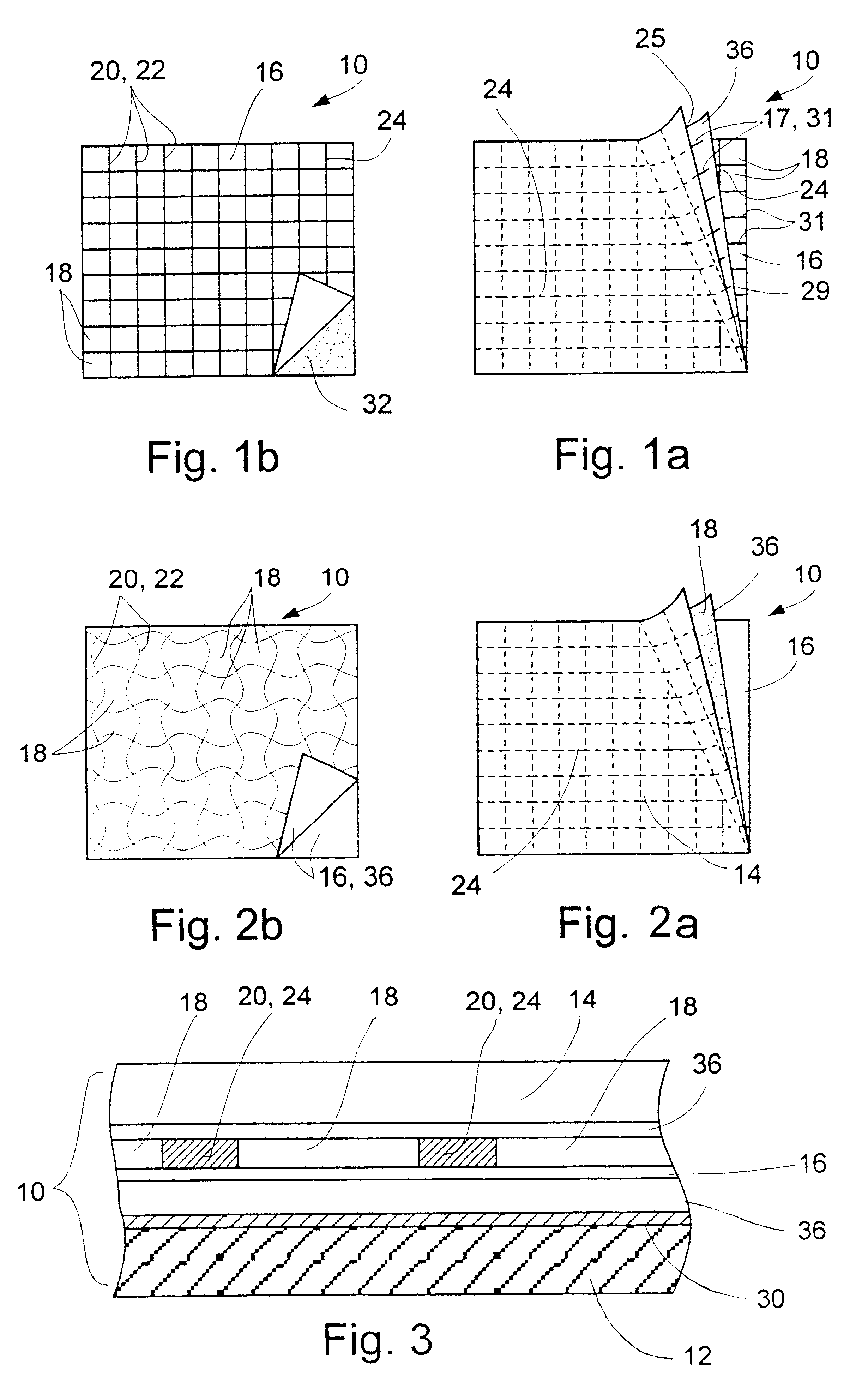

Sealing sheet assembly for construction surfaces and methods of making and applying same

InactiveUS6586080B1Low costReduce thicknessBuilding roofsRoof covering using flexible materialsRelative displacementClassical mechanics

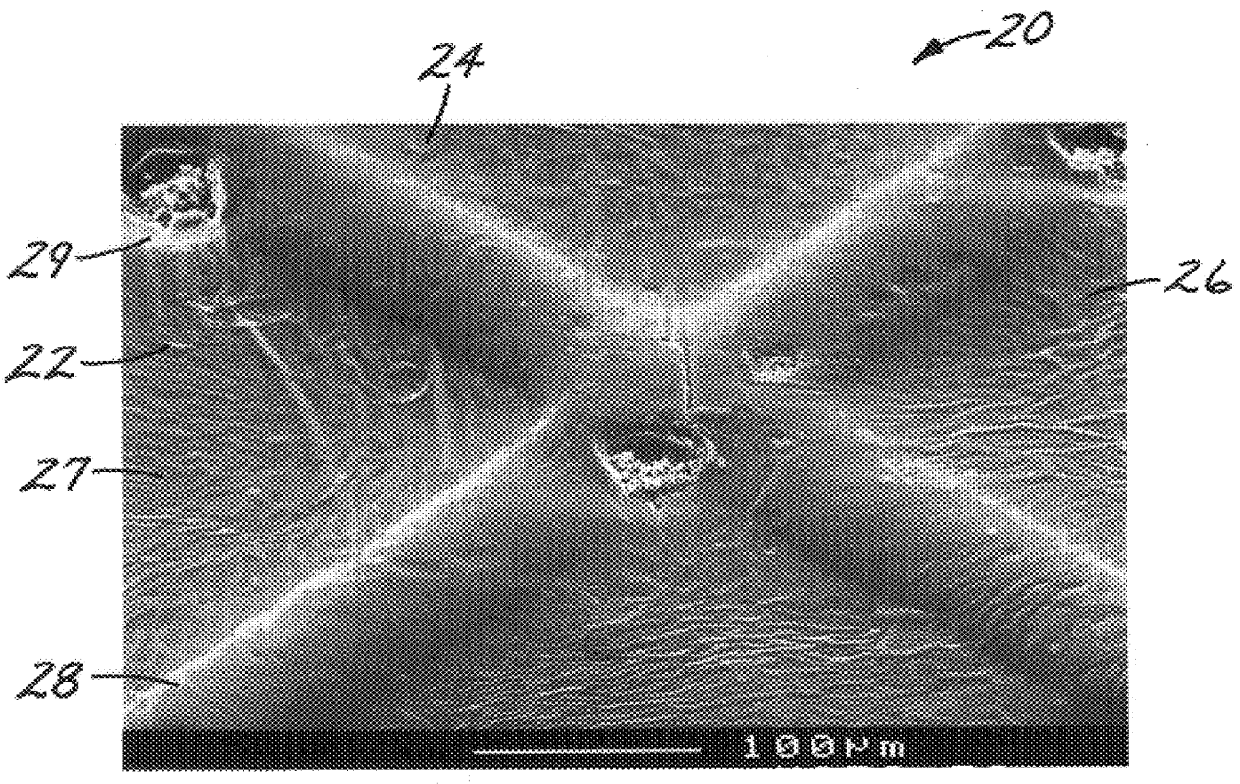

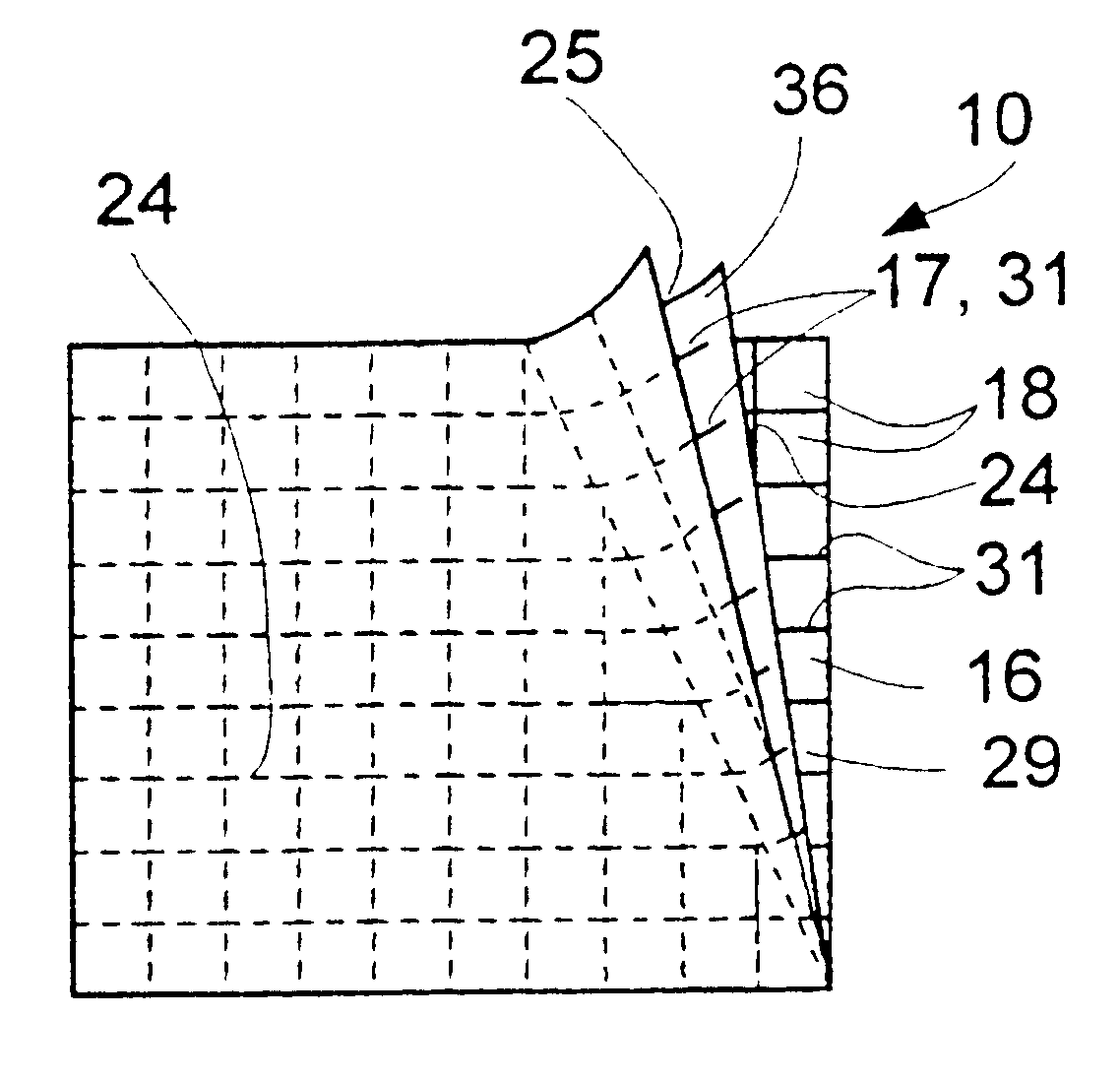

A sealing sheet (10) assembly bondable to a construction surface comprising (a) an upper layer (14) of a first substance, the upper layer being selected fluid impermeable; and (b) a lower flexible layer (16) of a second substance, the lower flexible layer being bondable to the construction surface. The upper layer and the lower flexible layer are at least partially attached to one another, wherein a combination of the upper layer, the lower layer and the attachment or the partial attachment of the layers to one another are selected such that tensile forces resulting from constructional movements acting upon the sealing sheet result in a local detachment or relative displacement of the upper layer and the lower flexible layer, thereby the ability of the lower flexible layer of transmitting the forces onto the upper layer is remarkably reduced, resulting in improved service of the sealing cover as a whole. The attachment is selected such that a spread of a leakage between the layers via a tear formed in the upper layer is locally restricted.

Owner:HEIFETZ RAPHAEL

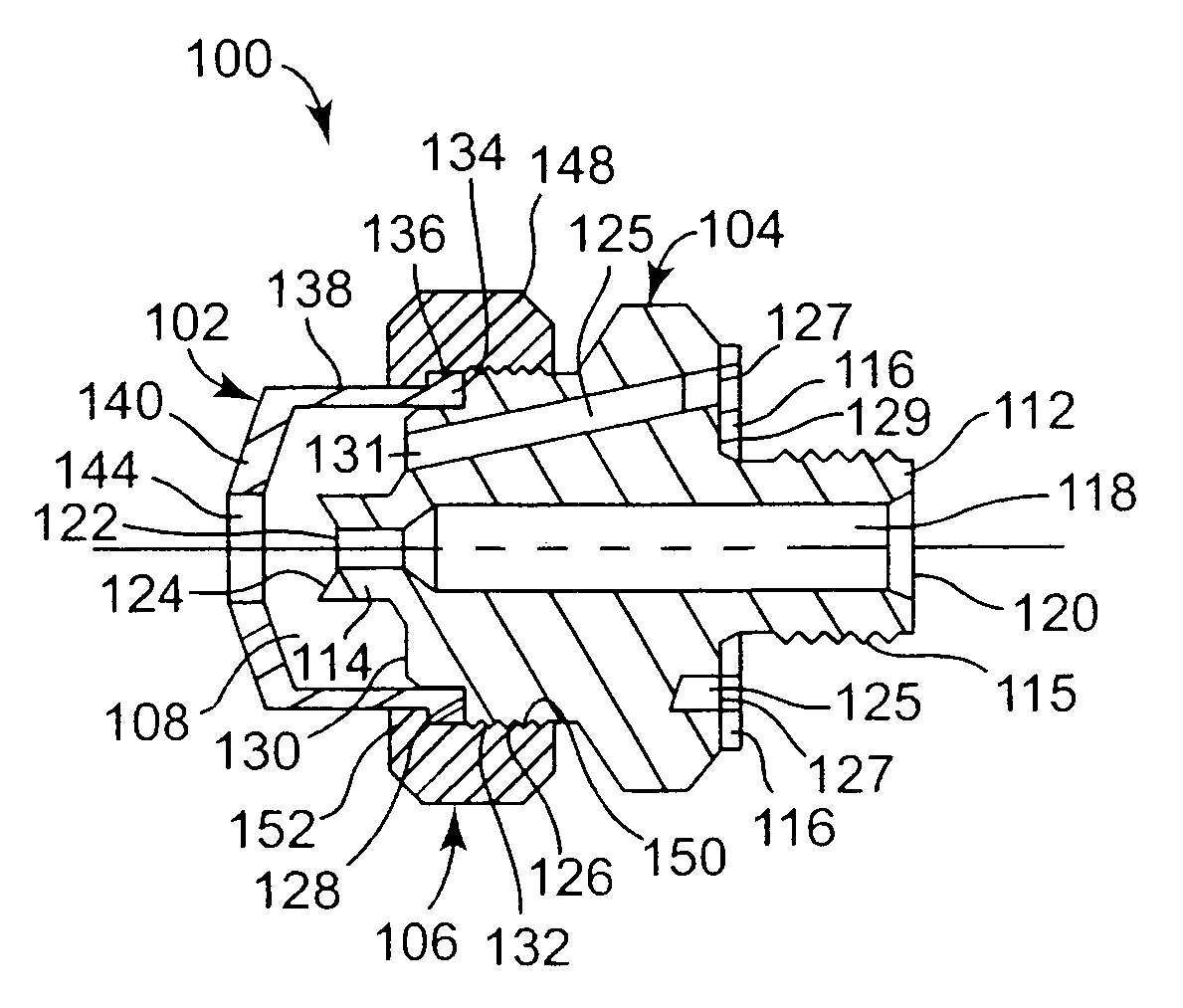

Method and apparatus for bonding and debonding adhesive interface surfaces

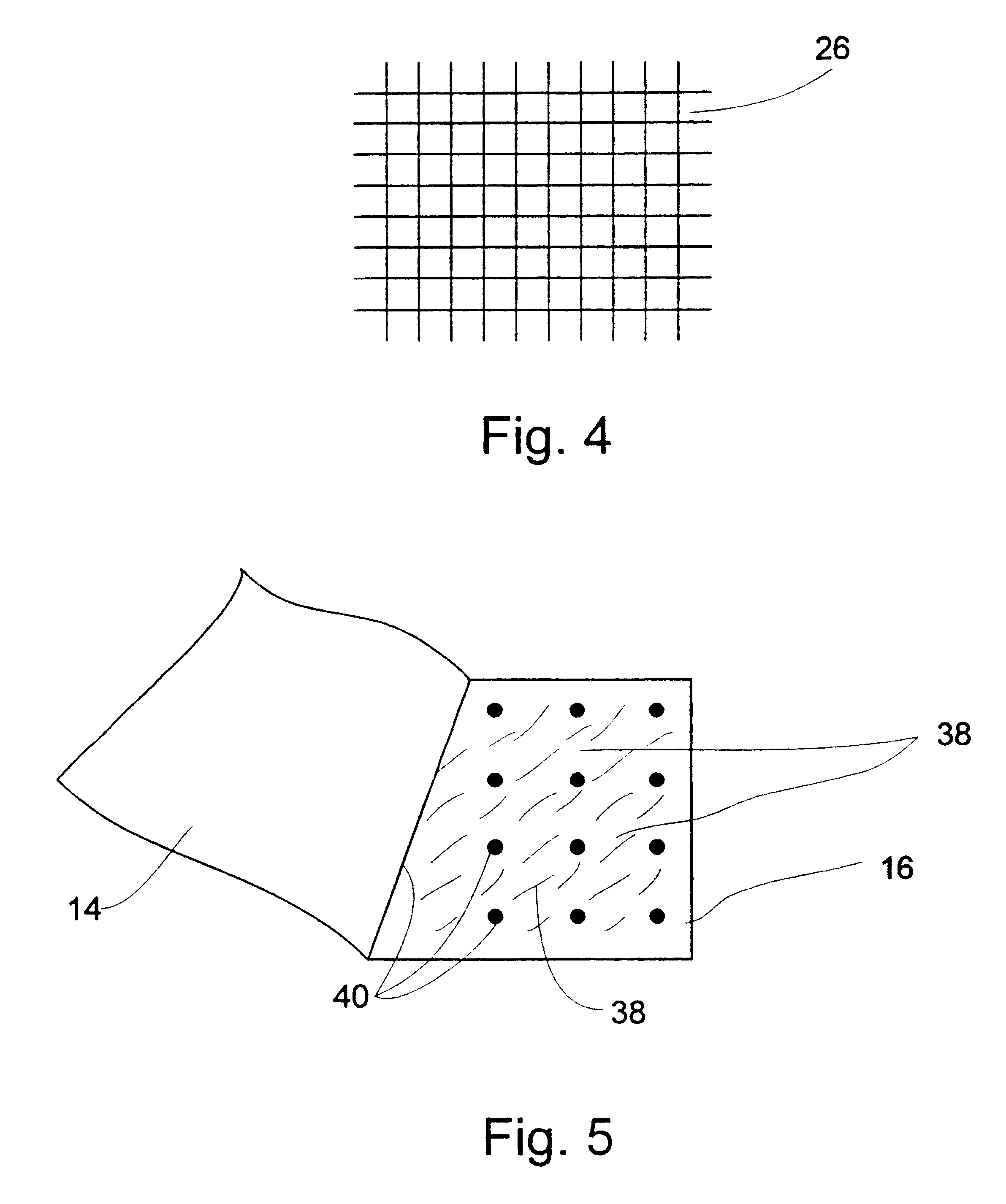

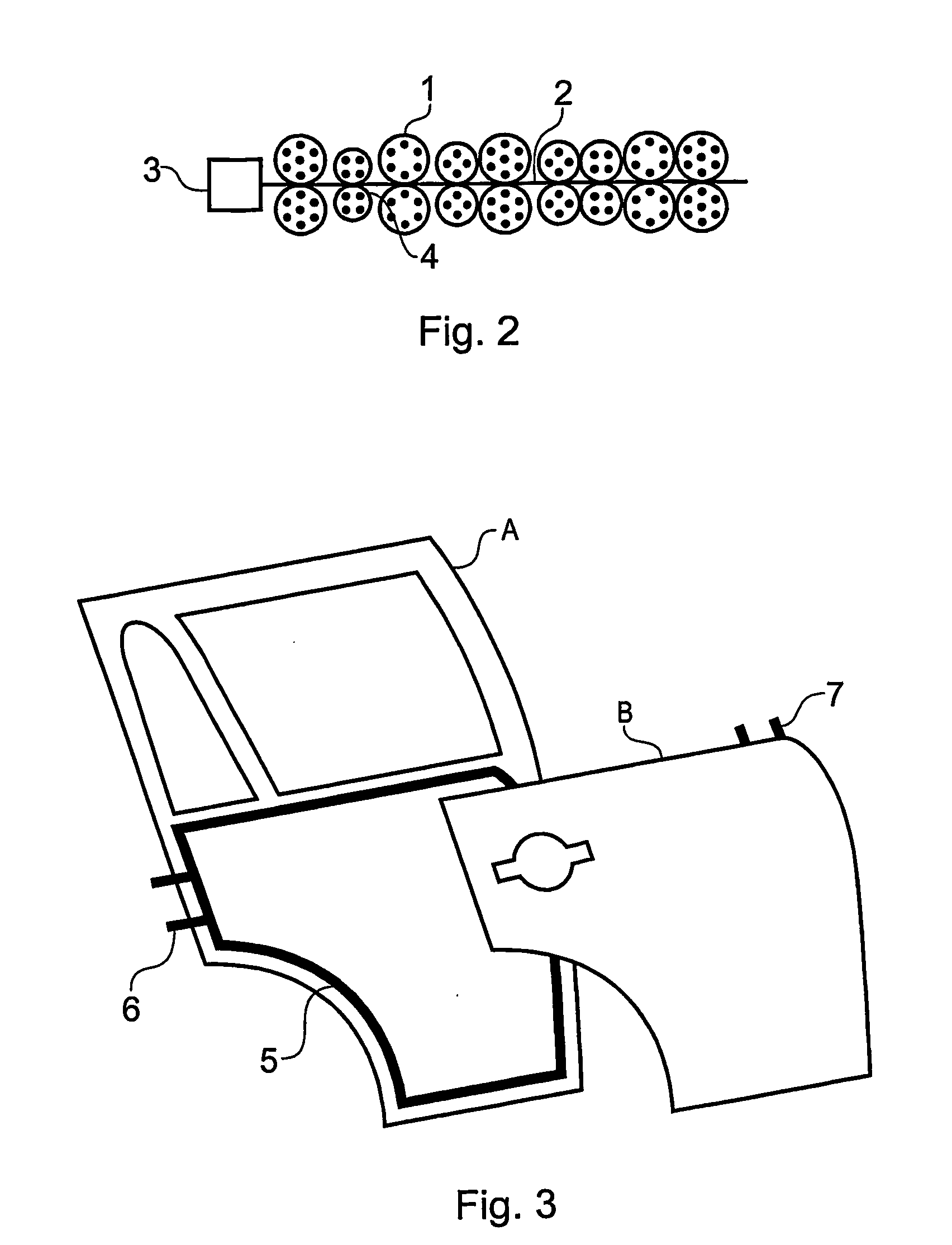

InactiveUS20060219350A1Shorten the timeEvenly distributedEngine sealsNanostructure manufactureThermal energyMicrosphere

The present invention relates to a system and a method of improving the debonding of two or more surfaces together. The invention utilises thermoexpanadable microspheres and thermal energy to debond interfaces in an adhesive system or as vehicle carriers. It also discloses a method of curing the adhesive system prior to the debonding step so that the same adhesive system may be used for both phases. It is especially useful in the automotive industry for end of vehicle life dismantling.

Owner:BAIN & COMPANY

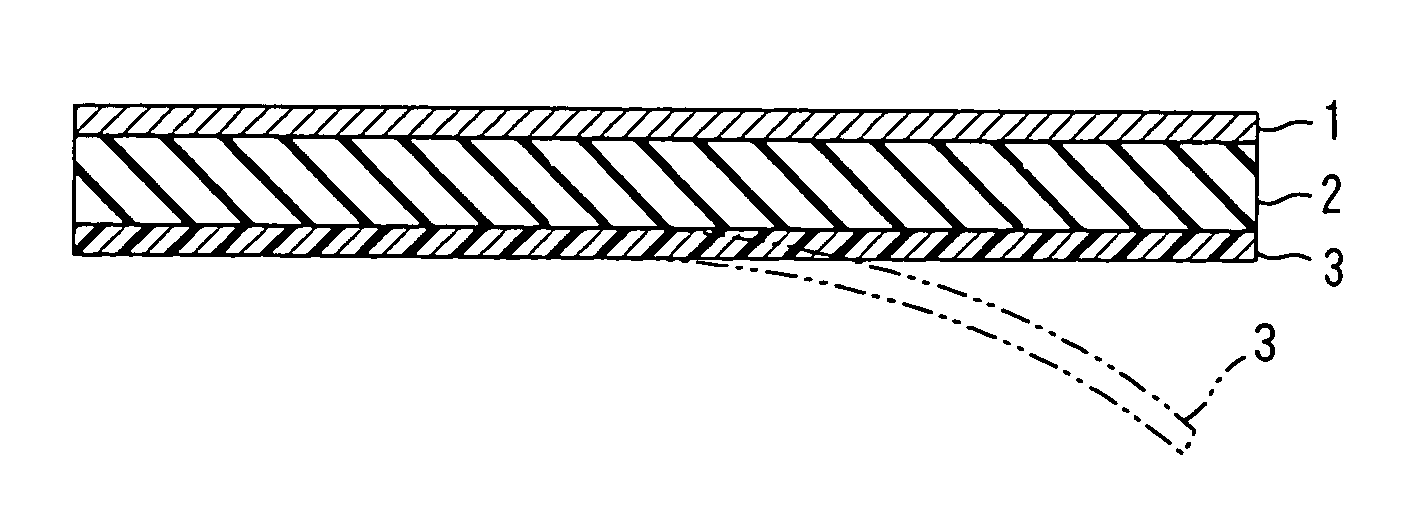

Heat-Peelable Pressure-Sensitive Adhesive Sheet and Method for Processing Adherend Using the Heat-Peelable Pressure-Sensitive Adhesive Sheet

InactiveUS20080019078A1Avoid deformationEasy to peelLayered productsFixed capacitor dielectricShear modulusFoaming agent

Disclosed is a heat-peelable pressure-sensitive adhesive sheet that can prevent the deformation of a pressure-sensitive adhesive layer due to pressurization in a pressing process and can be easily peeled off from the processed article. The heat-peelable pressure-sensitive adhesive sheet includes a substrate, and a heat-expandable pressure-sensitive adhesive layer arranged on or above at least one side of the substrate and containing a foaming agent, in which the heat-expandable pressure-sensitive adhesive layer has a shear modulus (23° C.) in an unfoamed state of 7×106 Pa or more. The heat-expandable pressure-sensitive adhesive layer preferably has a shear modulus (95° C.) in an unfoamed state of less than 7×106 Pa. The foaming agent in the heat-expandable pressure-sensitive adhesive layer preferably has a foam initiating temperature higher than 80° C.

Owner:NITTO DENKO CORP

Adhesive sheet for steel plate

ActiveUS20050032447A1Sufficiently reinforcingDischarge fullyNon-macromolecular adhesive additivesAdhesive articlesEpoxyGlass fiber

Owner:NITTO DENKO CORP

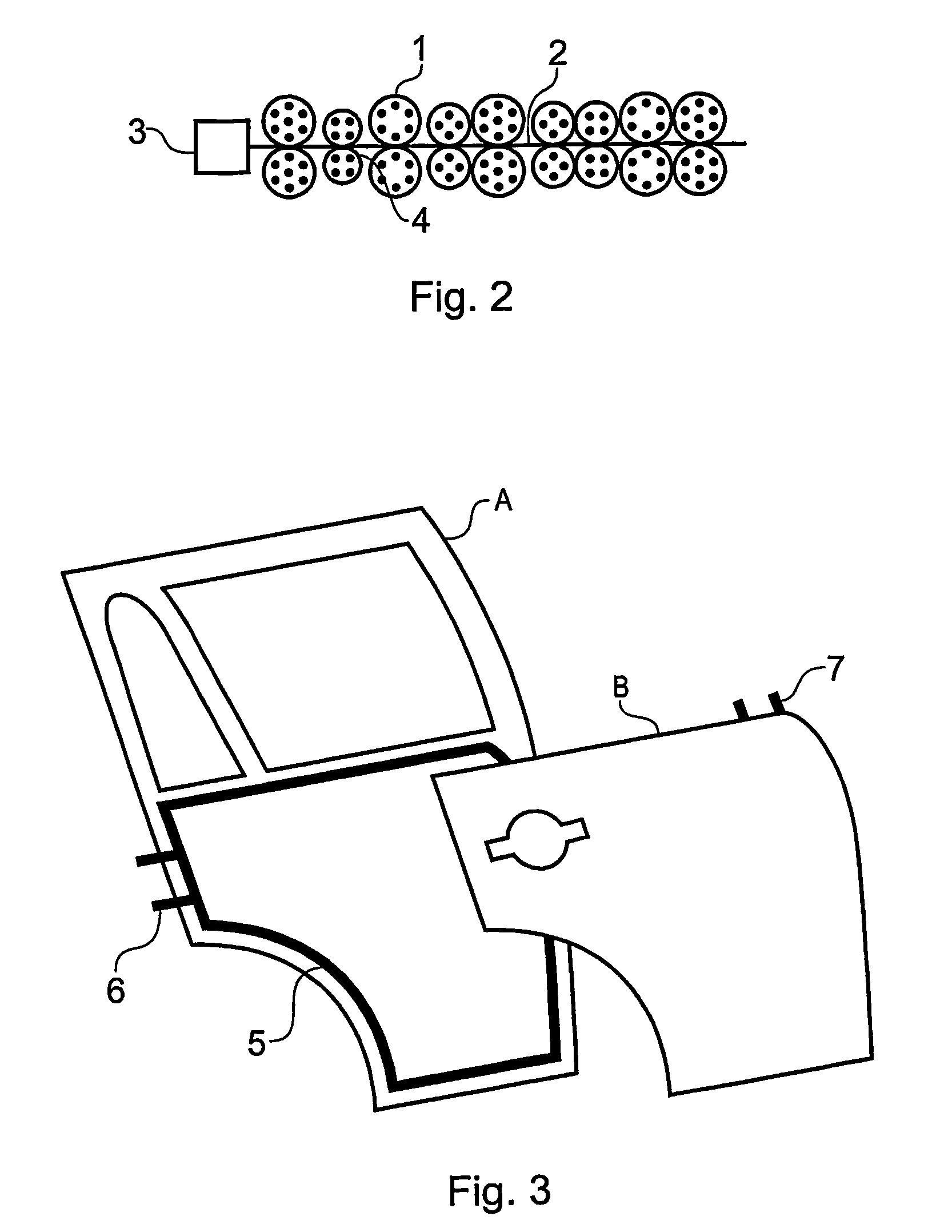

Paper laminates manufactured using foamed adhesive systems

InactiveUS20050045267A1Reliable and straightforwardNon-macromolecular adhesive additivesManual label dispensersAdhesivePaper towel

Foamed, aqueous adhesive compositions are used to manufacture tissue laminate products including or especially as bathroom tissue, facial tissue, paper towels, and the like. Foaming typically occurs by introducing pressurized gas and adhesive flows in a nozzle chamber on demand, wherein the kinetic energy of the flows is used to provide mixing energy. The adhesive preferably is dispensed as a plurality of discrete, foamed adhesive particles. The foamed adhesive can be used for intralamina bonds, interlaminate bonds, bonding loose sheet extremities, bonding roll to roll, and the like. The invention provides a reliable, straightforward way to accomplish in-nozzle foaming of an adhesive.

Owner:HB FULLER CO

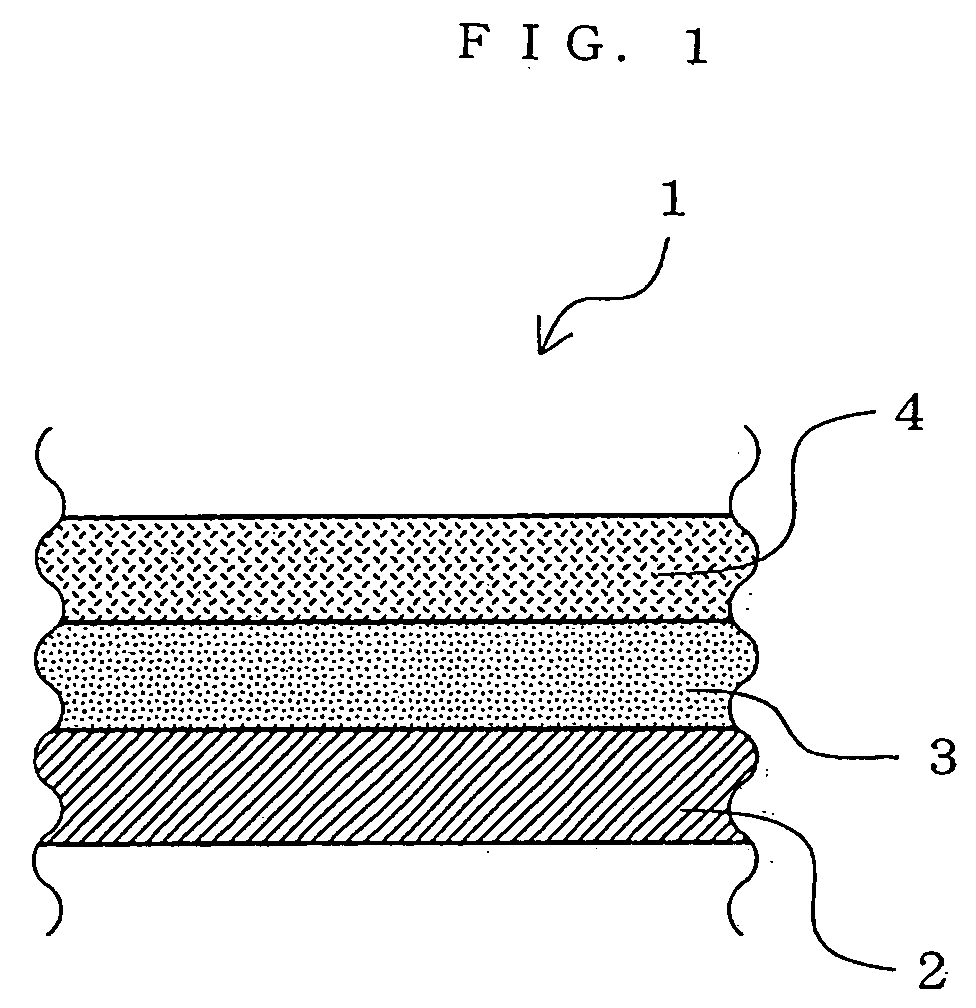

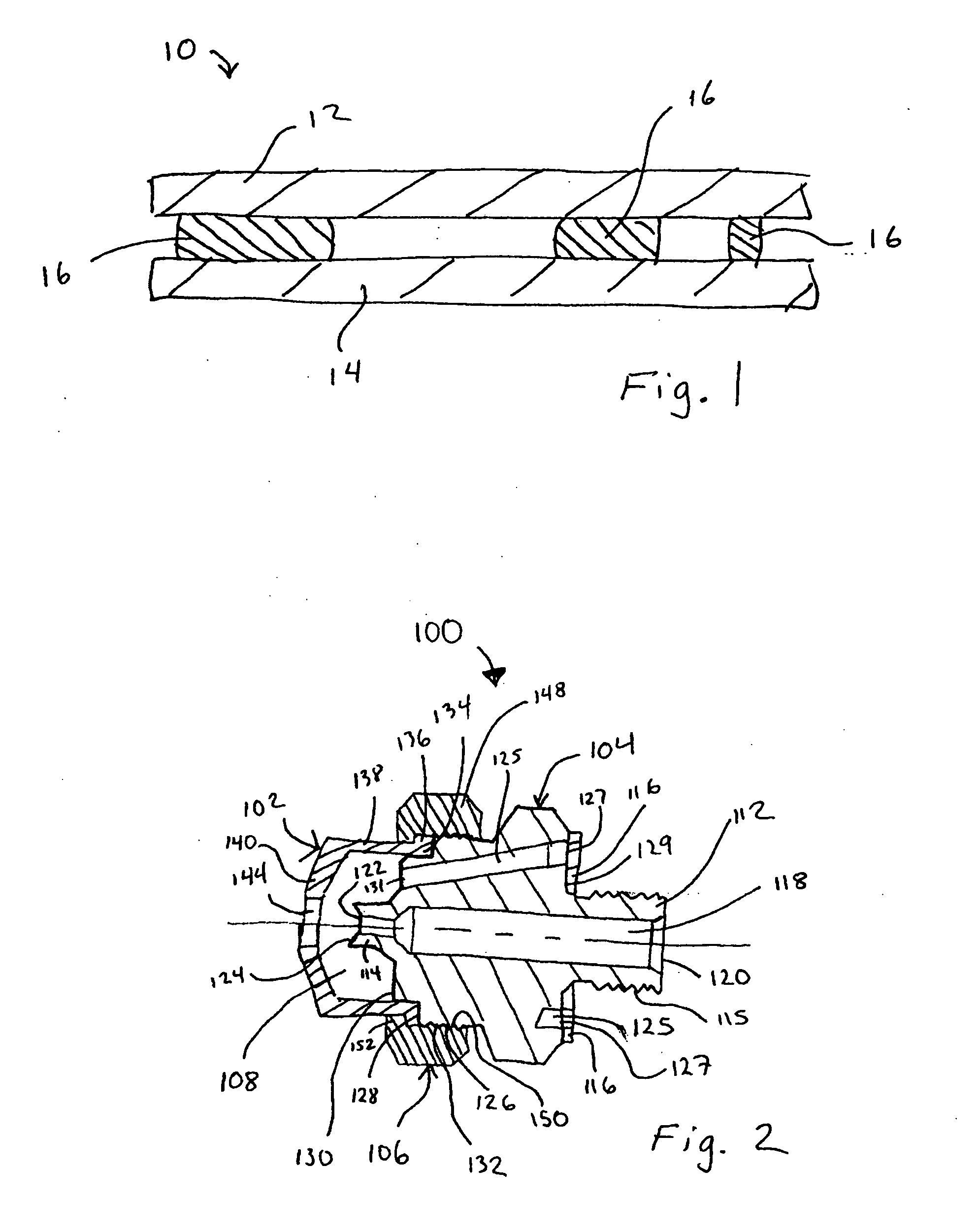

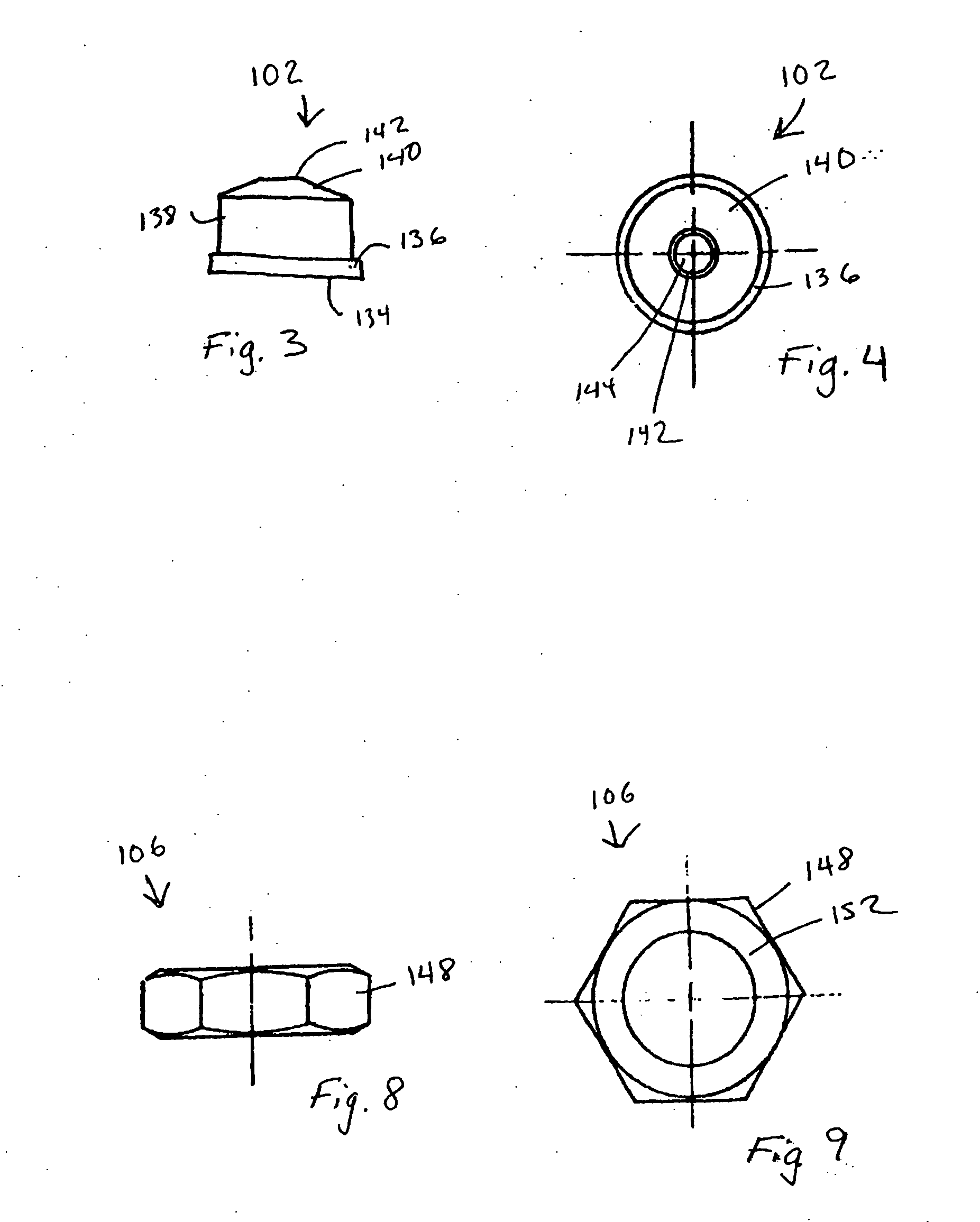

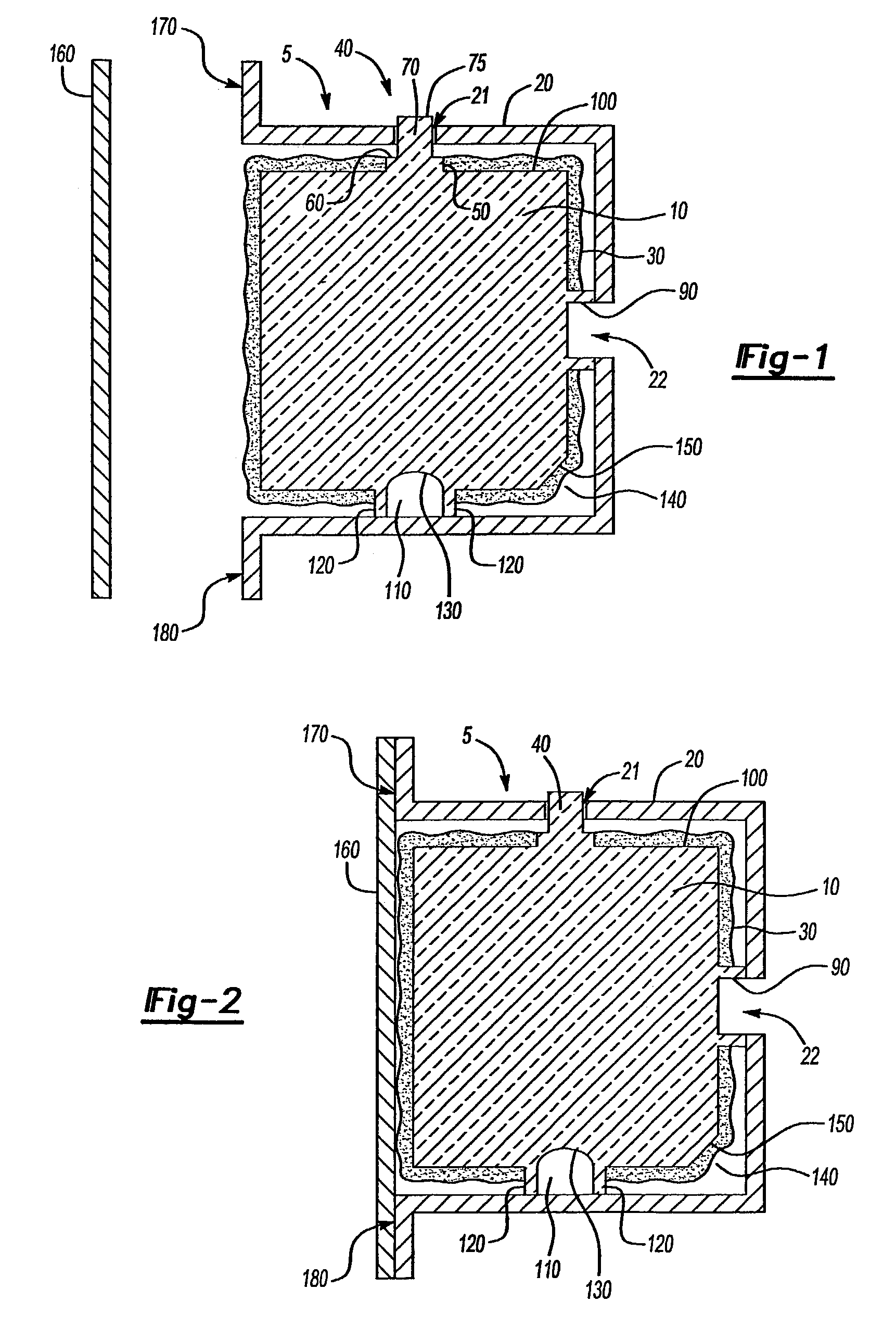

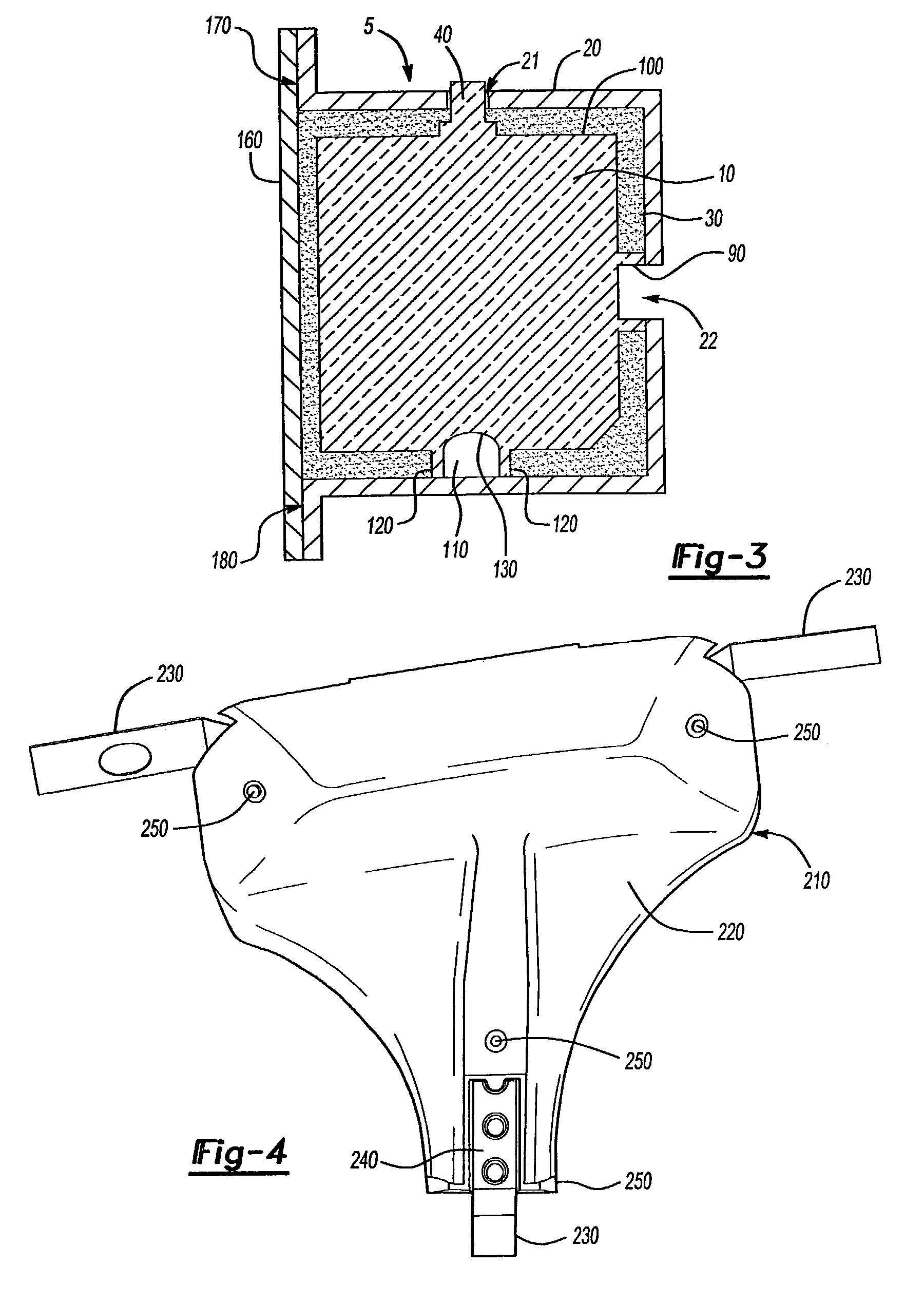

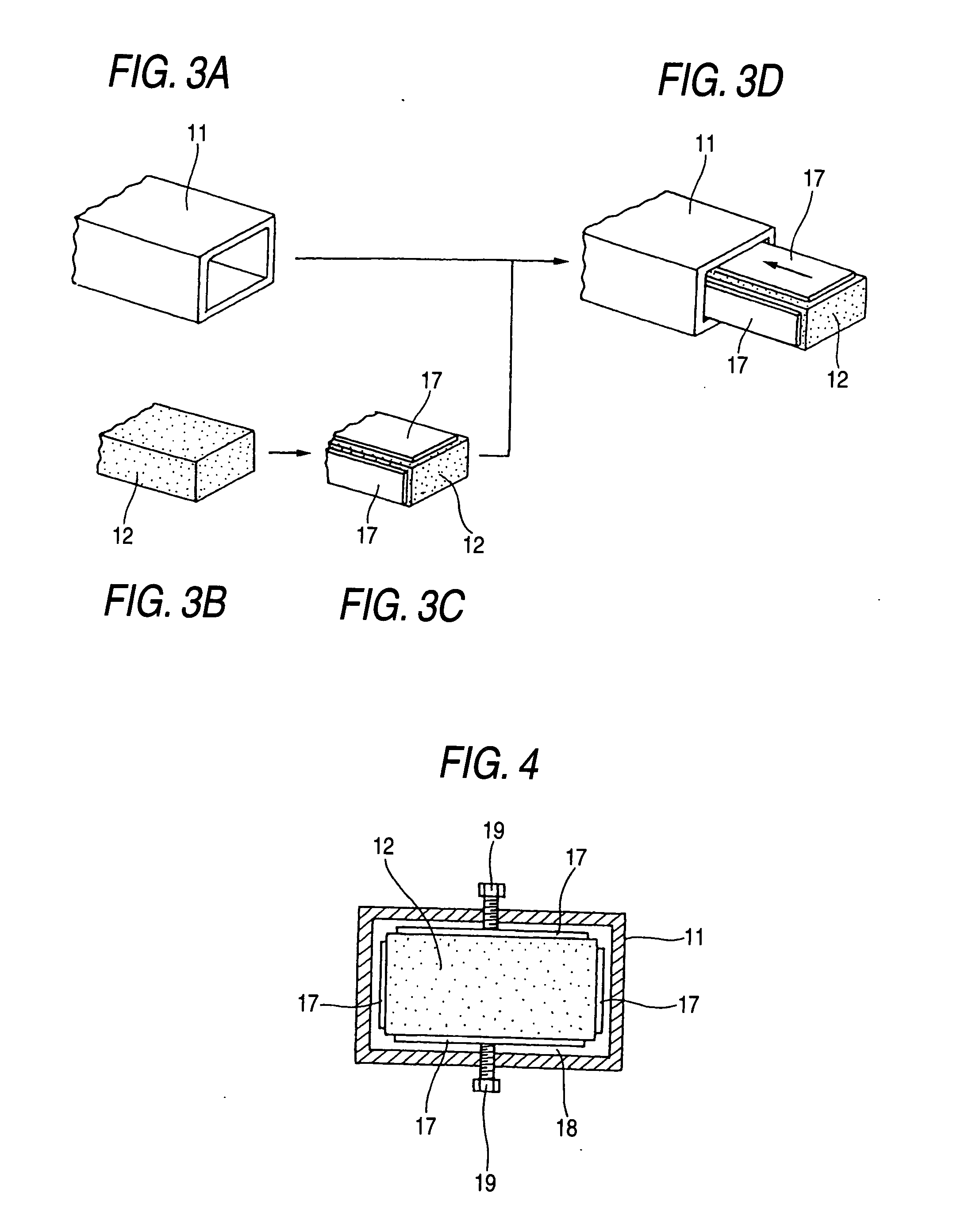

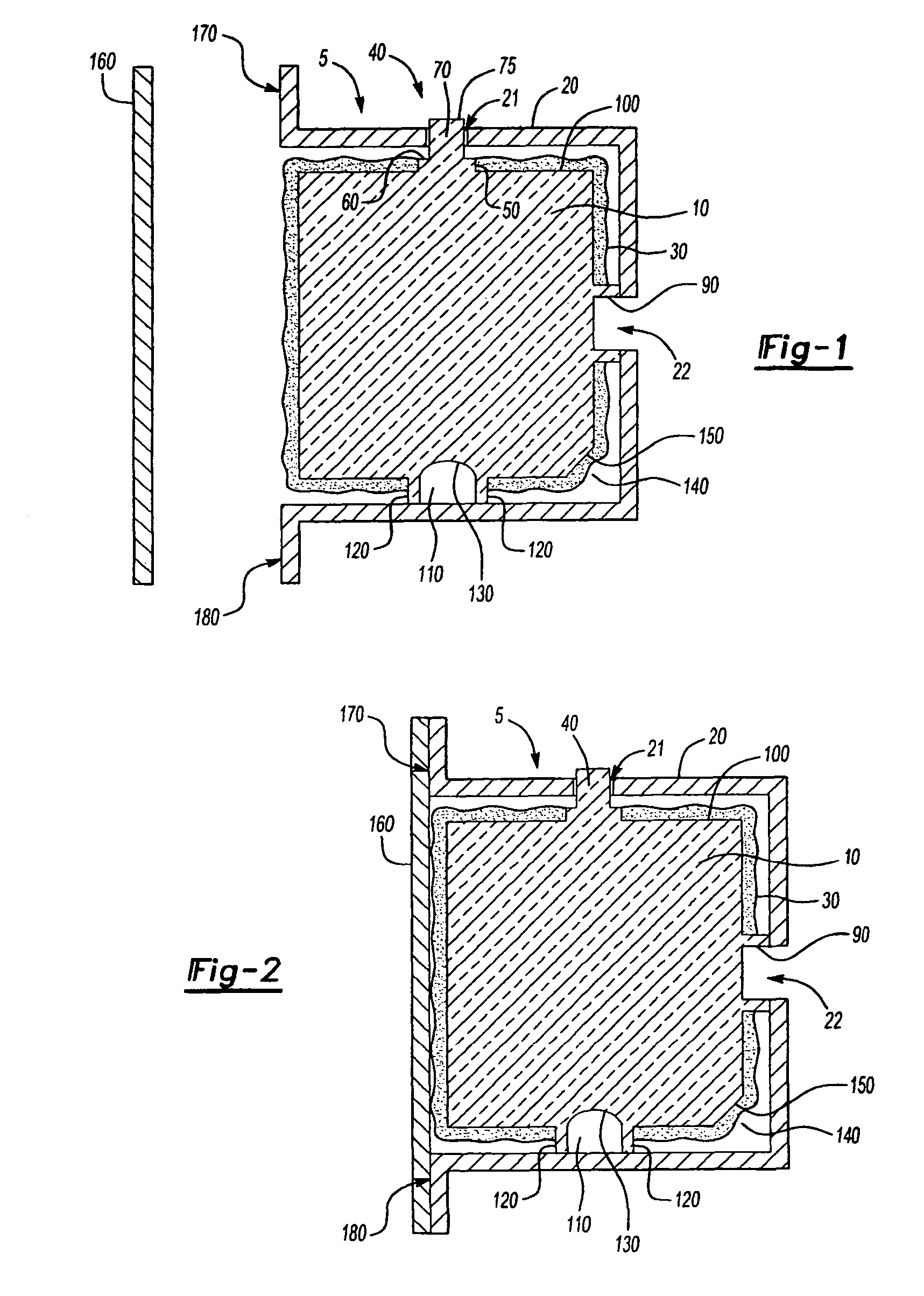

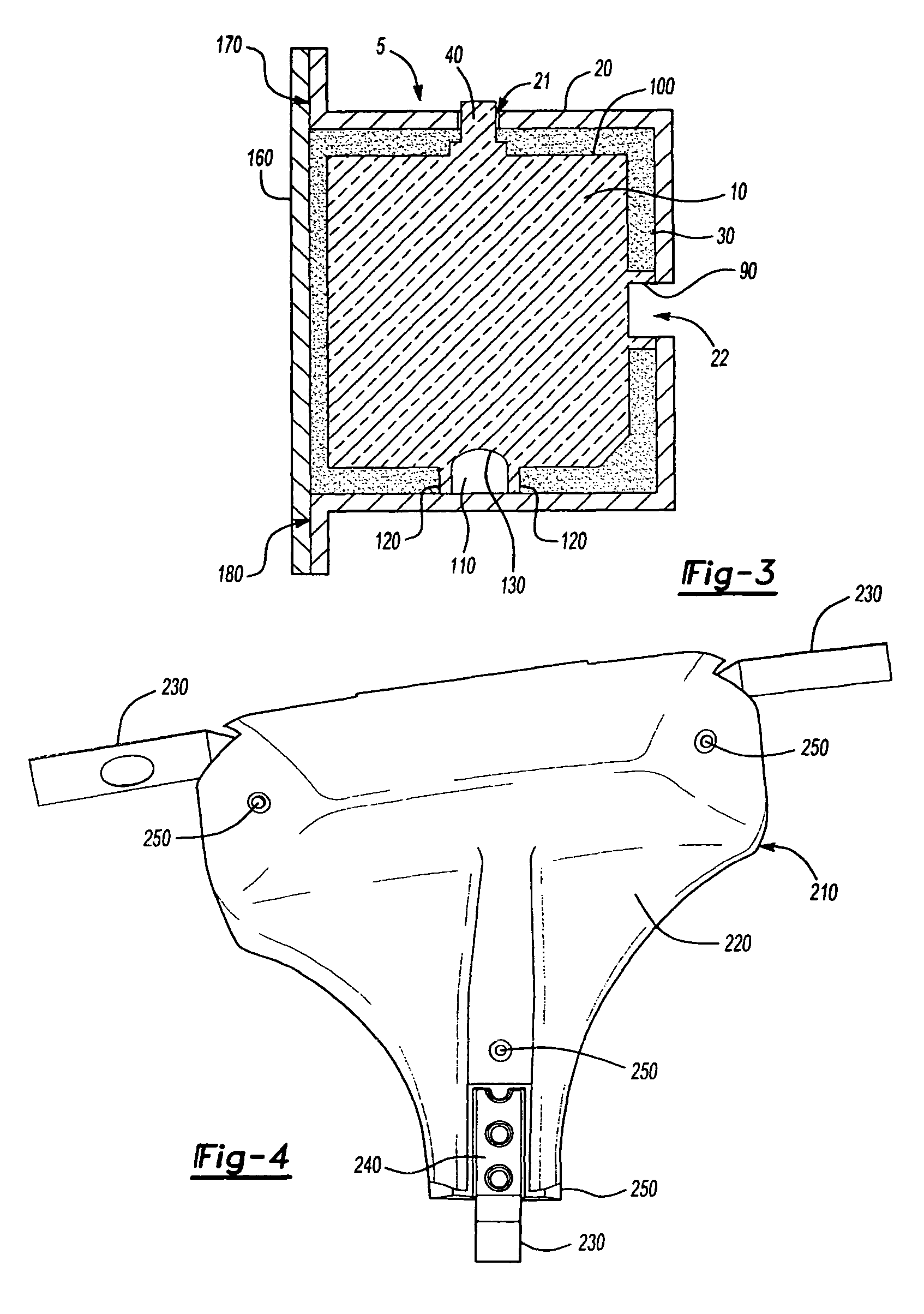

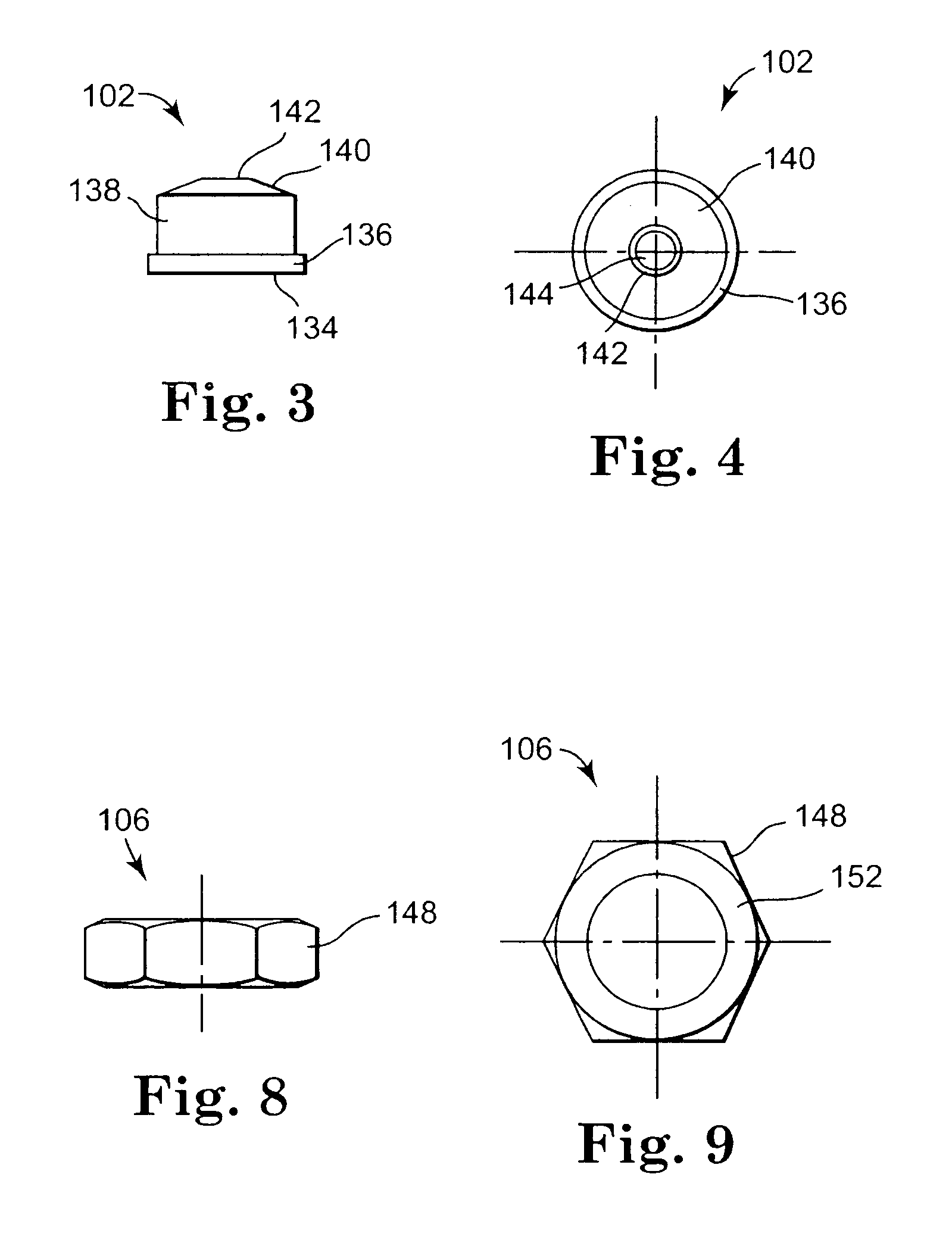

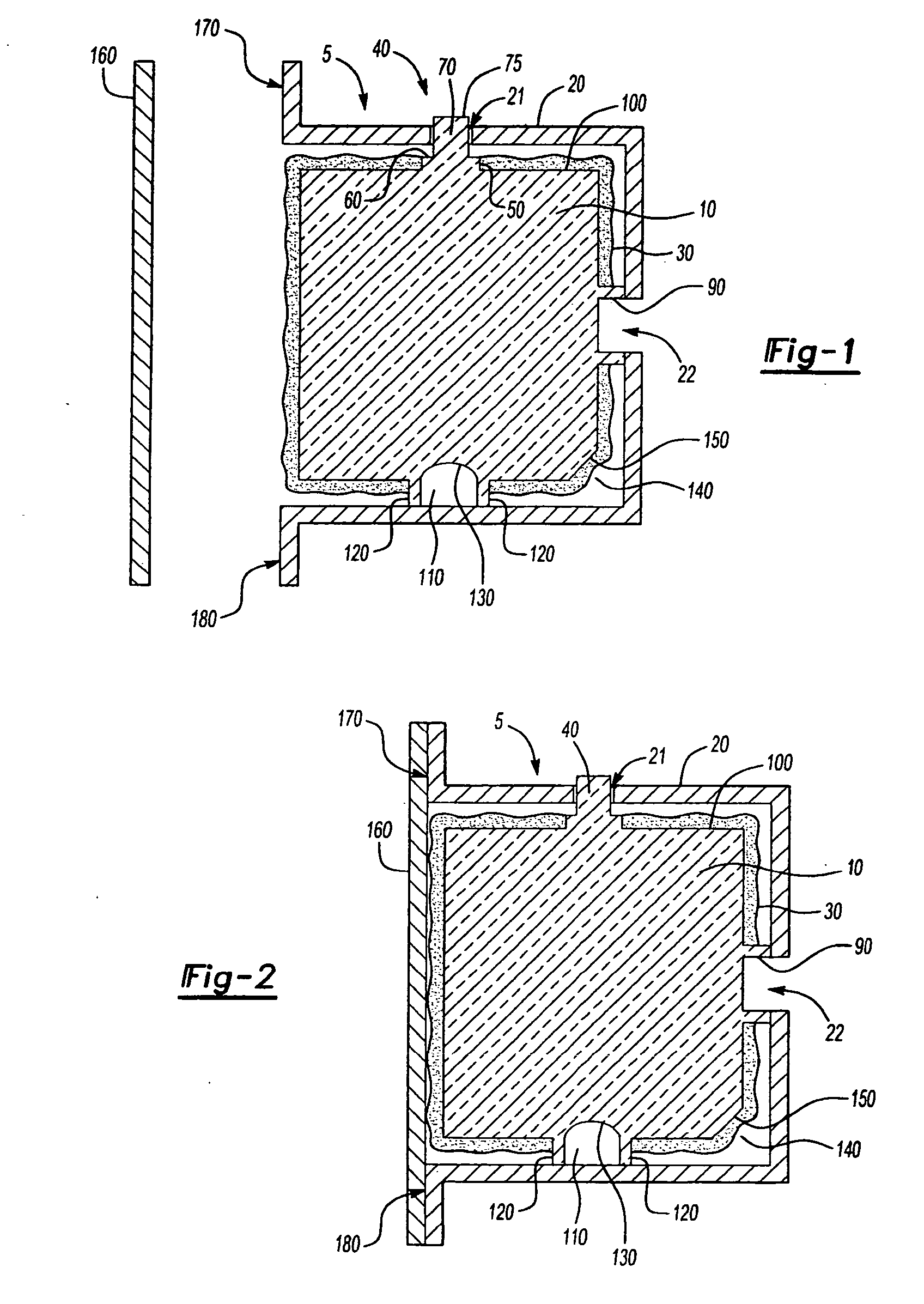

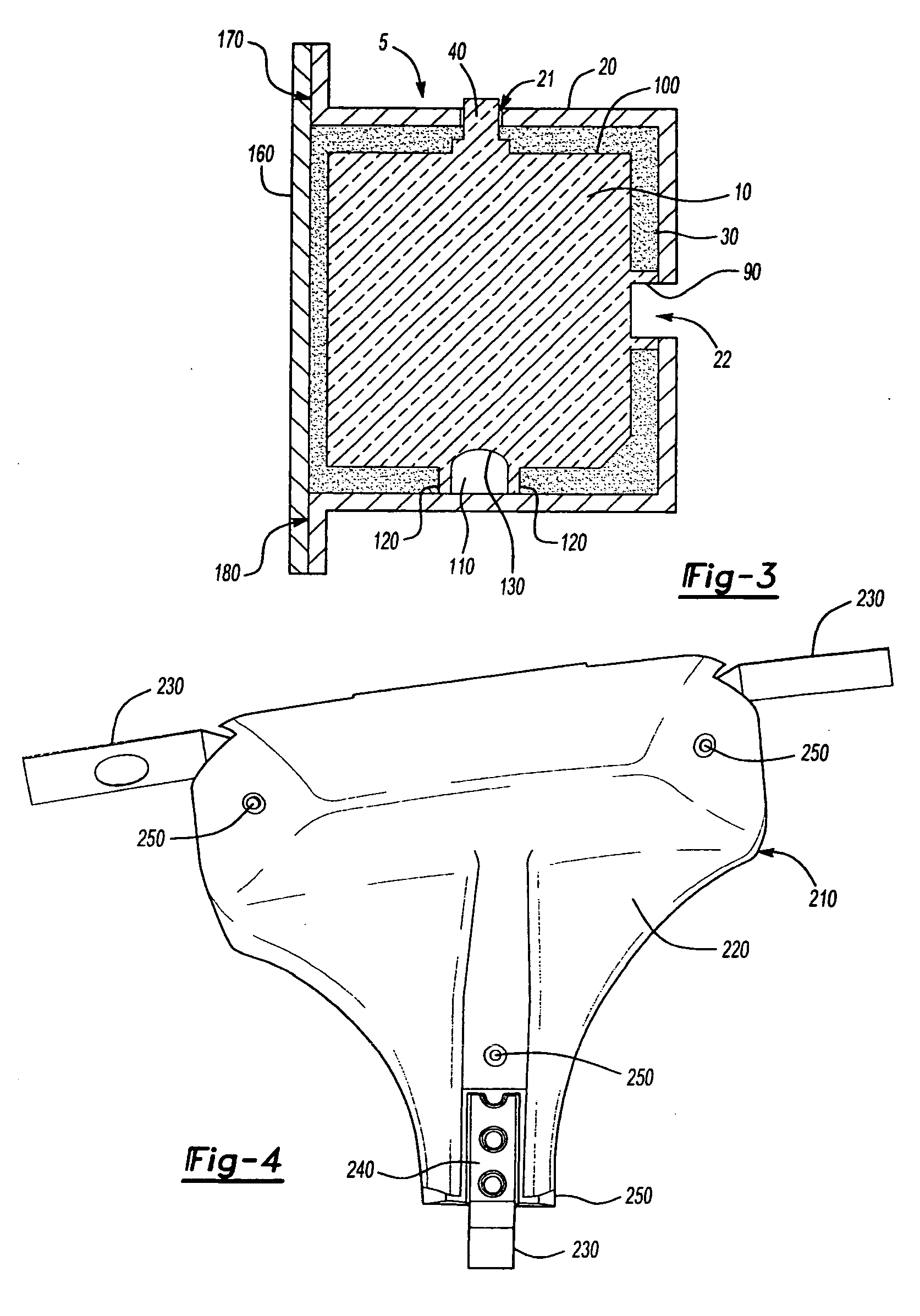

Vehicular structural members and method of making the members

The present invention is an article comprising a shaped rigid foam part; a heat activated foamable adhesive applied directly to at least a portion of the outer surface of the shaped foam part and an integral locating means. A second aspect of the invention is a method of forming a foam filled vehicle hollow member comprising, (a) inserting into a vehicular hollow member a rigid foam part comprised of a rigid foam having a heat activated foamable adhesive on at least a portion of the rigid foam insert and at least one integral locating means extending from a surface of the rigid foam, (b) engaging the locating means with the hollow member to locate the rigid foam part within the hollow member, and (c) heating the hollow member having the rigid foam part therein to a temperature and for a time sufficient to activate the heat activated expandable adhesive to form the foam filled vehicle hollow member.

Owner:DOW GLOBAL TECH LLC

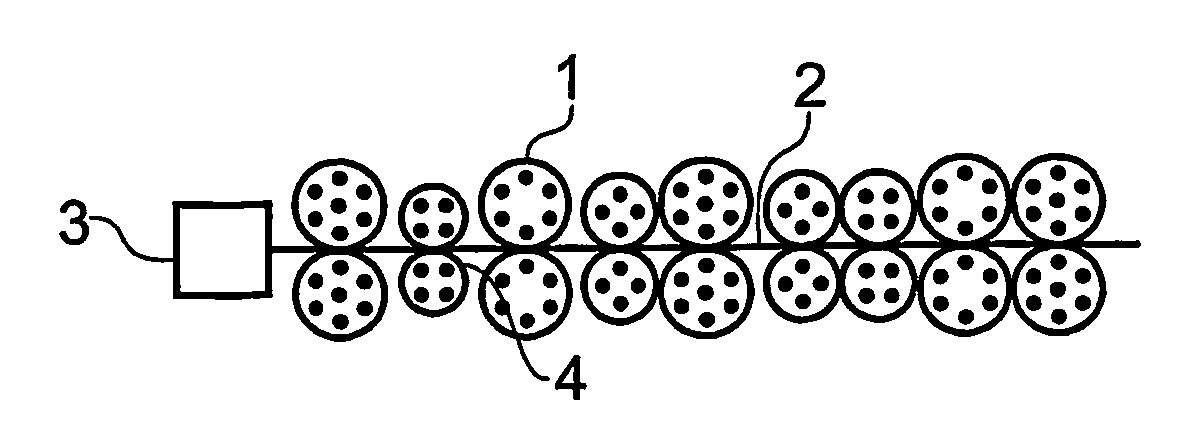

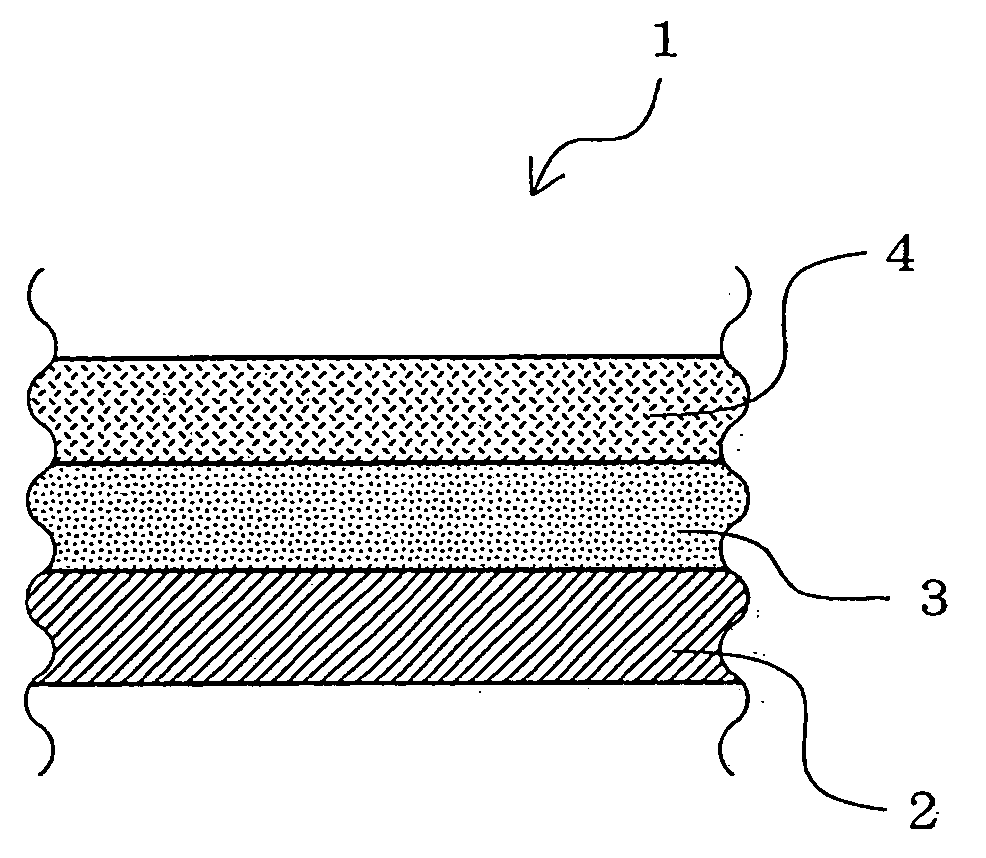

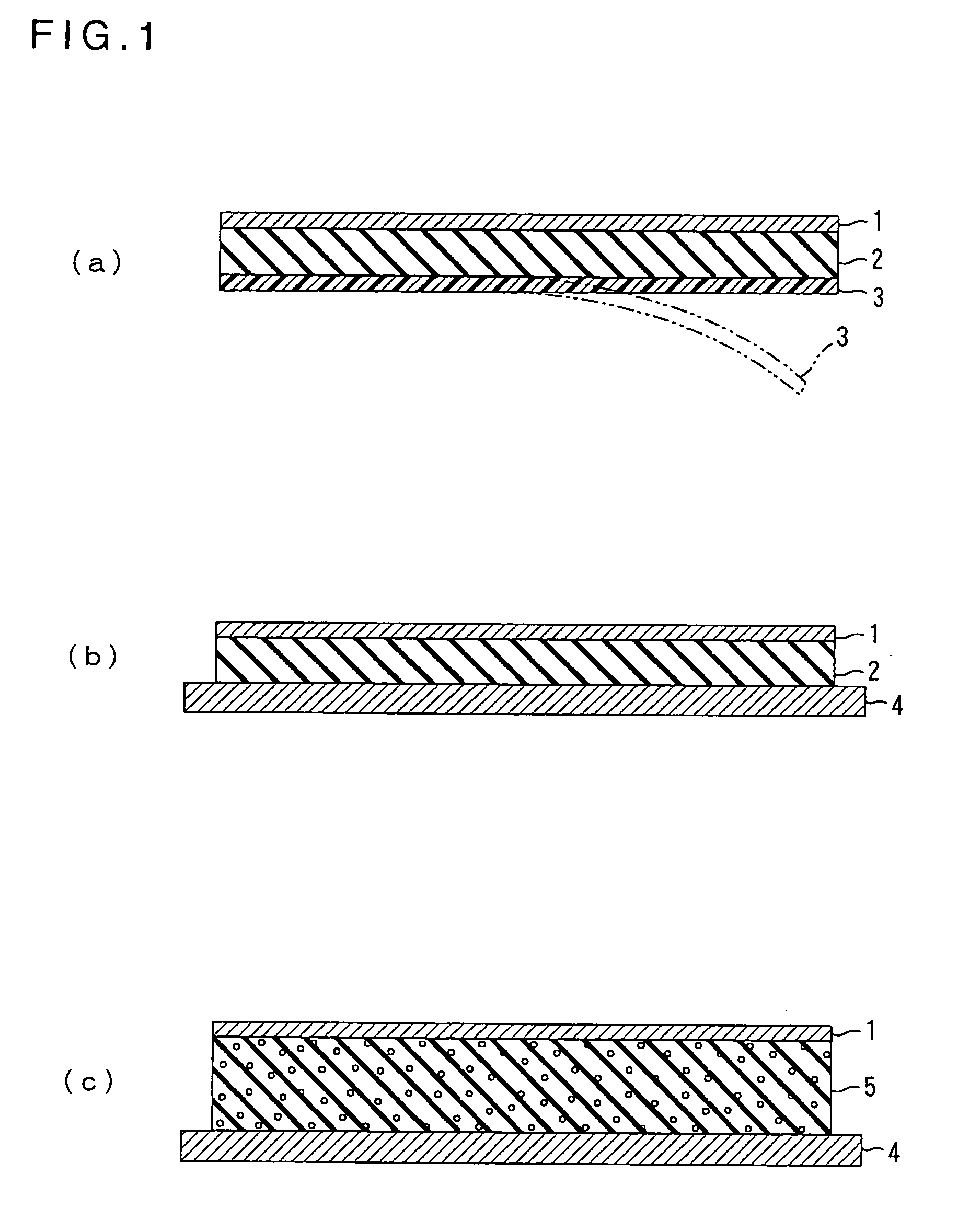

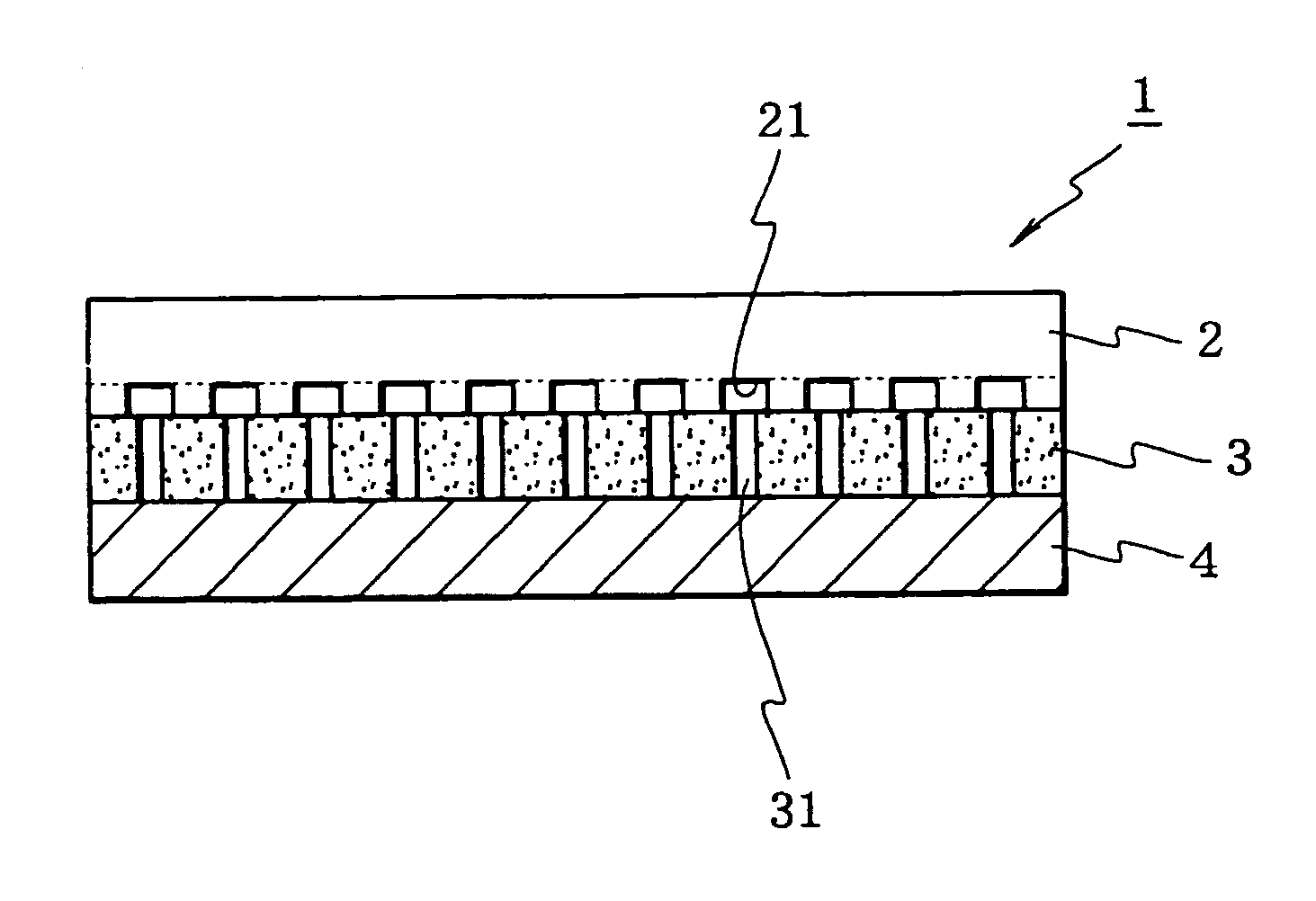

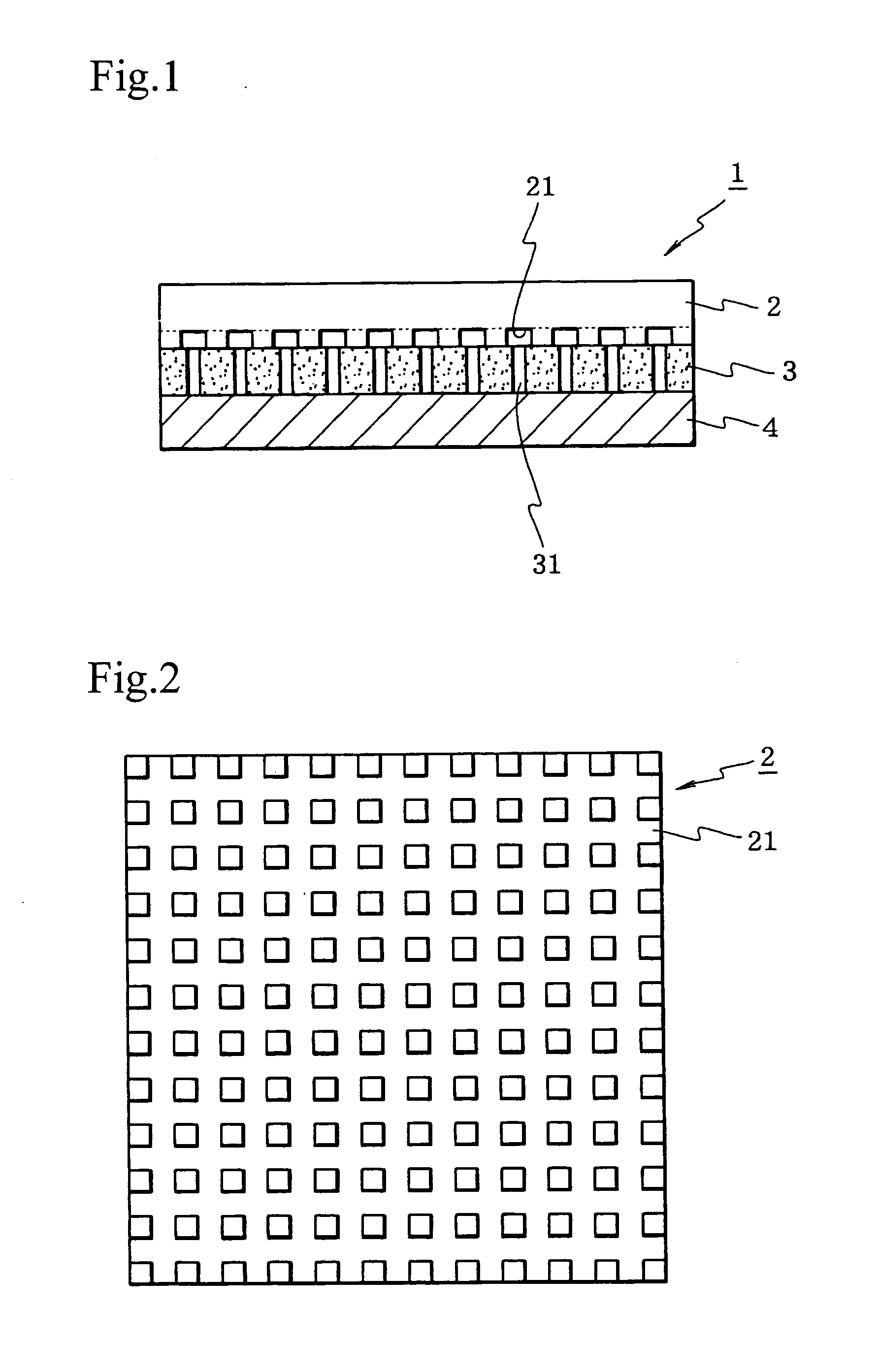

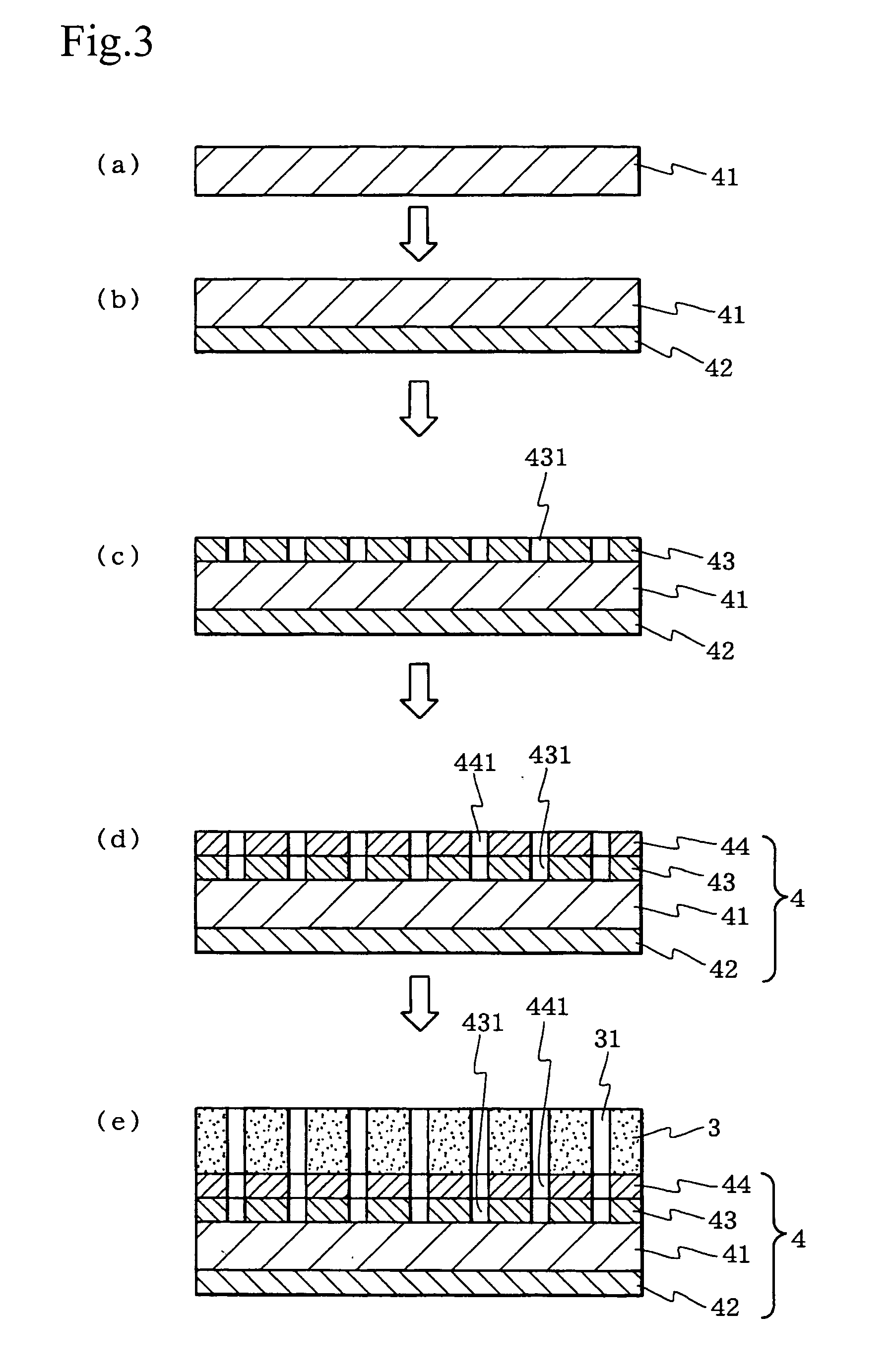

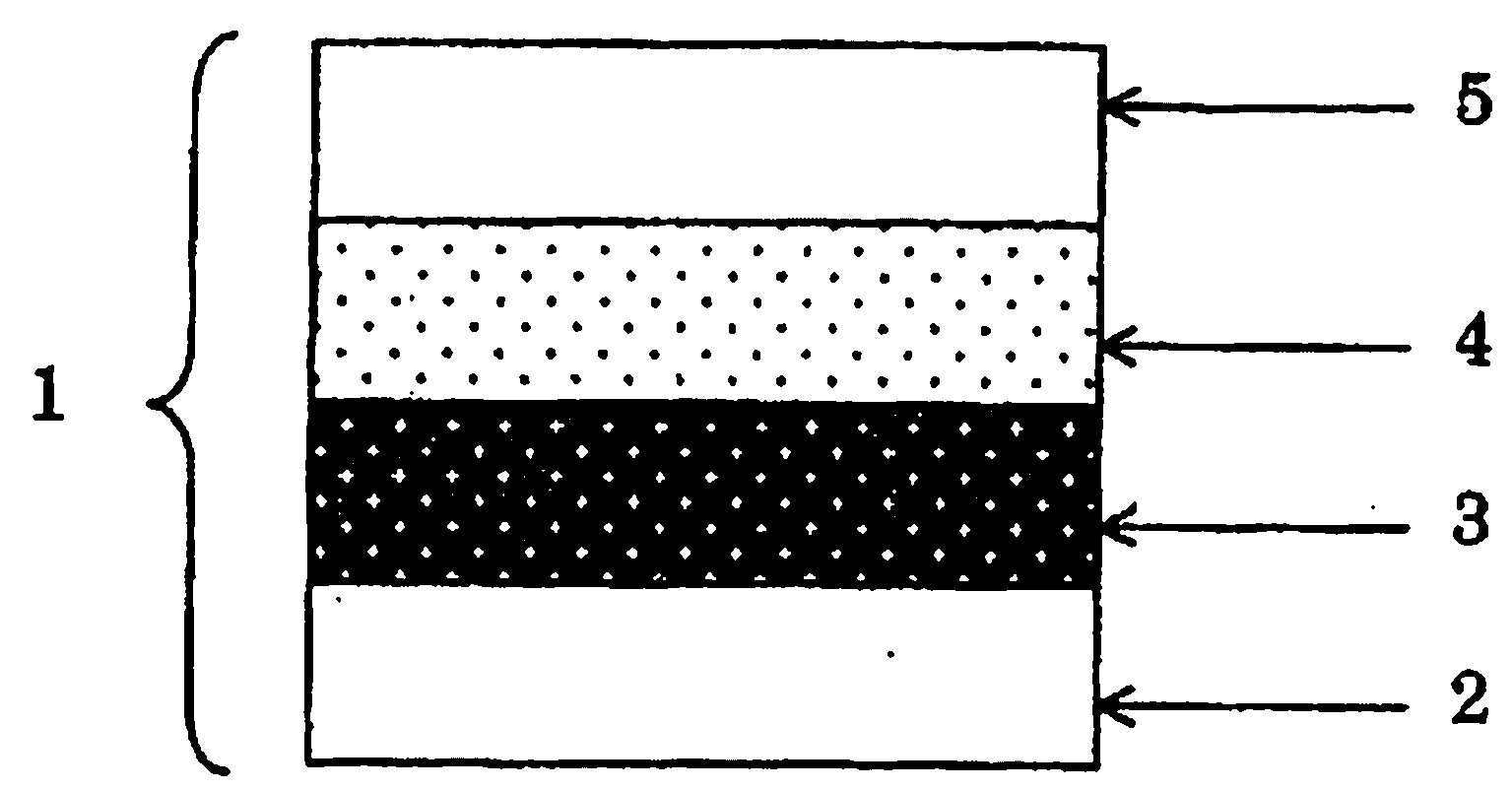

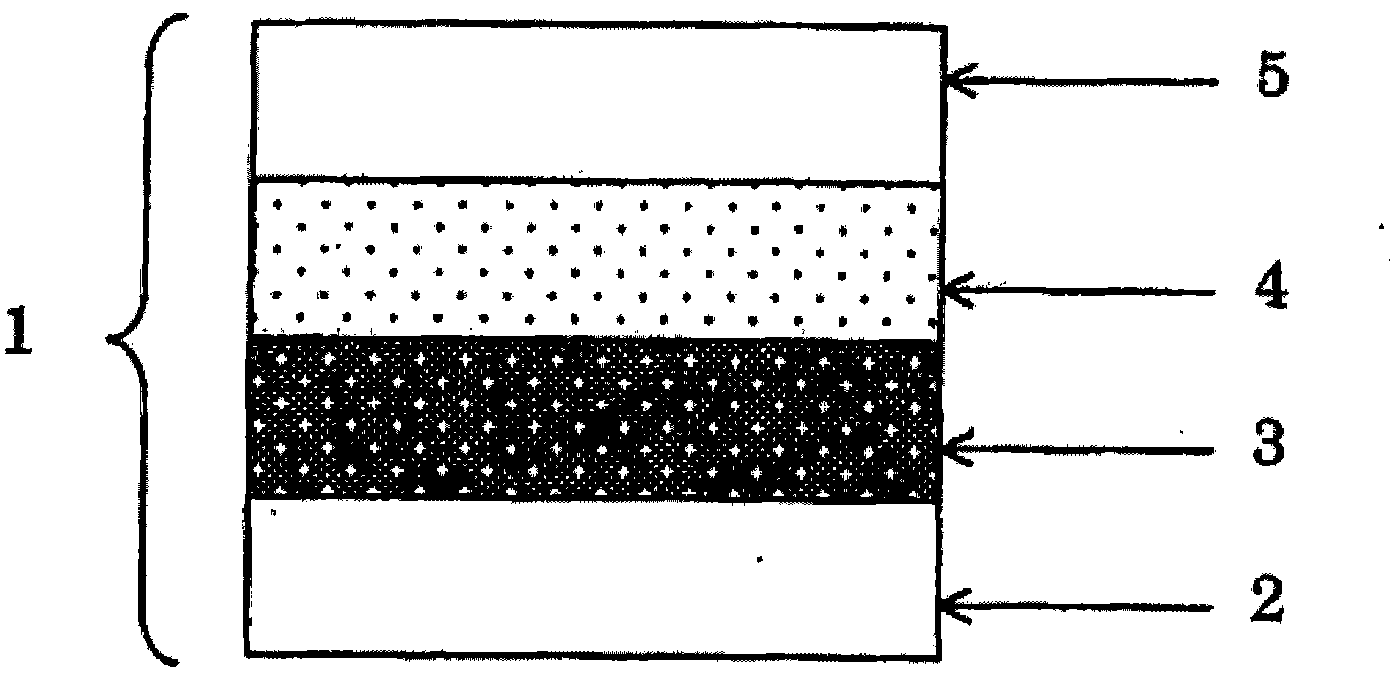

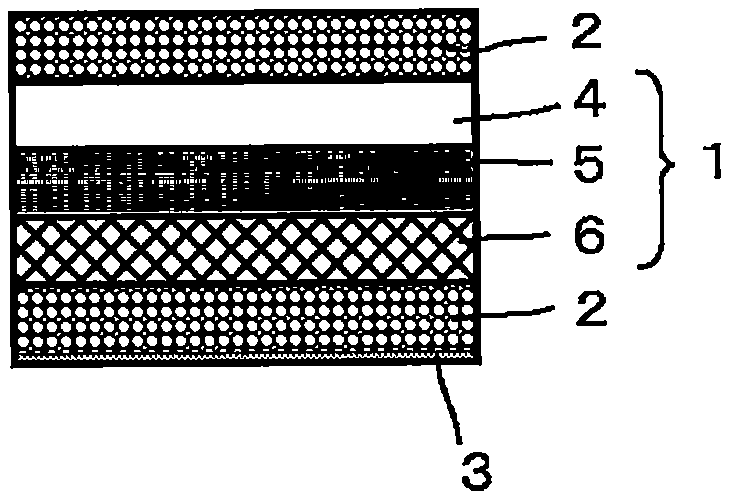

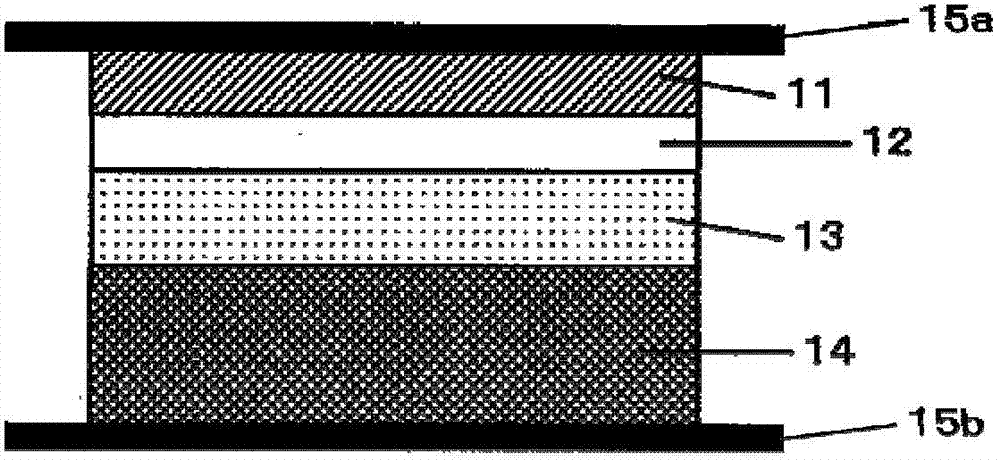

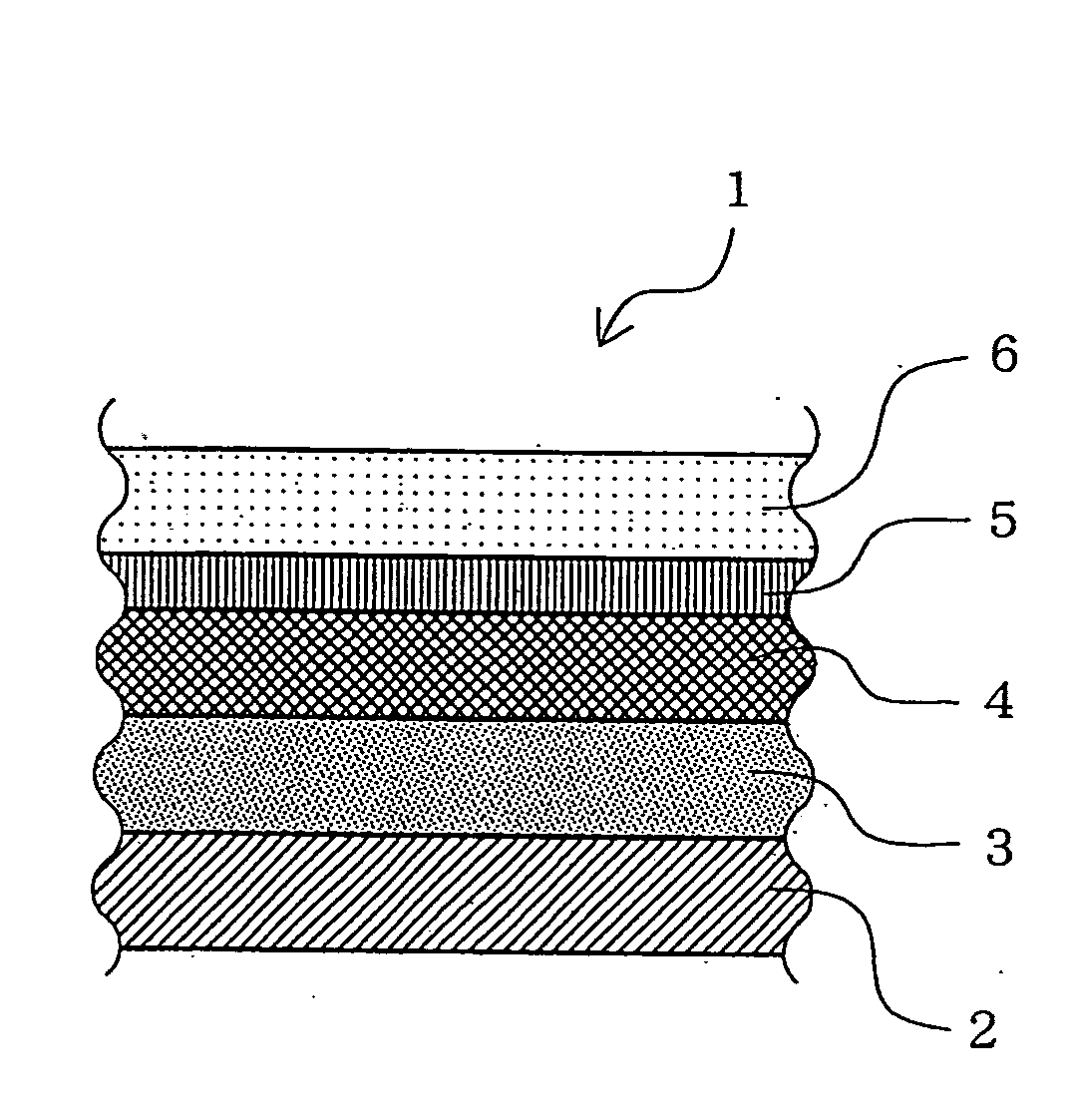

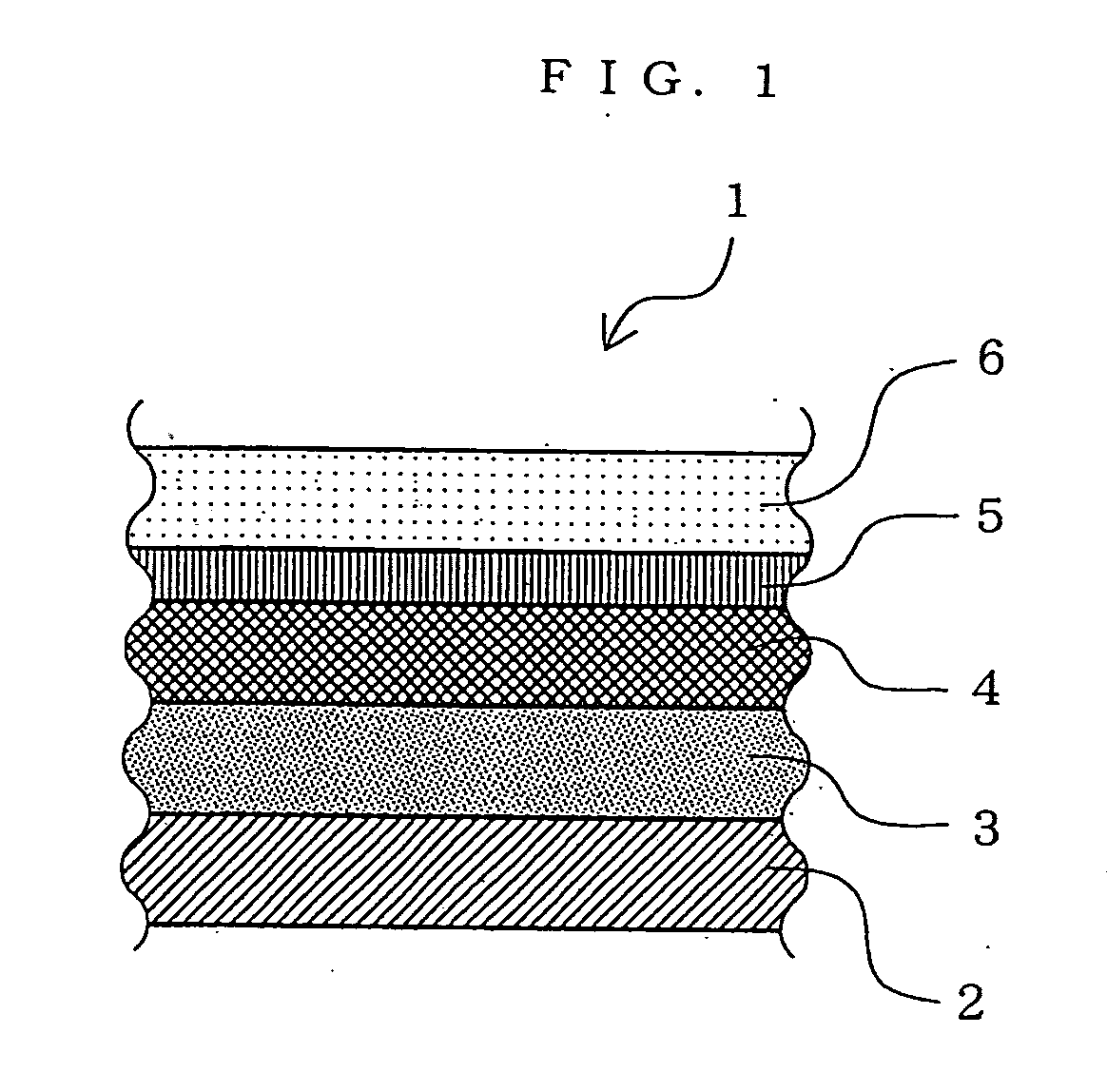

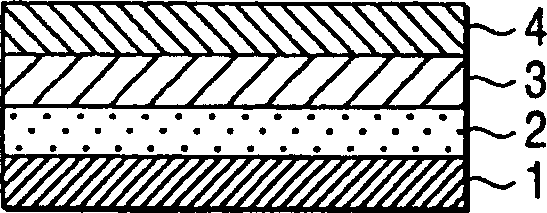

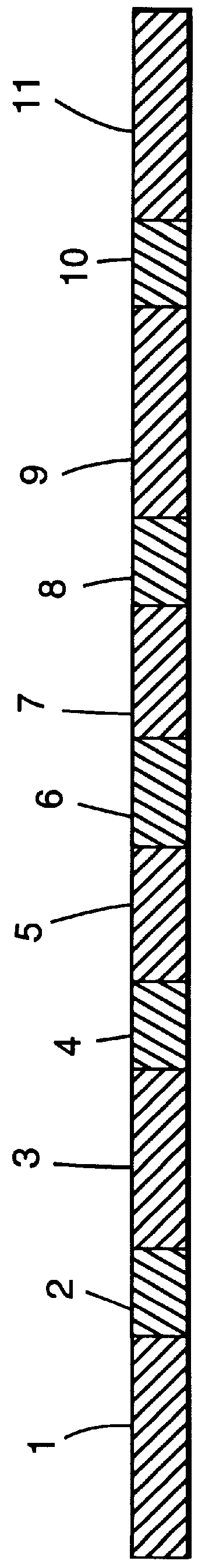

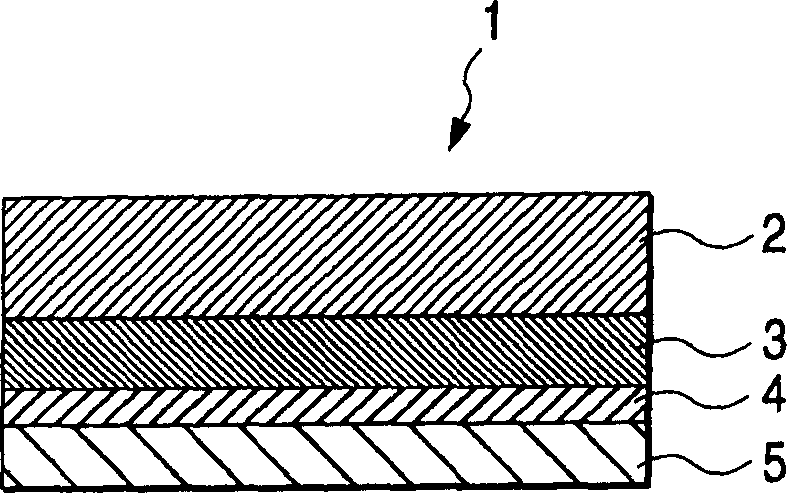

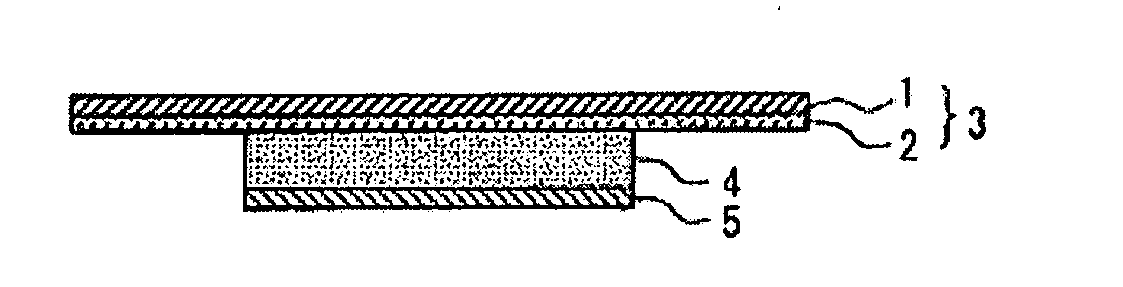

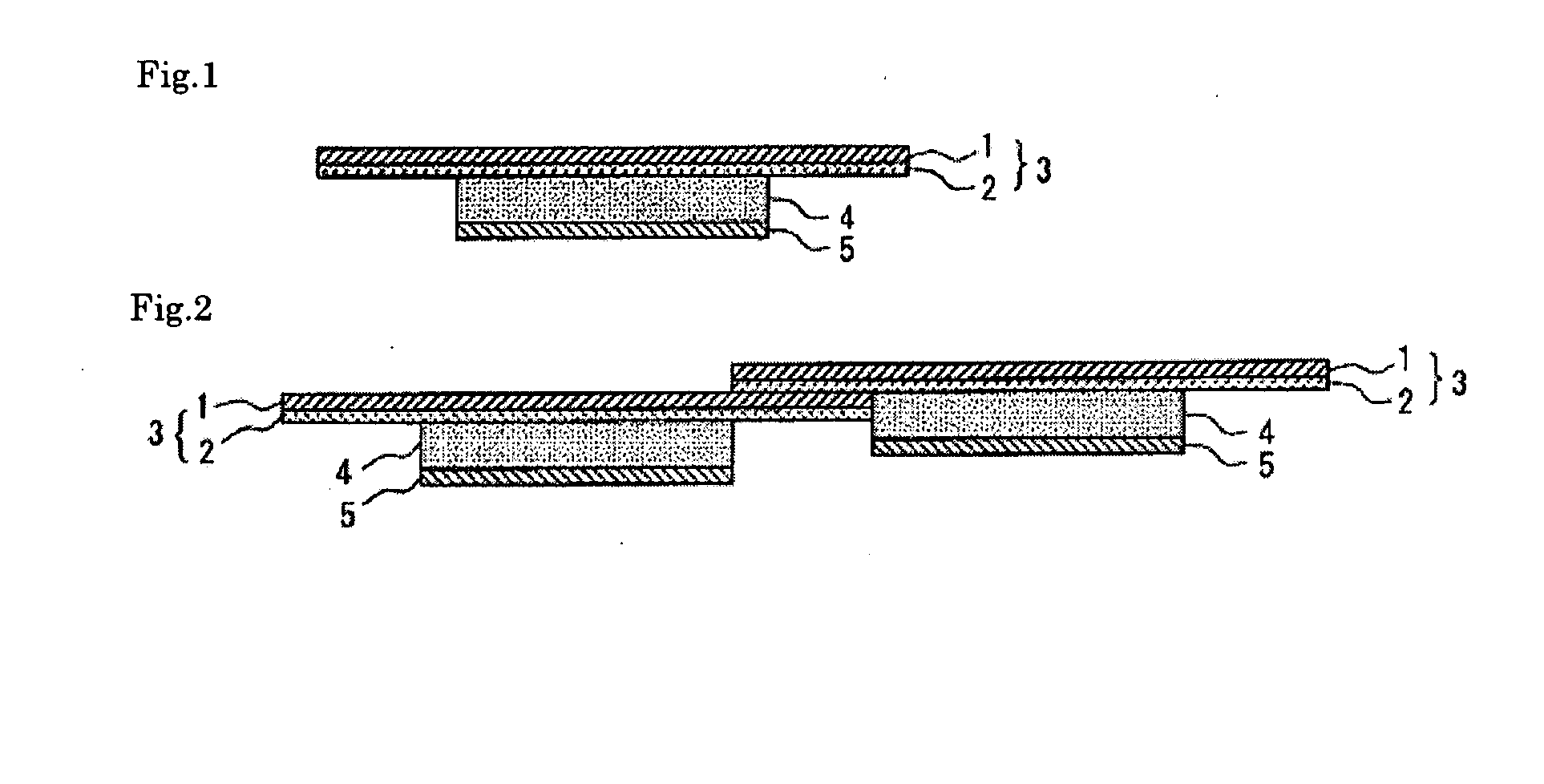

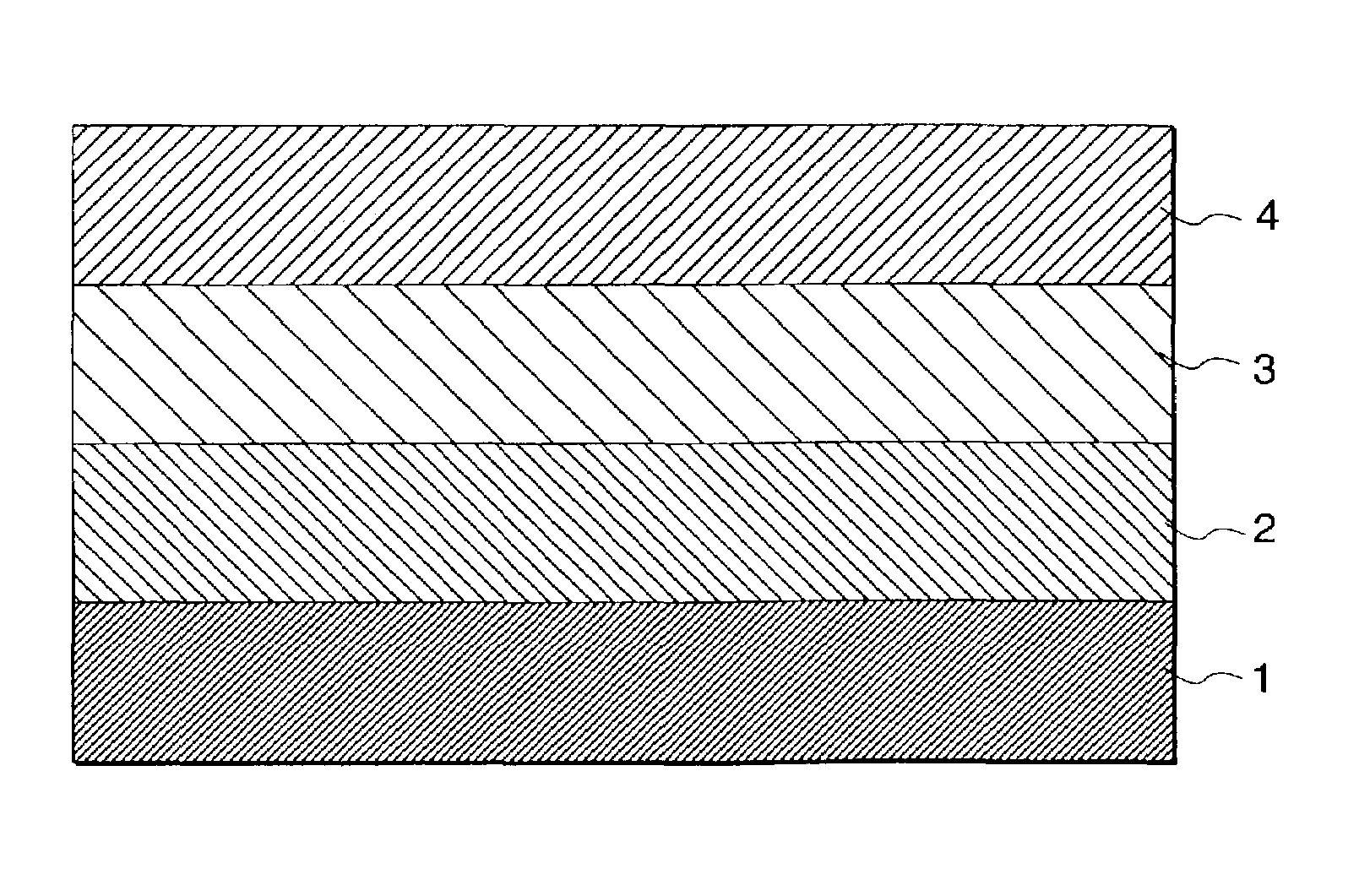

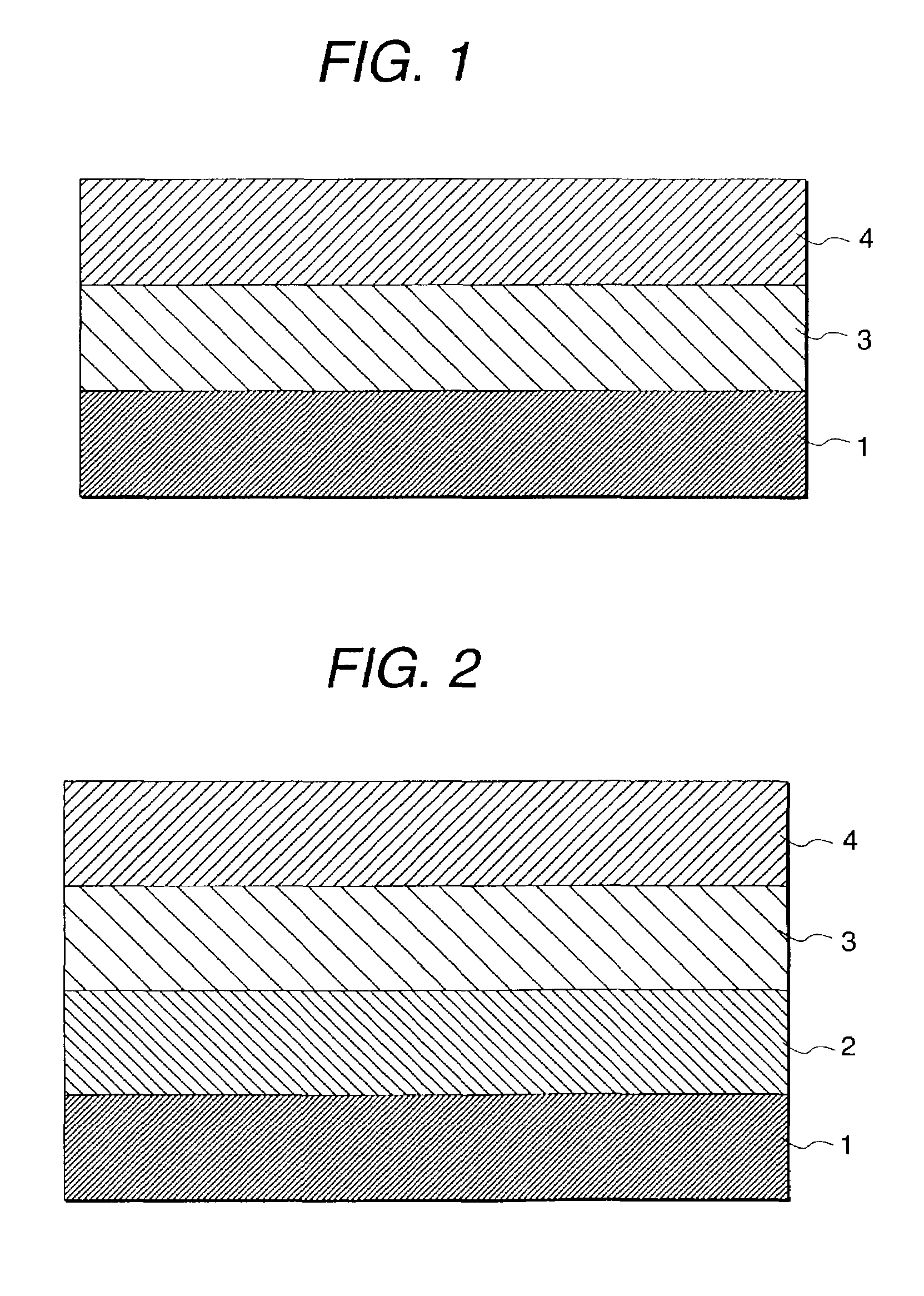

Pressure-Sensitive Adhesive Sheet And Method Of Manufacturing The Same

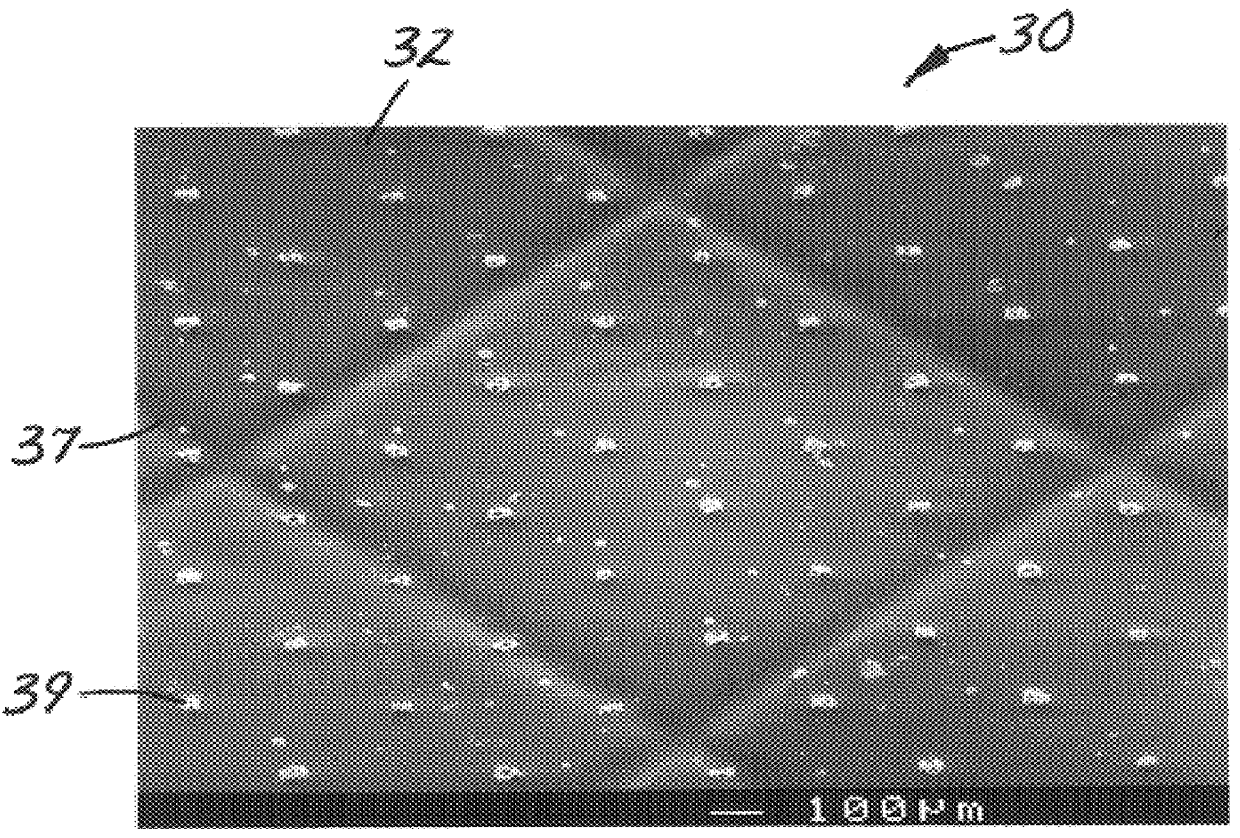

InactiveUS20070218269A1No loss of appearanceLayered productsAdhesive processes using foamed adhesivesEngineeringUltimate tensile strength

A substrate 2 having provided in a pressure-sensitive adhesive layer 3 side thereof recesses 21 that continue as far as side edges of the substrate 2, and a pressure-sensitive adhesive layer 3 in which are formed a plurality of penetrating passages 31 that penetrate through the pressure-sensitive adhesive layer 3 in a thickness direction are laminated together such that the recesses 21 in the substrate 2 and the penetrating passages 31 in the pressure-sensitive adhesive layer 3 communicate with one another, thus obtaining a pressure-sensitive adhesive sheet 1. According to this pressure-sensitive adhesive sheet 1, air entrapment and blistering can be prevented or eliminated while securing adequate adhesive strength and with no marring of the appearance of the pressure-sensitive adhesive sheet.

Owner:LINTEC CORP

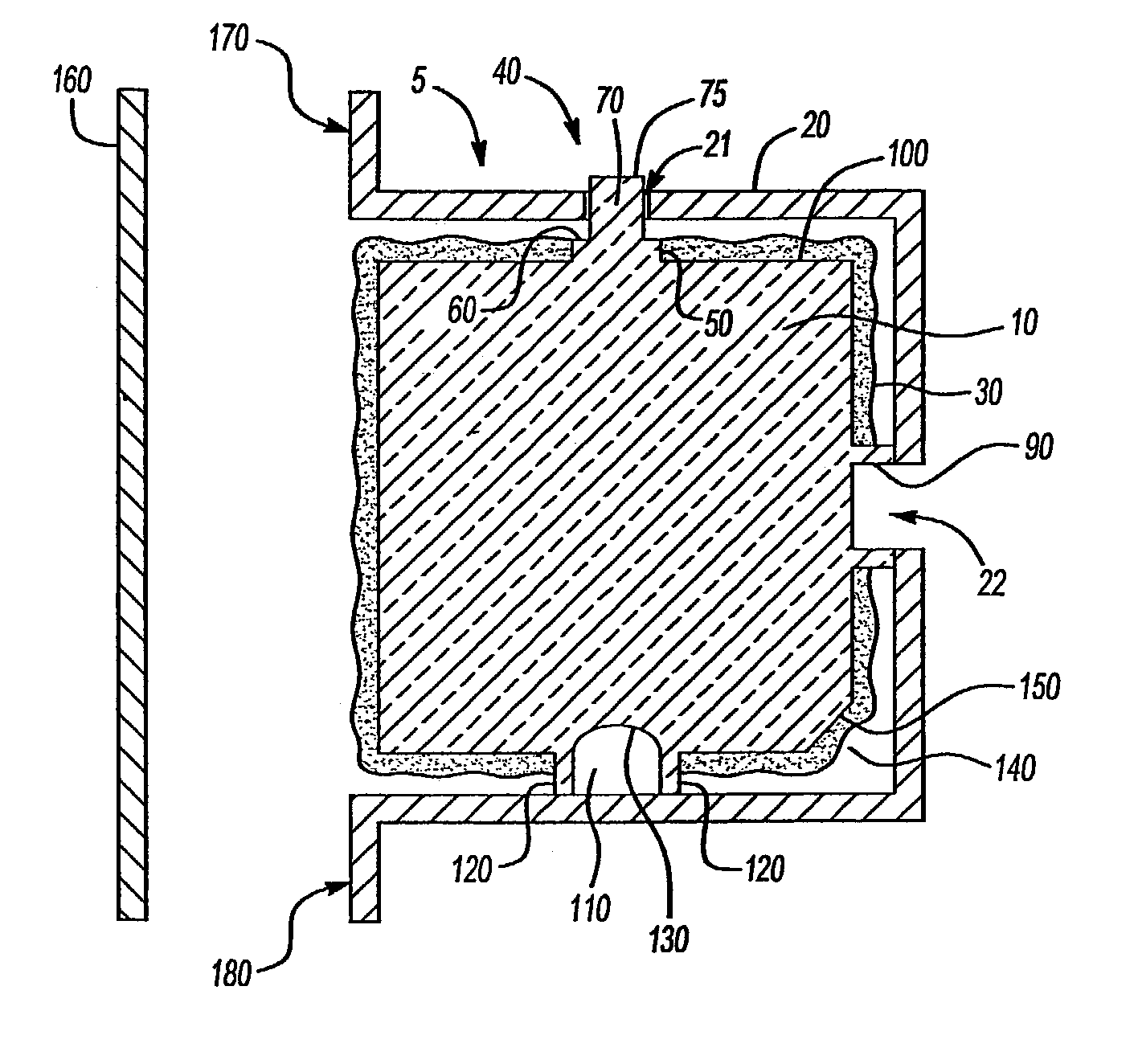

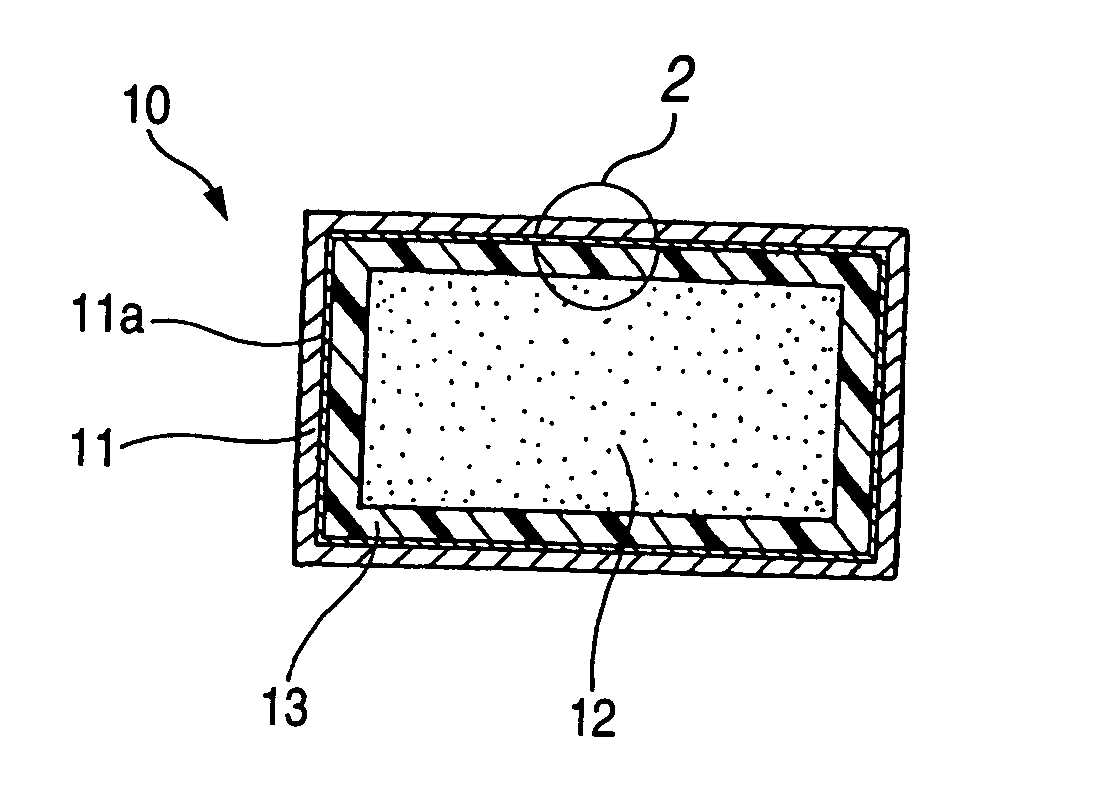

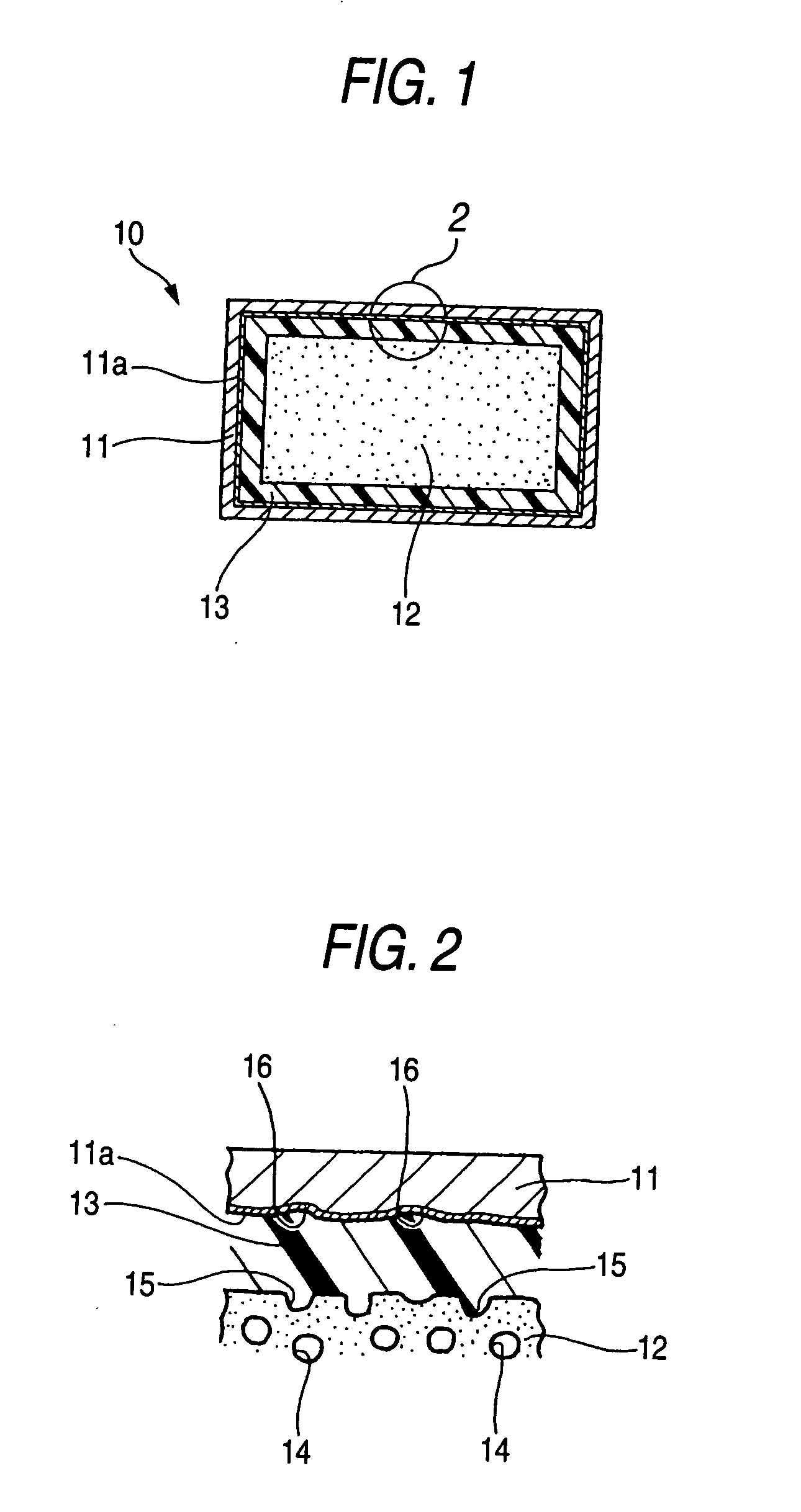

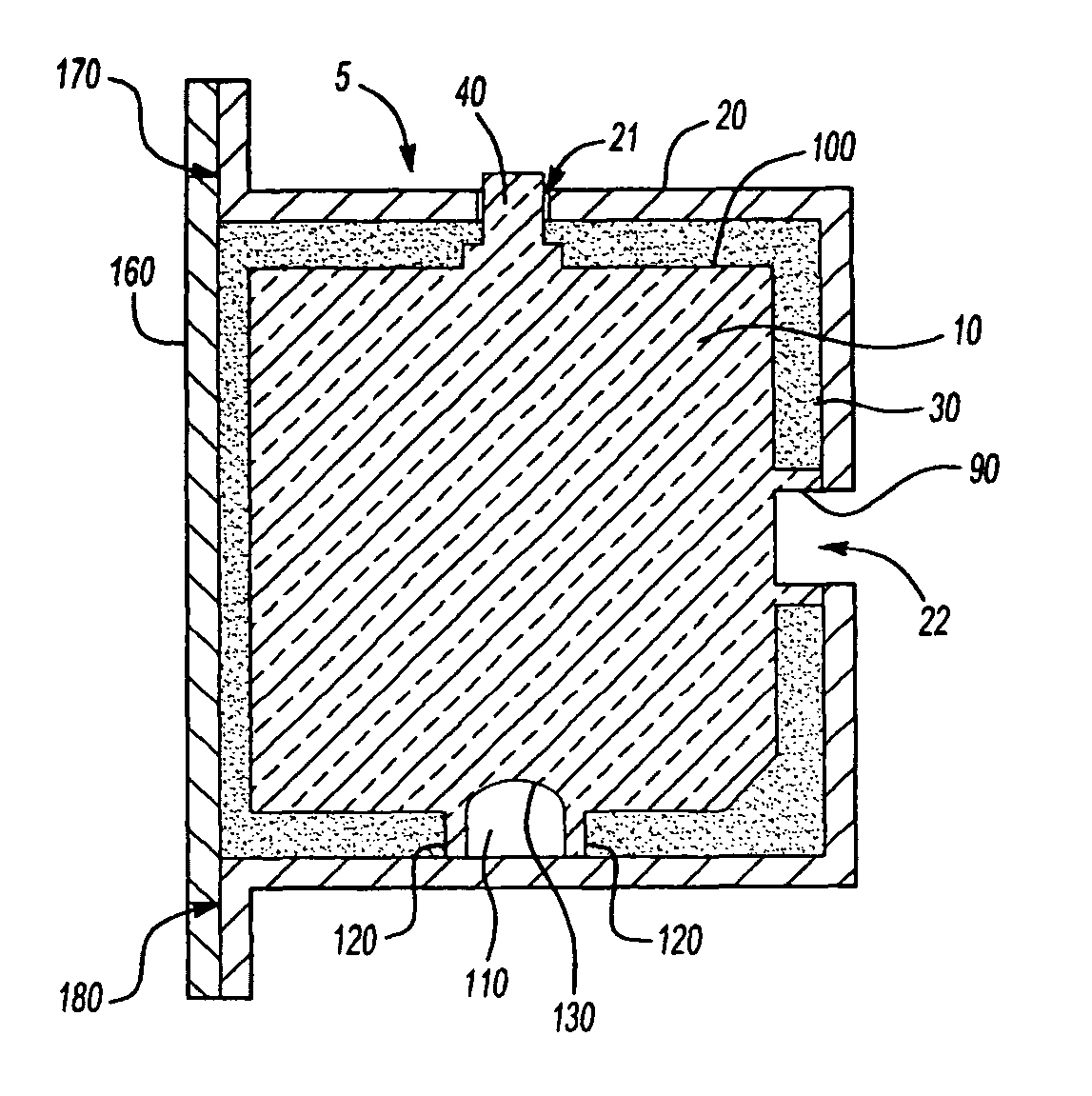

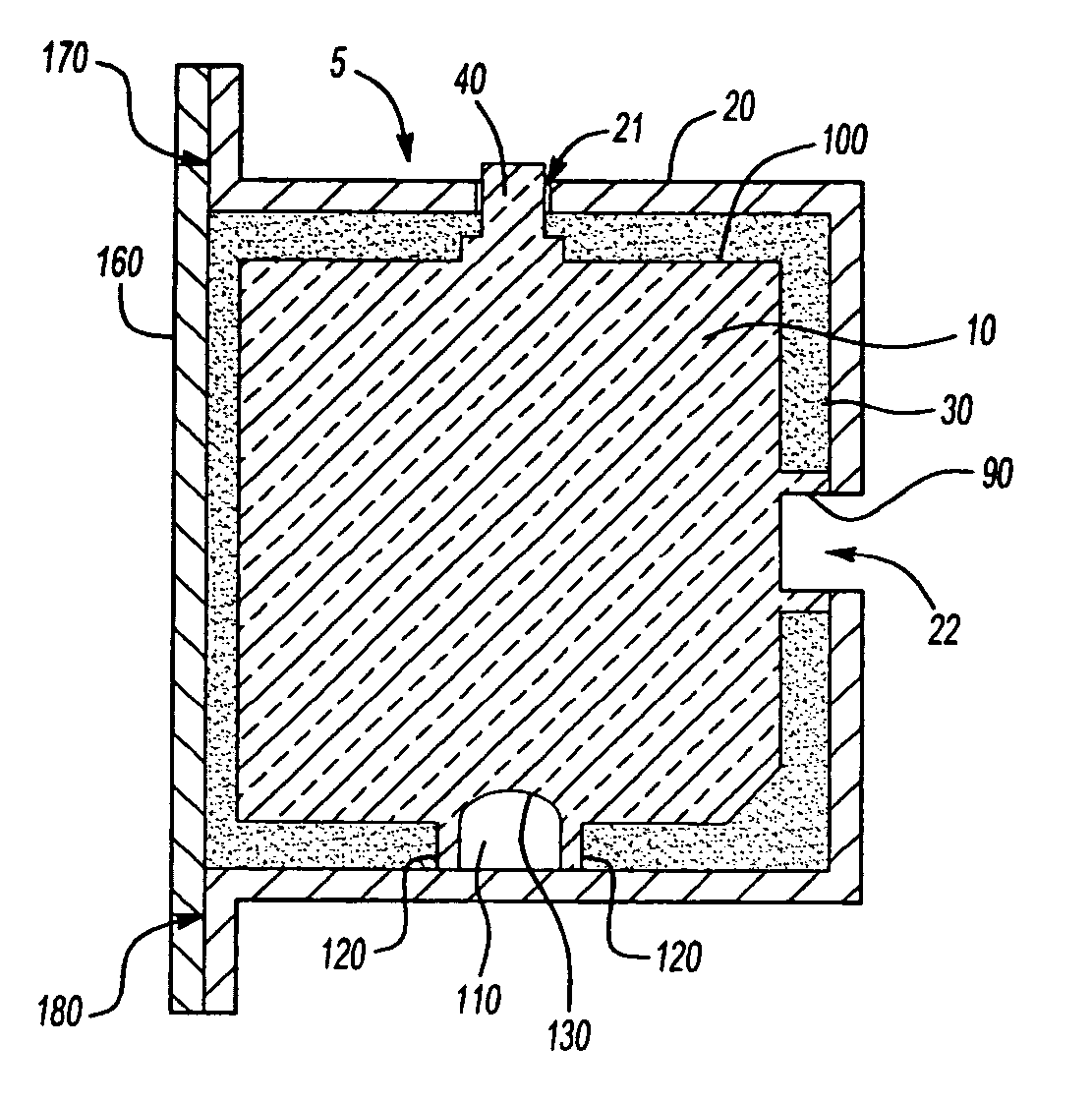

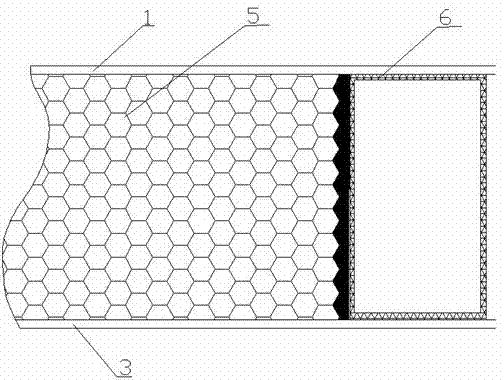

Filling structure

InactiveUS20050058787A1Speed up the flowIncrease volumeEnvelopes/bags making machineryLayered productsFilling materialsEngineering

A filling structure 10 is a structure in which a filling material 12 having a higher impact energy absorbing performance is inserted into the inner part of a hollow member 11, and the filling material 12 so inserted is fixed to the hollow member 11 with an adhesive layer 13 resulting when the filling material 12 is heated to expand and is cooled to set thereafter.

Owner:HONDA MOTOR CO LTD

Method and apparatus for bonding and debonding adhesive interface surfaces

InactiveUS7901532B2Strong and rapid powerEngine sealsNanostructure manufactureThermal energyMicrosphere

Owner:BAIN PETER STEWART

Vehicular structural members and method of making the members

The present invention is an article comprising a shaped rigid foam part; a heat activated foamable adhesive applied directly to at least a portion of the outer surface of the shaped foam part and an integral locating means. A second aspect of the invention is a method of forming a foam filled vehicle hollow member comprising, (a) inserting into a vehicular hollow member a rigid foam part comprised of a rigid foam having a heat activated foamable adhesive on at least a portion of the rigid foam insert and at least one integral locating means extending from a surface of the rigid foam, (b) engaging the locating means with the hollow member to locate the rigid foam part within the hollow member, and (c) heating the hollow member having the rigid foam part therein to a temperature and for a time sufficient to activate the heat activated expandable adhesive to form the foam filled vehicle hollow member.

Owner:DOW GLOBAL TECH LLC

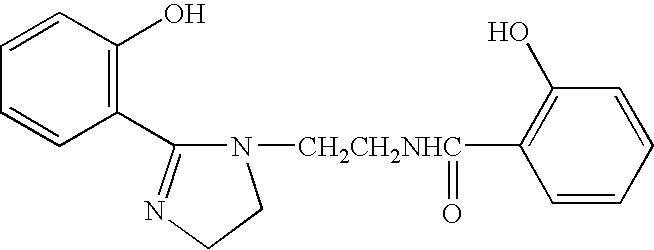

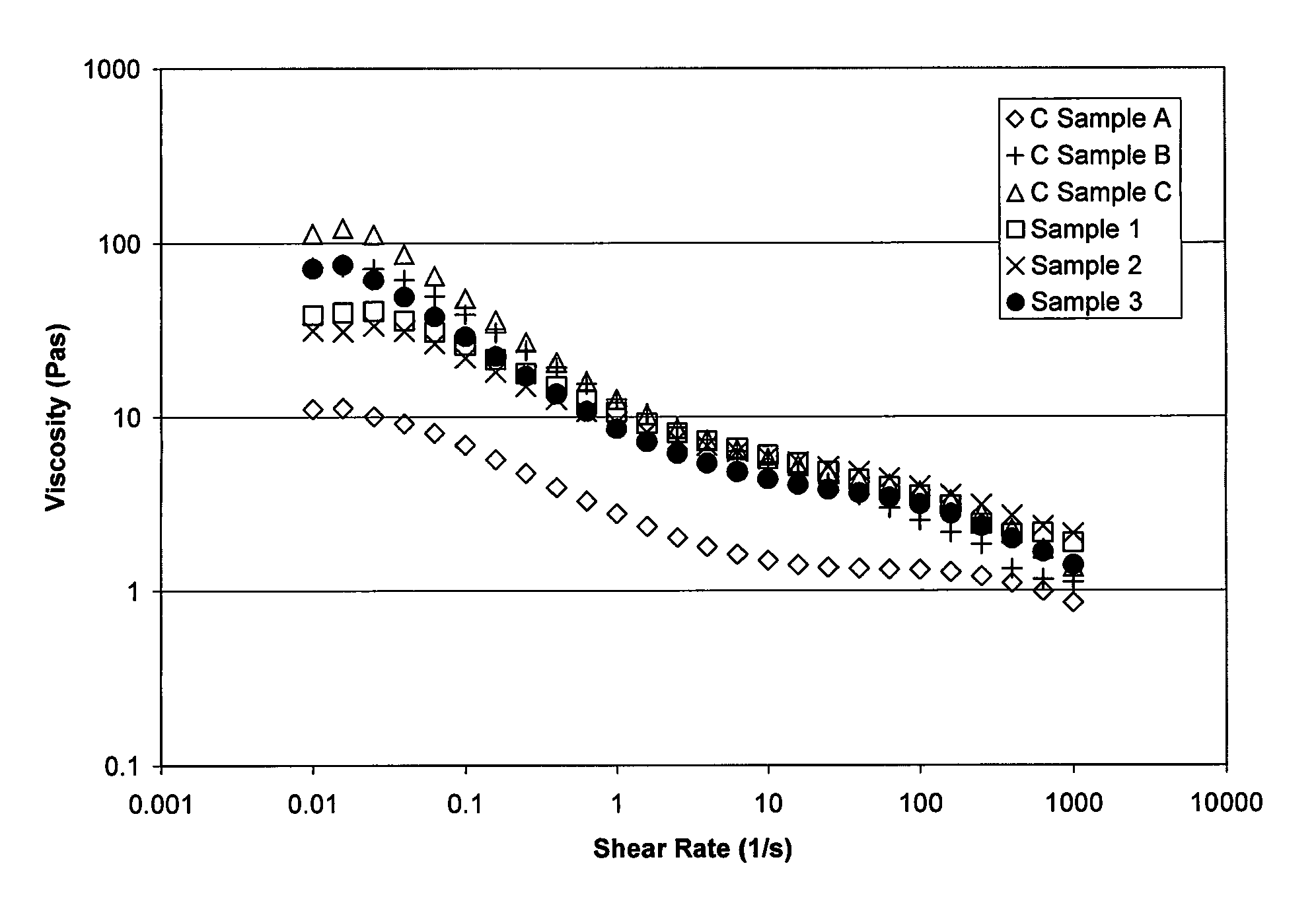

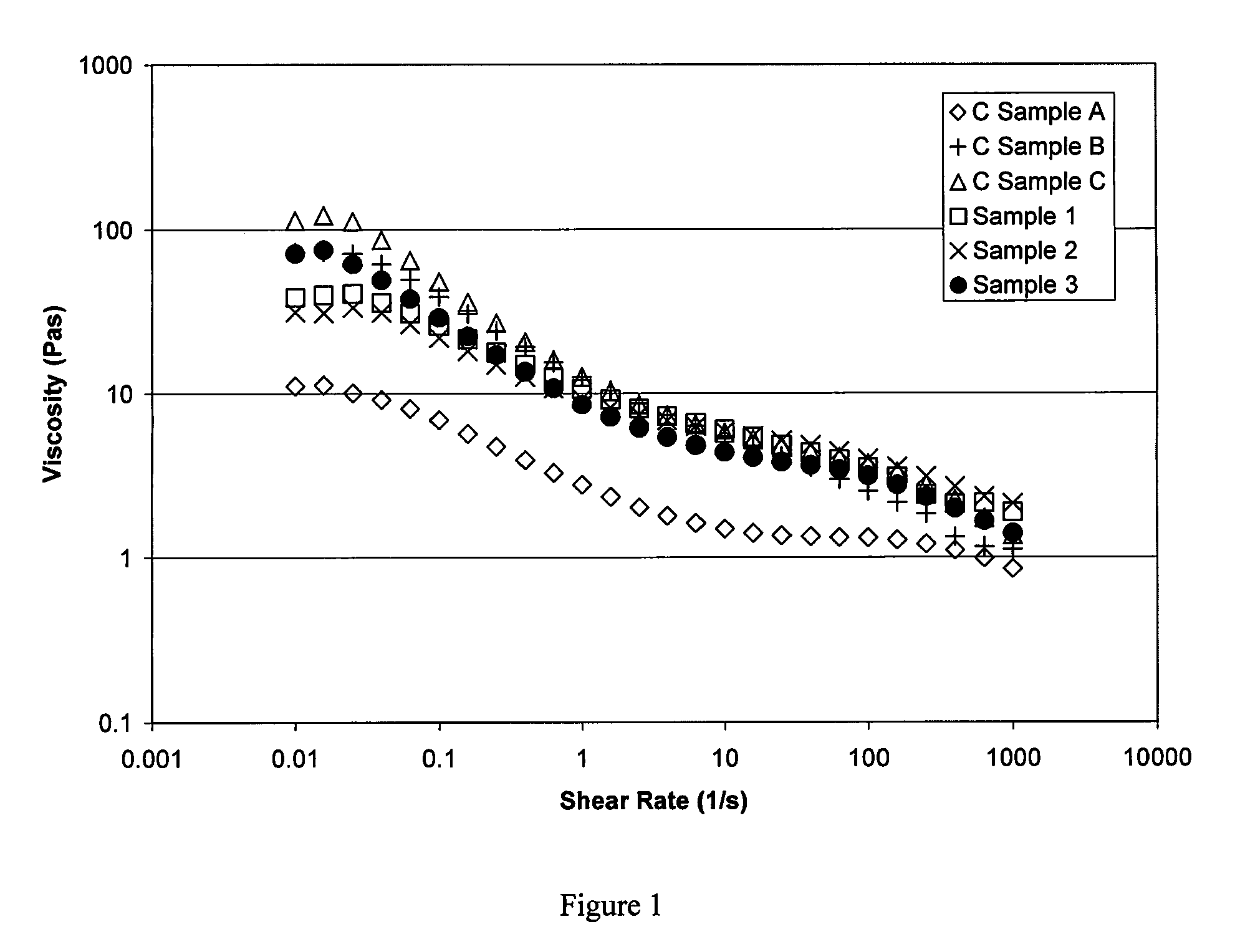

Heat activated epoxy adhesive and use in a structural foam insert

ActiveUS7084210B2Good chemical bondIncreased durabilityInorganic adhesivesAdhesive processes using foamed adhesivesYoung's modulusViscosity

An expandable adhesive for a structural foam insert useful for vehicular reinforcement is described. The adhesive is characterized by containing a viscosity enhancing agent such as a polymethylmethacrylate, which results in a cured adhesive having unusually small voids and unusually high Young's modulus.

Owner:DOW GLOBAL TECH LLC

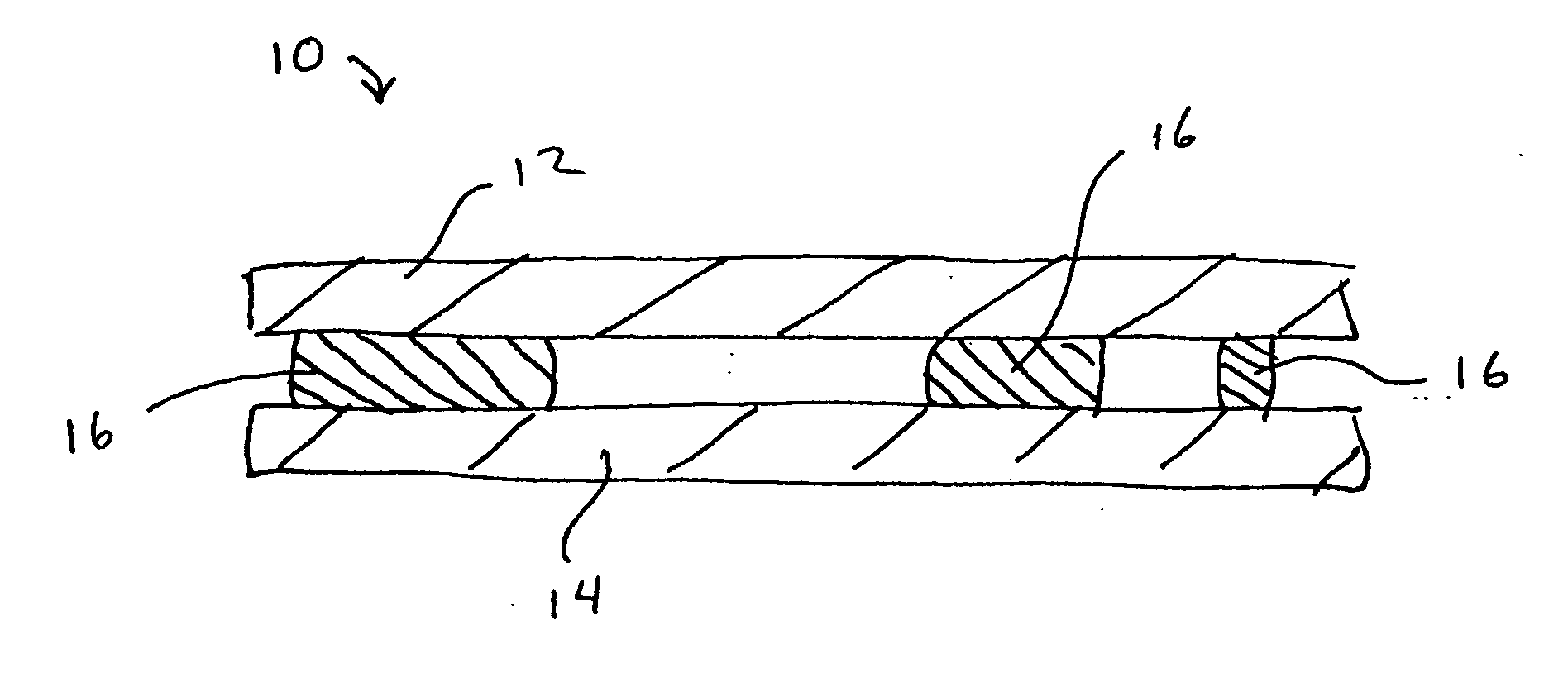

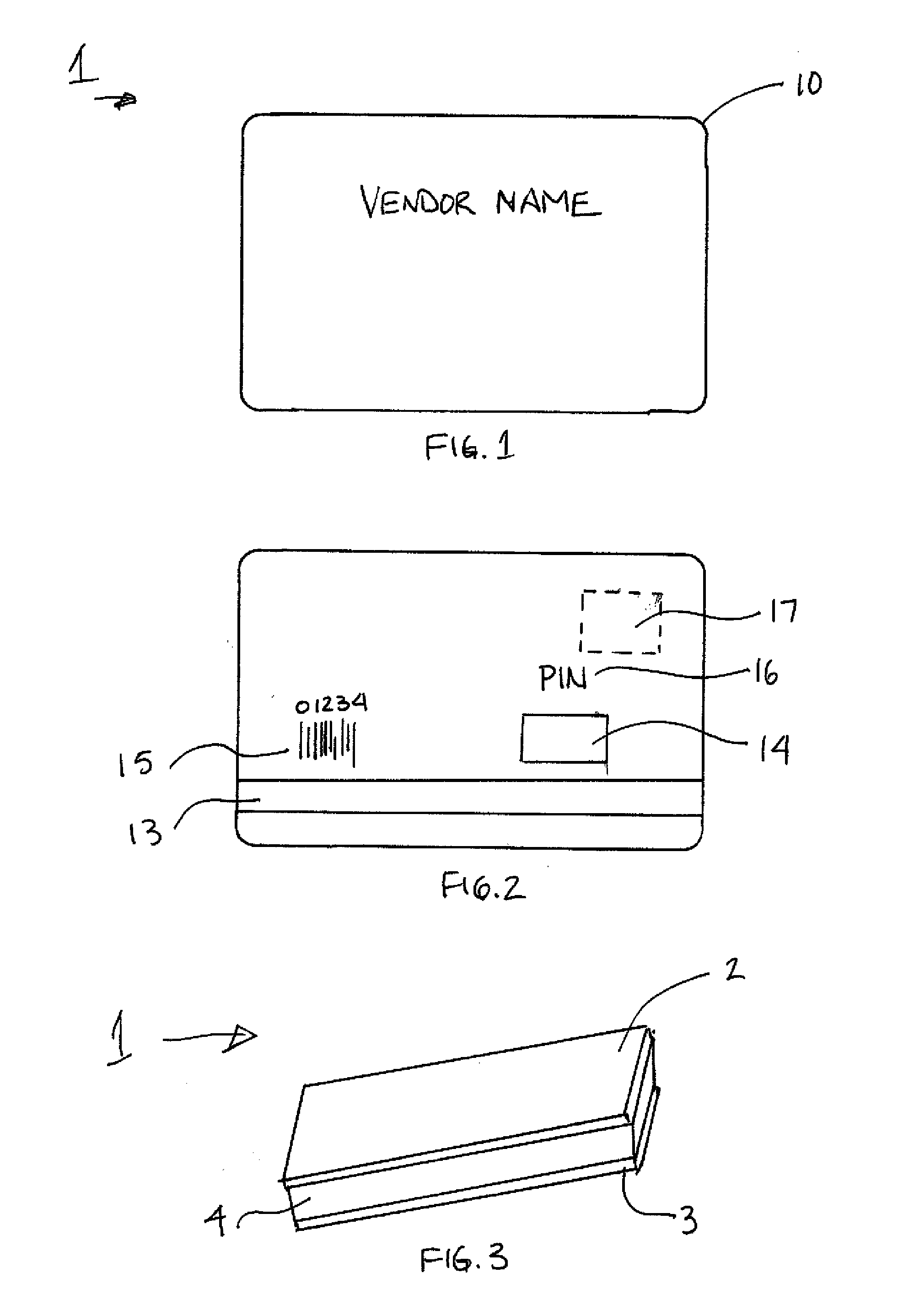

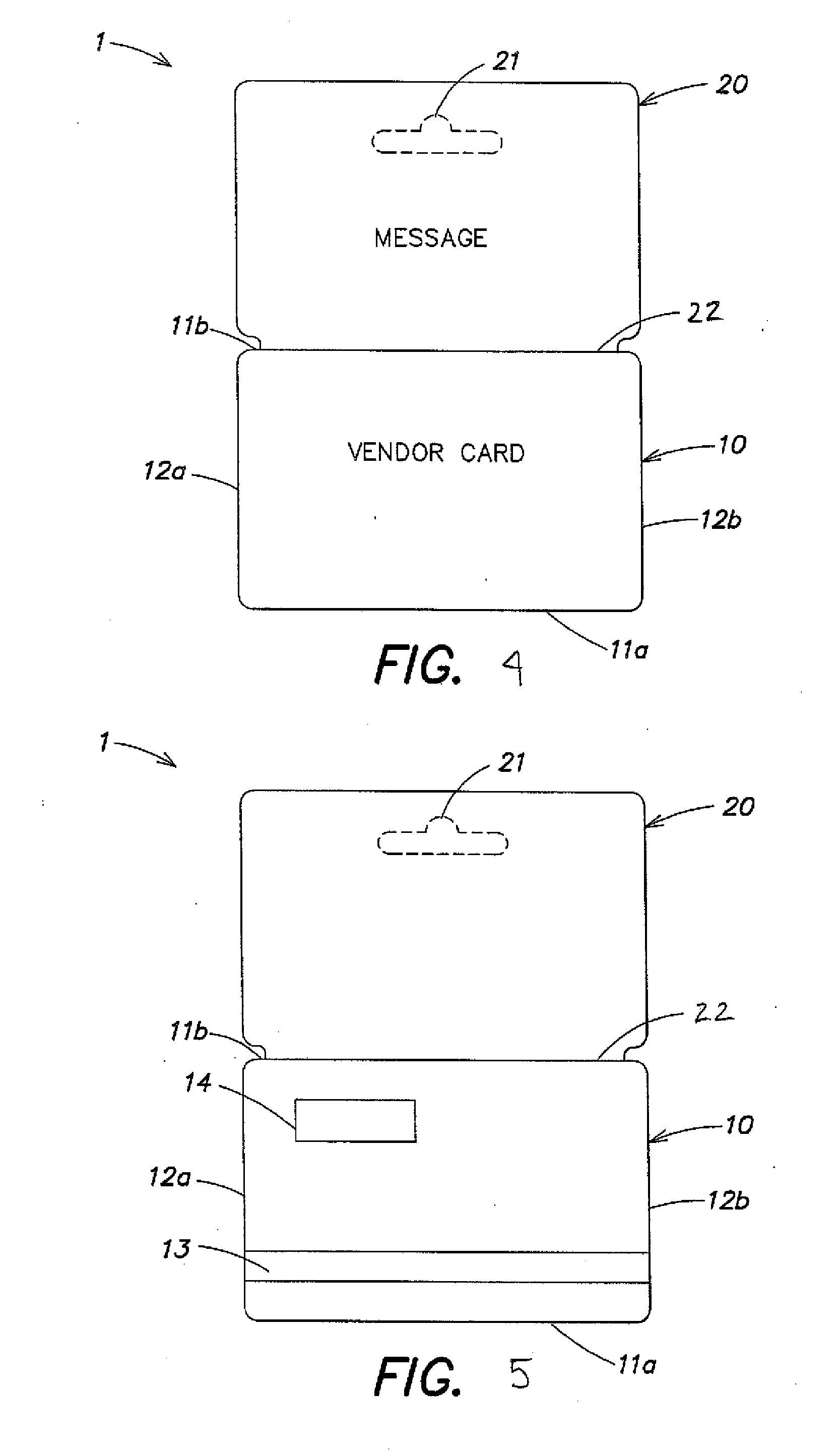

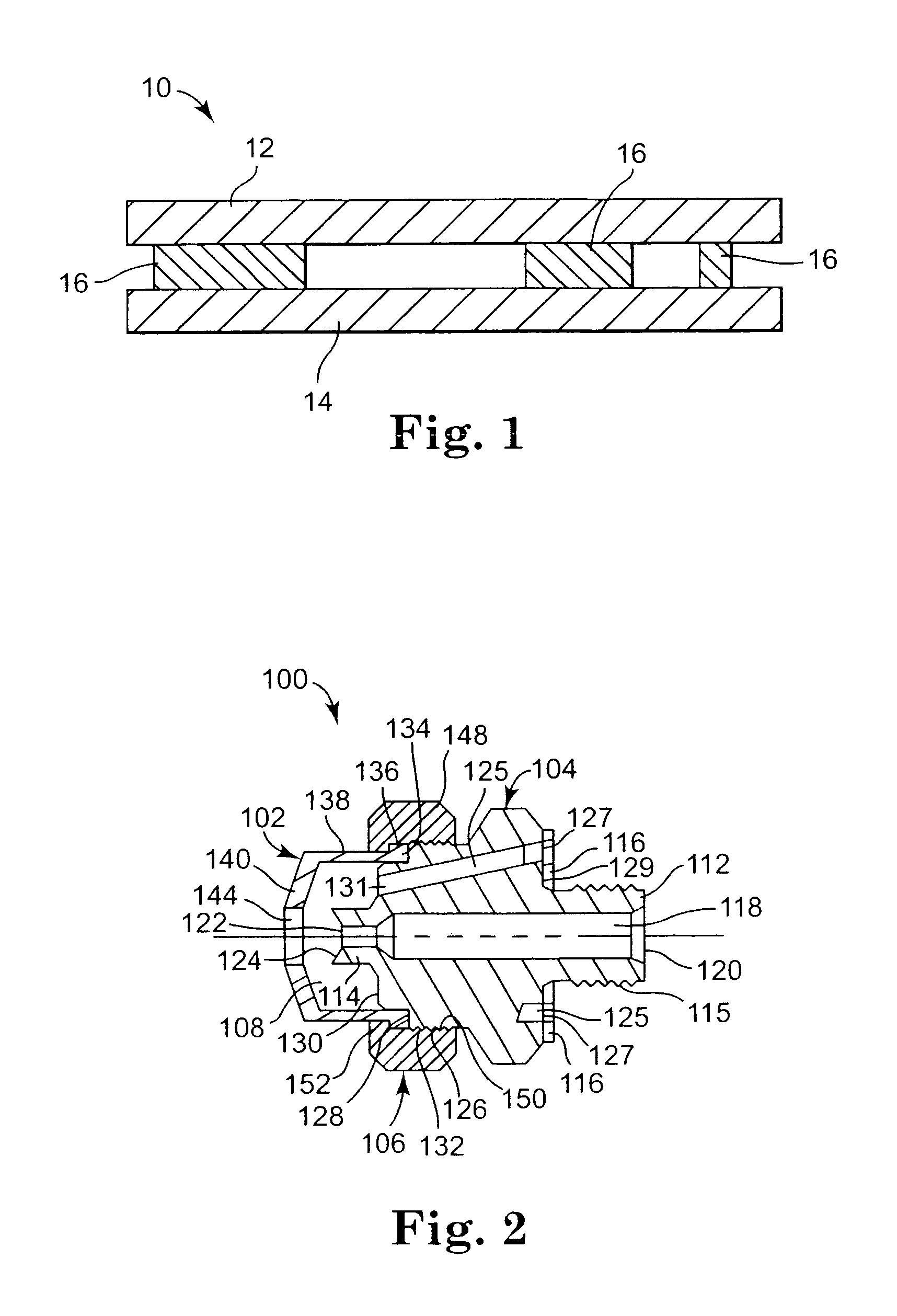

Transaction card assembly and methods of manufacture

A transaction card assembly may be constructed and arranged for use in a transaction by an issuee of the transaction card assembly. The transaction card assembly may include a first layer including a sheet of material, a second layer including a sheet of material, and an adhesive foam material between the first and second layers that expands to fill a space between the first and second layers and to define, at least in part, a finished thickness for the transaction card assembly and bonds the first and second layers together. Indicia, such as information representing an account number, biometric data representing a feature of the issuee, etc., may be included with the assembly for use in a transaction.

Owner:ARTHUR BLANK & CO

Heat-peelable pressure-sensitive adhesive sheet for cutting laminated ceramic sheet and method for cut-processing laminated ceramic sheet

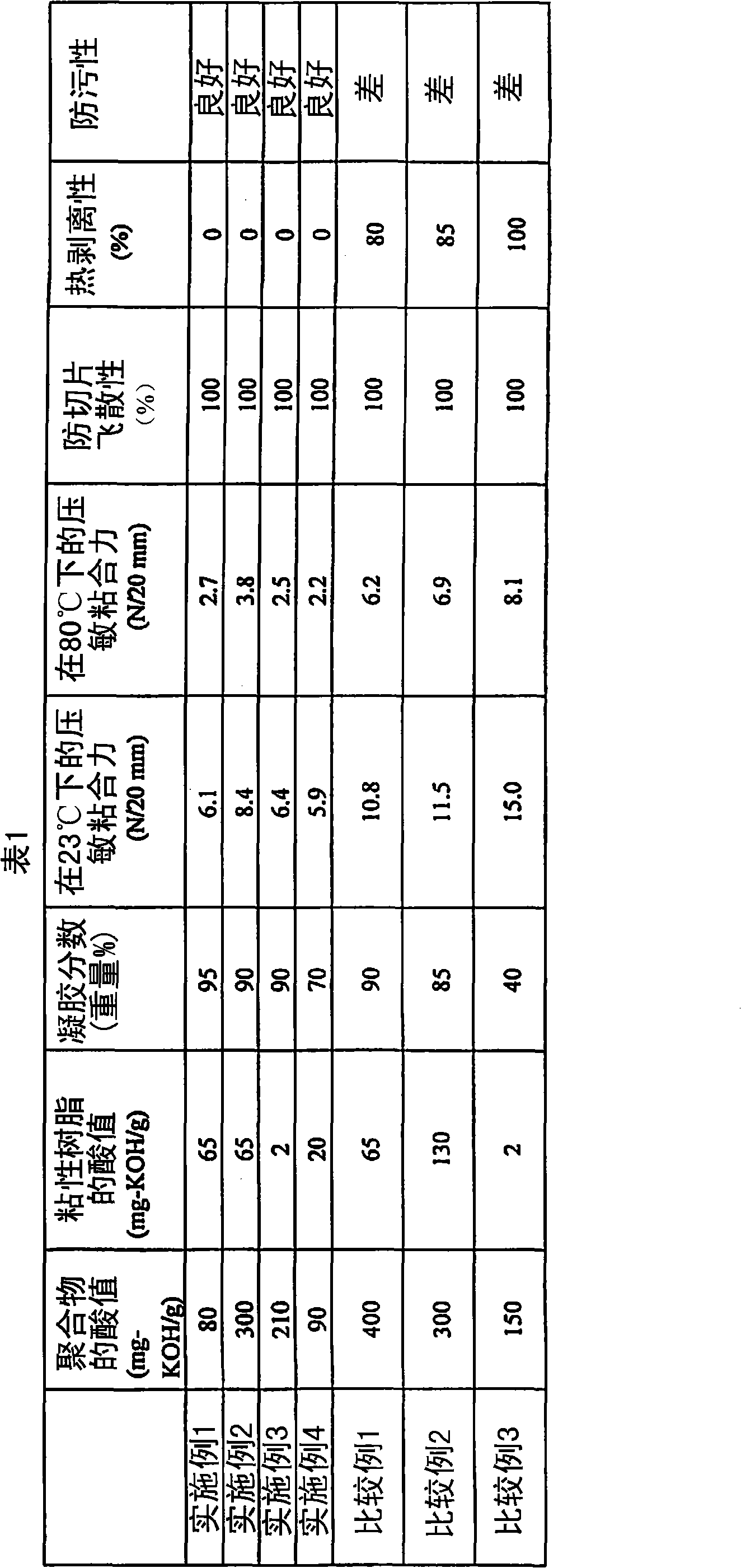

ActiveCN101812274AInhibit sheddingPollution suppressionEster polymer adhesivesAdhesive processes using foamed adhesivesFoaming agentPolymer

The invention relates to a heat-peelable pressure-sensitive adhesive sheet for cutting a laminated ceramic sheet and a method for cut-processing a laminated ceramic sheet. The heat-peelable pressure-sensitive adhesive sheet for cutting a laminated ceramic sheet is used for temporary fixing at cutting of the laminated ceramic sheet, and includes a base material and, formed on at least one surface of the base material, a heat-expandable pressure-sensitive adhesive layer containing a pressure-sensitive adhesive, a foaming agent and a tackifying resin, in which the heat-expandable pressure-sensitive adhesive layer has a gel fraction of 50% by weight or more, and the base polymer of the pressure-sensitive adhesive forming the heat-expandable pressure-sensitive adhesive layer has an acid value of 350mg-KOH / g or less and the tackifying resin contained in the heat-expandable pressure-sensitive adhesive layer has an acid value of 80mg-KOH / g or less.

Owner:NITTO DENKO CORP

Adhesive sheet

InactiveCN106414640AGood flexibilityImprove featuresWindings insulation materialWindings insulation shape/form/constructionEpoxyFoaming agent

Disclosed is an adhesive sheet comprising a base member (1) and an expansive adhesive agent layer (2) formed on one surface or both surfaces of the base member 1, wherein the expansive adhesive agent layer (2) comprises: an epoxy resin that comprises a polyfunctional epoxy resin; a phenolic resin that serves as a curing agent; an imidazole compound that serves as a curing catalyst; and a temperature-sensitive foaming agent. The adhesive sheet particularly has a good balance among properties including rapid curability, heat resistance and adhesion properties. The adhesive sheet also has satisfactory filling properties, and therefore has excellent various properties associated with the satisfactory filling properties, including heat conductivity.

Owner:TERAOKA SEISAKUSHO

Paper laminates manufactured using foamed adhesive systems

InactiveUS7201815B2Reliable and straightforwardNon-macromolecular adhesive additivesManual label dispensersAdhesivePaper towel

Foamed, aqueous adhesive compositions are used to manufacture tissue laminate products including or especially as bathroom tissue, facial tissue, paper towels, and the like. Foaming typically occurs by introducing pressurized gas and adhesive flows in a nozzle chamber on demand, wherein the kinetic energy of the flows is used to provide mixing energy. The adhesive preferably is dispensed as a plurality of discrete, foamed adhesive particles. The foamed adhesive can be used for intralamina bonds, interlaminate bonds, bonding loose sheet extremities, bonding roll to roll, and the like. The invention provides a reliable, straightforward way to accomplish in-nozzle foaming of an adhesive.

Owner:HB FULLER CO

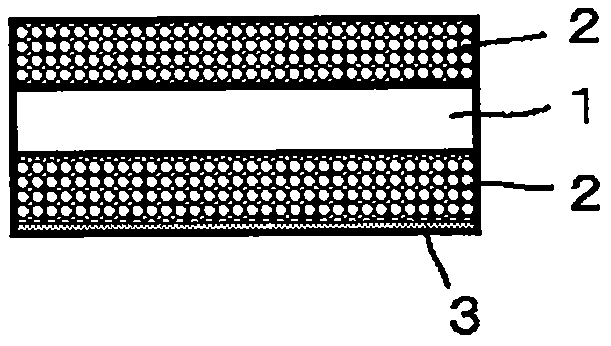

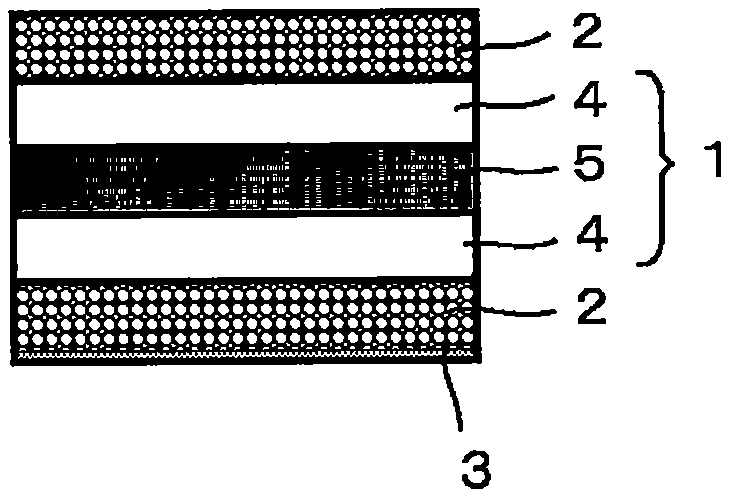

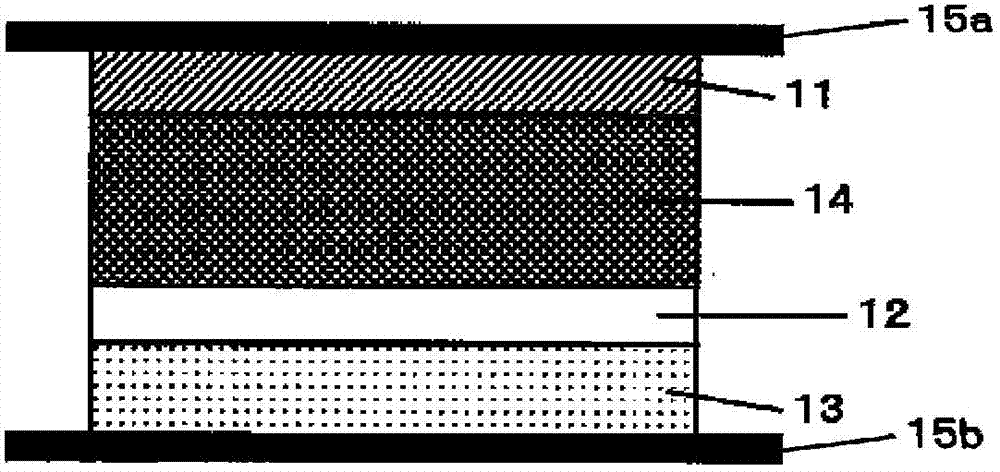

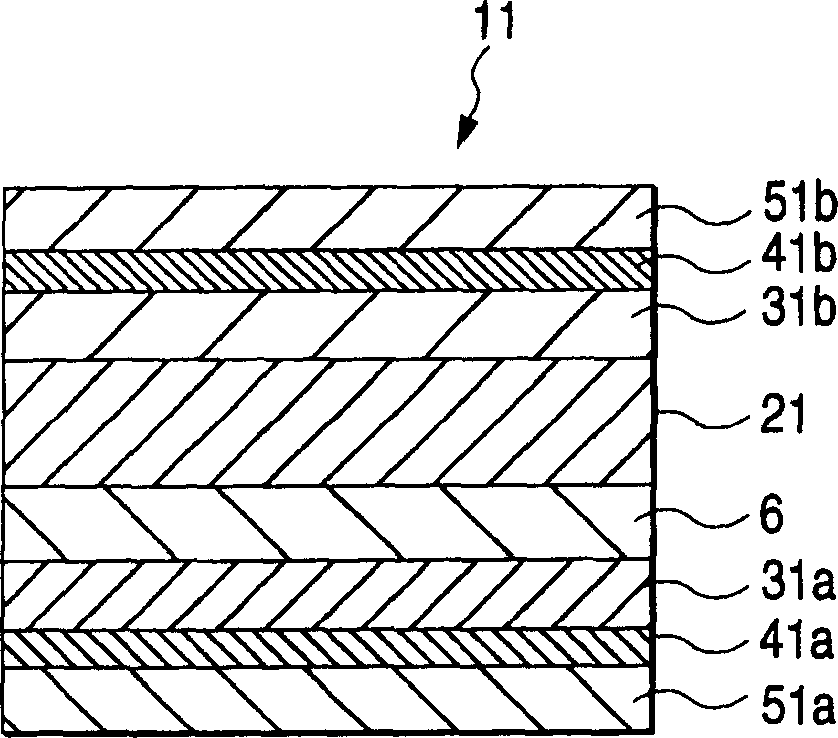

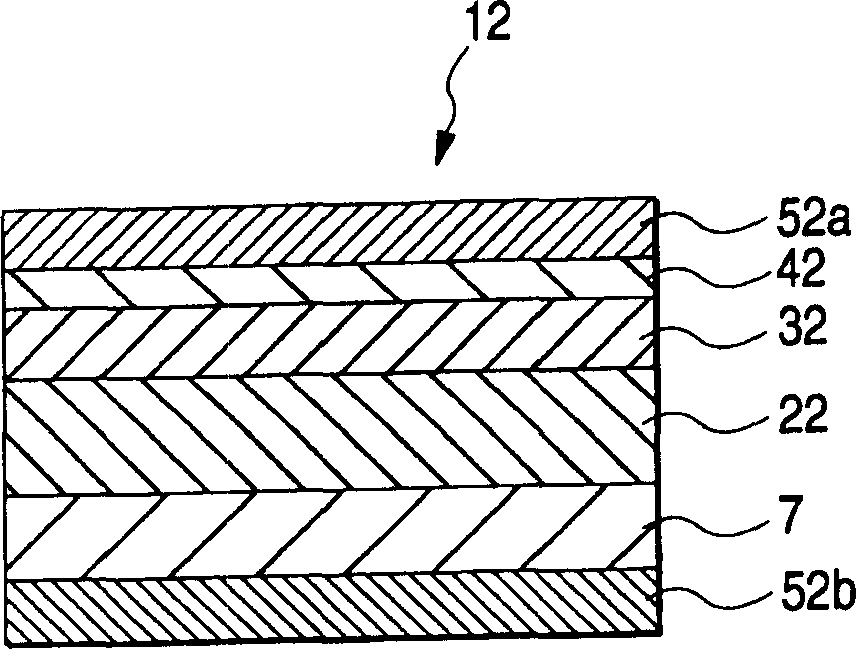

Heat-expandable removable pressure-sensitive adhesive tape or sheet, and method of removing the same

InactiveCN103031076AHigh Normal AdhesionEasy to separateSynthetic resin layered productsLaminationBlowing agentAtmosphere

To provide a heat-expandable removable pressure-sensitive adhesive tape that maintains a high normal adhesive strength during bonding as well as can be readily separated or debonded by heat for separation or debonding even after the storage or use for a long time, regardless of an adherend type. The heat-expandable removable pressure-sensitive adhesive tape of the present invention includes at least a blowing agent-containing pressure-sensitive adhesive layer A, a microparticle-containing viscoelastic substrate B, a peelable or peel-assisting film layer C, and a pressure-sensitive adhesive layer D. A multilayer structure containing at least the peelable or peel-assisting film layer C and the pressure-sensitive adhesive layer D is arranged on at least one side of the blowing agent-containing pressure-sensitive adhesive layer A where the blowing agent-containing pressure-sensitive adhesive layer A is in direct contact with the peelable or peel-assisting film layer C. The peelable or peel-assisting film layer C can be removed from the blowing agent-containing pressure-sensitive adhesive layer A by heat treatment after storage in an atmosphere of 75 DEG C for 8 weeks.

Owner:NITTO DENKO CORP +1

Heat-Peelable Pressure-Sensitive Adhesive Sheet and Method for Processing Adherend Using the Heat-Peelable Pressure-Sensitive Adhesive Sheet

InactiveUS20080160293A1Increase stickinessReduce debrisLaminating printed circuit boardsSolid-state devicesShear modulusFoaming agent

Disclosed is a heat-peelable pressure-sensitive adhesive sheet that can prevent the deformation of a pressure-sensitive adhesive layer caused by pressurization, further reduce chipping in grinding and cutting processes, be easily peeled off from a processed article after processing, and can be easily applied to an adhered at ordinary temperature.The heat-peelable pressure-sensitive adhesive sheet includes a substrate, and a heat-expandable pressure-sensitive adhesive layer arranged on or above at least one side of the substrate, the heat-expandable pressure-sensitive adhesive layer containing a foaming agent and having a shear modulus (23° C.) in an unfoamed state of 7×106 Pa or more. The adhesive sheet further includes a pressure-sensitive adhesive layer being arranged on or above the heat-expandable pressure-sensitive adhesive layer and having a shear modulus (23° C.) of less than 7×106 Pa. The pressure-sensitive adhesive layer arranged on the heat-expandable pressure-sensitive adhesive layer preferably has a thickness of 0.01 to 10 μm.

Owner:NITTO DENKO CORP

Vehicular structural members and method of making the members

The present invention is an article comprising a shaped rigid foam part; a heat activated foamable adhesive applied directly to at least a portion of the outer surface of the shaped foam part and an integral locating means. A second aspect of the invention is a method of forming a foam filled vehicle hollow member comprising, (a) inserting into a vehicular hollow member a rigid foam part comprised of a rigid foam having a heat activated foamable adhesive on at least a portion of the rigid foam insert and at least one integral locating means extending from a surface of the rigid foam, (b) engaging the locating means with the hollow member to locate the rigid foam part within the hollow member, and (c) heating the hollow member having the rigid foam part therein to a temperature and for a time sufficient to activate the heat activated expandable adhesive to form the foam filled vehicle hollow member.

Owner:DOW GLOBAL TECH LLC

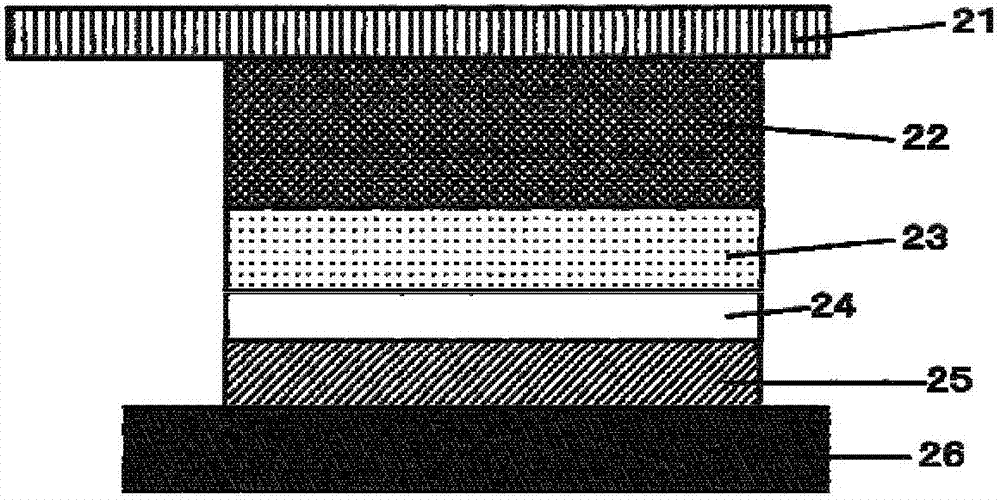

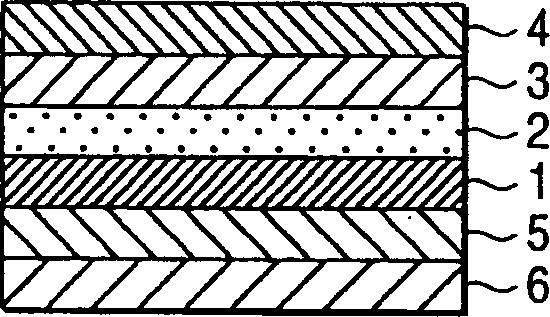

Energy-beam curable thermal-releasable pressure-sensitive adhesive sheet and method for producing cut pieces using the same

InactiveCN1471565AReduce pollutionSynthetic resin layered productsSolid-state devicesMicrosphereContamination

An energy-beam-curable thermal-releasable pressure-sensitive adhesive sheet having, on at least one side of a base material, an energy-beam-curable thermo-expandable viscoelastic layer containing thermo-expandable microspheres and a pressure-sensitive adhesive layer stacked in this order. The pressure-sensitive adhesive layer has a thickness of about 0.1 to 10 mum and can be formed from a pressure-sensitive adhesive. The energy-beam-curable thermo-expandable viscoelastic layer, on the other hand, can be formed from a tacky substance. The energy-beam-curable thermal-releasable pressure-sensitive adhesive sheet according to the invention has adhesion enough to withstand a carrying step of an adherend, causes neither winding up of the adhesive nor chipping upon cutting and facilitates peeling and collection of cut pieces after cutting. In addition, it exhibits low contamination on the adherend after peeling.

Owner:NITTO DENKO CORP

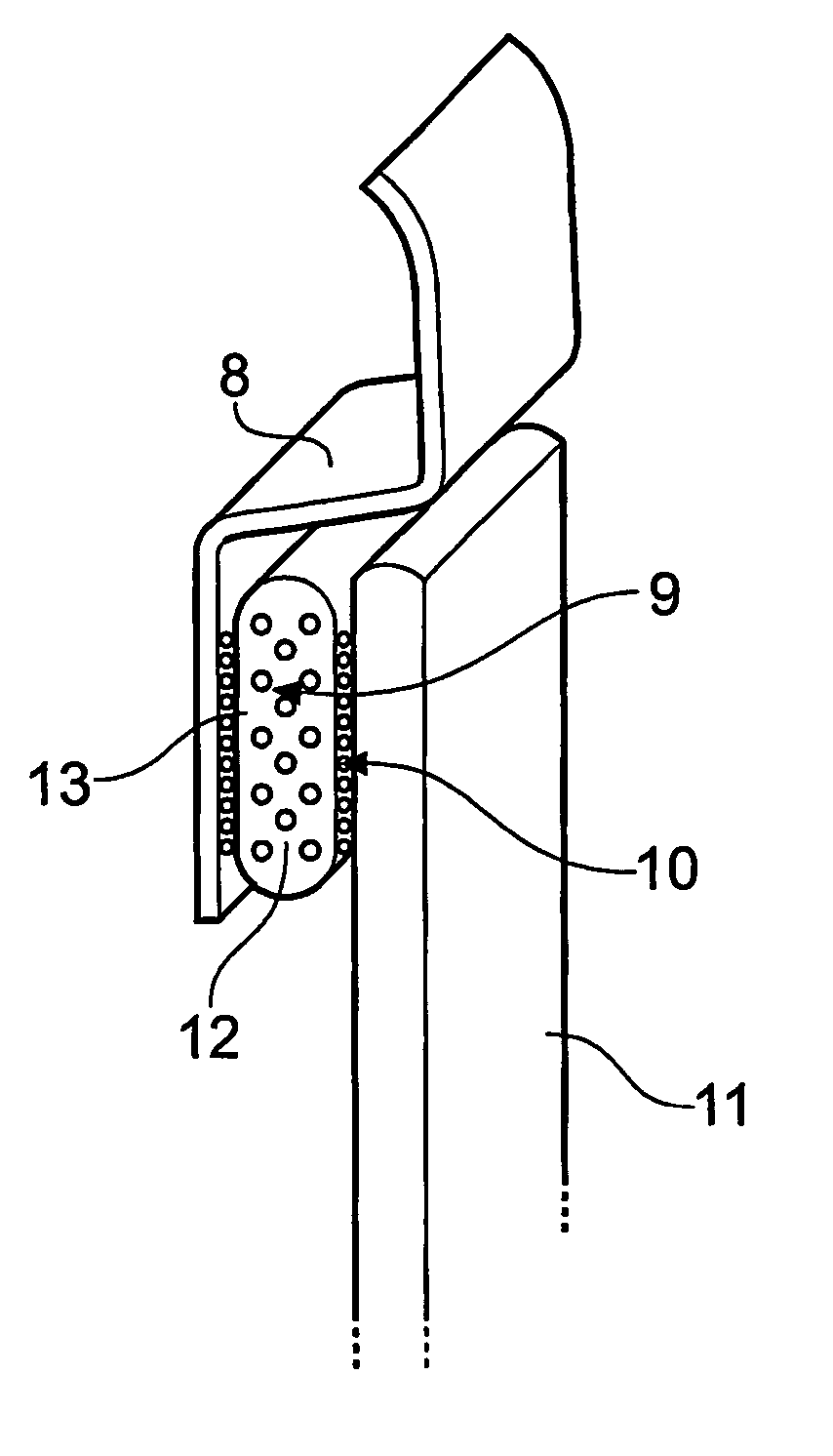

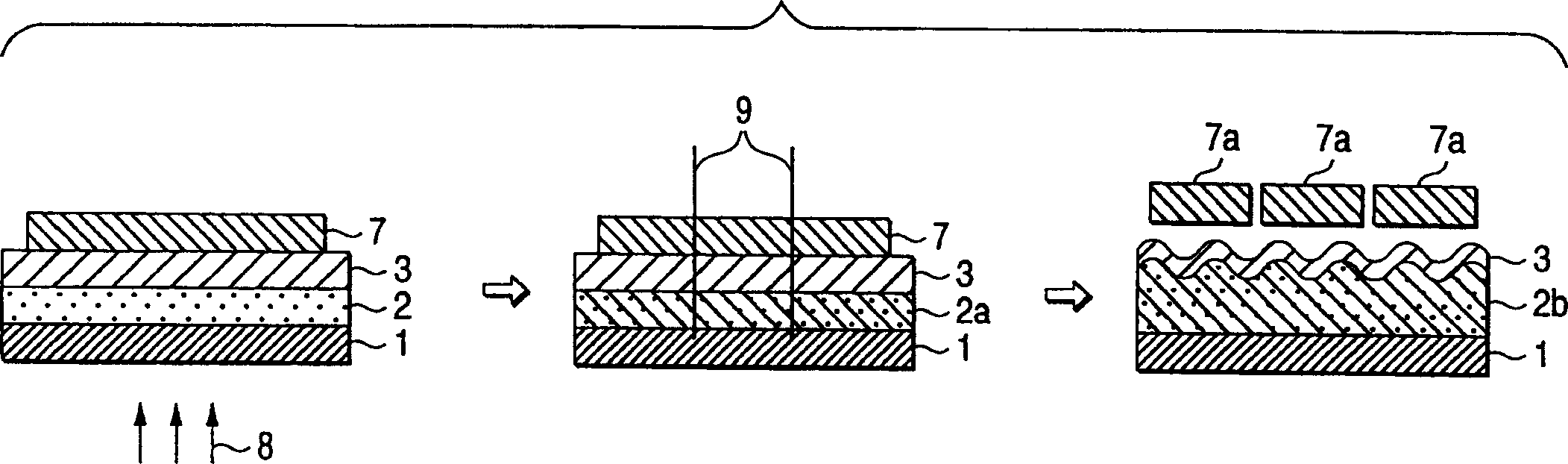

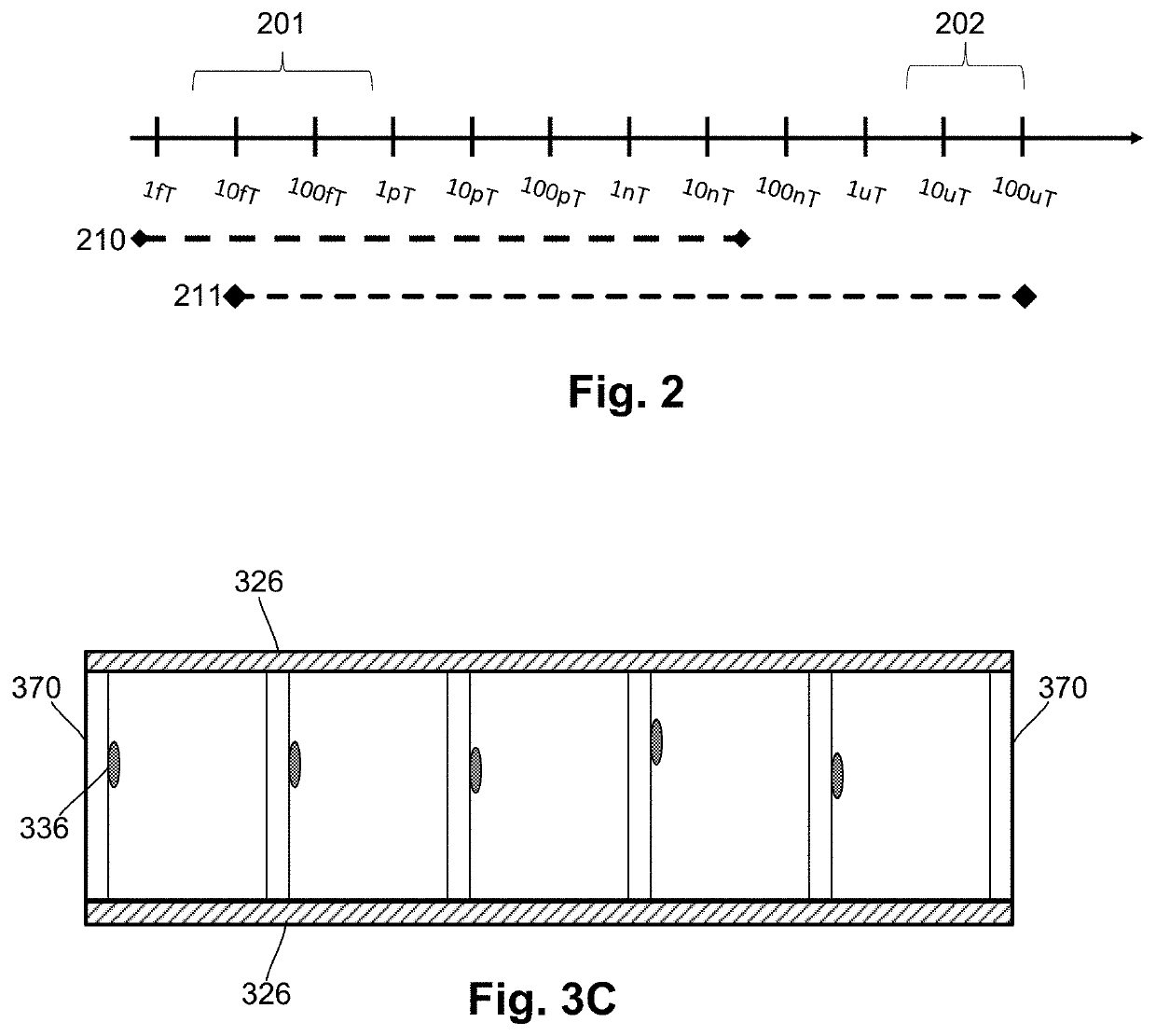

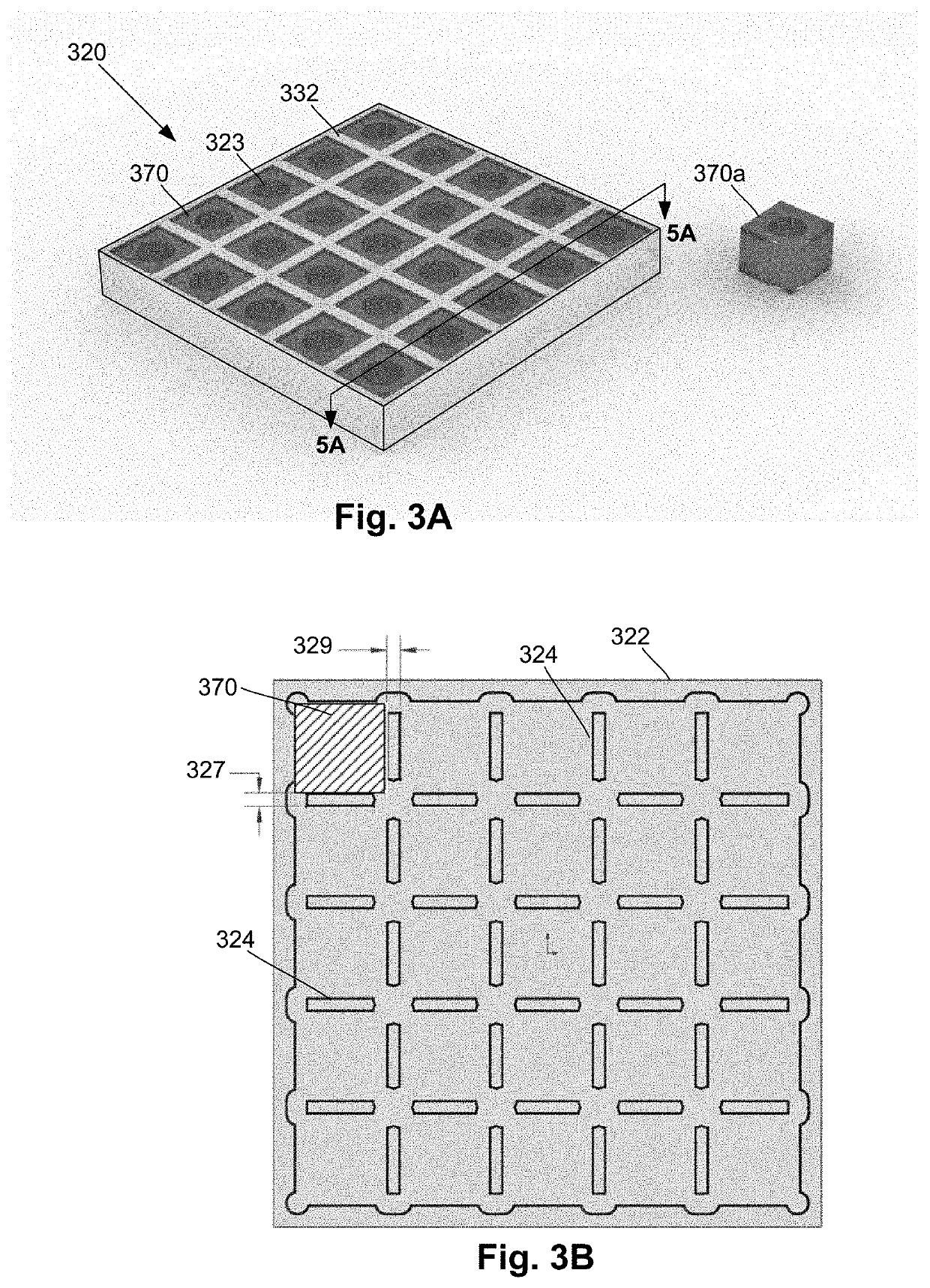

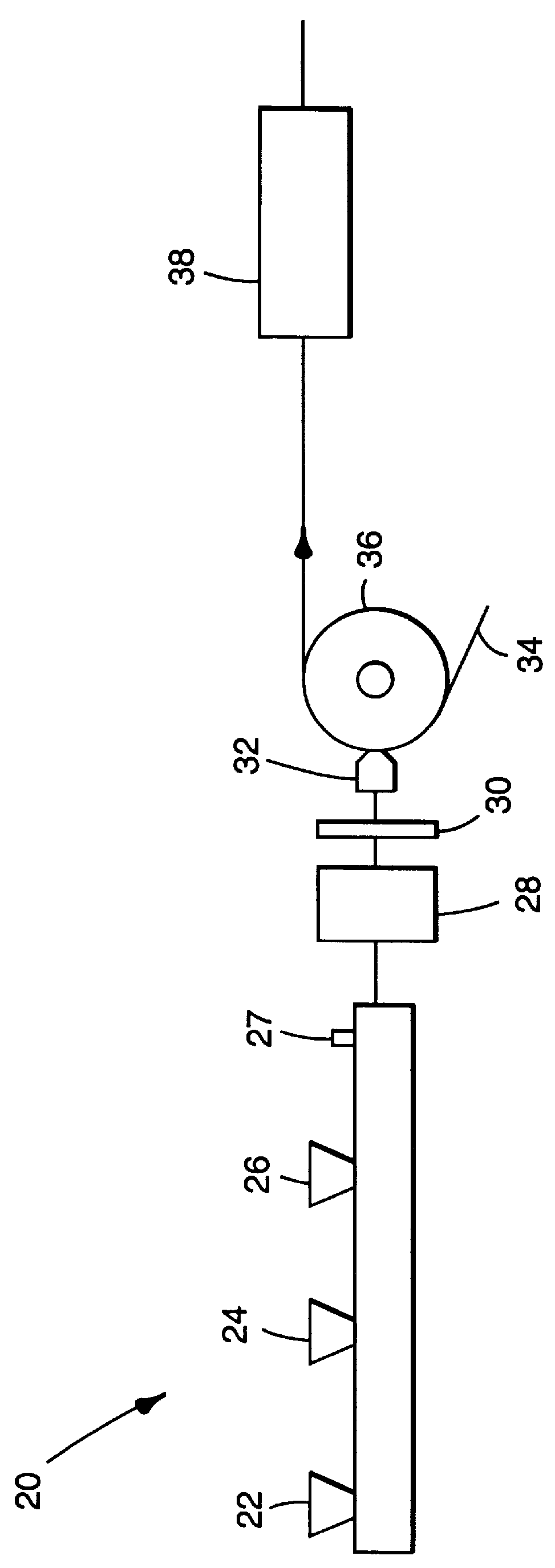

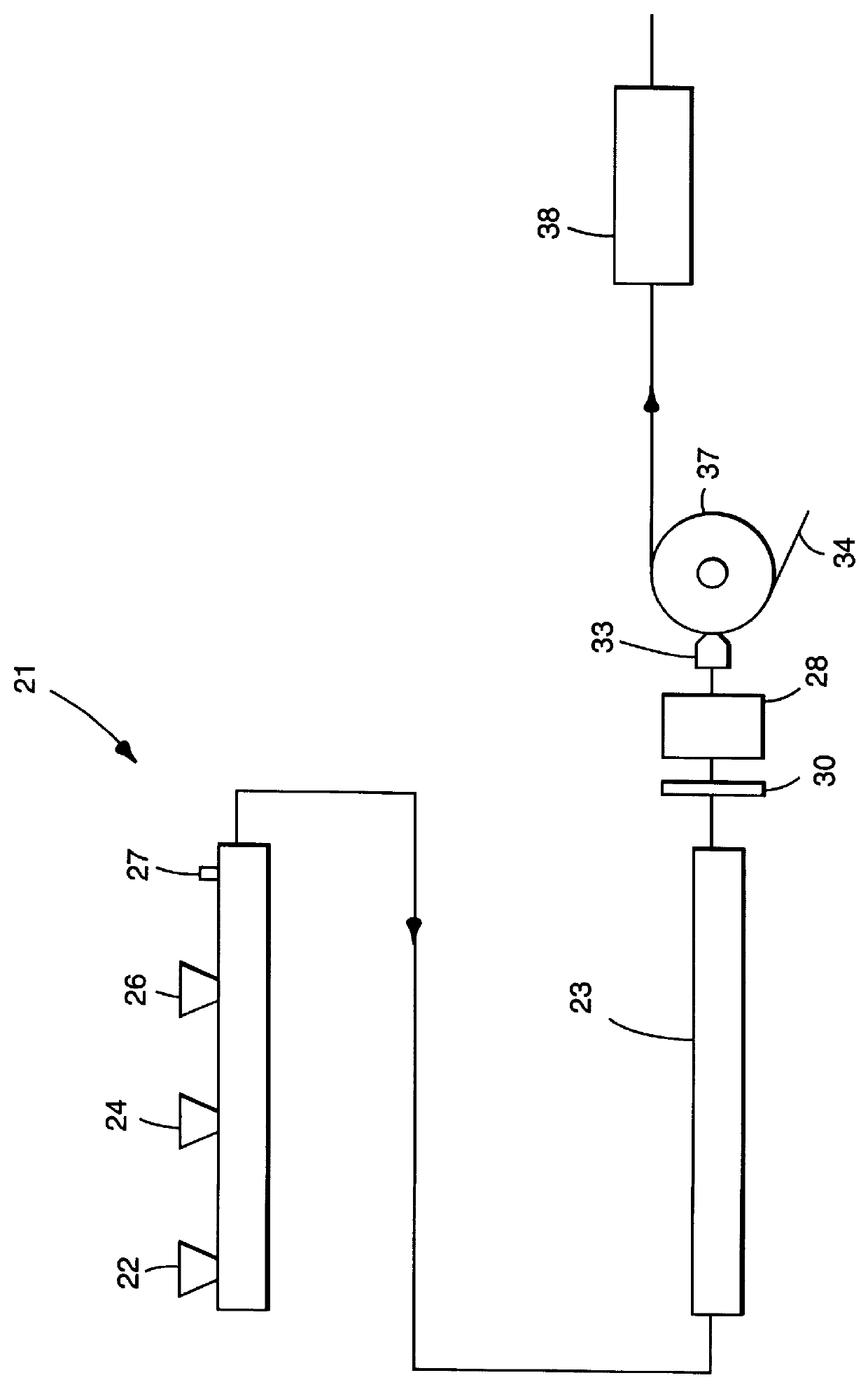

Methods and systems for homogenous optically-pumped vapor cell array assembly from discrete vapor cells

ActiveUS20210139742A1Easy to insertReduce widthApparatus using atomic clocksManufacture of electrical instrumentsEngineeringBiology

A method of making an array of vapor cells for an array of magnetometers includes providing a plurality of separate vapor cell elements, each vapor cell element including at least one vapor cell; arranging the vapor cell elements in an alignment jig to produce a selected arrangement of the vapor cells; attaching at least one alignment-maintaining film onto the vapor cell elements in the alignment jig; transferring the vapor cells elements and the at least one alignment-maintaining film from the alignment jig to a mold; injecting a bonding material into the mold and between the vapor cell elements to bond the vapor cell elements in the selected arrangement; removing the at least one alignment maintaining film from the vapor cell elements; and removing the bonded vapor cells elements in the selected arrangement from the mold to provide the array of vapor.

Owner:HI LLC

Solventless compounding and coating of non-thermoplastic hydrocarbon elastomers

InactiveUSRE36855E1Great molecular weightShort timeFilm/foil adhesivesLaminationElastomerPolymer science

A solvent-free hot melt process, for preparing a non-thermosettable, pressure-sensitive adhesive from a tackified non-thermoplastic hydrocarbon elastomer. The process employs a continuous compounding device that has a sequence of alternating conveying and processing zones. The processing zones masticate and mix materials in them. Non-thermoplastic elastomers having high molecular weight may be readily compounded into adhesives in the process.

Owner:3M INNOVATIVE PROPERTIES CO

Double-sided pressure-sensitive adhesive tape or sheet

InactiveUS20070190280A1Easy to peelDifference in peel strengthLayered productsAdhesive processes using foamed adhesivesAir bubbleSilicone

The present invention provides a double-sided pressure-sensitive adhesive tape or sheet including a bubble-containing pressure-sensitive adhesive layer; and a releasable liner protecting a pressure-sensitive adhesive surface of the bubble-containing pressure-sensitive adhesive layer, said releasable liner comprising at least a releasably treated layer formed by an ionizing radiation-curable silicone type releasing agent, in which the releasably treated layer formed by the ionizing radiation-curable silicone type releasing agent is employed onto a pressure-sensitive adhesive surface on the heavier releasable side. The double-sided pressure-sensitive adhesive tape or sheet may employ a bubble-containing pressure-sensitive adhesive layer formed by a bubble-containing pressure-sensitive adhesive composition in the form in which a gas component is mixed in a pressure-sensitive adhesive composition.

Owner:NITTO DENKO CORP

Heat strippable pressure-sensitive adhesive sheet for electronic element, method for producing electronic element and electronic element

InactiveCN1451707AEasy to peelDoes not cause pollutionSolid-state devicesSemiconductor/solid-state device manufacturingMicrosphereEngineering

Disclosed is a heat-peelable pressure-sensitive adhesive sheet for electronic components that is easily peeled off from electronic components with little contamination after heat treatment. The heat-peelable pressure-sensitive adhesive sheet for electronic components includes a heat-expandable layer containing heat-expandable microspheres and a non-heat-expandable pressure-sensitive adhesive layer formed on at least one side of the heat-expandable layer, wherein when When a pressure-sensitive adhesive sheet is applied to the surface of a silicon wafer on one side of the non-heat-expandable pressure-sensitive adhesive layer, and then heated and peeled off from the silicon wafer, the surface of the silicon wafer measured by XPS The ratio RC1 (%) of the carbon element on the surface satisfies at least one of the following relationships (1) and (2): RC1≤50+RC2 (1), RC1≤2.5RSi (2); wherein RC2 represents that it is formed by The ratio (%) of the carbon element on the surface of this silicon wafer measured by XPS; The proportion of silicon element on the surface of the sheet.

Owner:NITTO DENKO CORP

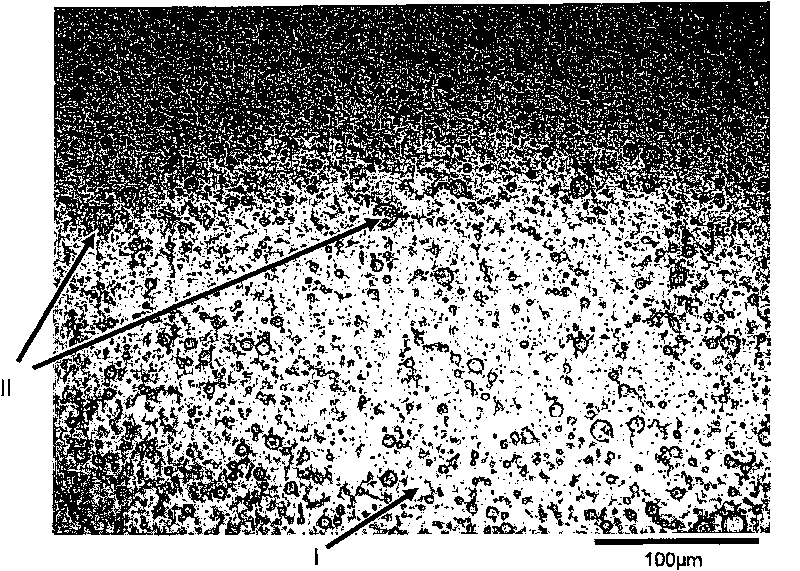

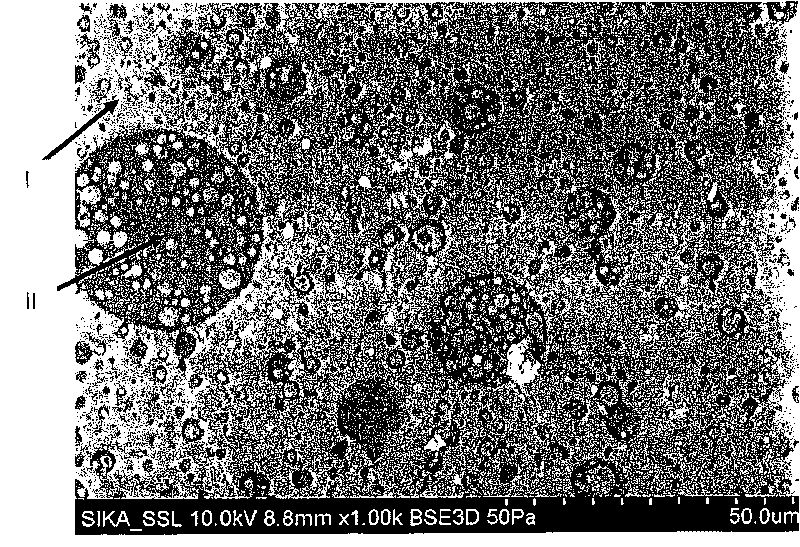

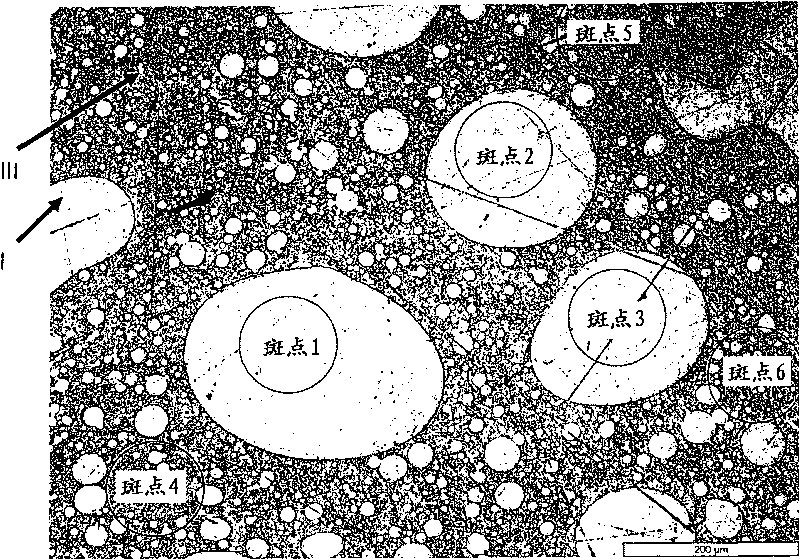

Hot-curing epoxy resin compositions that can be used as bodyshell adhesive or structural foam

ActiveCN101724225AIsolate the inner spaceHigh strengthLayered product treatmentSynthetic resin layered productsVitrificationEpoxy

Hot-curing epoxy resin compositions are disclosed which firstly are solid in a hardened state at room temperature and secondly form an adhesion-free surface and are impact-resistant and can have high glass transition temperatures, above, for example, 110 DEG C. An exemplary hot-curing epoxy resin composition can form separate phases on hardening, a continuous phase being formed by epoxy resins. If the compositions include a blowing agent, they can have excellent suitability for production of foams, such as structural foams.

Owner:SIKA TECH AG

Release liners, pressure-sensitive adhesive tape, and pressure-sensitive adhesive tape roll

InactiveUS20090258176A1Improve adhesionGood lookingAdhesive articlesSynthetic resin layered productsBobbinEthylene

A first release liner of the present invention comprises a single- or multilayered film having a releasable layer in which the peel strength in application to an acrylic plate (23 DEG C.) is 0.02-0.5 N / 20 mm. Also provided is a second release liner which comprises a single- or multilayered film having a releasable layer comprising an ethylene / vinyl acetate resin. The release liners each may be a multilayered film composed of a substrate and a releasable layer. When each of the release liners is used as a release liner in winding a pressure-sensitive adhesive tape on a bobbin, the tape winding operation is free from troubles that the release liner undesirably peels off, tape shifting occurs, and air inclusion occurs between tape layers. When the pressure-sensitive adhesive tape is used, the release liner can be easily peeled from the pressure-sensitive adhesive layer.

Owner:NITTO DENKO CORP

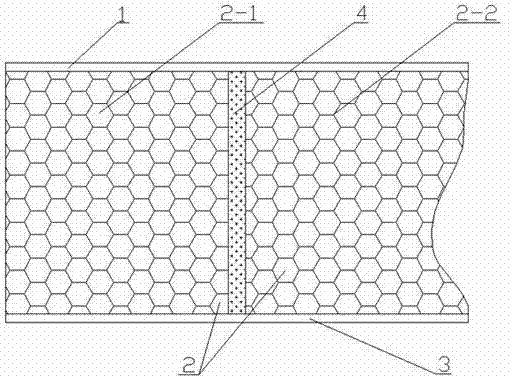

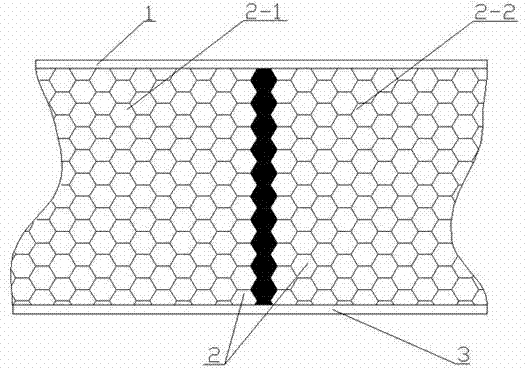

Honeycomb core splicing method

InactiveCN103589349AEasy to operateHigh strengthAdhesive processes with adhesive heatingAdhesive processes using foamed adhesivesAdhesive cementWhole body

A honeycomb core splicing method comprises the following steps: inserting strip-shaped foaming glue satisfying a prescribed strength requirement between the honeycomb core groups or between the honeycomb core of a honeycomb panel and a frame skeleton, carrying out heating expansion of the foaming glue in a high temperature state of a hot pressed plate, carrying out synchronous hot pressing solidification with an adhesive or a glue membrane in the plate making process, and bonding the honeycomb core group or the honeycomb core and the frame skeleton which are butted into a whole body. The splicing method is simple to operate, is suitable for the splicing of honeycomb core groups, and is also suitable for the splicing and reinforcing of the honeycomb core and the frame skeleton; and additionally, the strength of a honeycomb core splicing position is higher than the strength of the body, so the honeycomb panel has a high overall strength and a good rigidity, and can satisfy strength requirements of a honeycomb shelter.

Owner:衡阳泰豪通信车辆有限公司

Heat-peelable pressure-sensitive adhesive sheet

InactiveUS7163597B2Sufficient efficient contact areaAvoid adhesion failurePaper/cardboard articlesSolid-state devicesMicrosphereExpandable microsphere

A heat-peelable pressure-sensitive adhesive sheet which ensures an efficient contact area even in case where the area of an adherend to be adhered is decreased and thus makes it possible to avoid adhesion failures such as chip-scattering or chipping. The heat-peelable pressure-sensitive adhesive sheet comprises a substrate and a heat-expandable pressure-sensitive adhesive layer containing heat-expandable microspheres, formed on at least one side of the substrate, wherein the surface of the heat-expandable pressure-sensitive adhesive layer before heating has a center line average roughness of 0.4 μm or less.

Owner:NITTO DENKO CORP

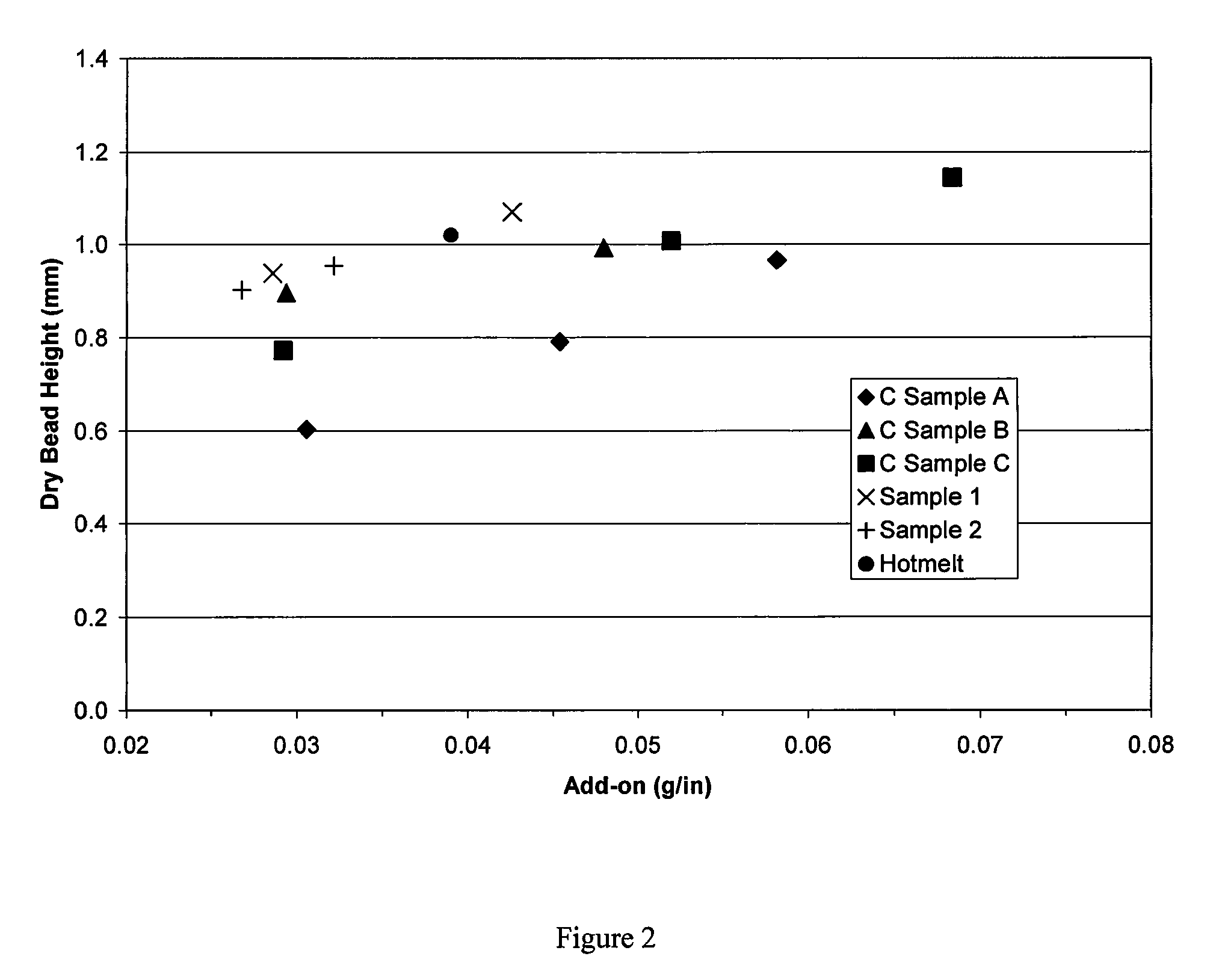

Hot melt assist waterborne adhesives and use thereof

ActiveUS9273230B2Less energyHigh profileMonocarboxylic acid ester polymer adhesivesPaper/cardboard layered productsPolymer scienceMicrosphere

A hot melt assist waterborne adhesive having high amplitude bead profile and higher heat resistance is provided. The hot melt assist waterborne adhesive includes an emulsion polymer, a preservative, a plurality of pre-expanded hollow microspheres and water. The hot melt assist waterborne adhesive is suitable as a partial or complete replacement to hot melt adhesives for use in converting paper and packaging process.

Owner:HENKEL KGAA

Foam sheet of crosslinked polyolefin resin,process for producing the same and pressure-sensitive adhesive tape

InactiveUS20060177642A1Increase flexibilityImprove heat resistanceFilm/foil adhesivesLayered productsPolyolefinHeat resistance

The present invention provides a crosslinked polyolefin-based resin-extruded foam sheet capable of reducing its thickness while retaining excellent flexibility and heat resistance. The crosslinked polyolefin-based resin foam sheet of the present invention is obtained by feeding a polyolefin-based resin and a thermally degradable blowing agent to an extruder, melting and kneading them, extruding the kneaded material through the extruder into a sheet to form an expandable polyolefin-based resin sheet, and expanding the sheet. Herein, a degree of crosslinking of the crosslinked polyolefin-based resin foam sheet is 5 to 60% by weight, an aspect ratio of a cell (MD average cell diameter / CD average cell diameter) is 0.25 to 1, and the polyolefin-based resin contains 40% by weight or more of a polyethylene-based resin obtained using a metallocene compound containing a tetravalent transition metal as a polymerization catalyst.

Owner:SEKISUI CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com