Honeycomb core splicing method

A technology of honeycomb core and honeycomb, which is applied in the field of shelters, can solve the problems of complex splicing structure and unsuitable structure for splicing of honeycomb cores, and achieve the effect of meeting strength requirements, good rigidity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

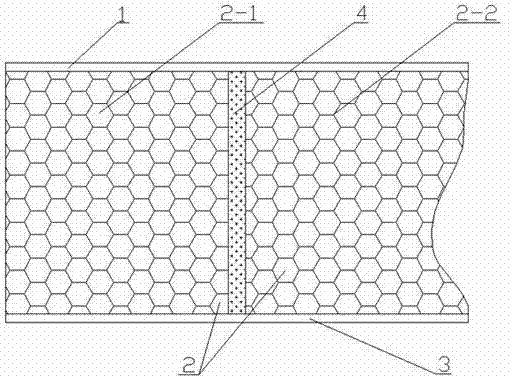

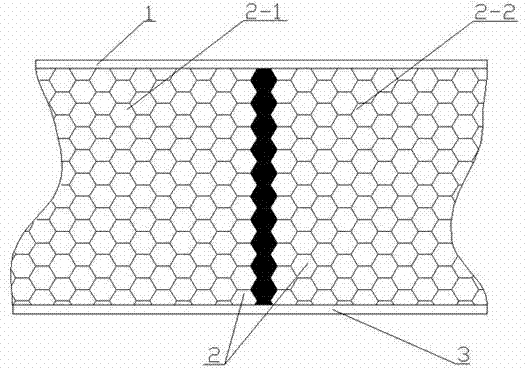

[0018] refer to figure 1 : A kind of honeycomb core splicing method of the present embodiment, the steps are as follows: insert between the honeycomb core groups 2 of the honeycomb sandwich panel (between the first honeycomb core 2-1 and the first honeycomb core 2-2) to meet the specified strength requirements The strip-shaped foam glue 4, the foam glue 4 is thermally expanded at a high temperature of 120° C. of the hot-pressed board, and is simultaneously hot-pressed and cured with the adhesive or adhesive film in the board-making process, and the butt-connected honeycomb core group 2 is bonded into one.

[0019] The honeycomb sandwich panel includes an outer skin 1 , a honeycomb core group 2 , and an inner skin 3 from outside to inside.

[0020] The honeycomb core is a NOMEX aramid fiber honeycomb.

[0021] The foam glue is a prepolymer composed of epoxy resin and foaming agent.

[0022] In this embodiment, a honeycomb core splicing method is used for splicing between hone...

Embodiment 2

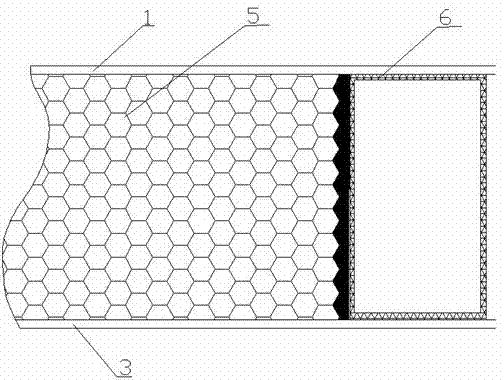

[0024] A honeycomb core splicing method of the present embodiment, the steps are as follows: Insert a strip of foam glue that meets the specified strength requirements between the honeycomb core 5 and the frame frame 6 of the honeycomb sandwich panel, and the foam glue is heated at a high temperature of the hot pressed board. It expands under heat at 130°C, and is simultaneously hot-pressed and solidified with the adhesive or adhesive film in the panel making process, bonding the butted honeycomb core 5 and frame frame 6 into one.

[0025] The honeycomb sandwich panel includes an outer skin 1 , a honeycomb core 5 and an inner skin 3 from outside to inside.

[0026] The honeycomb core is a NOMEX aramid fiber honeycomb.

[0027] The foam glue is a prepolymer composed of epoxy resin and foaming agent.

[0028] In this embodiment, a honeycomb core splicing method is used for splicing between the honeycomb core and the frame frame. The effect diagram is as follows image 3 As sho...

Embodiment 3

[0030] refer to figure 1 : A kind of honeycomb core splicing method of the present embodiment, the steps are as follows: insert between the honeycomb core groups 2 of the honeycomb sandwich panel (between the first honeycomb core 2-1 and the first honeycomb core 2-2) to meet the specified strength requirements The strip-shaped foam glue 4, the foam glue 4 is thermally expanded at the high temperature of 125° C. of the hot-pressed board, and is simultaneously hot-pressed and cured with the adhesive or film in the board-making process, and the butt-connected honeycomb core group 2 is bonded into one.

[0031] The honeycomb sandwich panel includes an outer skin 1 , a honeycomb core group 2 , and an inner skin 3 from outside to inside.

[0032] The honeycomb core is a NOMEX aramid fiber honeycomb.

[0033] The foam glue is a prepolymer composed of epoxy resin and foaming agent.

[0034] In this embodiment, a honeycomb core splicing method is used for splicing between honeycomb c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com