Heat-expandable removable pressure-sensitive adhesive tape or sheet, and method of removing the same

A technology of heating foaming and adhesive tapes, applied in the direction of bonding methods using foaming adhesives, heat-activated films/sheets, chemical instruments and methods, etc., which can solve problems such as not being easy to separate and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1)

[0212] 90 parts by weight of 2-ethylhexyl acrylate, 10 parts by weight of acrylic acid, 0.05 parts by weight of a photoinitiator (trade name "Irgacure184", manufactured by BASF Japan Co., Ltd.), a photoinitiator (trade name "Irgacure651", BASF Japan Co., Ltd.) 0.05 parts by weight was put into a four-necked flask, and photopolymerized by exposure to ultraviolet rays in a nitrogen atmosphere to obtain a partially polymerized monomer slurry with a polymerization rate of 7%.

[0213] To 100 parts by weight of the partially polymerized monomer slurry was added 30 parts by weight of a thermal foaming agent (heat-expandable microspheres, trade name "マツモチマィクロスフェマF-80SD", manufactured by Matsumoto Oil & Oil Pharmaceutical Co., Ltd.), trimethylol 0.2 parts by weight of propane triacrylate was uniformly mixed to obtain a thermal foaming agent-containing adhesive composition (sometimes referred to as "thermal foaming agent-containing adhesive composition (A)").

[0214] (Preparation exam...

preparation example 1

[0218] 90 parts by weight of 2-ethylhexyl acrylate, 10 parts by weight of acrylic acid, 0.05 parts by weight of a photoinitiator (trade name "Irgacure184", manufactured by BASF Japan Co., Ltd.), a photoinitiator (trade name "Irgacure651", BASF Japan Co., Ltd.) 0.05 parts by weight was put into a four-necked flask, and photopolymerized by exposure to ultraviolet rays in a nitrogen atmosphere to obtain a partially polymerized monomer slurry with a polymerization rate of 7%.

[0219] 0.2 part by weight of trimethylolpropane triacrylate was added to 100 parts by weight of the partially polymerized monomer syrup, and the mixture was uniformly mixed to obtain an adhesive composition (sometimes referred to as "adhesive composition (A)" ”).

[0220] (Example 1 of the use of process spacers)

[0221] As a process spacer, a polyester film (trade name "MRN-38", manufactured by Mitsubishi Plastics Co., Ltd.) (sometimes called a process spacer ( A)).

[0222] (Example 2 of the use of pr...

Embodiment 1)

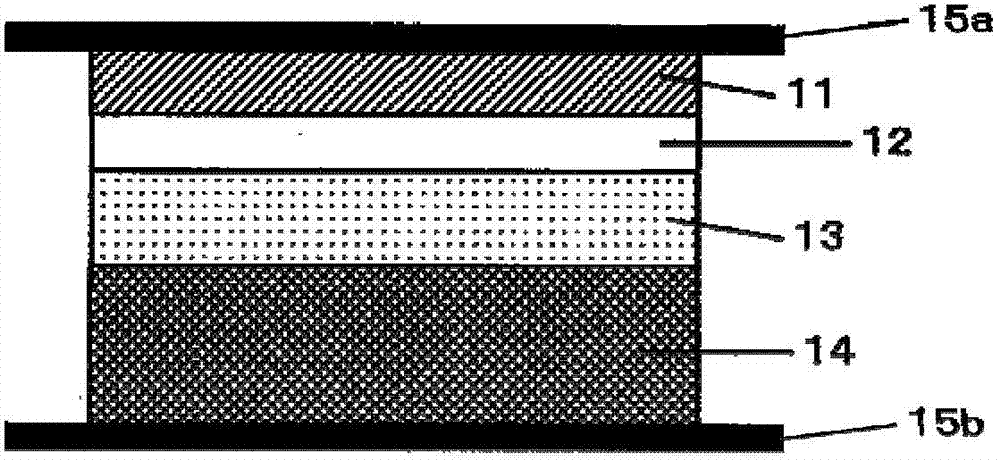

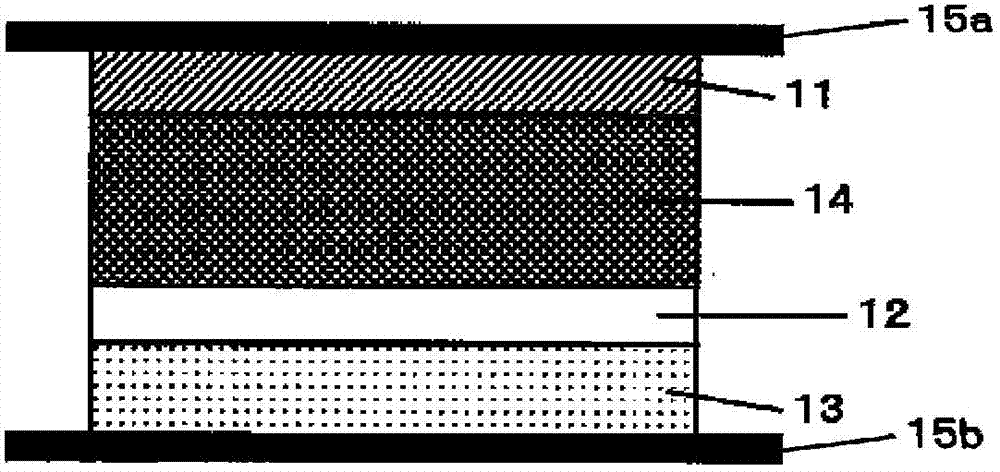

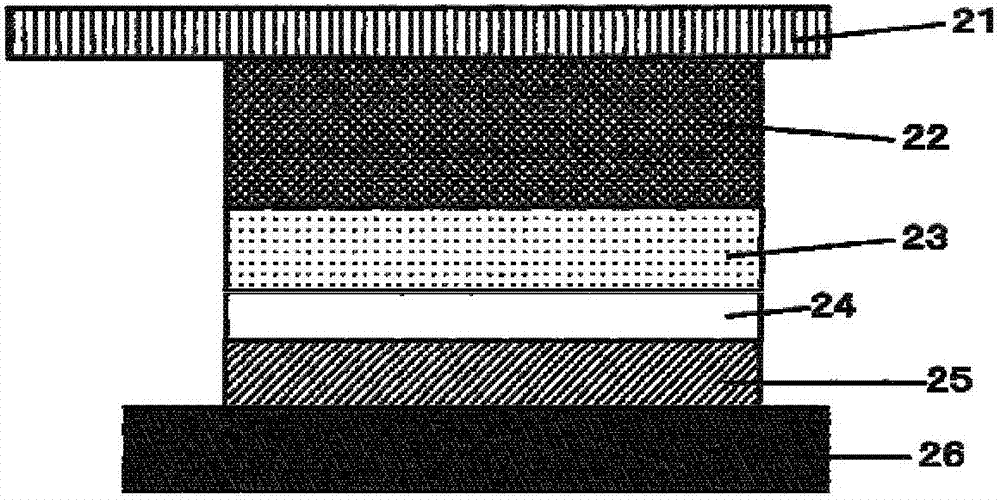

[0240] An adhesive layer sheet (A) having an adhesive layer exposed by peeling off one process spacer (B) was adhered on one surface side of the peelable film (A) under the following adhesion conditions to obtain a process spacer having a process spacer (B). (B) / Adhesive layer / Peelable film (A) Single-sided adhesive sheet of a laminated structure.

[0241] Then, on the peelable film (A) side surface of this single-sided pressure-sensitive adhesive sheet, under the following sticking conditions, a thermal foaming agent-containing pressure-sensitive adhesive layer having a thermal foaming agent-containing pressure-sensitive adhesive layer exposed by peeling off the process separator (B) was stuck. A sheet with a laminated structure of a microparticle-containing viscoelastic base material containing air bubbles and a thermal foaming agent-containing adhesive layer to obtain a process separator (B) / adhesive layer / peelable film (A) / thermal foaming agent-containing Foaming agent adh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com