Solventless compounding and coating of non-thermoplastic hydrocarbon elastomers

a technology of non-thermoplastic hydrocarbon elastomers and solvent-free compounding, which is applied in the direction of adhesive processes using foamed adhesives, adhesive types, film/foam adhesives, etc., can solve the problem that no oxygen-available gas is intentionally injected into the compounding device, and achieves the problem of elastomer crosslinking during processing, short time period, and reduced molecular weight of elastomer reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

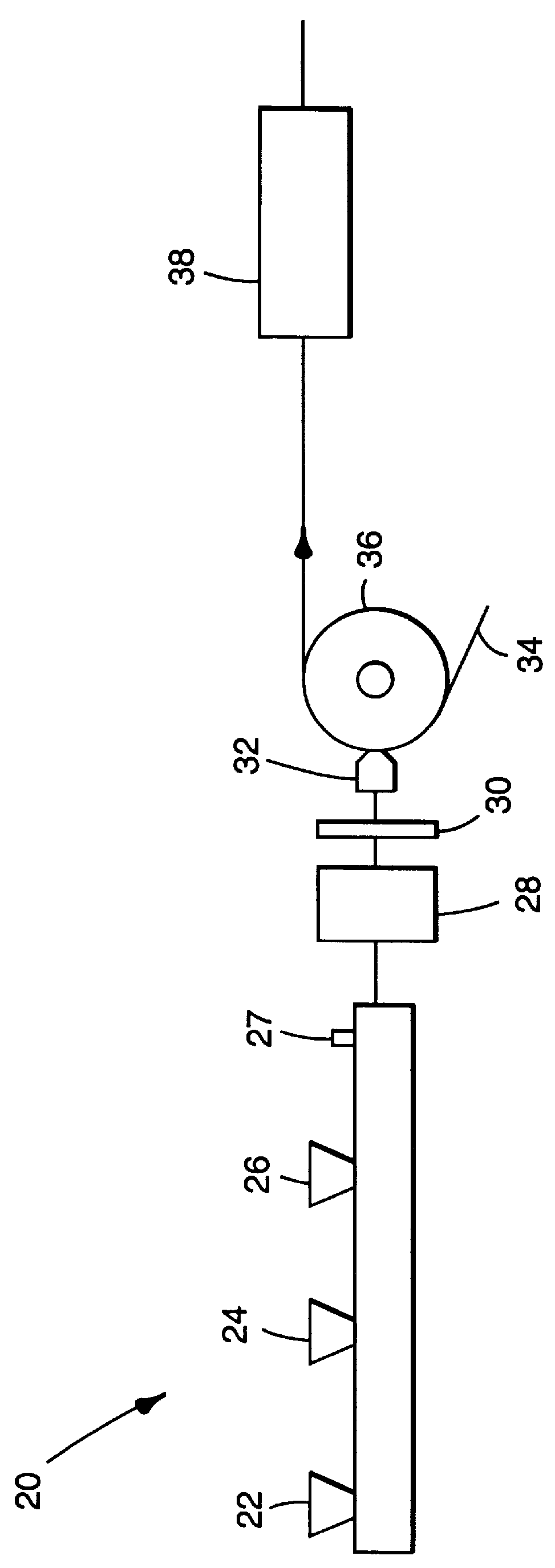

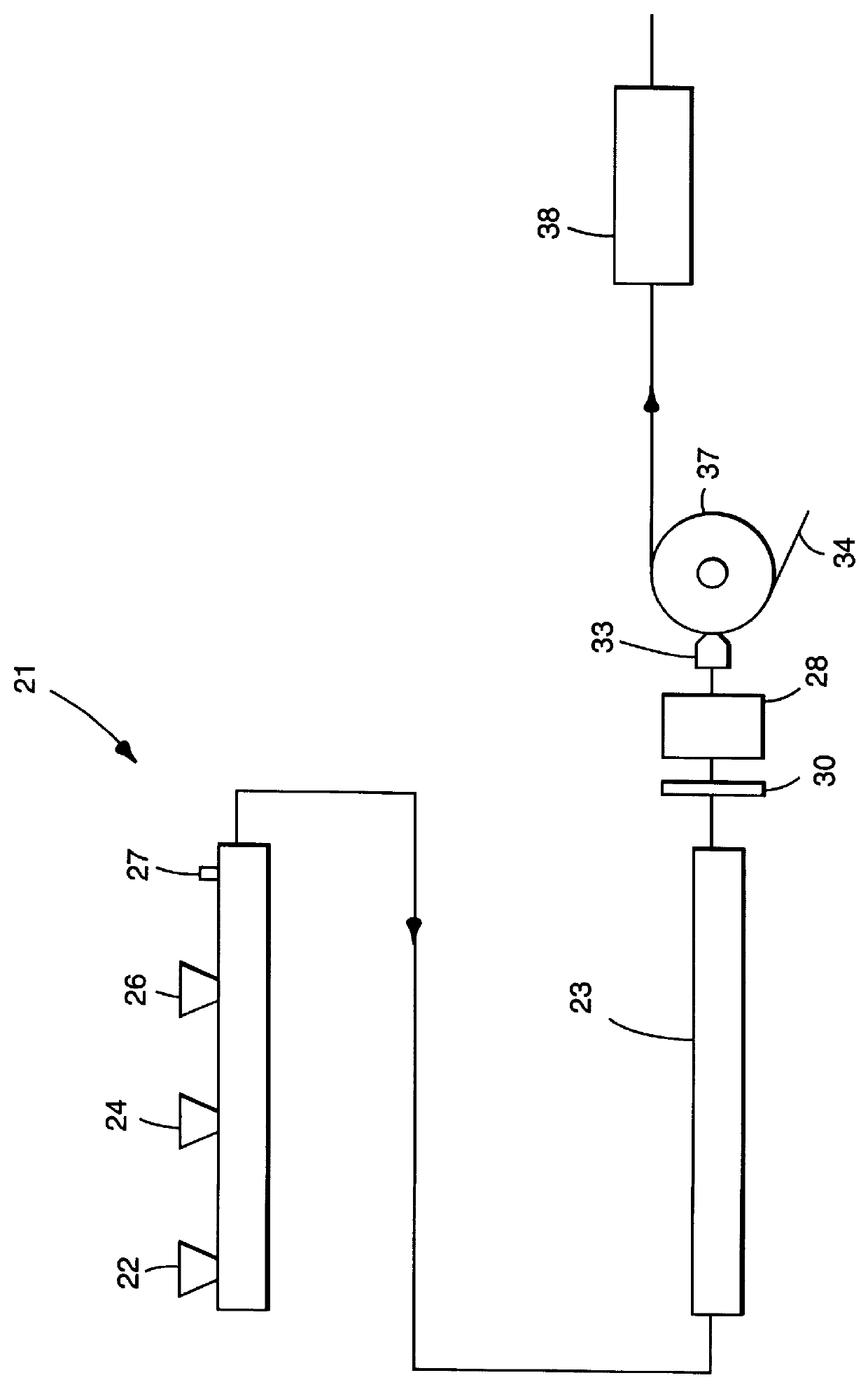

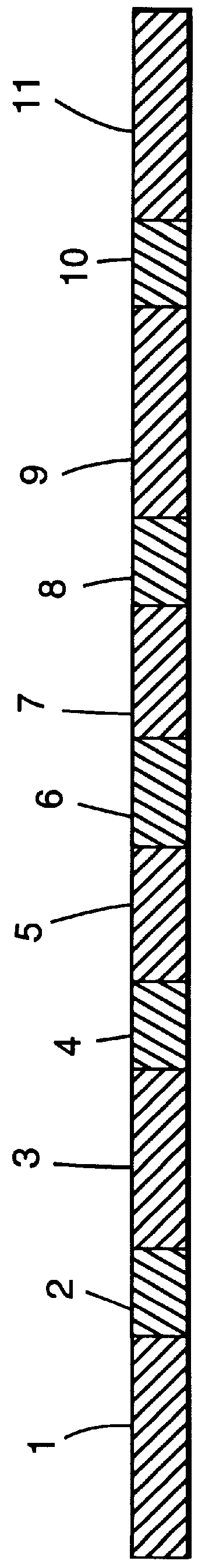

Natsyn.TM. 2210 synthetic polyisoprene (available from Goodyear Tire and Rubber Co.) was pelletized using a Moriyama pelletizer and dusted with talc. This material was then fed to .[.Zone.]. .Iadd.Section .Iaddend.1 of the .[.twin screw.]. .Iadd.screw, shown in FIG. 3 which was installed in the .Iaddend.extruder 20 .Iadd.of FIG. 1, .Iaddend.at a rate of 68.0 g / min using a K-Tron loss-in-weight feeder which continuously monitored the weight of the material in the hopper. The elastomer and talc were transported from .[.Zone.]. .Iadd.Section .Iaddend.1 to .[.Zone.]. .Iadd.Section .Iaddend.2 .[.by.]. .Iadd.of .Iaddend.the screw and was masticated in .[.Zone.]. .Iadd.Section .Iaddend.2. The elastomer was transported through .[.zones.]. .Iadd.Section .Iaddend.3 .[.and.]. .Iadd.to Section .Iaddend.4 where additional mastication occurred, to .[.zone.]. .Iadd.Section .Iaddend.5 where a sample of the elastomer was removed and found to have an inherent viscosity (IV) of 2.68 dl / g in toluene me...

example 2

Example 1 was repeated except that after being coated onto the creped paper backing, the backing continued to move at 30 ft / min (9.1 m / min) and the adhesive layer was exposed in line to electron beam radiation at a dose of 6 MRads. The irradiated PSA masking tape had improved cohesive strength.

example 3

The equipment and conditions employed in Examples 1 were repeated in Example 3 with the following exceptions. Smoked sheet natural rubber

(available from The Ore and Chemical Company, Inc.) was ground to particles approximately one quarter inch (0.63 cm) in diameter and dusted with talc. The rubber particles were fed to .[.Zone.]. .Iadd.Section .Iaddend.1 of the .[.twin screw.]. .Iadd.screw, shown in FIG. 3 which was installed in the .Iaddend.extruder 20 .Iadd.of FIG. 1.Iaddend., at a rate of 68.0 g / min. The elastomer and talc were transported from .[.Zone.]. .Iadd.Section .Iaddend.1 to .[.Zone.]. .Iadd.Section .Iaddend.2. The elastomer was masticated there and was then transported through .[.zones.]. .Iadd.Section .Iaddend.3 .[.and.]. .Iadd.to Section .Iaddend.4, where additional mastication occurred, to .[.zone.]. .Iadd.Section .Iaddend.5 where a sample of the elastomer was removed and found to have an inherent viscosity of 4.7 dl / g in toluene measured at a concentration of 0.15 g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com