Heat strippable pressure-sensitive adhesive sheet for electronic element, method for producing electronic element and electronic element

A pressure-sensitive adhesive, pressure-sensitive adhesive layer technology, applied in the direction of bonding methods using foamed adhesives, film/sheet-like adhesives, electrical components, etc., can solve the problem of increased pollution, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The preparation of the heat-expandable layer can be carried out by, for example, a conventional method comprising mixing heat-expandable microspheres and an adhesive such as a pressure-sensitive adhesive and optional components such as solvents and other additives, and forming the mixture into a sheet-like layer . Specifically, for example, the heat-expandable layer can be prepared by coating a mixture containing heat-expandable microspheres, an adhesive such as a pressure-sensitive adhesive, and optional other components such as a solvent onto a substrate or rubber or apply the mixture to a suitable backing (such as release paper) to form a thermally expandable layer, and transfer this layer to a substrate or a rubbery organic elastic layer. The thermally expandable layer may have a single-layer or multi-layer structure.

[0068] The thickness of the heat-expandable layer can be appropriately selected depending on the desired degree of adhesion reduction and the like....

Embodiment 1

[0125] Add 50 parts by weight of n-butyl acrylate, 50 parts by weight of 2-ethylhexyl acrylate, 5 parts by weight of acrylic acid, 0.1 parts by weight of 2,2'-azobisisobutyronitrile, and 200 parts by weight of ethyl acetate into 500ml Equipped with a thermometer, a stirrer, a nitrogen introduction tube and a three-necked flask with a reflux condenser, so as to obtain a total amount of 200 g. The resulting mixture was stirred for about 1 hour while nitrogen gas was blown thereinto, thereby replacing the air in the reactor with nitrogen gas. After that, the temperature in the reactor was adjusted to 58°C, and the reaction mixture was kept in this state for about 4 hours to conduct polymerization. Thus, an acrylic polymer (often referred to as "acrylic copolymer A") is obtained.

[0126] Add 2 parts by weight of isocyanate crosslinking agent to the ethyl acetate solution containing 100 parts by weight of acrylic copolymer A and prepare the acrylic pressure-sensitive adhesive and...

Embodiment 2

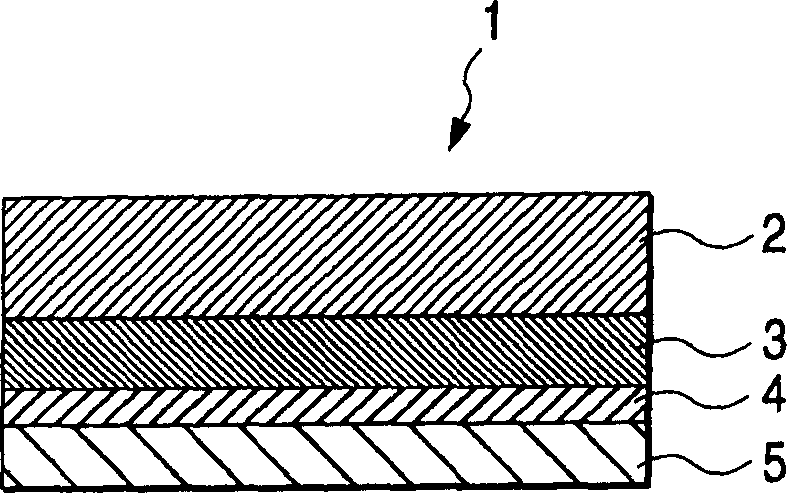

[0130] The same thermally expandable layer as in Example 1 (thickness 40 μm) was formed on one side of a 50 μm thick PET film in the same manner as in Example 1. A non-heat-expandable pressure-sensitive adhesive layer (stain-resistant, radiation-curable adhesive layer) (thickness 2 µm) formed by the method described below was transferred onto the heat-expandable layer. Thus, it is formed as figure 1 Heat-peelable pressure-sensitive adhesive sheet of the construction shown.

[0131] Non-thermally expandable pressure-sensitive adhesive layer B:

[0132] 100 parts by weight of acrylic urethane, 3 parts by weight of isocyanate crosslinking agent and 3 parts by weight of radiation curing initiator (photopolymerization initiator) were added to 100 parts by weight of acrylic type copolymer B and prepared acrylic pressure sensitive The adhesive was applied to the liner at a thickness of 2 μm on a dry basis and allowed to dry. Thus, a non-heat-expandable pressure-sensitive adhesive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com