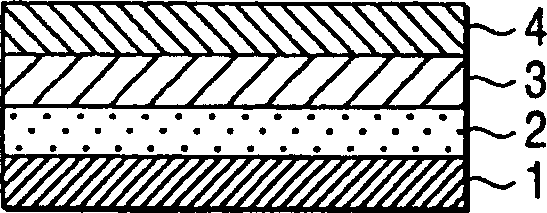

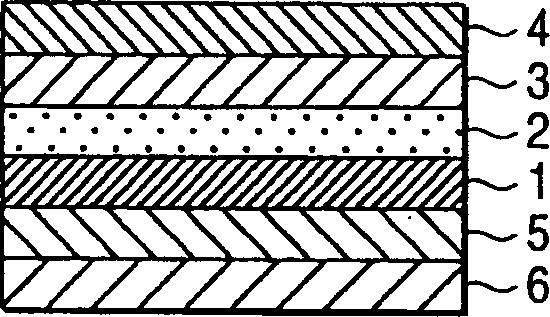

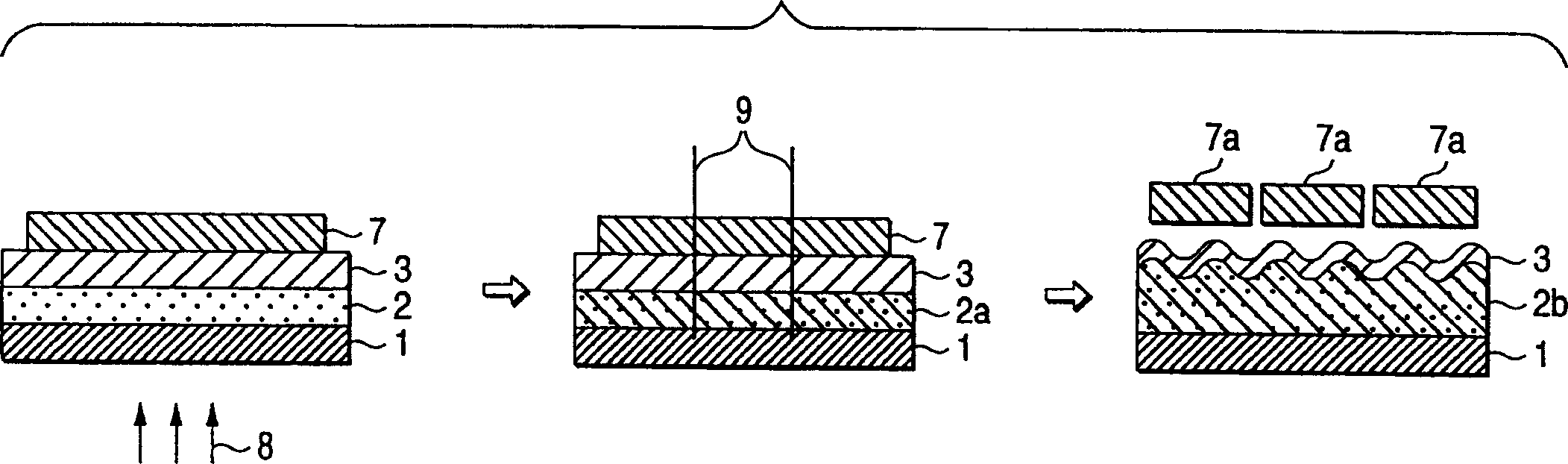

Energy-beam curable thermal-releasable pressure-sensitive adhesive sheet and method for producing cut pieces using the same

A pressure-sensitive adhesive, thermal peeling technology, applied in the direction of bonding method using foam adhesive, chemical instrument and method, adhesive heating bonding method, etc., can solve the adhesive pollution, damage, etc. Smoothness, fine bond failures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] By adding 0.5 parts by weight of an epoxy crosslinking agent, 40 parts by weight of a hexa-functional ultraviolet polymerizable compound, and 35 parts by weight of heat-expandable microspheres ("Matsumot Microspheres F-50 D", trade name; Matsumoto Yushi-Seiyaku Co. Ltd. The product of .) and 2.5 parts by weight of ultraviolet polymerization initiators are added in 100 parts by weight of acrylic copolymer (weight average molecular weight: 700000) to prepare mixture solution 1, and described acrylic acid copolymer is made of 80 parts by weight of ethyl acrylate, 20 parts by weight of acrylic acid 2-ethylhexyl ester and 3 parts by weight of acrylic acid. The resulting mixture solution was applied on the surface of a corona-treated polyester film (substrate) to a thickness of 50 μm, followed by drying, whereby a 45 μm thick acrylic ultraviolet curable viscoelastic layer was formed.

[0054] A mixed solution 2 consisting of 100 parts by weight of the above-mentioned acrylic ...

Embodiment 2

[0063] By adding 3 parts by weight of an energy beam polymerization initiator and 30 parts by weight of heat-expandable microspheres ("Matsumot microspheres F-50 D", trade name; product of Matsumoto Yushi-Seiyaku Co. Ltd.) to 100 parts by weight of the energy beam active A mixed solution 3 was prepared in a polymer (weight average molecular weight: 600000) in which the energy beam active polymer was composed of 70 parts by weight of ethyl acrylate, 30 parts by weight of butyl acrylate and 8 parts by weight of 2-hydroxyethyl acrylate. Acrylic copolymer is obtained by adding methacryloxy isocyanate with 2-hydroxyethyl equivalent of 0.6 (molar ratio). In a similar manner to Example 1 except that this mixture solution was used, an energy beam curable thermally expandable viscoelastic layer was formed.

[0064] In a similar manner to Example 1, except that mixed solution 4 obtained by adding 3 parts by weight of an energy beam polymerization initiator to 100 parts by weight of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com