Hot-curing epoxy resin compositions that can be used as bodyshell adhesive or structural foam

A solid epoxy resin, epoxy resin technology, used in the field of skeleton construction adhesives, structural reinforcements and structural foams, can solve problems such as deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

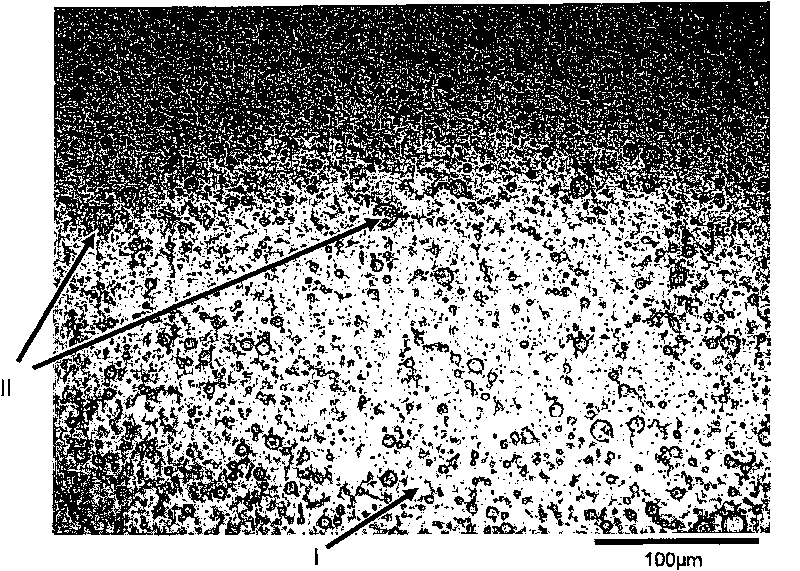

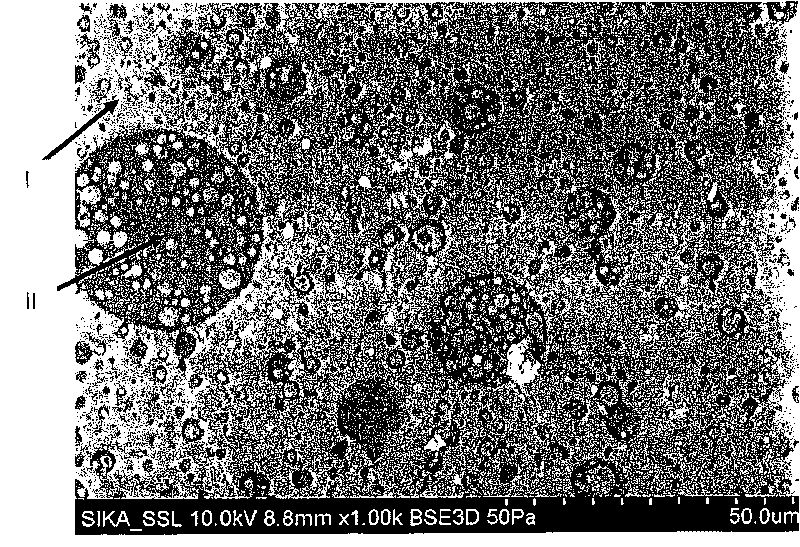

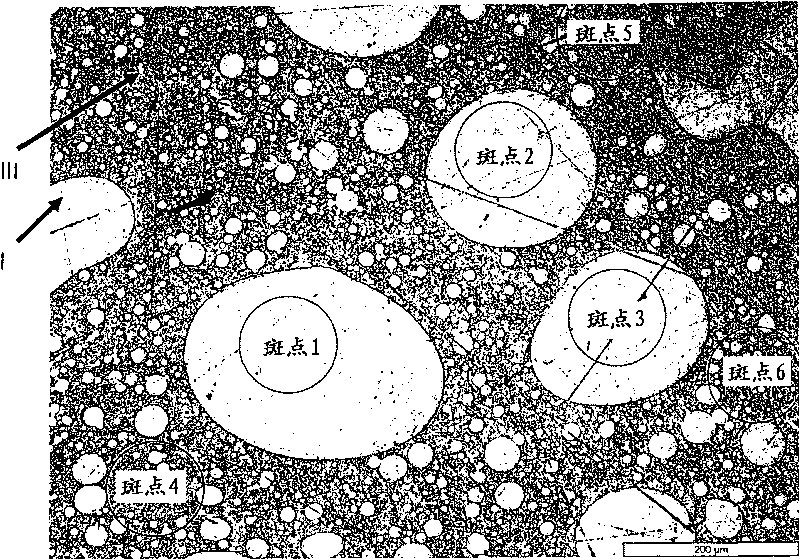

Image

Examples

Embodiment

[0189] Some examples will be described below, which further illustrate the invention, but are in no way intended to limit the scope of the invention in any way. The raw materials used in the examples are listed in Table 1.

[0190]

[0191]

[0192] Table 1. Raw materials used

[0193] Compositions were prepared from the ingredients indicated in Tables 2 and 3 in parts by weight. Comparative Example Ref. 1 is Example 4A of US 6387470 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com