Heat-peelable pressure-sensitive adhesive sheet for cutting laminated ceramic sheet and method for cut-processing laminated ceramic sheet

A pressure-sensitive adhesive sheet, a technology of a pressure-sensitive adhesive layer, applied in the direction of an adhesive method using a foaming adhesive, an adhesive method, a film/sheet-shaped adhesive, etc., capable of solving a decrease in productivity , product defects and other problems, to achieve or prevent pollution, excellent productivity, excellent thermal peeling effect

Active Publication Date: 2010-08-25

NITTO DENKO CORP

View PDF10 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When the accuracy drops in any of these steps, the product becomes bad and the productivity drops

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

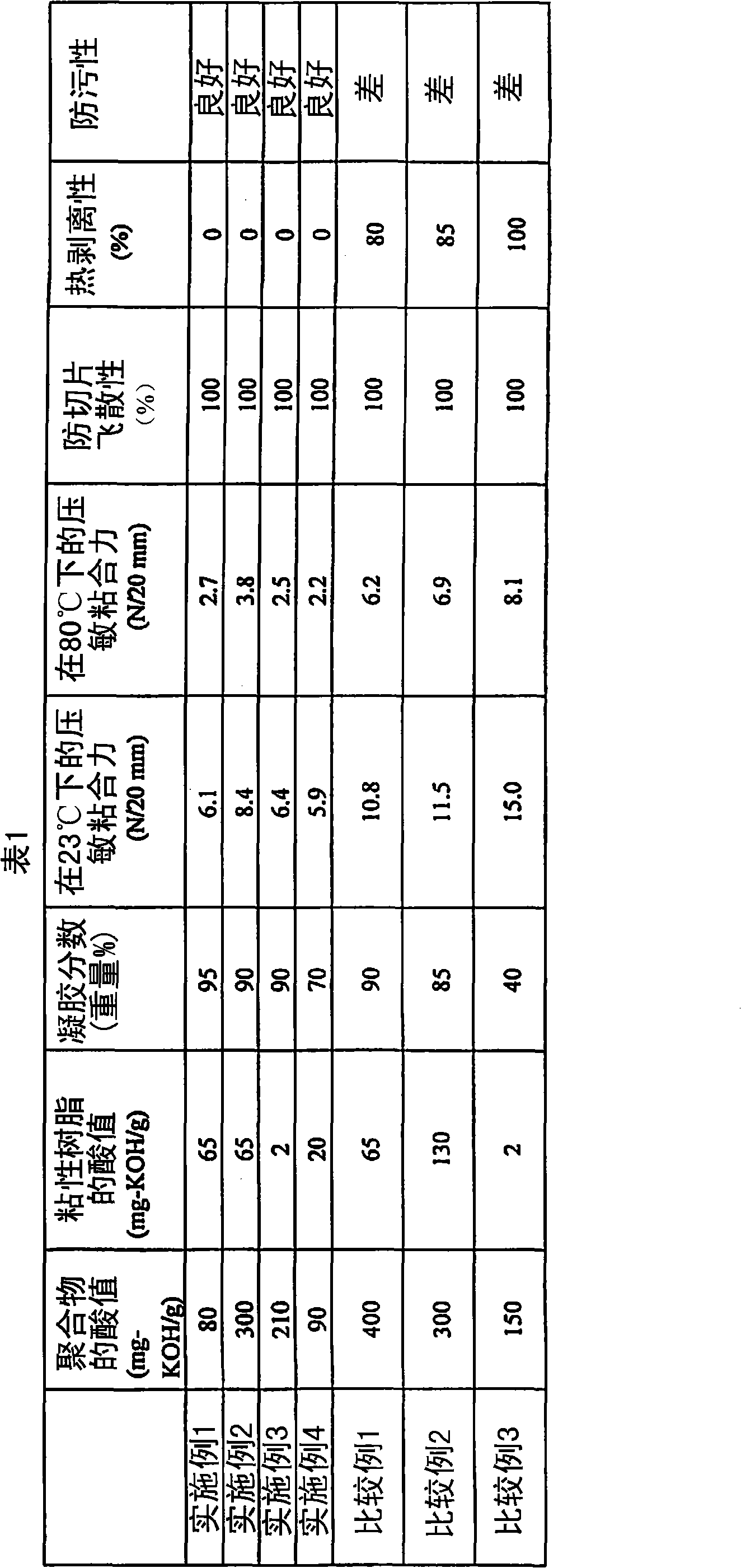

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

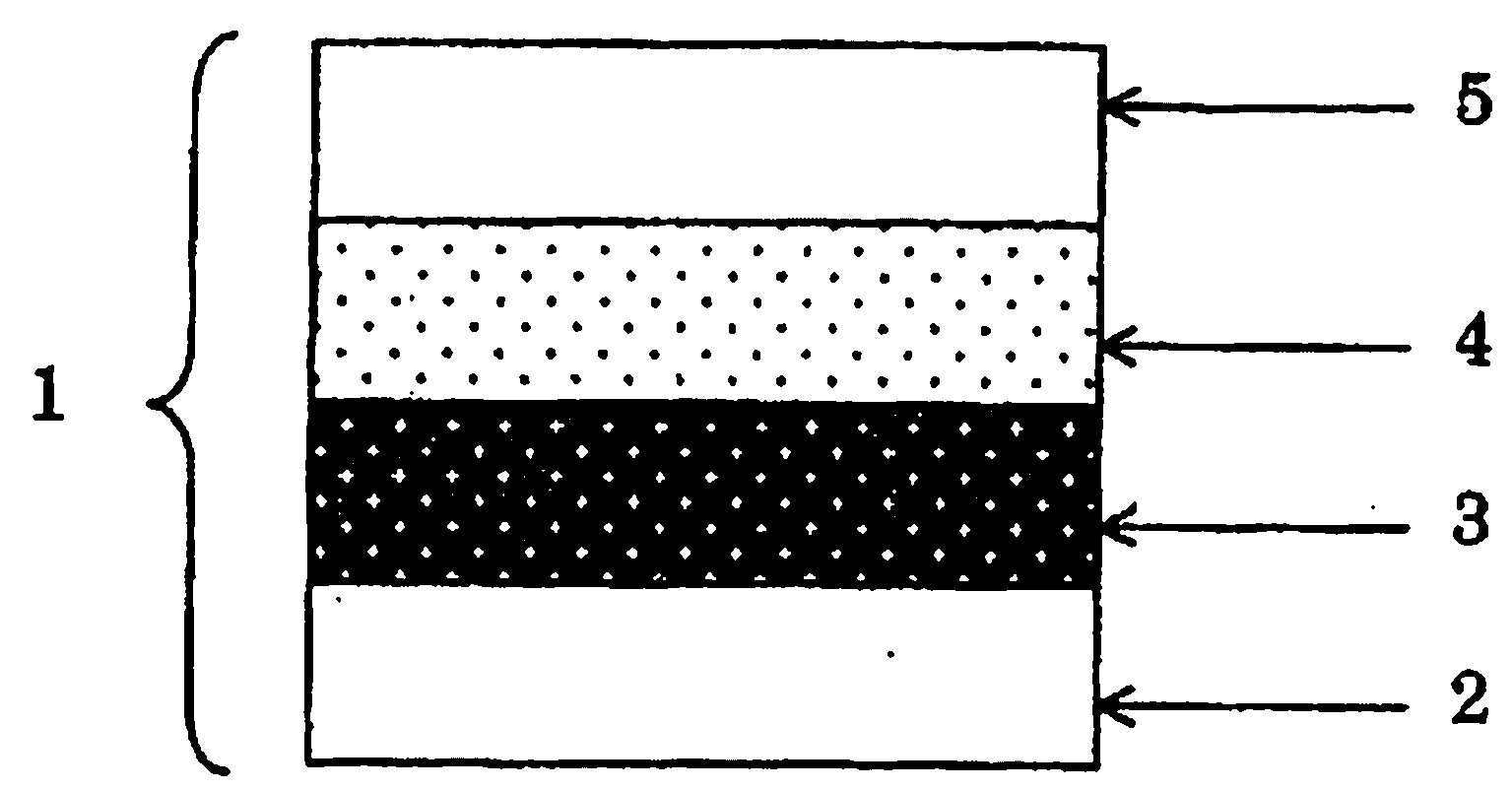

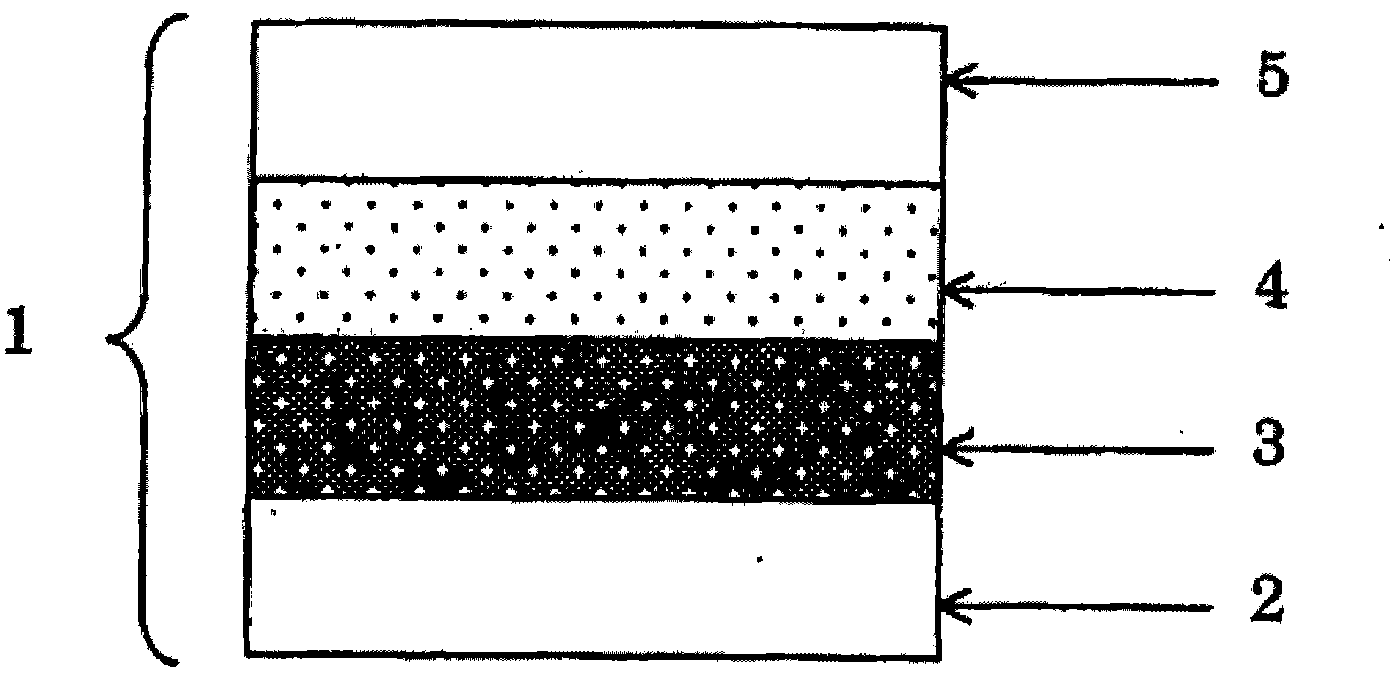

The invention relates to a heat-peelable pressure-sensitive adhesive sheet for cutting a laminated ceramic sheet and a method for cut-processing a laminated ceramic sheet. The heat-peelable pressure-sensitive adhesive sheet for cutting a laminated ceramic sheet is used for temporary fixing at cutting of the laminated ceramic sheet, and includes a base material and, formed on at least one surface of the base material, a heat-expandable pressure-sensitive adhesive layer containing a pressure-sensitive adhesive, a foaming agent and a tackifying resin, in which the heat-expandable pressure-sensitive adhesive layer has a gel fraction of 50% by weight or more, and the base polymer of the pressure-sensitive adhesive forming the heat-expandable pressure-sensitive adhesive layer has an acid value of 350mg-KOH / g or less and the tackifying resin contained in the heat-expandable pressure-sensitive adhesive layer has an acid value of 80mg-KOH / g or less.

Description

technical field The present invention relates to a heat-peelable pressure-sensitive adhesive sheet for cutting a laminated ceramic sheet and a method for cutting and processing a laminated ceramic sheet using the heat-peelable pressure-sensitive adhesive sheet. Background technique The recent demand for electronic components is miniaturization and precision of the components themselves. For example, in ceramic capacitors, typified by so-called "0603" or so-called "0402", miniaturization and high-capacity formation through high-level lamination of layers exceeding several hundred or more have become remarkable. In particular, in the field of lamination of prebaked sheets (green sheets) of ceramics such as ceramic capacitors, precision in processing is increasingly required for miniaturization and precision. For example, as an example of a method for producing a ceramic capacitor, a production method including the following steps is mentioned: (1) a step of printing electrod...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09J7/02C09J133/00B28D1/22C09J7/22C09J7/38

CPCC09J2205/11C09J2400/123C08L33/064C09J133/08C09J7/0246C09J5/00C09J2433/00C08L33/08C09J2203/326C09J2201/606C09J2205/302C09J7/38C09J7/22Y10T156/108Y10T428/1452C09J2301/412C09J2301/502C09J2301/302C09J7/35C09J5/08C09J11/00

Inventor 柳雄一朗下川大辅有满幸生

Owner NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com