Filling structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

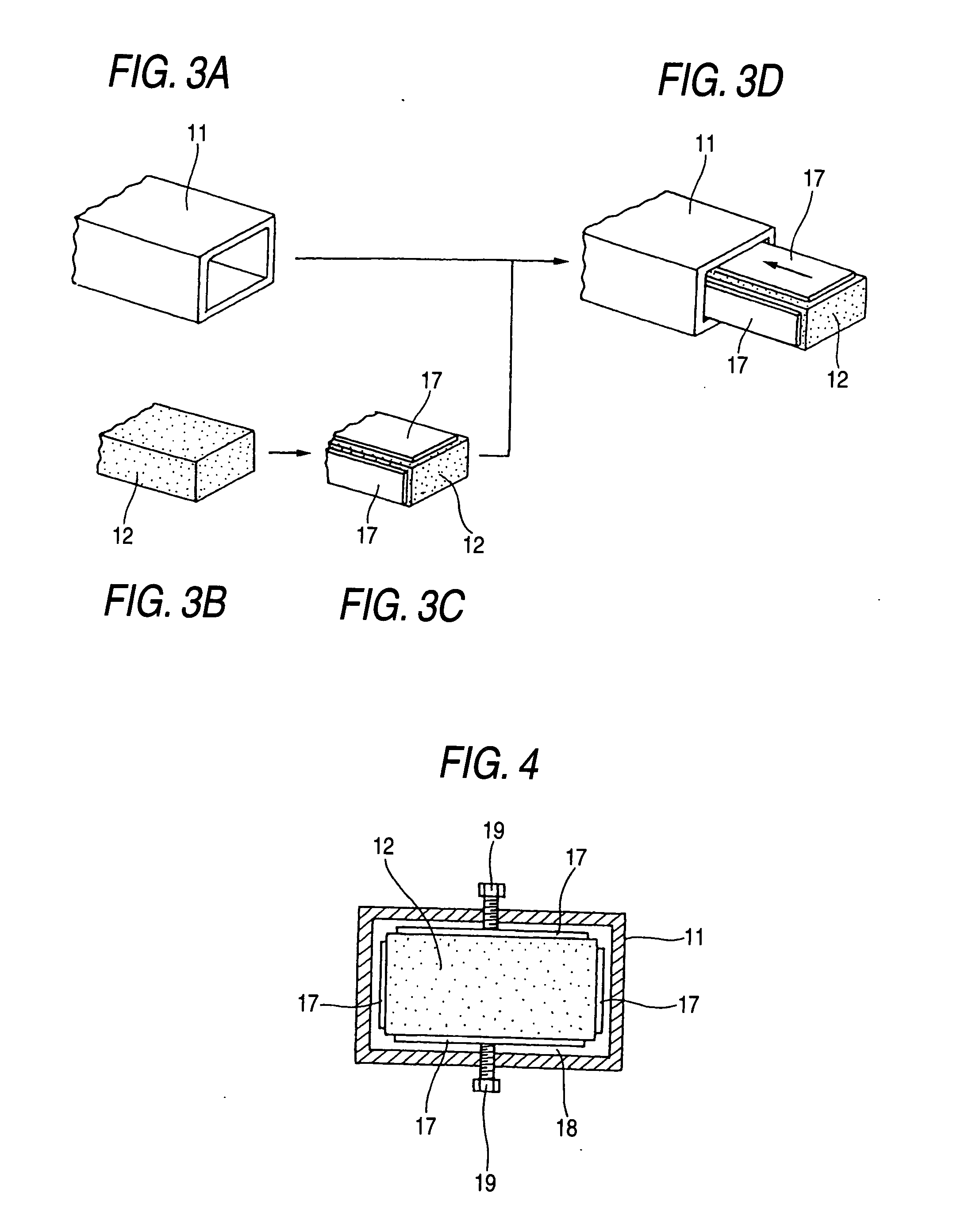

[0027] Hereinafter, a best mode for carrying out the invention will be described based on the accompanying drawings.

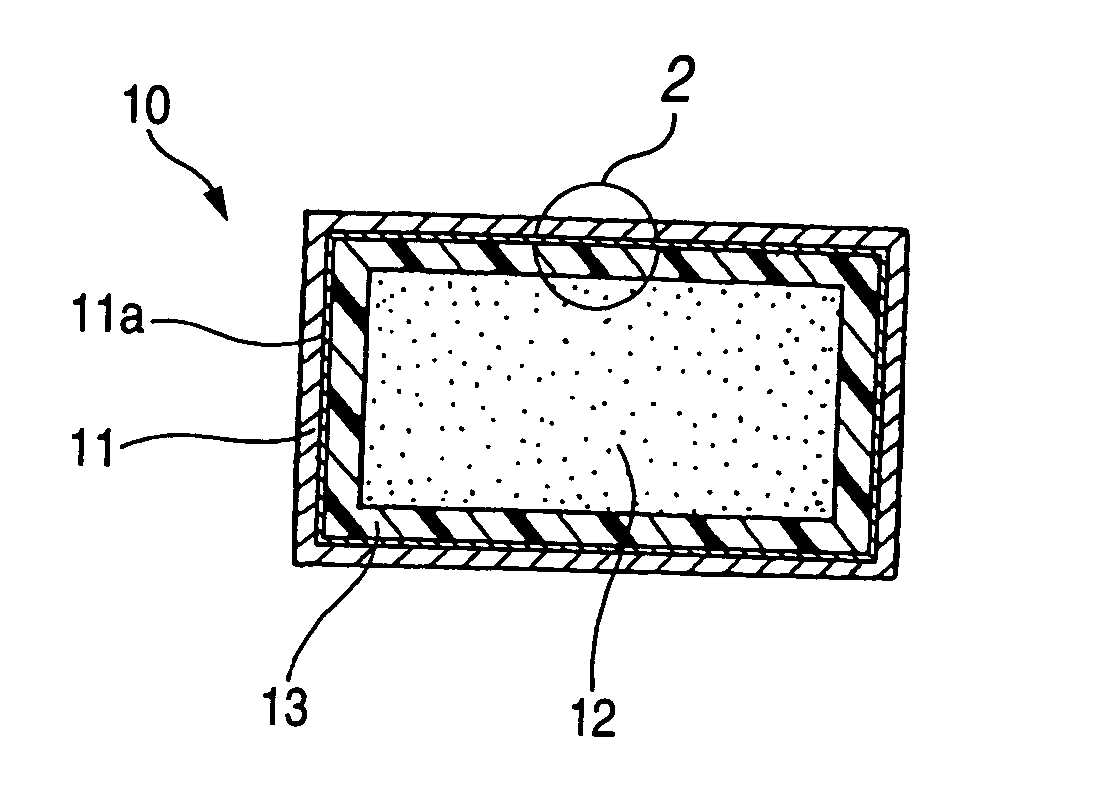

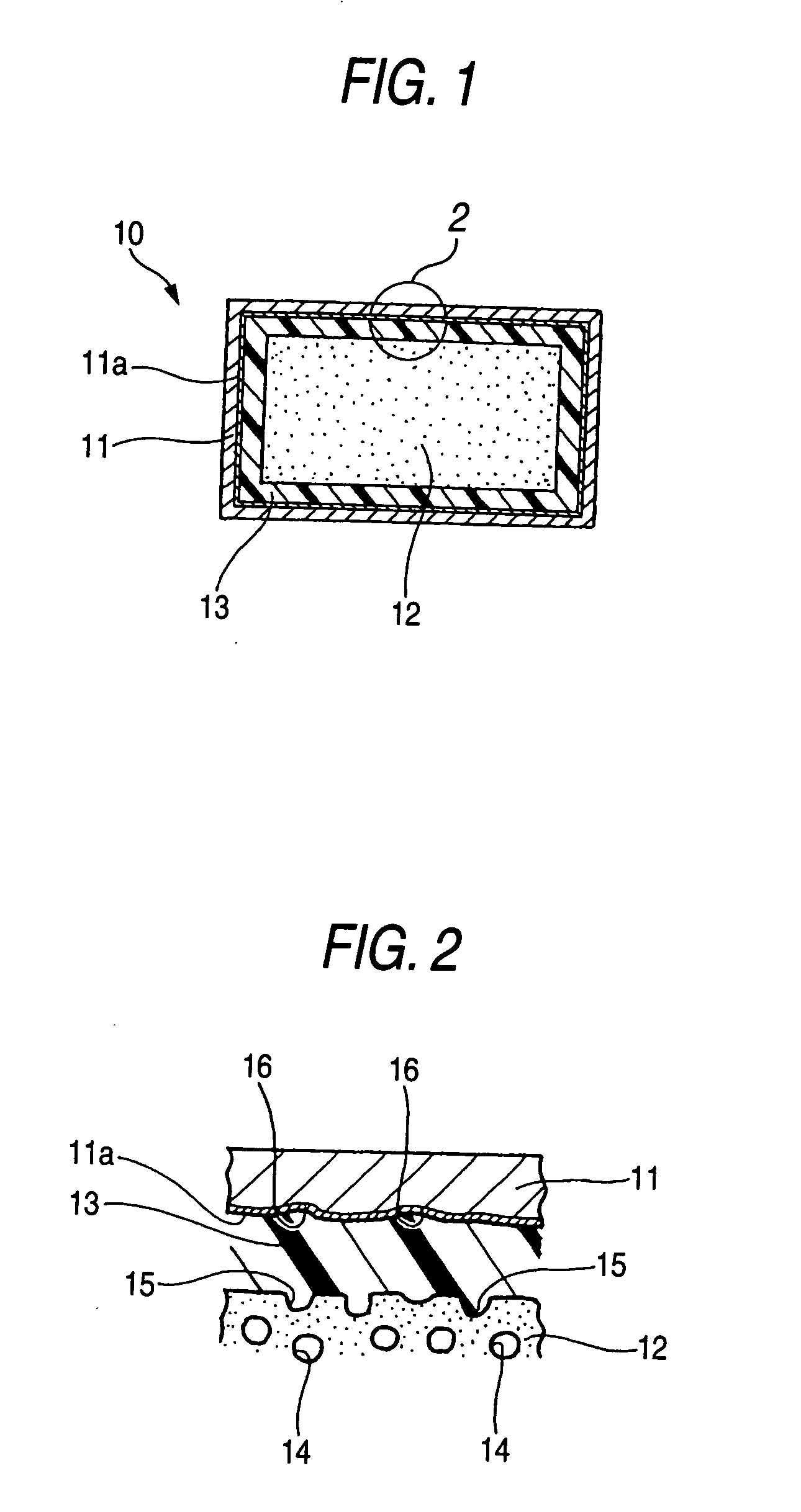

[0028]FIG. 1 is a cross-sectional view of a filling structure according to the invention, and a filling structure 10 is a structure in which a filling material 12 having a higher impact energy absorbing performance is inserted into the inner part of a hollow member 11 whose inner part surface is provided with a layer to which a corrosion protection treatment is applied, and the filling material 12 is fixed to the hollow member 11 with an adhesive layer 13 which results when the filling material 12 expands by being heated and sets thereafter.

[0029] The hollow member 11 is an extruded material produced by extruding a metallic ingot, a pressed product obtained by applying a plastic working on a sheet metal with a pressing machine, or a tubular member obtained in other manufacturing methods. An aluminum alloy, zinc alloy, iron alloy or other materials can be adopted as a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com