Patents

Literature

52results about How to "Reliable corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

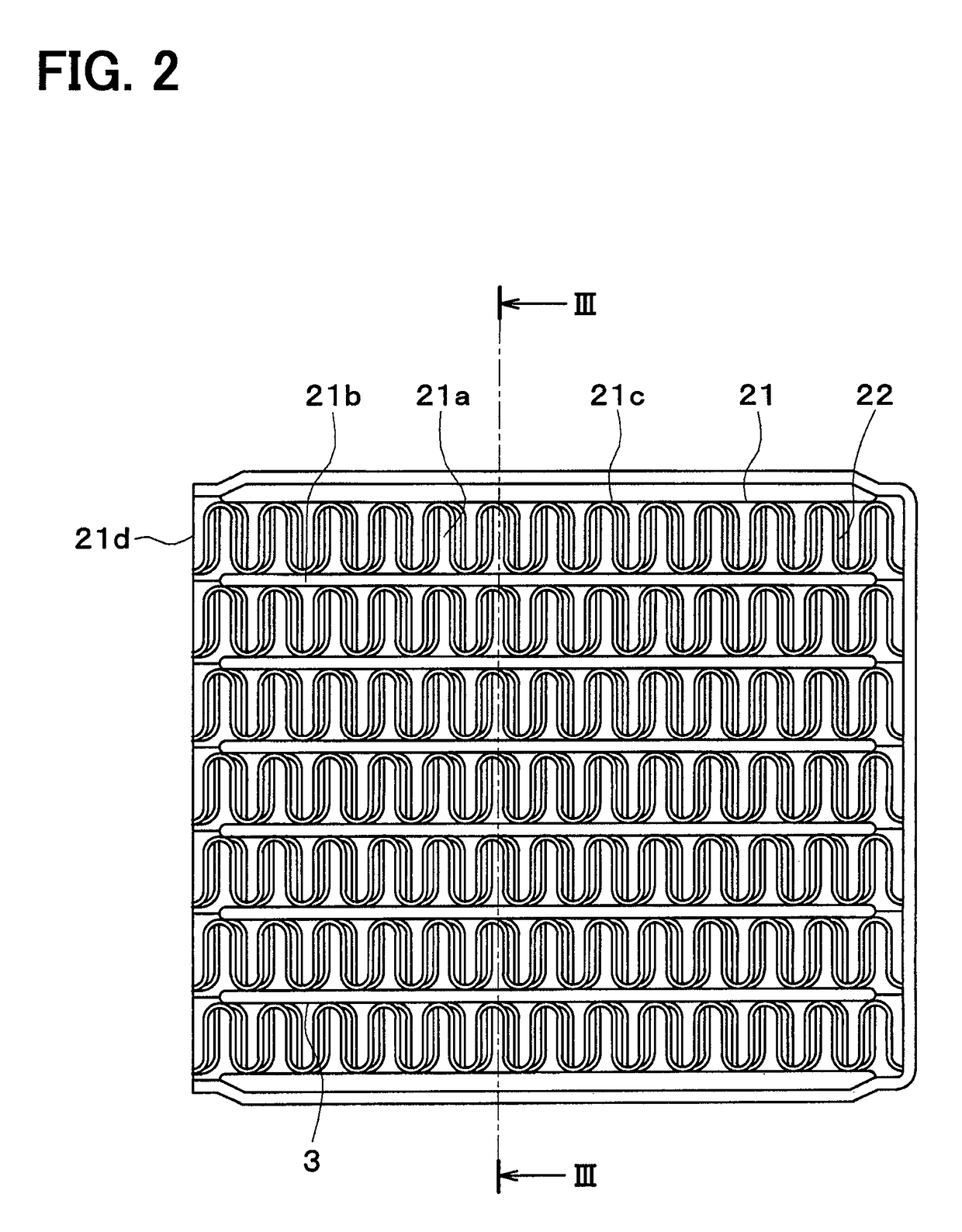

Heat exchanger

InactiveUS6988539B2Accelerated corrosionCorrosion resistanceSoldering apparatusCorrosion preventionPlate heat exchangerEngineering

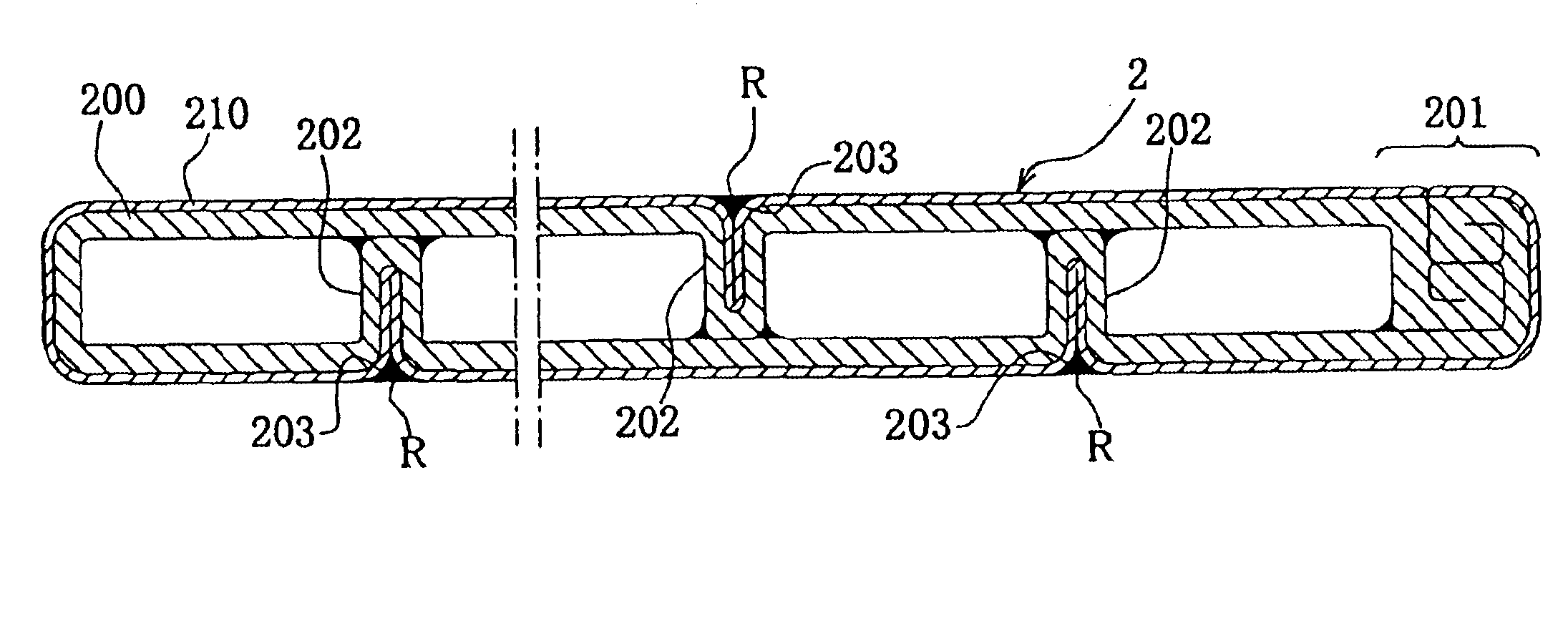

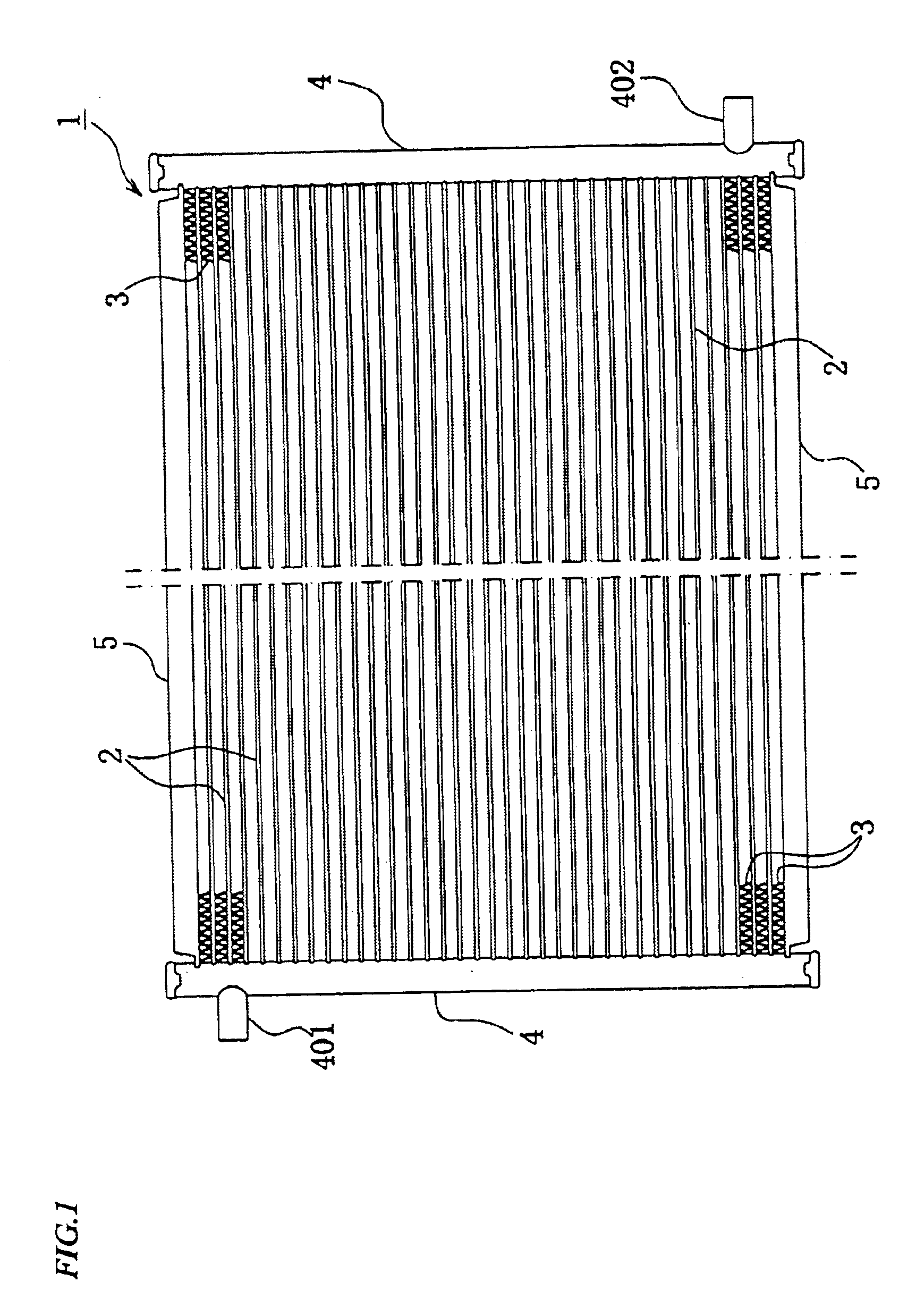

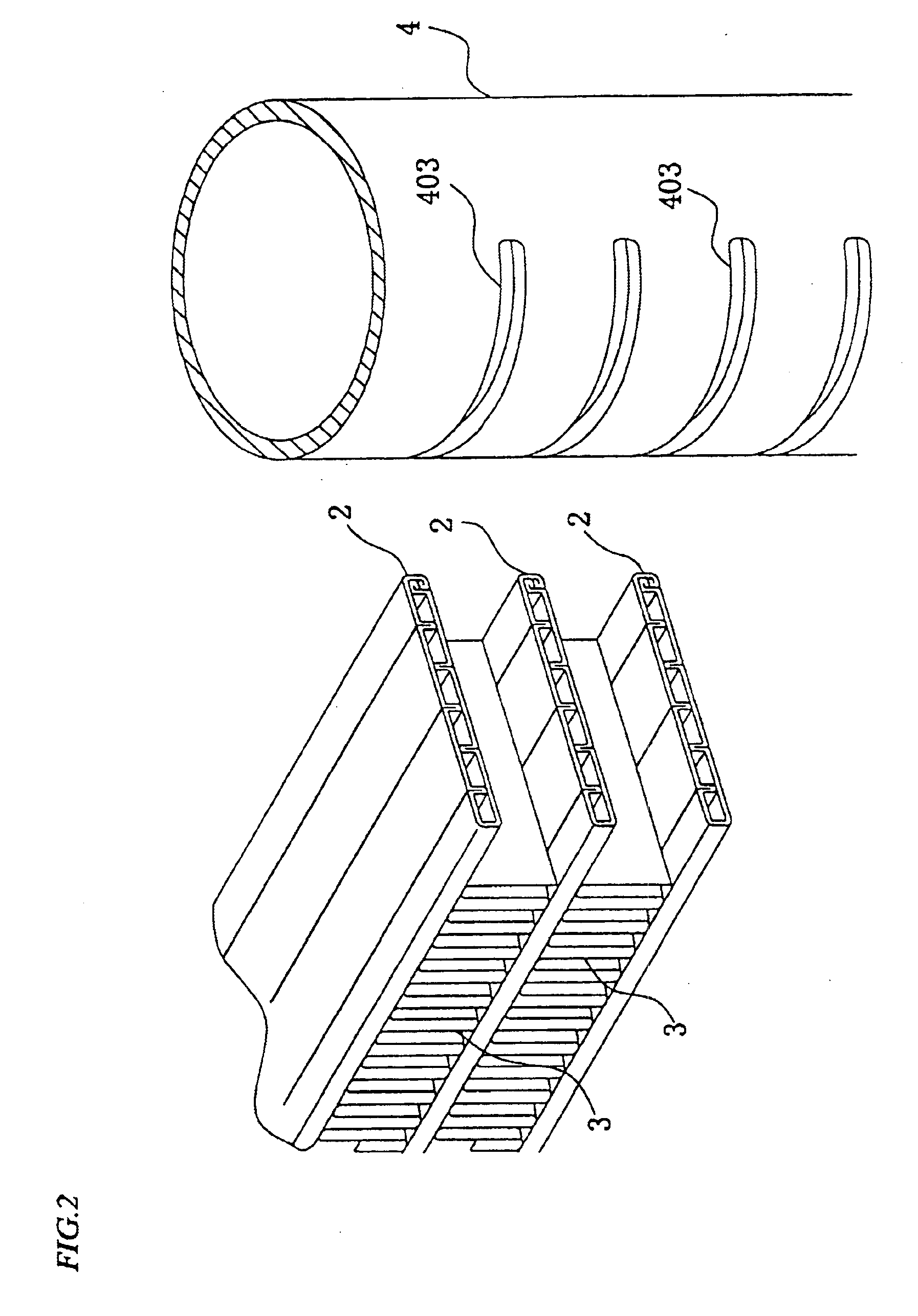

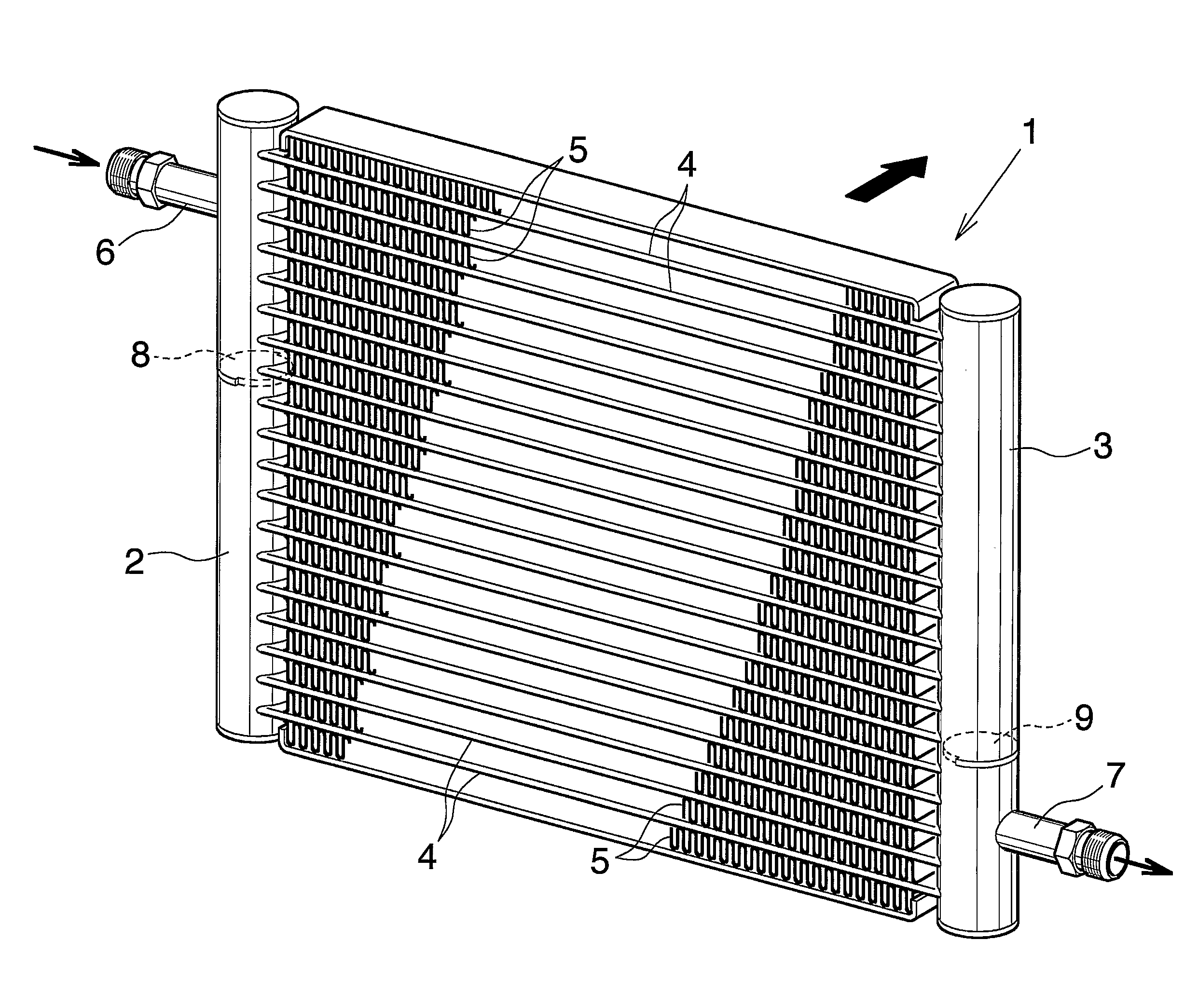

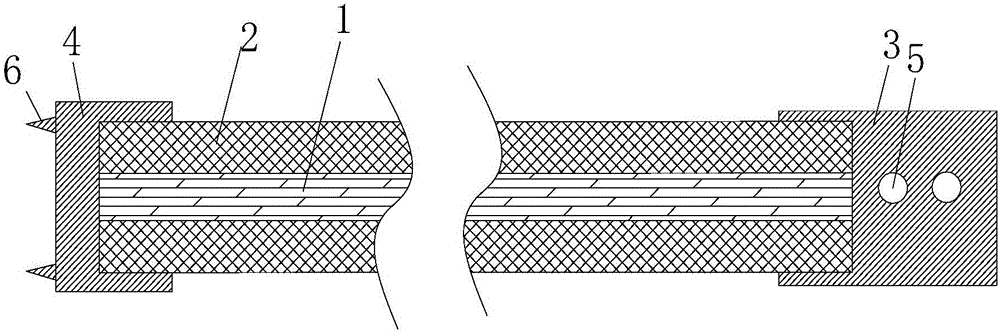

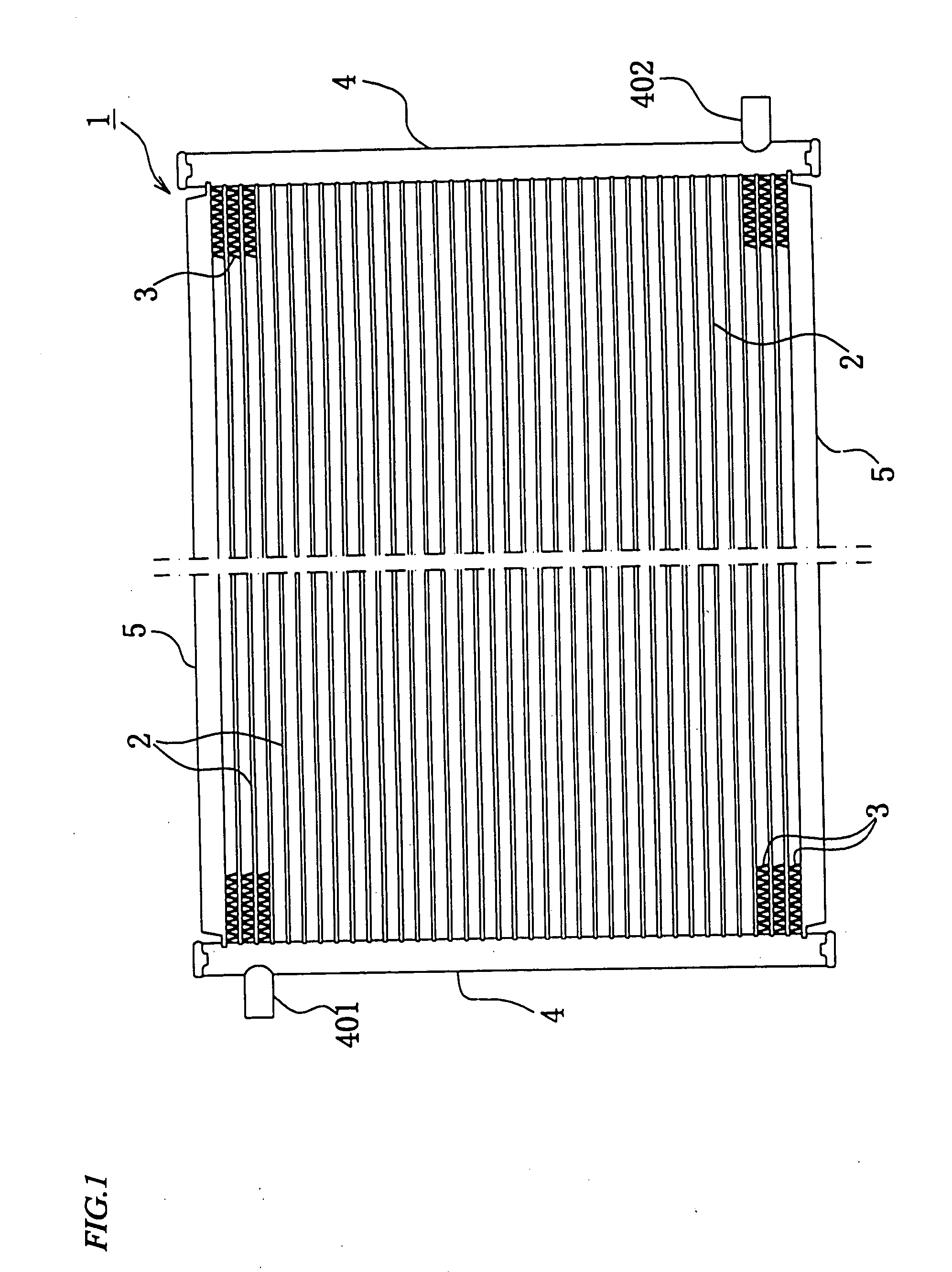

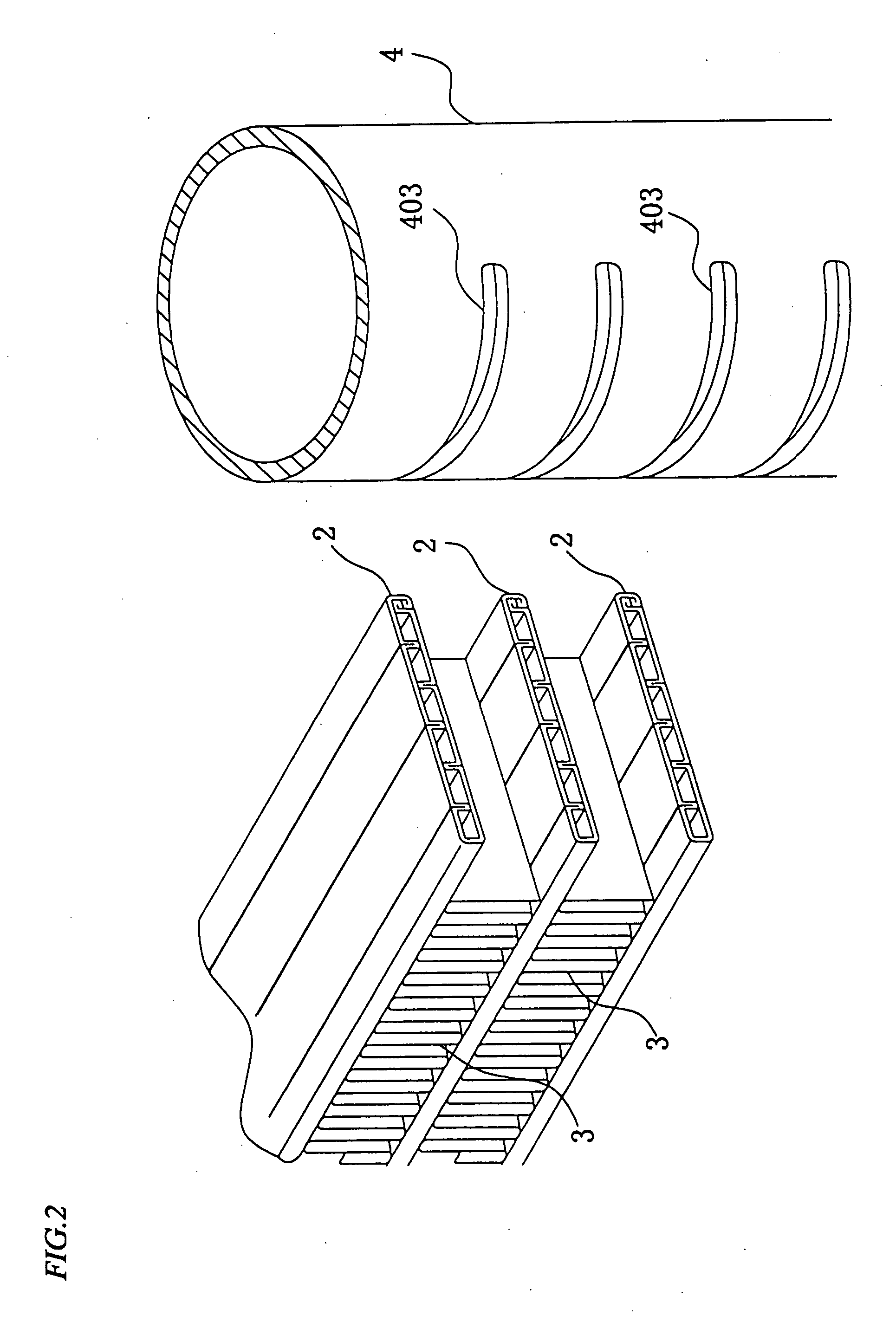

A heat exchanger comprising a heat exchange core (1) including a plurality of tubes (2) flowing a medium for heat exchange and a pair of tanks (4) to which ends of said tubes are connected, each tube formed by shaping a plate member (200) not clad with a row laminated brazing material and having a sacrifice layer (210) on an outer surface thereof and a plurality of recessed portions (203) formed on an outer surface of said sacrifice layer and filled with a brazing material (R).

Owner:ZEXEL VALEO CLIMATE CONTROL CORP SAITAMA

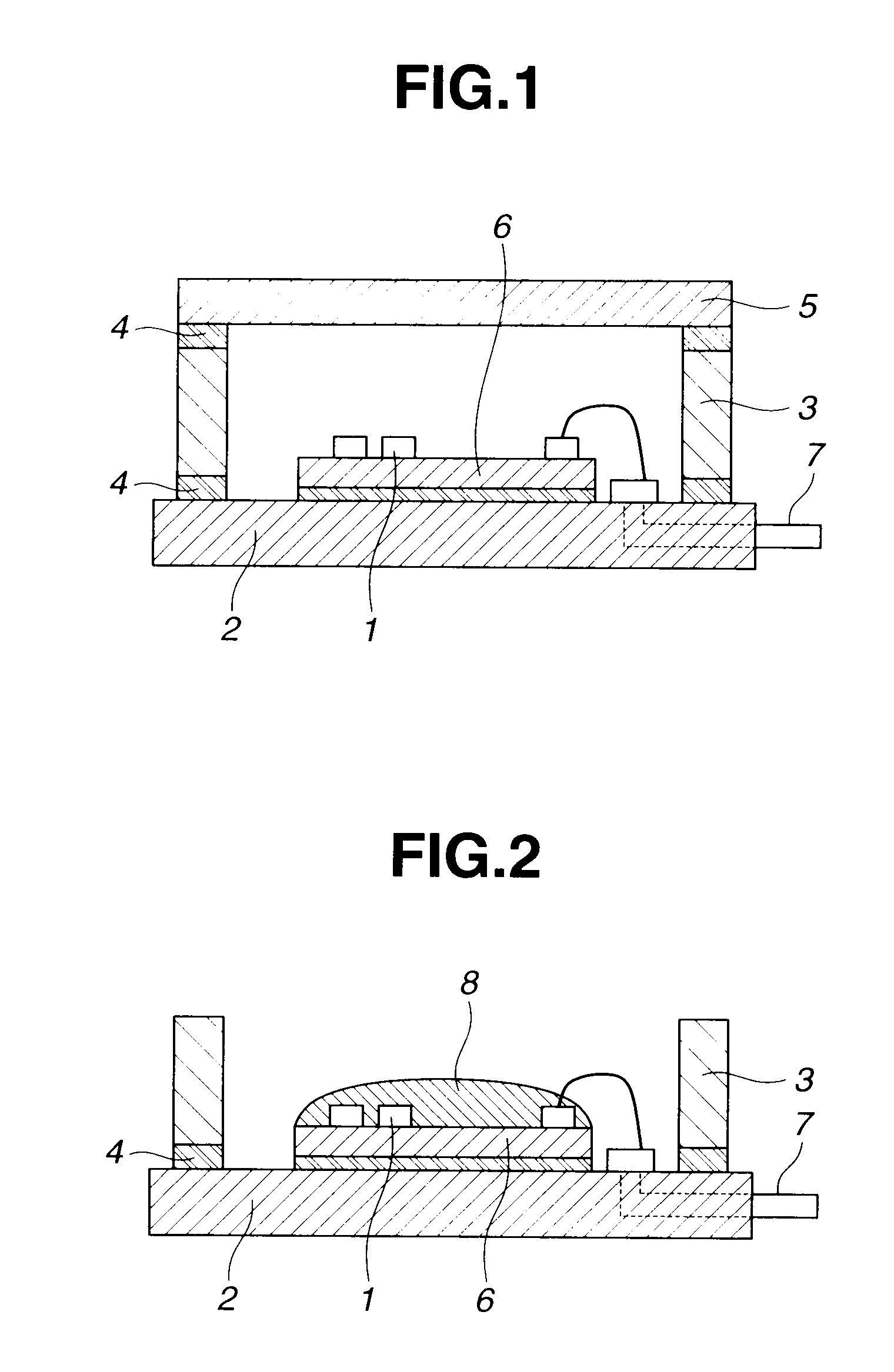

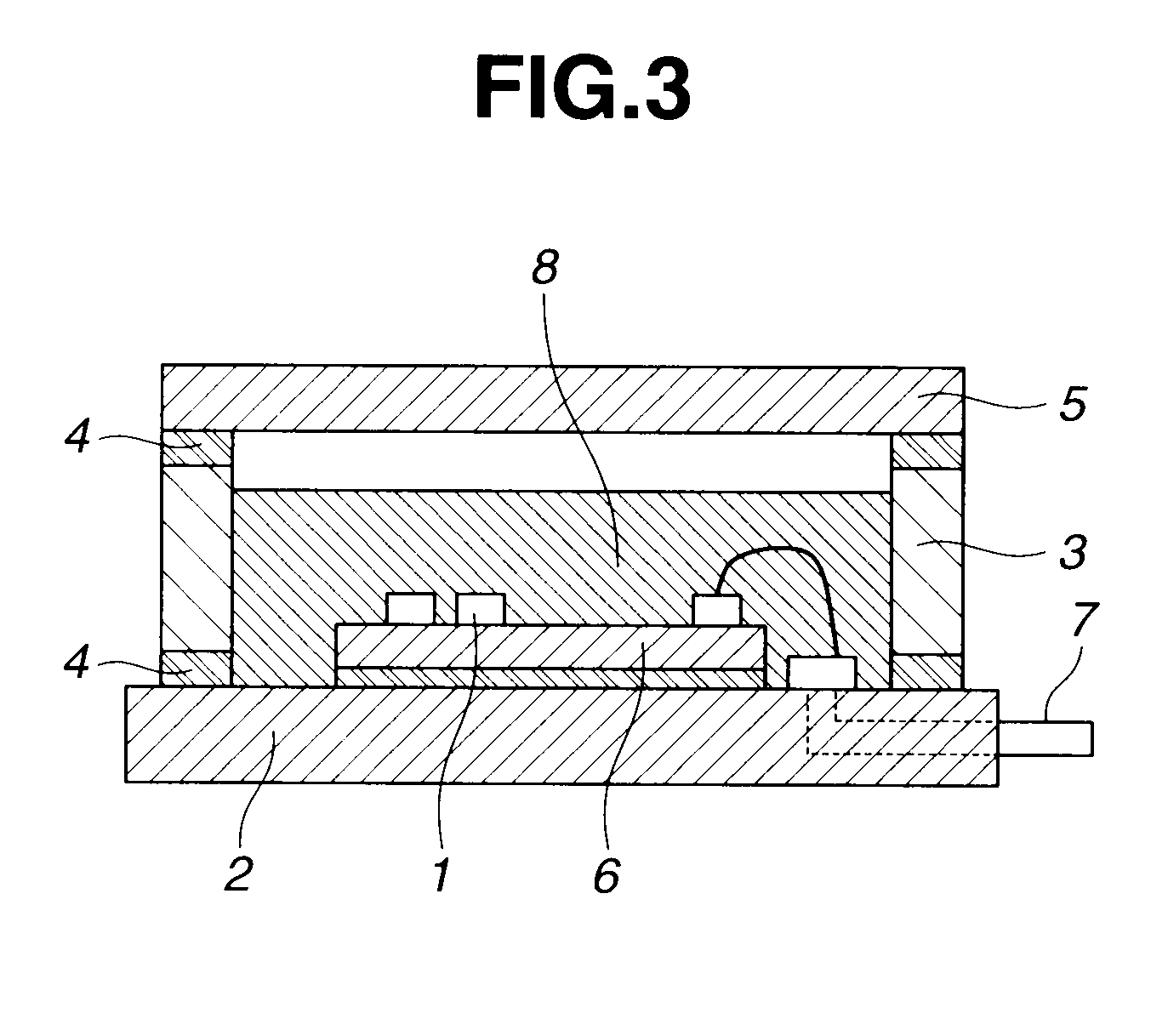

Automotive electric/electronic package

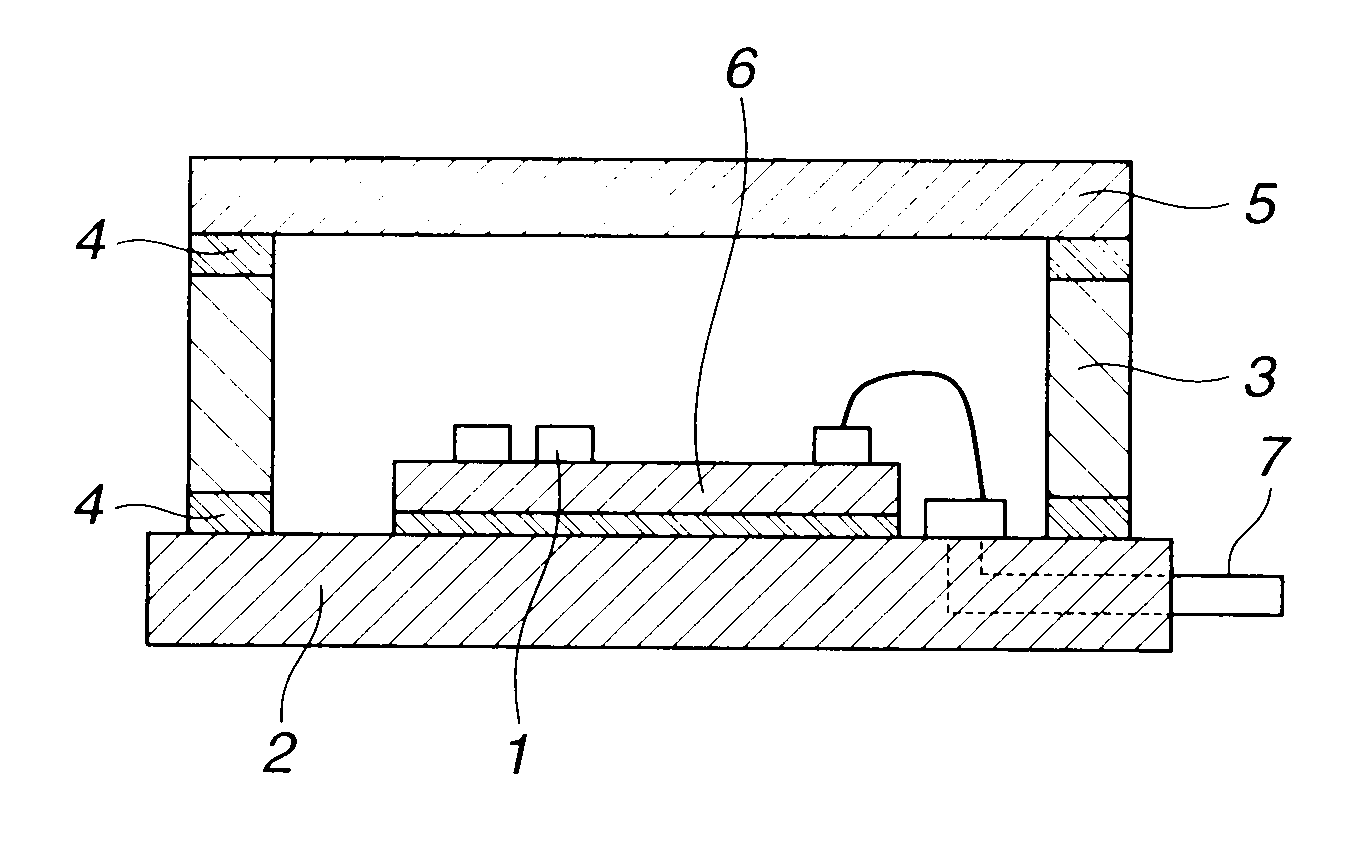

InactiveUS20090084602A1Durable corrosion resistanceReliable corrosion resistanceMeasurement apparatus componentsSemiconductor/solid-state device detailsChemistryCorrosion

In an automotive electric / electronic package comprising an electronic component, a case for receiving the electronic component therein, and a lid covering an open top of the case, the case and the lid are joined together with a fluorochemical adhesive capable of chemically and / or physically adsorbing a corrosive gas. The package has highly reliable corrosion resistance in that the electronic component is protected from corrosion by corrosive acidic or basic gases such as sulfur compound and nitrogen oxide gases.

Owner:SHIN ETSU CHEM IND CO LTD

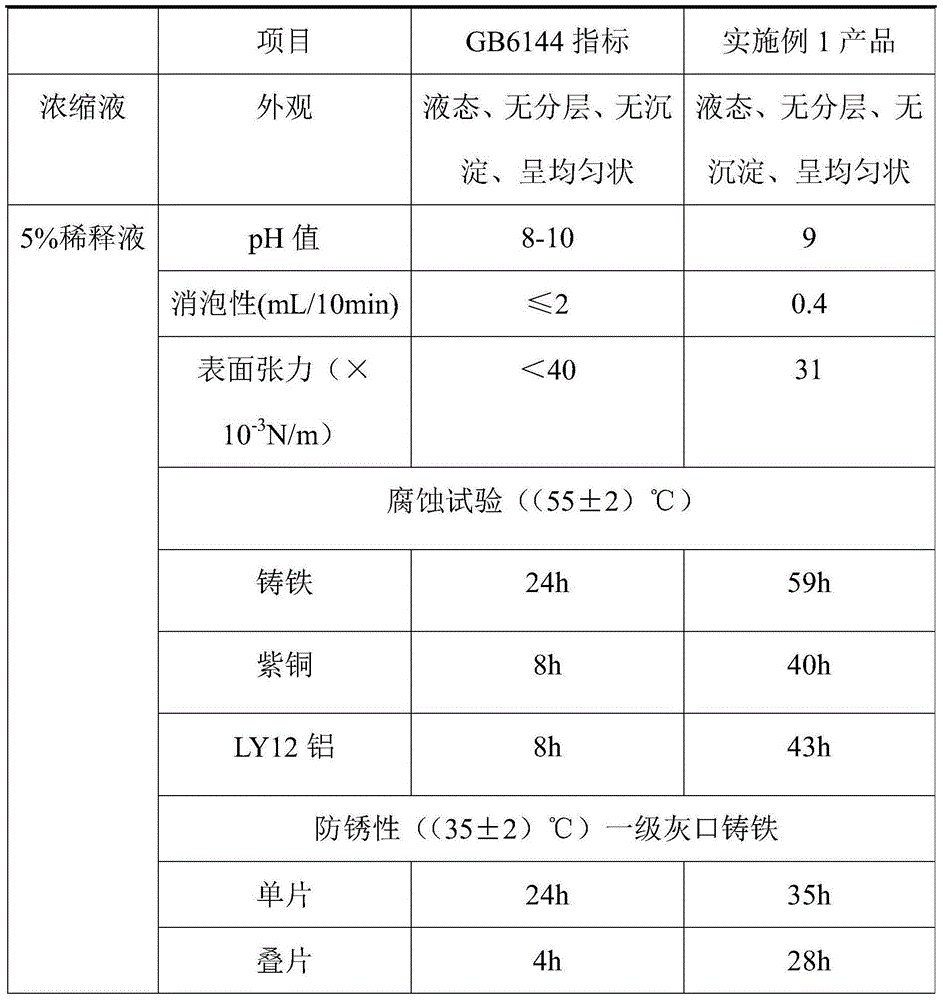

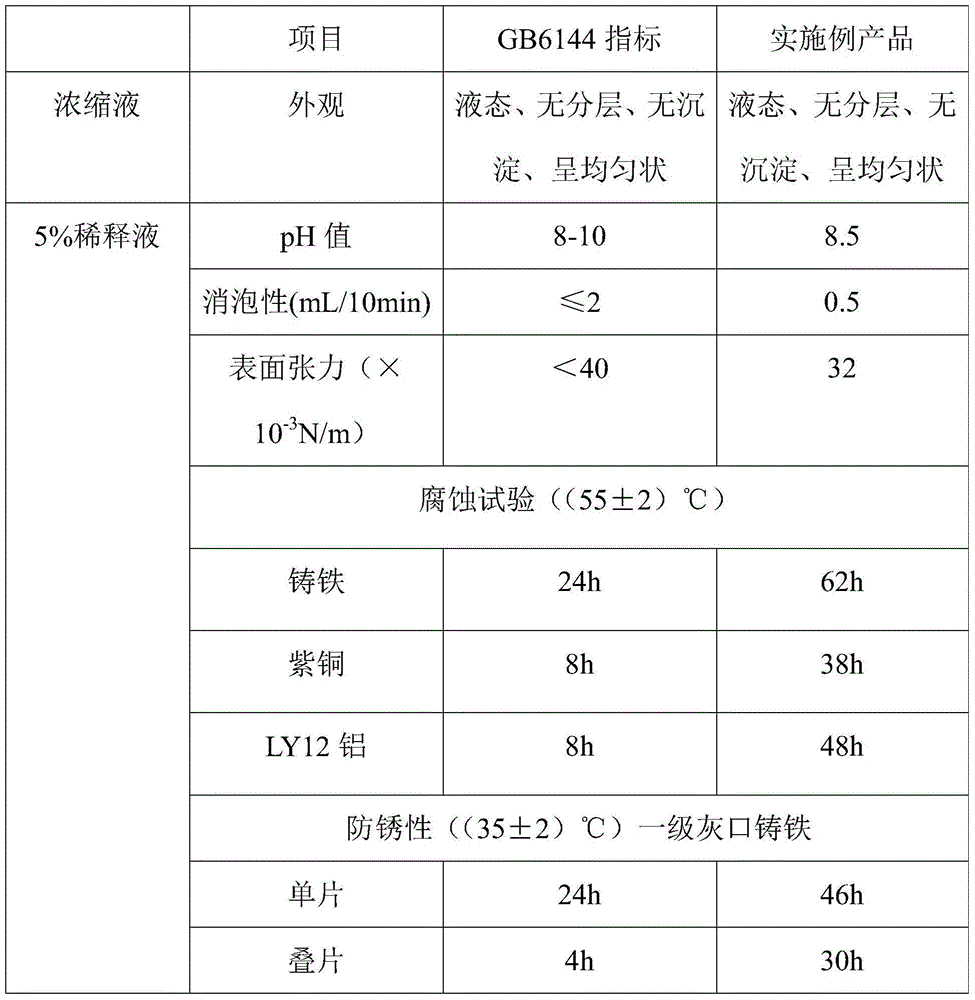

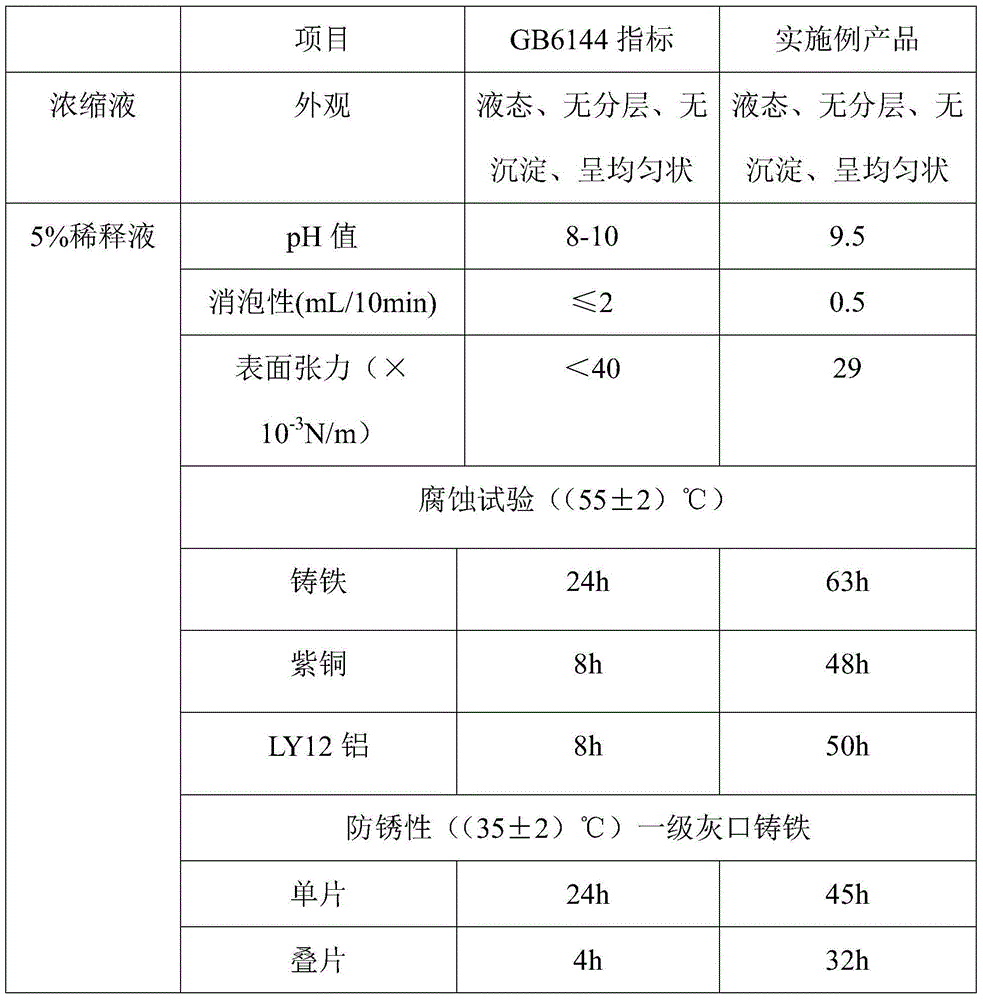

High-performance metal cutting fluid

InactiveCN104403772AEasy to cleanImprove anti-corrosion performanceLubricant compositionPhosphateChemistry

The invention discloses a high-performance metal cutting fluid including following raw materials, by weight: 3-15 parts of an oleamide-based nonionic surfactant, 5-12 parts of twain, 10-25 parts of dodecyl aminopropionic acid, 5-10 parts of a betaine-typed ampholytic surfactant, 10-20 parts of sodium alkyl benzene sulfonate, 1-10 parts of sophorolipid, 10-25 parts of a water-soluble lubricant, 5-18 parts of triethanolamine oleate, 5-15 parts of sodium borate, 1-5 parts of benzotriazole, 5-20 parts of cyclohexanehexol phosphate, 8-25 parts of an organic borate, 5-15 parts of a molybdate, 3-8 parts of copper citrate, 3-10 parts of a chelating agent, 3-10 parts of sodium citrate, 4-15 parts of citric acid and 80-150 parts of water. The high-performance metal cutting fluid is excellent in cleaning performance, corrosion-resistant performance, cooling performance, lubricating performance and anti-hard-water performance, is stable when being stored and is suitable for various materials.

Owner:CHAOHU GUANGFENG METAL PROD

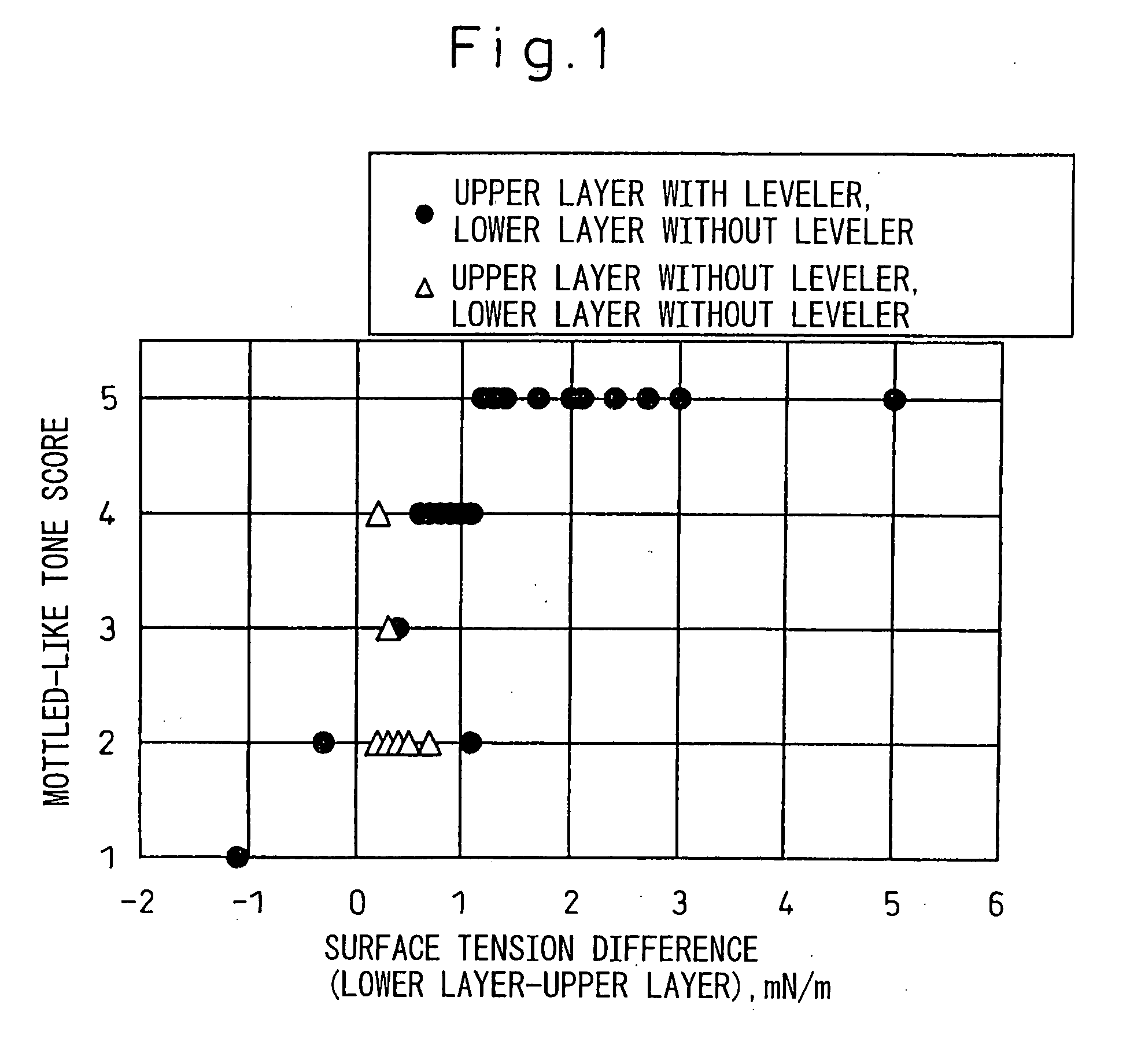

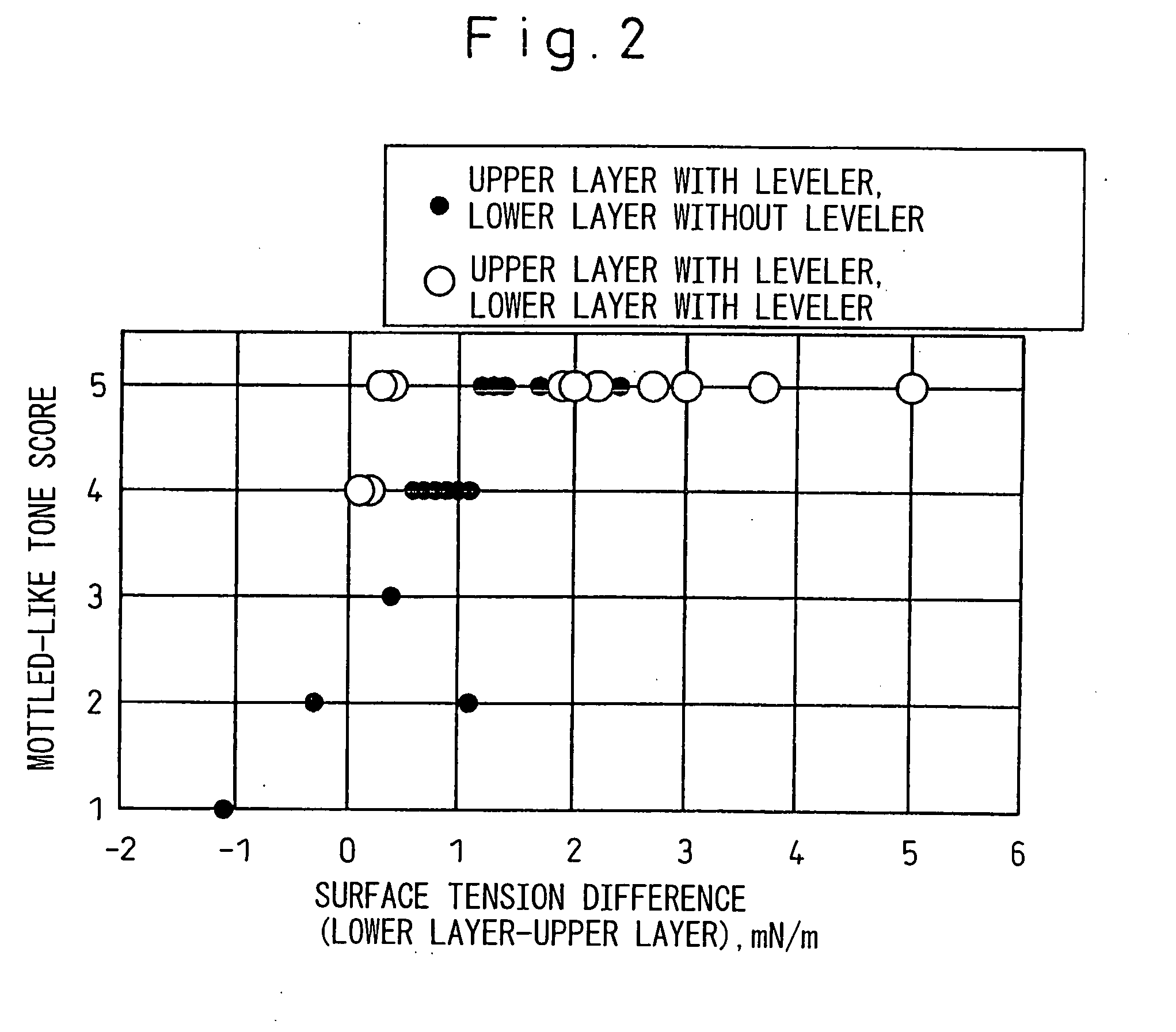

Precoated Metal Sheet and Method of Production of Precoated Metal Sheet

ActiveUS20080003446A1Improve corrosion resistanceImprove workabilityInsulating substrate metal adhesion improvementLiquid surface applicatorsClear LayerConcentration gradient

This invention provides a precoated metal plate that is improved in color shading prevention and adhesion and is produced by simultaneous multilayer coating. In the precoated metal plate, the center line average roughness Ra in the coating film interface is not less than 0.3 μm, and the maximum height from the waviness center line in the interface is not more than 50% of the layer thickness. There are also provided a top clear coated metal plate, which comprises a clear layer as an upper layer, has an interfacial center line average roughness Ra of 0.3 to 0.7 μm and has excellent weathering resistance, a precoated metal plate having excellent processability and corrosion resistance, which contains not less than 30% by mass on average of a rust preventive pigment so that the average rust preventive content of the upper layer is lower than that in the average rust preventive pigment of the lower layer, the concentration gradient is lowered so that the position from around the interface of the upper layer and the lower layer is increased, and the roughness Ra in the interface of the lower layer and the upper layer is 0.3 to 0.7 μm, and a process for producing the same.

Owner:NIPPON STEEL CORP

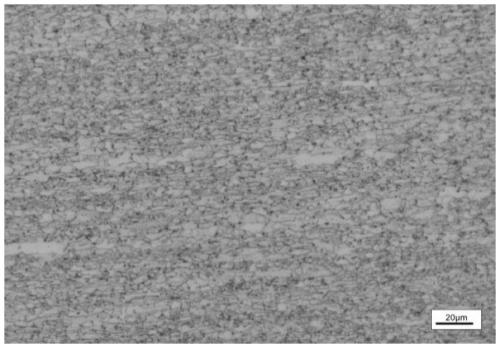

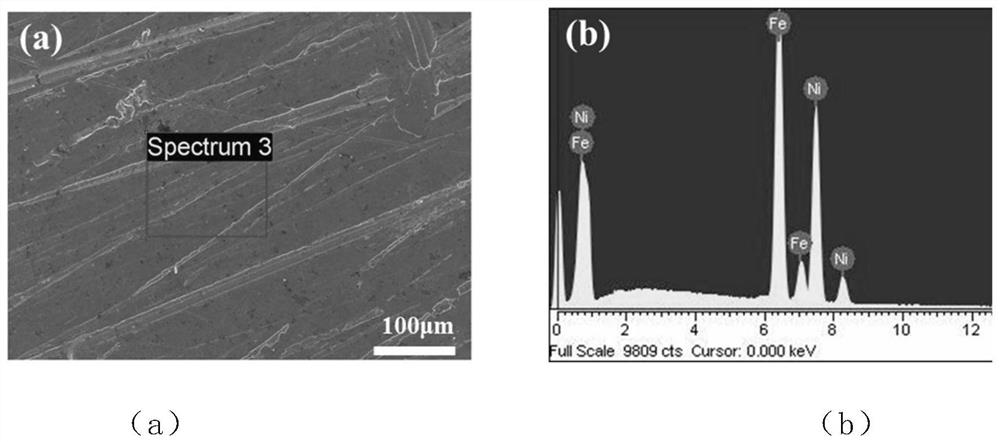

High-strength weather-resistant steel with yield strength of 700 MPa and production method thereof

InactiveCN109898032AReliable corrosion resistanceGood weather resistanceChemical compositionWeather resistance

The invention discloses high-strength weather-resistant steel with yield strength of 700 MPa and a production method thereof, and belongs to the technical field of steel and iron production. The high-strength weather-resistant steel with the yield strength of 700 MPa is prepared from the following chemical components in percentage by mass: 0.05 to 0.09 percent of C, 0.25 to 0.35 percent of Si, 1.50 to 1.60 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.005 percent of S, 0.25 to 0.30 percent of Cu, 0.30 to 0.40 percent of Cr, 0.05 to 0.15 percent of Ni, 0.040 to 0.050 percent of Nb 0.10 to 0.15 percent of Ti, less than or equal to 0.006 percent of N, less than or equal to 0.005 percent of O, and the balance of Fe and unavoidable impurities. Compared with the prior art, a final product is reliable in corrosion resistance and has good weather resistance.

Owner:RIZHAO STEEL HLDG GROUP

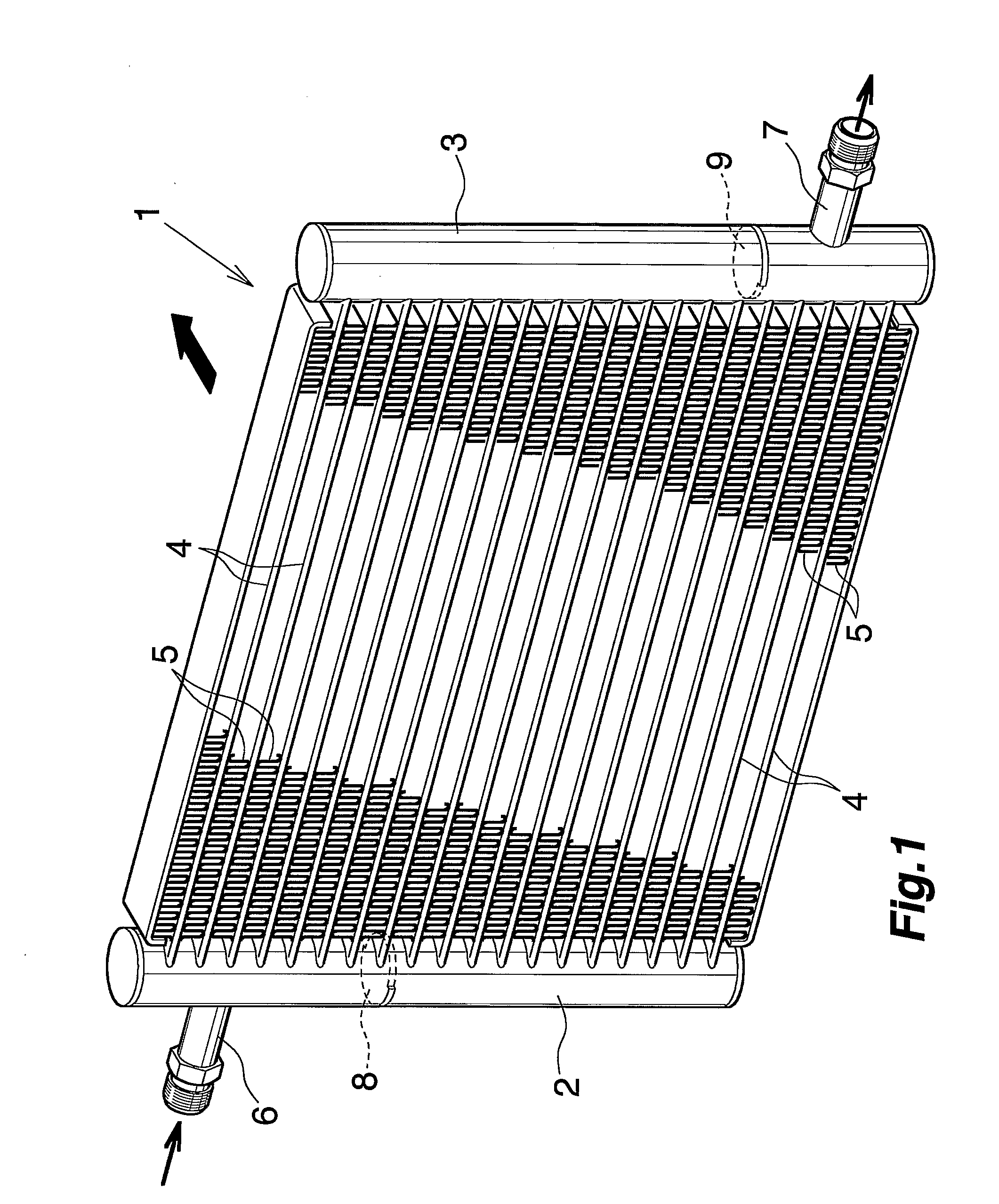

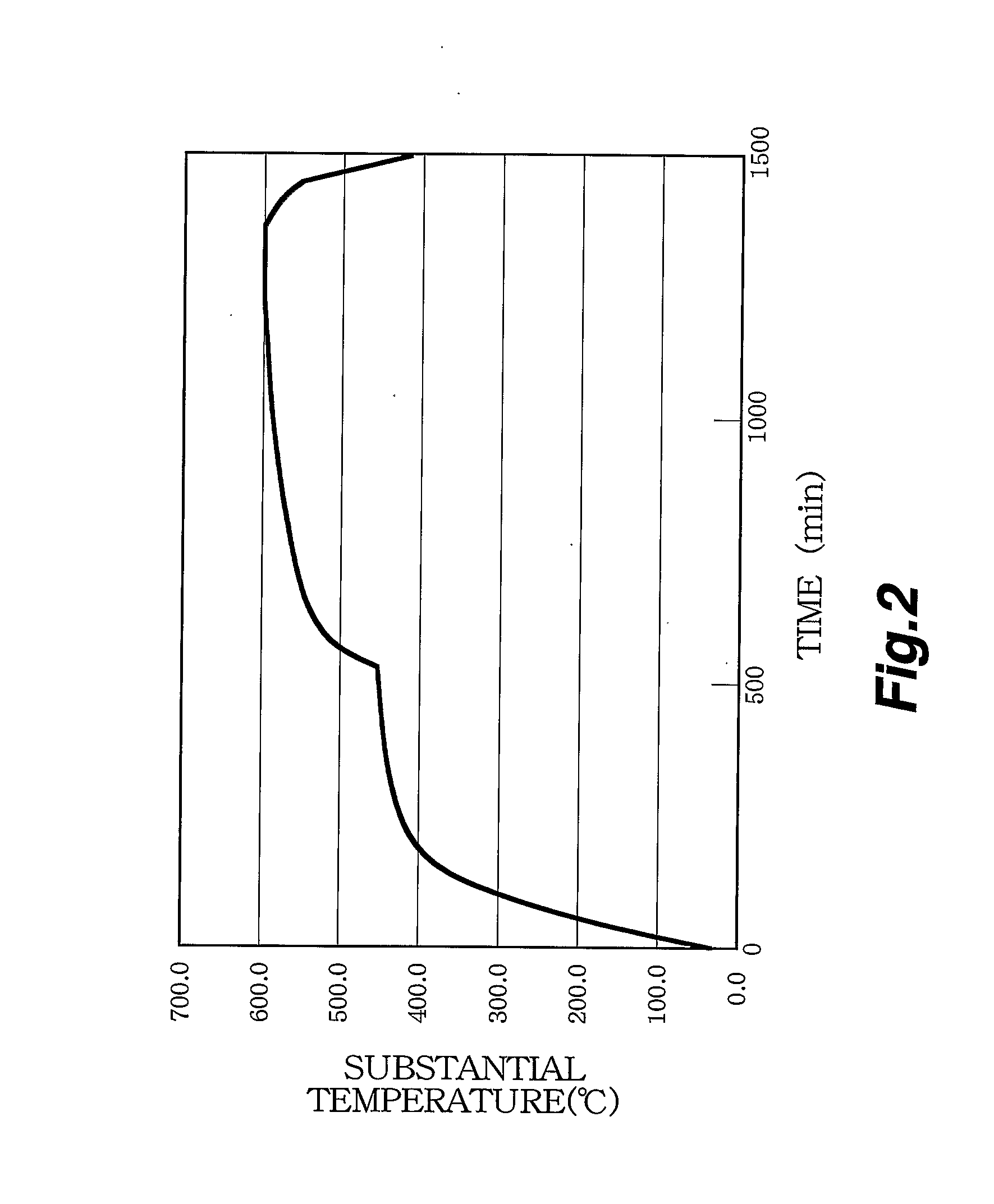

Aluminum Heat Exchange Tube and Process for Fabricating Same

InactiveUS20080047683A1Avoid developmentHigh strengthAir-treating devicesMetal-working apparatusAlloyImpurity

An aluminum heat exchange tube 4 is made of an alloy comprising 0.90 to 1.50 mass % of Mn, and the balance Al and inevitable impurities, and has electric conductivity of 30 to 43% IACS. The tube 4 is fabricated from a tube blank made of an alloy comprising 0.90 to 1.50 mass % of Mn, and the balance Al and inevitable impurities, by holding the blank heated at 550 to 600 C in the atmosphere or in an inert gas atmosphere for 10 to 600 minutes and subsequently cooling the blank. The tube is easy and inexpensive to make and satisfactory in resistance to pitting corrosion.

Owner:SHOWA DENKO KK

Efficient environment-friendly concrete preservative

The invention relates to an efficient environment-friendly concrete preservative, which comprises the following components in portion by weight: 10 to 18 portions of various benzoic acids and boric acids, 20 to 40 portions of silica fume, 20 to 35 portions of alkalis; 35 to 50 portions of ethanolamine, and 15 to 20 portions of active components. The preservative can be widely applied to various building materials, especially to concrete and cement, and is reliable in rust prevention and corrosion resistance and good in environmental indexes. The preservative has the advantages of containing no mineral oil, containing no nitrite, chromate and the like harmful to human body, adapting to compressive strength (50 MPa in general) of actual requirements, improving strength, durability and heat resistance and meeting the requirements for high-performance concrete, along with no toxicity, no stimulation, no pollution, good construction performance, high dimensional stability, less shrinkage and no cracking in the hardening process.

Owner:凌明明

Carbon fiber graphite grounding connector and manufacturing method thereof

InactiveCN106684585AImprove conductivityImprove featuresLine/current collector detailsConnection contact member materialFiberPower flow

The invention relates to a carbon fiber graphite grounding connector which comprises carbon fibers, wherein the carbon fibers are glued into one row through first conductive glue; a puffing furnace is used for puffing graphite into graphite worms; the graphite worms are respectively compounded on upper and lower sides of the carbon fibers, and then the carbon fibers are pressed to form graphite paper; the graphite paper is cut into strips and then the strips are rolled, so that the graphite lines are prepared; the mass ratio of the graphite to the carbon fibers to the conductive glue is (77-83):(10-12):(0.5-1.5); the carbon content of the graphite is more than or equal to 99.9%; the graphite lines are arranged in parallel so as to form a line core; the graphite lines are weaved into a weaved conductive layer on the periphery of the line core. The carbon fiber graphite grounding connector provided by the invention has excellent conductivity and surge current tolerance, reliable corrosion resistance, stable mechanical structure, high thermal stability, convenience in transportation and construction and high soil compactness.

Owner:武汉政荣科技有限公司

Fuel pipe and method of production of same

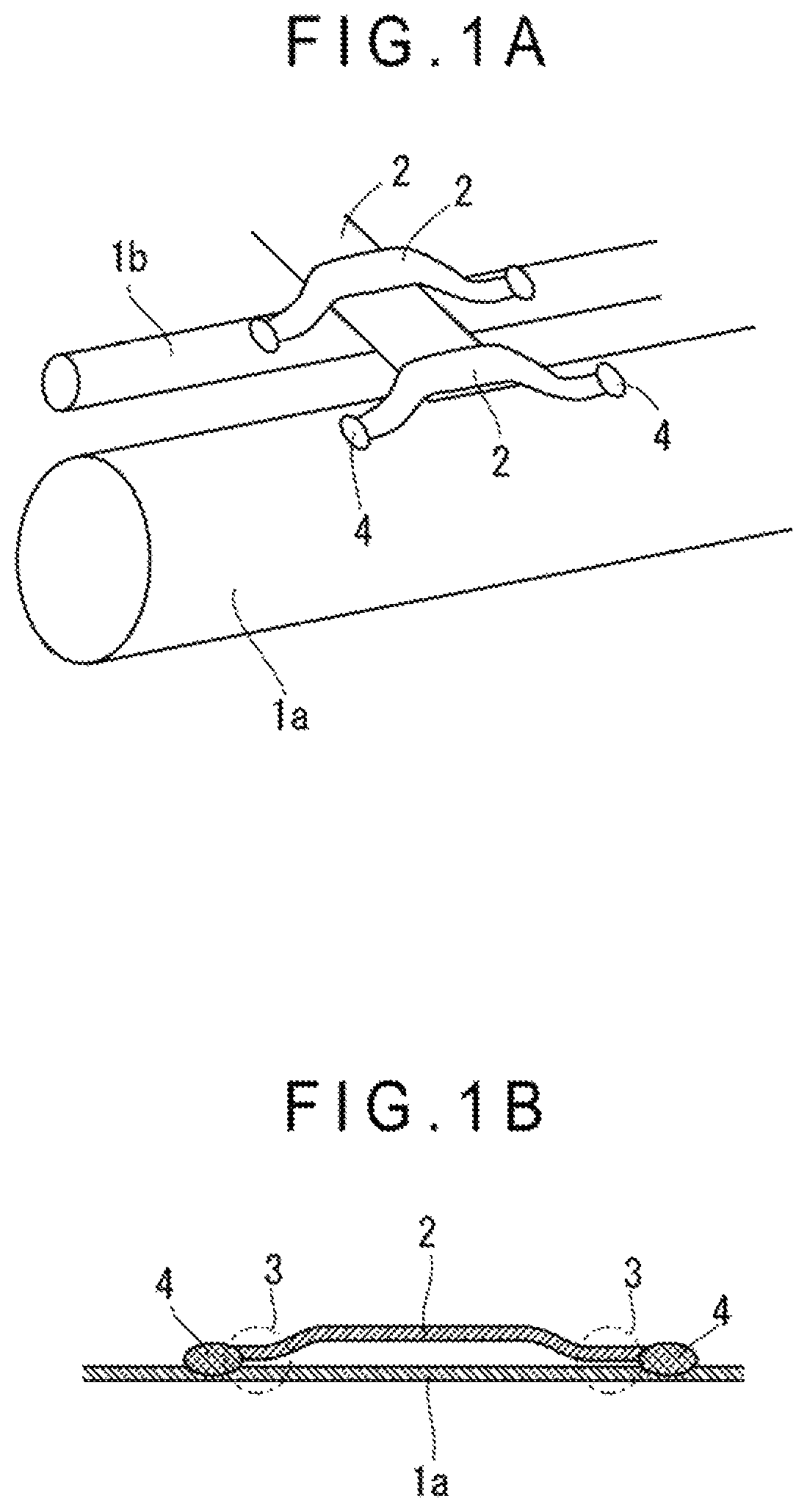

ActiveUS20130074971A1Reliable corrosion resistanceInexpensive fuel pipeCooking-vessel materialsPipe supportsMethods of productionFerric

A fuel pipe which is inexpensive and is excellent in salt spray corrosion resistance, characterized by being comprised of a steel pipe member having as a material a ferritic stainless steel which contains, by mass %, C: 0.015% or less, Si: 0.01 to 0.50%, Mn: 0.01 to 0.50%, P: 0.050% or less, S: 0.010% or less, N: 0.015% or less, Al: 0.010 to 0.100%, and Cr: 13.0 to 18.0% and further, one or both of Ti: 0.03 to 0.30% and Nb: 0.03 to 0.30% and a metal fitting part, the metal fitting part and the steel pipe member having between them a crevice structure at the surface which the structure is exposed to a salt spray environment, an opening amount at a crevice part of the crevice structure being 0.2 mm or more, and an inside of the crevice part being coated by electrodeposition.

Owner:NIPPON STEEL & SUMIKIN STAINLESS STEEL CORP

Manufacturing method of cationic water-based vinylidene chloride metal anti-corrosion paint

ActiveCN103044600AImprove mechanical stabilityGood ion toleranceAnti-corrosive paintsWater basedVinylidine chloride

The invention discloses a manufacturing method of cationic room-temperature crosslinking water-based vinylidene chloride metal anti-corrosion paint, which is characterized in that resin of the paint is cationic vinylidene chloride latex; an cationic emulsifier is polymerized with high pressure emulsions of a vinylidene chloride monomer and an acrylate monomer; an initiator is mixed by an oil-soluble initiator and a water-based initiator; the prepared vinylidene chloride latex is good in mechanical stability, and can be grinded together with a rust-resistant pigment; the cationic durability is good; cations dissociated from the rust-resistant pigment do not influence the storage stability of the water-based paint; and the anti-corrosion effect is excellent.

Owner:JIANGSU RONGCHANG NEW MATERIAL TECH

Process for production of aluminum wheel

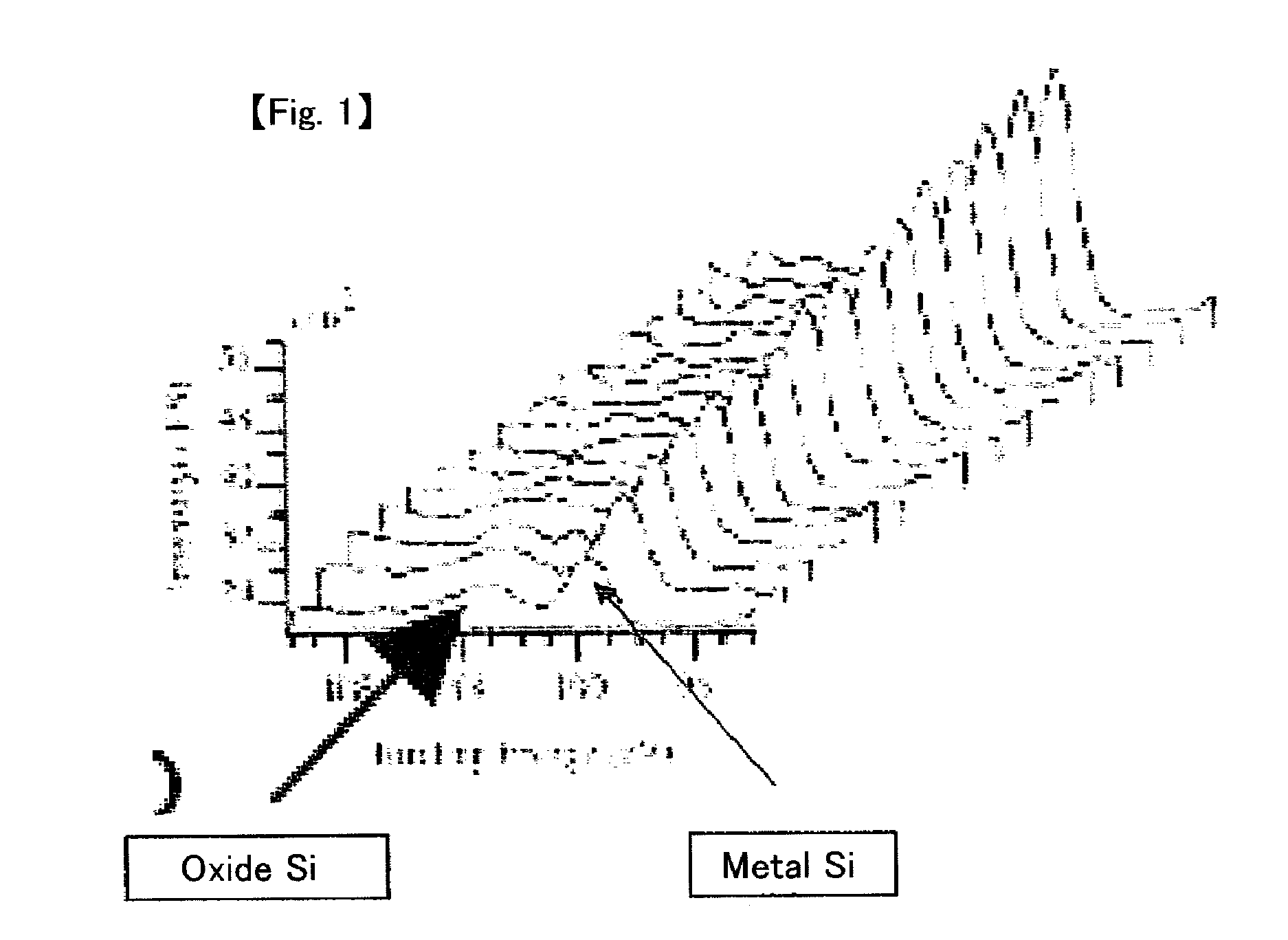

ActiveUS20110155949A1Solve the lack of adhesionReliable corrosion resistanceDecorative surface effectsMetallic material coating processesPeeningMetal

A process for producing an aluminum wheel includes a cleaning step, in which the surface of the aluminum wheel is chemically etched with an alkali cleaning liquid which contains an alkali builder, an organic builder, and a chelating agent to such an extent that the Si atomic ratio of metal Si to oxide Si is from 0.01 to 9, and a shot blast treatment step can be omitted for cleaning the surface of the aluminum wheel.

Owner:CENTRAL MOTOR WHEEL CO LTD +1

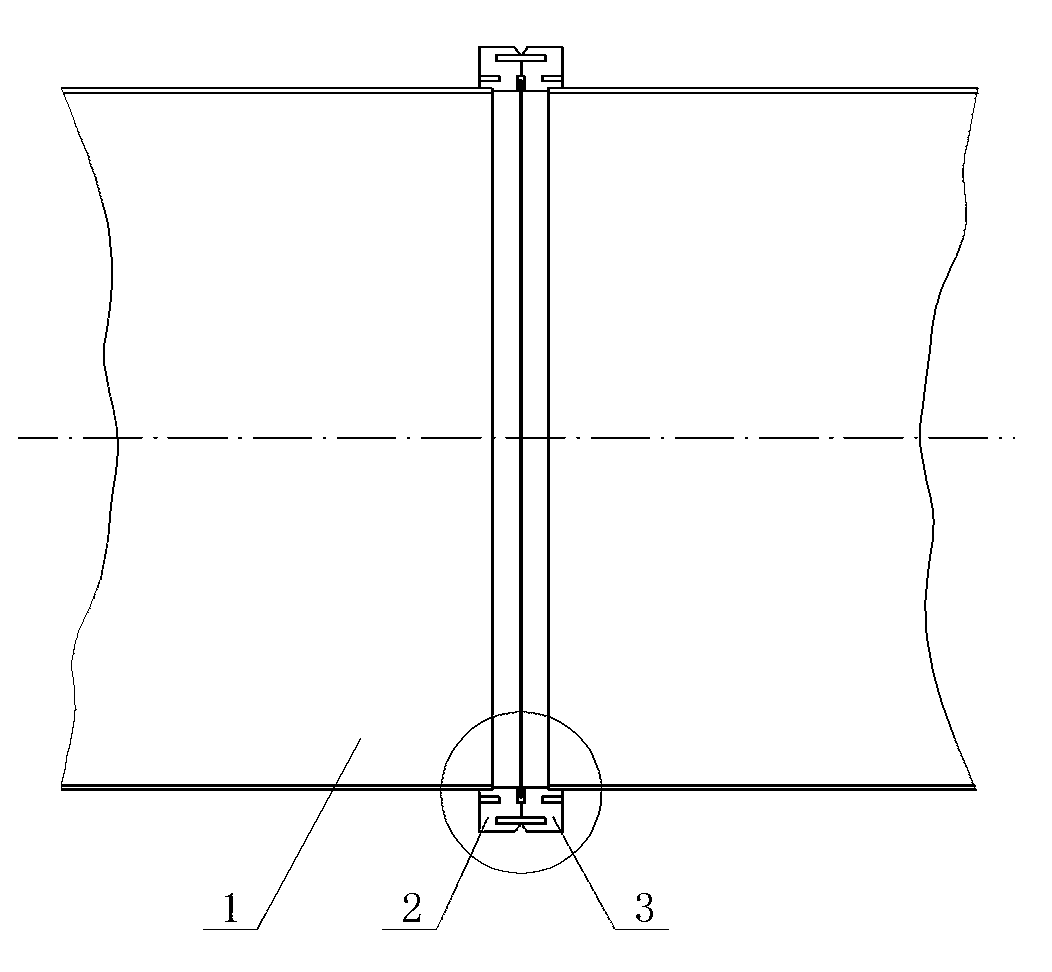

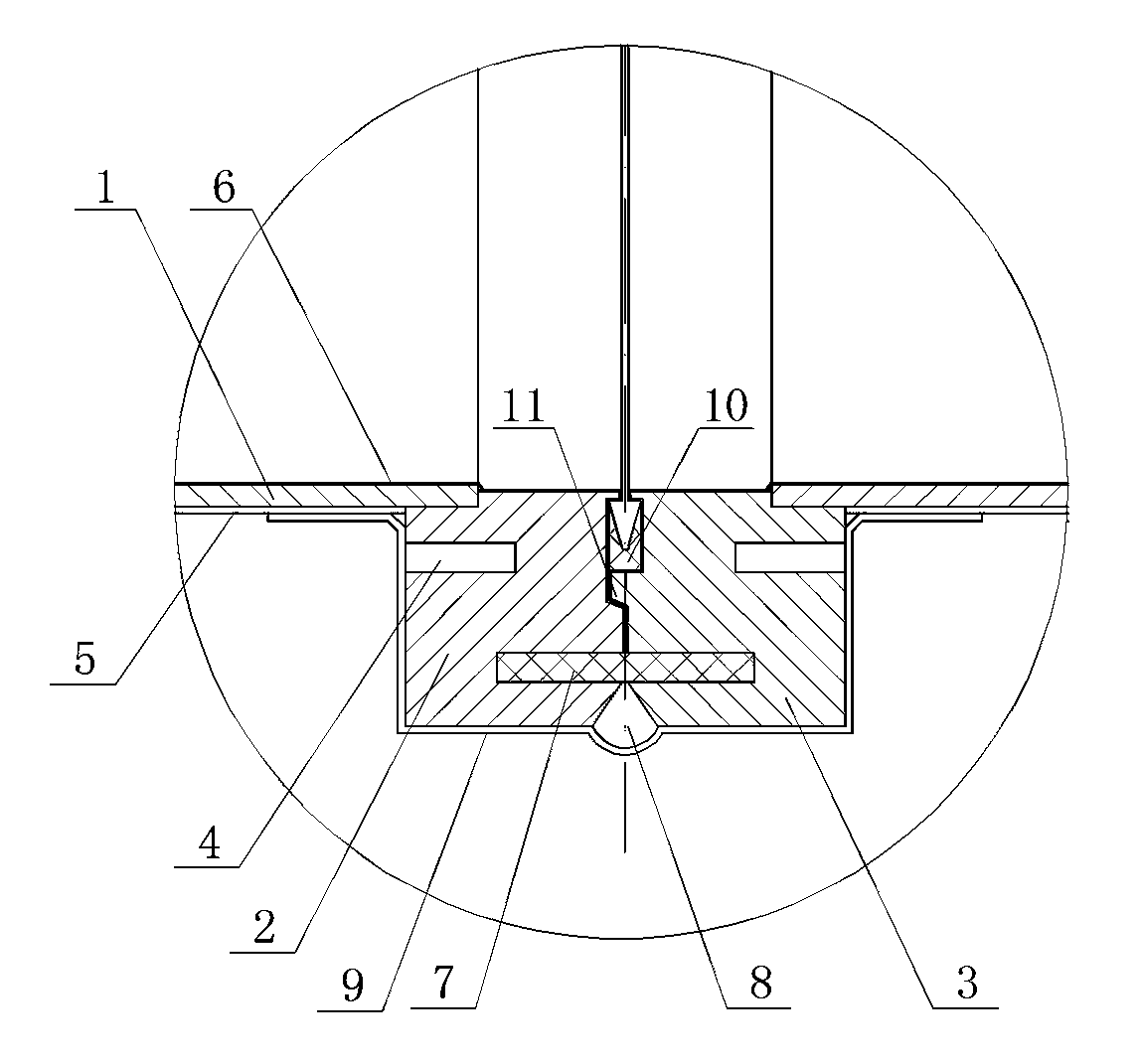

Connecting device and connecting method of internal and external anti-corrosion plastic-steel composite pipe

InactiveCN103322364ASimple structureQuick installationPipe connection arrangementsThermal insulationThermal shrinkage

The invention relates to the technical field of connection of internal and external anti-corrosion pipelines, in particular to a connecting device and connecting method of an internal and external anti-corrosion plastic-steel composite pipe. In the prior art, internal anti-corrosion on the joint of steel pipes needs to be welded at a construction site to be processed manually, and anti-corrosion quality cannot be guaranteed; allowable errors of pipe openings of the steel pipes are large, connecting strength is generally guaranteed by means of increasing of wall thicknesses, and butt joint difficulty of the pipelines is high. According to the technical scheme of the connecting device and connecting method, a joint A and a joint B are welded at the two ends of a pipeline in a factory and anti-corrosion treatment is carried out on the joint A and the joint B; at the construction site, joints A and joints B of end portions of two sections of pipelines just need to be butted and welded, and then an anti-corrosion thermal shrinkage belt is utilized to carry out external anti-corrosion treatment on welded junctions; internal thermal insulation grooves and external thermal insulation grooves are formed in the joints, thermal insulation linings are filled in the internal thermal insulation grooves, and seal rings are installed on end faces of the joints. The connecting device is simple in structure, convenient and fast to install, and suitable for industrialized production, on-site construction procedures are simplified, mechanical strength of the end portions of the pipelines is improved, steel is saved, and anti-corrosion performance is reliable.

Owner:李晓明

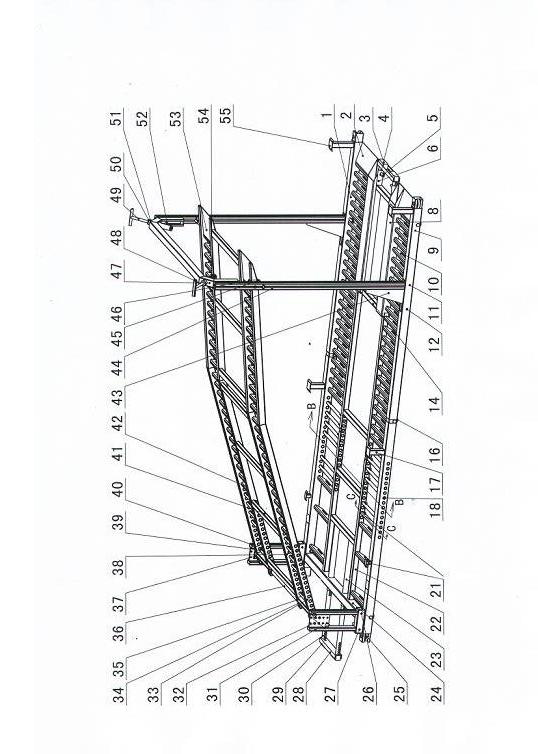

Double-layer car pallet

The invention discloses a double-layer car pallet, which comprises a bottom pallet component, an upper pallet component, a small frame, a big frame component, a front roof box device, a rear roof box device and a roof support device. A side wheel is arranged at the end part of the side surface of a bottom main beam of the bottom pallet component; multiple bearing wheels are arranged on the bottom surface; the bottom main beam and a bottom auxiliary beam of the bottom pallet component are correspondingly provided with bolt pin holes for mounting bottom lane rods; lane boards with equal space are arranged between the bottom main beam of the bottom pallet component as well as the bottom auxiliary beam and a forklift sleeve, and form car carrying lanes in pairs with the lane rods; and oblique guide boards are also fixed on the car carrying lanes at one end close to the big frame component, of the bottom pallet component. The double-layer car pallet disclosed by the invention has the advantages that: the product is lighter, the production organization is convenient, the appearance quality is consistent, the shortcomings of high possibility of loosening and rusting of threads are overcome, the pallet assembly / disassembly operation is quick, the complete functions of the double-layer car pallet can be maintained, and the functions of a conveyor are exerted furthest.

Owner:JIANGXI KEBUKE AUTOMOTIVE TECH

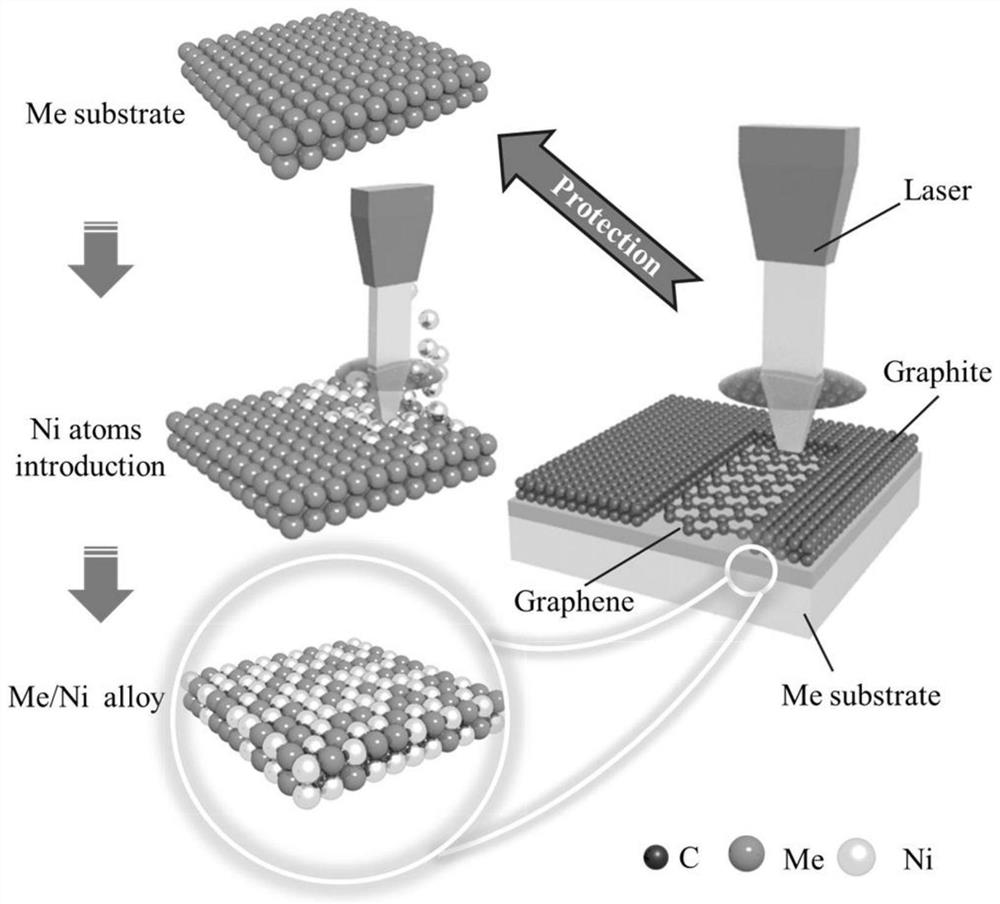

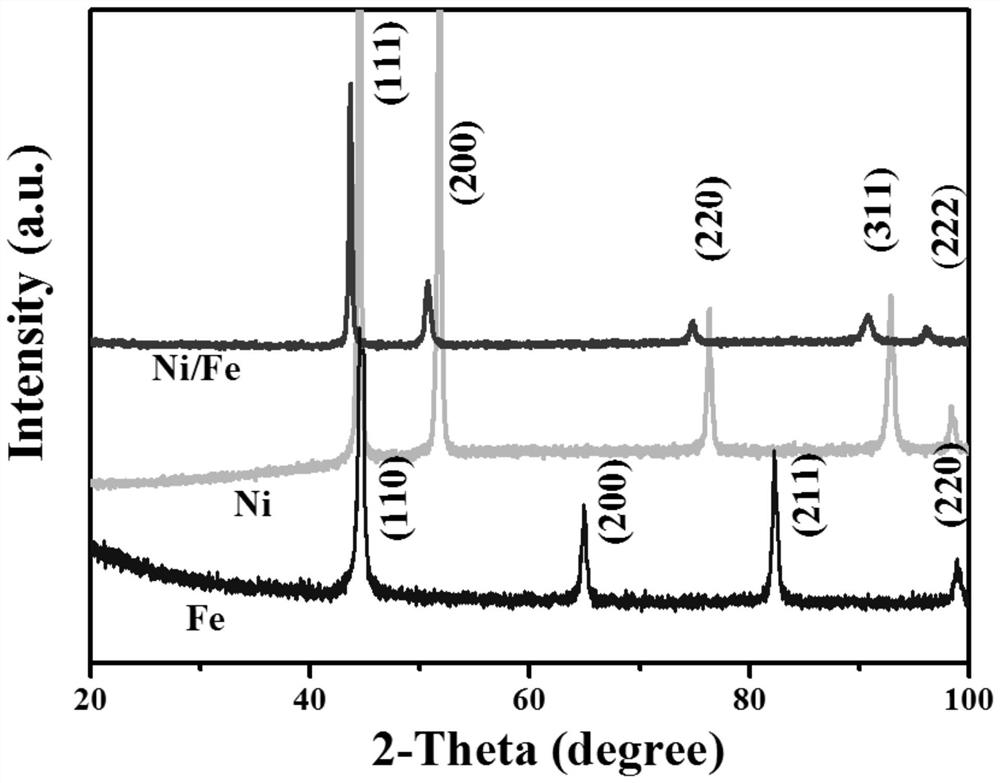

Method for in-situ growth of graphene on metal surface based on laser and application of method

PendingCN111621768AReliable wear and corrosion resistanceIncreased safety and longevityChemical vapor deposition coatingLap jointCorrosion resistant

The invention discloses a method for in-situ growth of graphene on a metal surface based on laser and application of the method. Powdery metallic nickel is introduced to a metal substrate through a laser, and an alloy coating of the metallic nickel and the metal substrate is formed in a lap joint scanning mode; a solid carbon source is pre-coated on the alloy coating, and in-situ growth of graphene is achieved through laser irradiation. According to the method, the excellent mechanical property and corrosion and friction resistance of graphene are fully exerted, so that the metal material is high in mechanical property, corrosion resistance and friction resistance at the same time, and finally the purposes of reducing the machining cost and prolonging the service life of a metal workpieceand equipment are achieved.

Owner:SHAANXI UNIV OF SCI & TECH

Surface-treated aluminum alloy and surface-treated aluminum alloy clad material

InactiveUS20170115076A1Deterioration of corrosion resistanceSufficient corrosion prevention effectLiquid surface applicatorsLiquid/solution decomposition chemical coatingFree energiesAlloy composite

The present invention provides an aluminum alloy and an aluminum alloy clad material which are capable of retaining corrosion resistance even when a sacrificial material is not used.The present invention is a surface-treated aluminum alloy, in which: a surface film is formed at least on one surface of the aluminum alloy; the thickness of the surface film is 0.1 to 10 μm; a material forming the surface film contains oxides having a standard free energy of formation of 500 kJ / mol or less at a temperature of 500 K by 80% by mass or more in total; and the average particle size of the oxides is 5 to 50 nm.

Owner:KOBE STEEL LTD

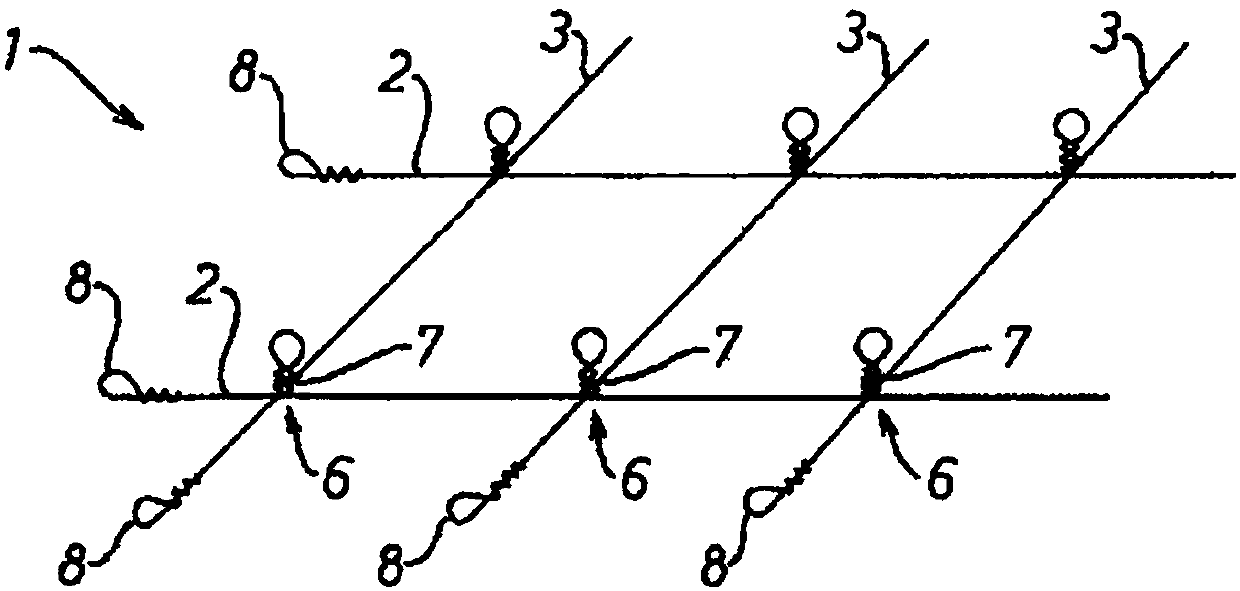

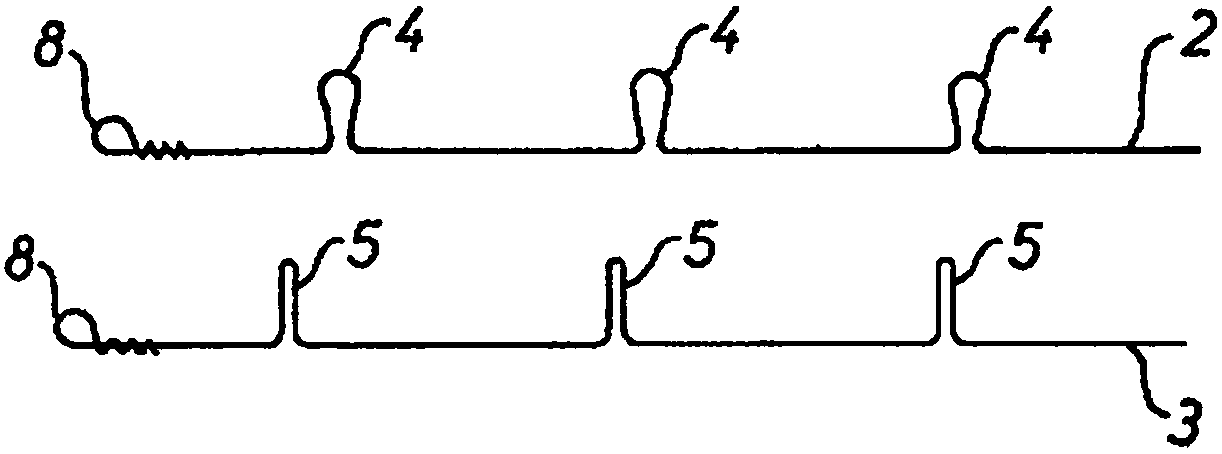

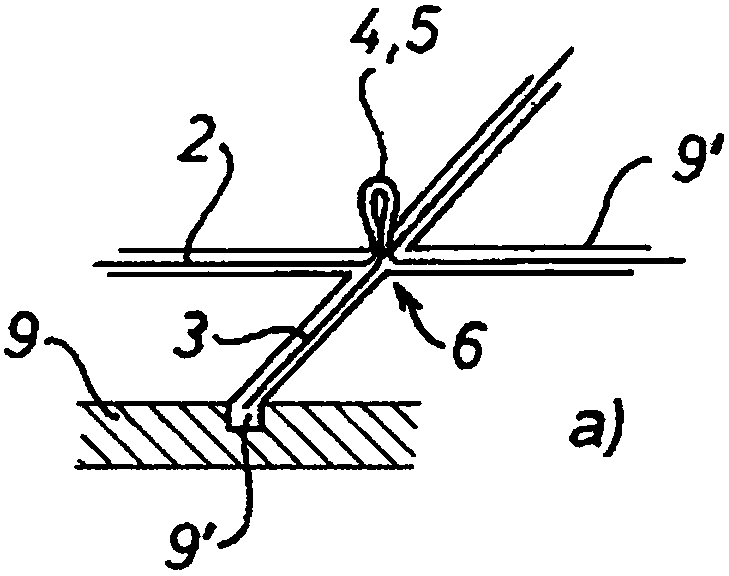

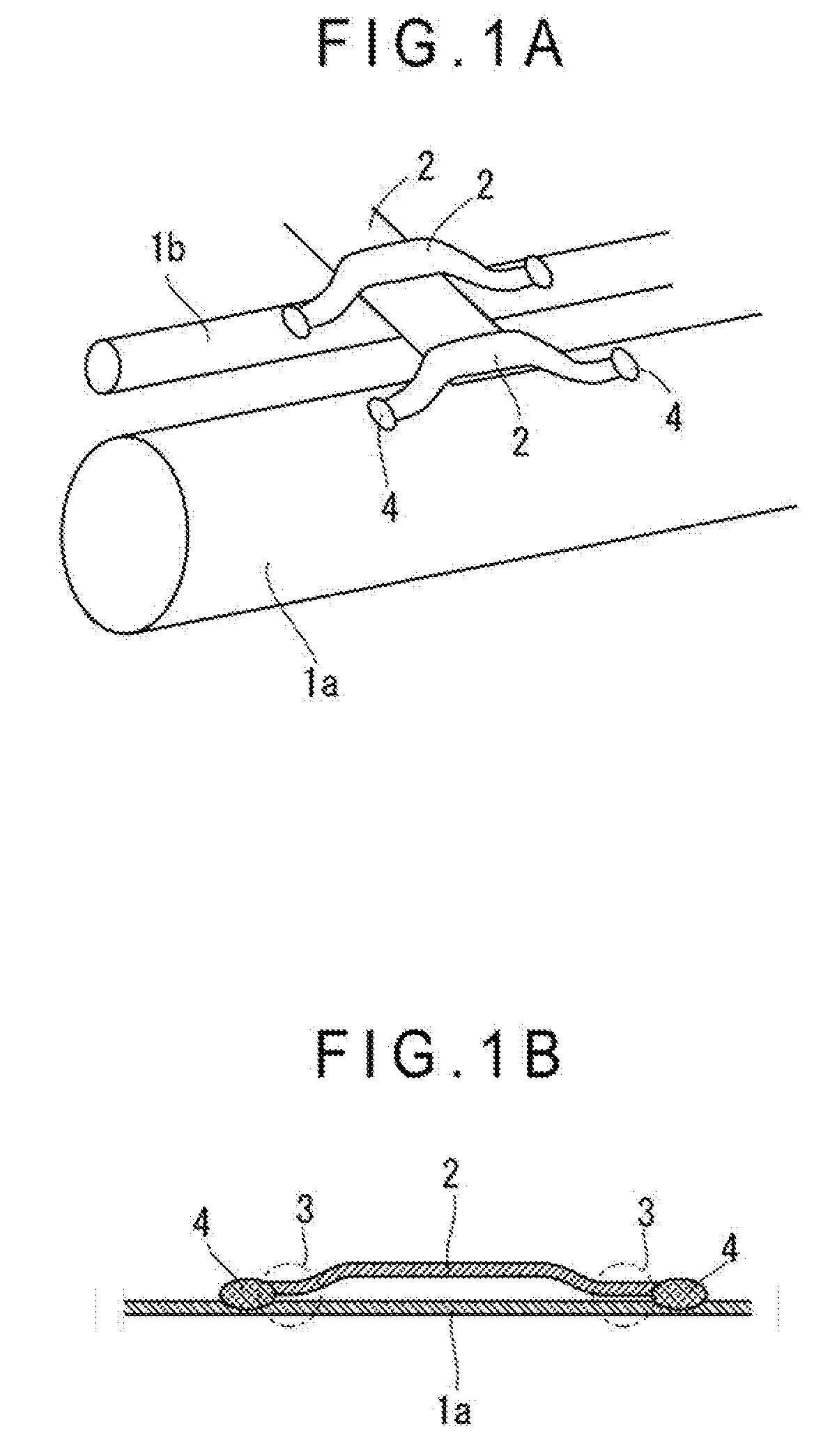

Lattice structure and a device and method for producing same

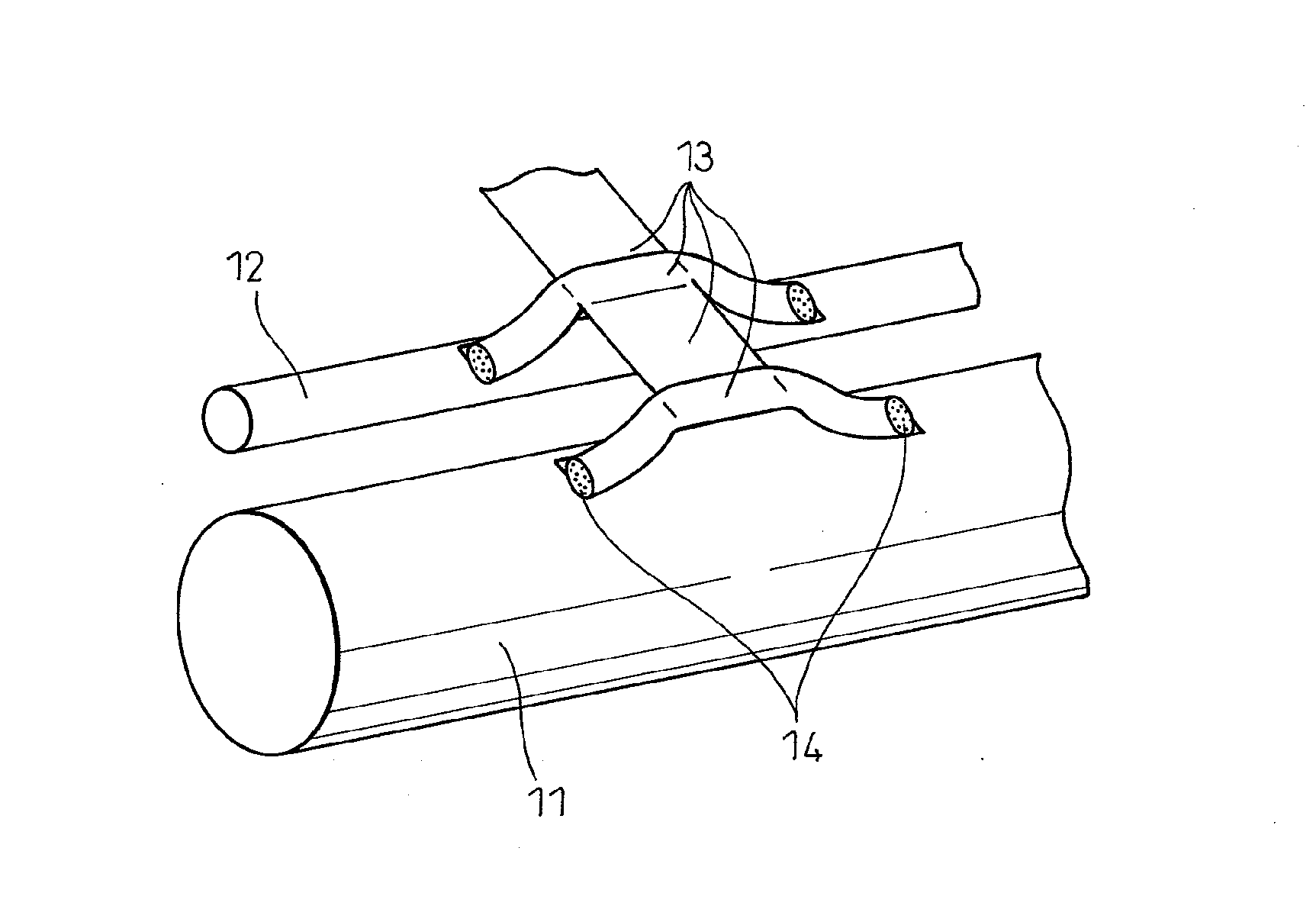

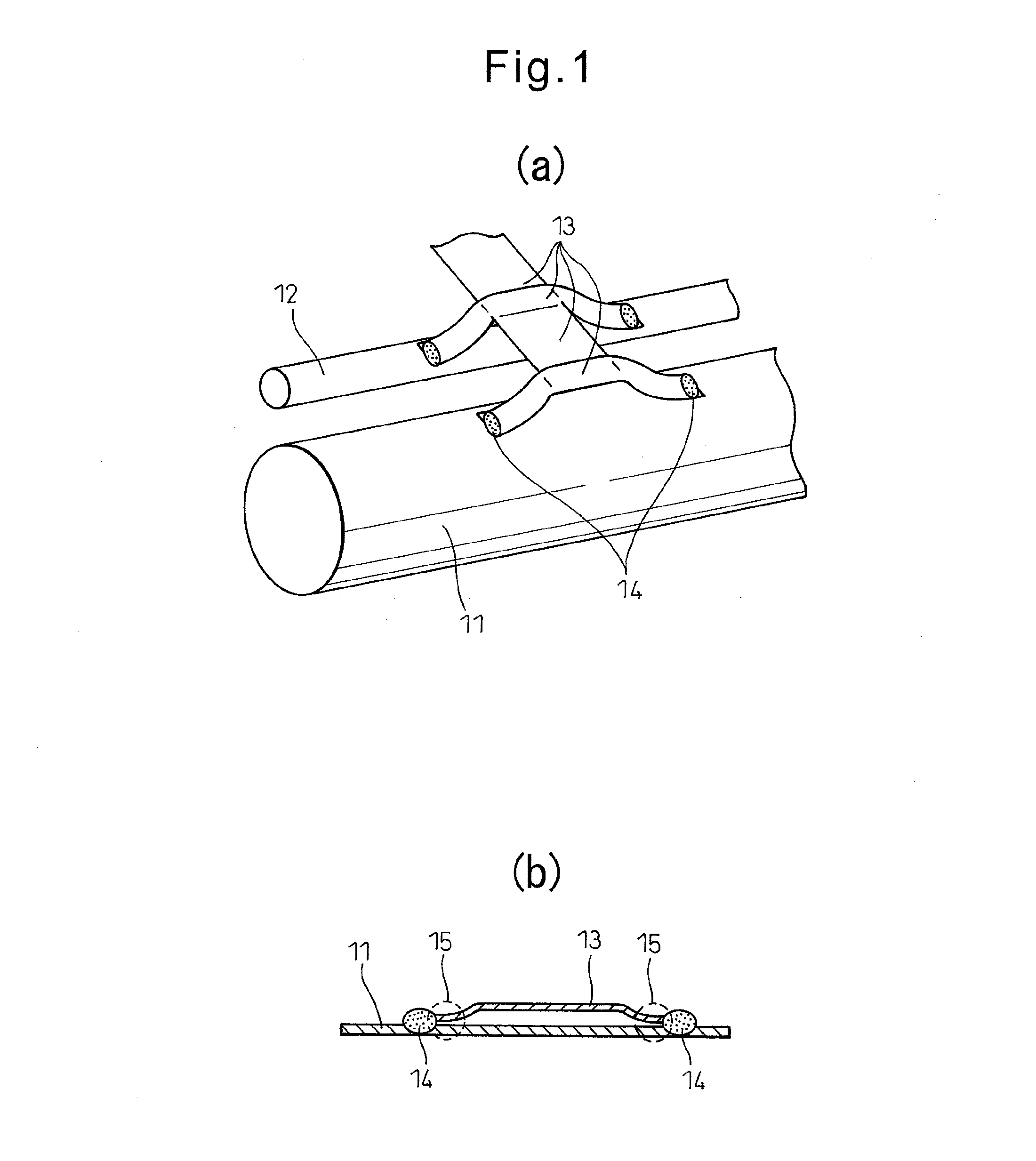

ActiveCN107849845AReliable corrosion resistanceElongated constructional elementsWire networkEngineeringLow overhead

The invention relates to a lattice structure consisting of intersecting longitudinal and transverse elements (2 and 3) such as wires, stranded wires, ropes, rods and / or profiled sections, having intersection points (6) associated therewith. These longitudinal and transverse elements (2 and 3) are interconnected by twisting at least at said intersection points (6). The connection may also be established by insertion one into another and / or by knotting. This results in a connection between the longitudinal and transverse elements which can be established without external connector means and withcomparatively low overheads.

Owner:GEOBRUGG AG

Inexpensive automobile component and oil feed pipe having excellent salt corrosion resistance

ActiveUS20180031169A1Reduce corrosionConservation usefulnessVehicle sub-unit featuresCorrosion preventionChlorideMetal

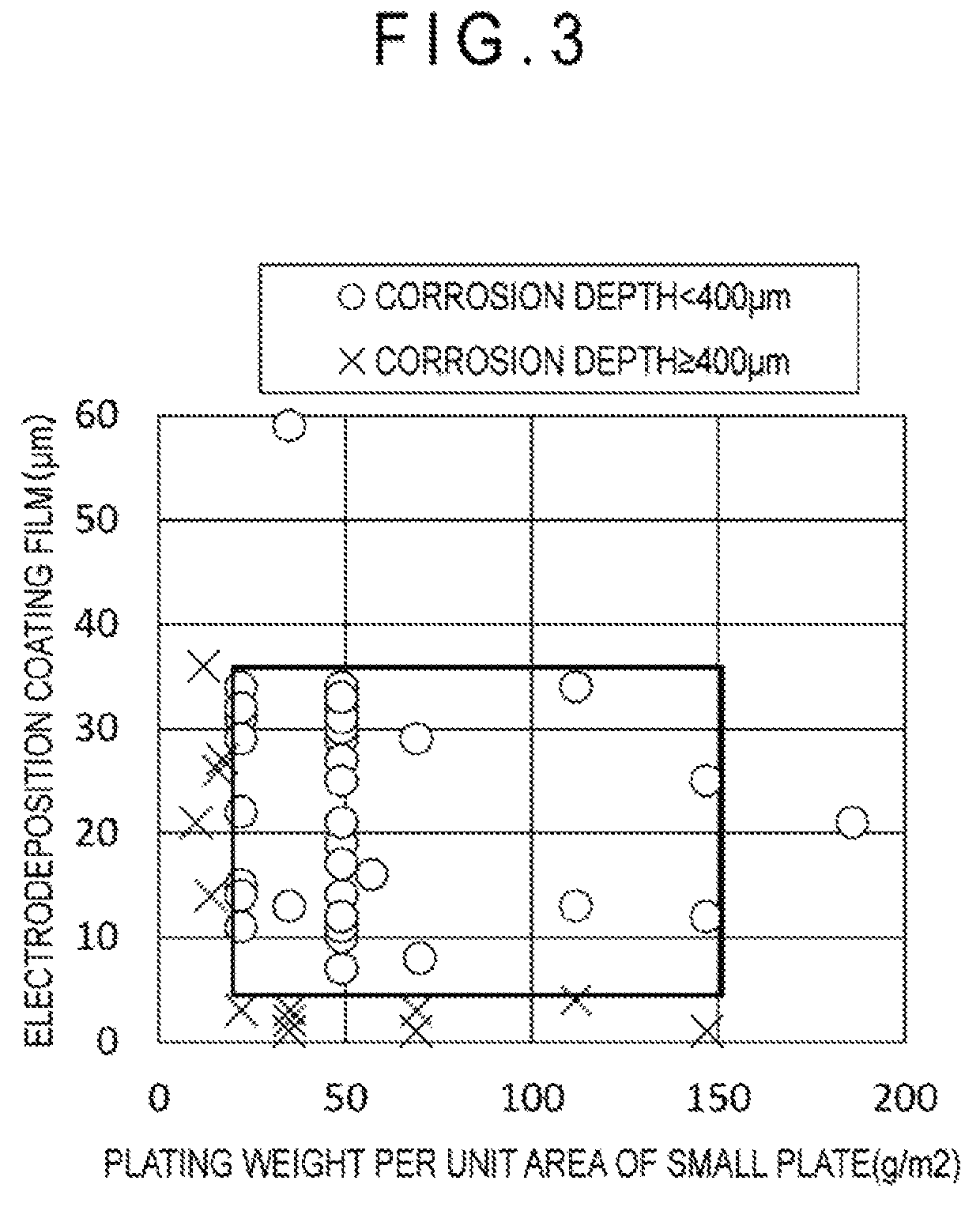

An automotive member or oil filler pipe includes: a member of ferritic stainless steel containing, in mass %, at most 0.015% of C, at most 0.015% of N, 10.5 to 18.0% of Cr, 0.01 to 0.80% of Si, 0.01 to 0.80% of Mn, at most 0.050% of P, at most 0.010% of S, 0.010 to 0.100% of Al, more than 0.3 to 1.5% of Mo, and one or both of 0.03 to 0.30% of Ti and Nb; and a metal fitting of an aluminized stainless steel sheet, which is attached to the member to define therebetween a gap structure to be exposed to a chloride environment, and has an Al-plating weight per unit area ranging from 20 to 150 g / m2 in the gap structure. Surfaces of the metal fitting and member not facing the gap are coated with a cation electrodeposition coating film having a thickness of 5 to 35 μm.

Owner:NIPPON STEEL STAINLESS STEEL CORP

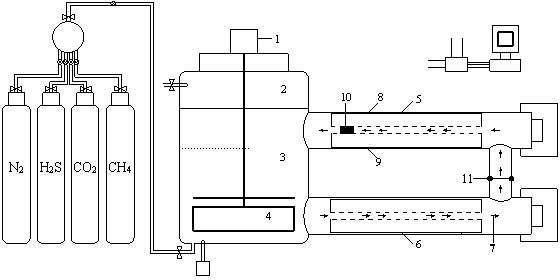

High-temperature high-pressure multiphase flow corrosion testing method and device

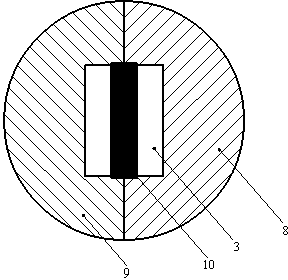

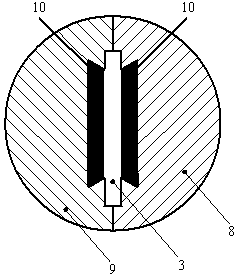

InactiveCN102654446BFully contactedReliable corrosion resistanceWeather/light/corrosion resistanceSuspended particlesTest sample

The invention discloses a high-temperature high-pressure multiphase flow corrosion testing method and a high-temperature high-pressure multiphase flow corrosion testing device. The key points are as follows: under high temperature and high pressure conditions, circular flow of a gaseous-phase corrosive medium and a liquid-phase corrosive medium and thorough contact of the two mediums with the surface of a test sample are kept so that the mechanisms of corrosive actions of factors such as flow velocity, tube ponding, and deposited elemental sulphur can be simulated and researched; and the study on the influencing rules of gaseous-phase, liquid-phase, solid-phase and multiphase flows, suspension and suspended particles on the corrosion actions is also included. The testing method and the device are capable of realizing simulation of various corrosive working conditions: measuring the corrosion resistance of a metal material under various corrosive working conditions and in corrosive environments in high-temperature high pressure gaseous-phase, liquid-phase and multiphase flow states, and measuring the corrosion resistance and the corrosion rate of an oil sleeve in exploitation states such as water-carrying exploitation and water-gathered exploitation. Besides, the corrosion resistance of the metal material is comprehensively evaluated under the multiphase flow high-temperature high-pressure corrosion condition; and the preference of the metal material in a specific corrosive environment is realized according to testing results.

Owner:SOUTHWEST PETROLEUM UNIV

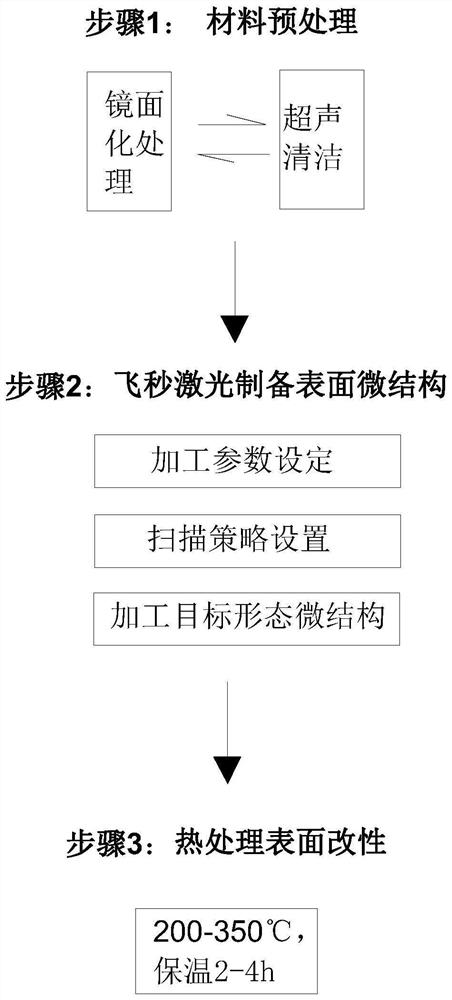

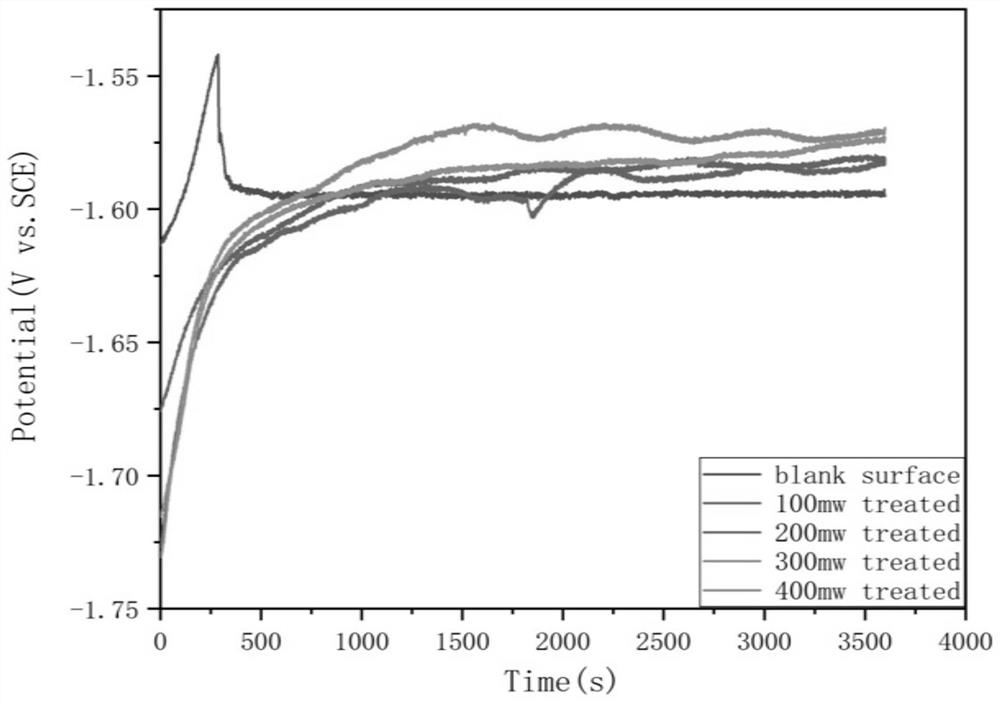

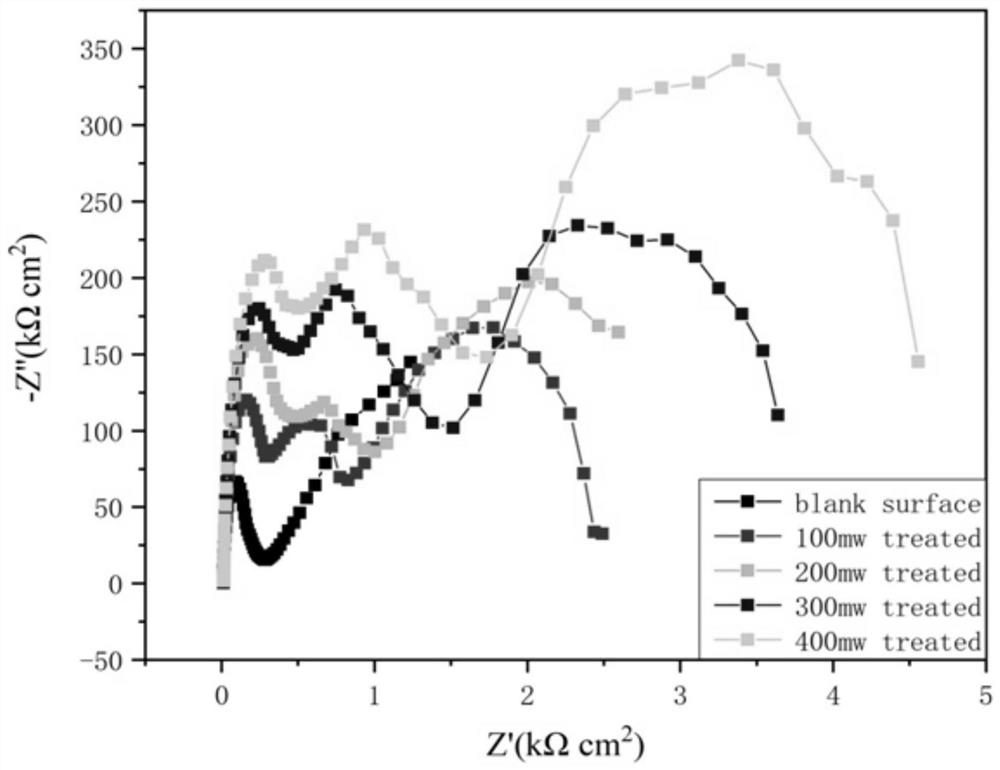

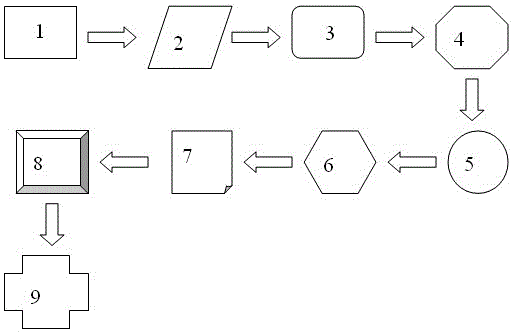

Method for enhancing corrosion resistance of magnesium alloy material

PendingCN114686894AImprove corrosion resistanceEliminate performance impactGrinding machinesLaser beam welding apparatusFemto second laserMetallic materials

The invention belongs to the field of metal material processing, and particularly relates to a method for enhancing the corrosion resistance of a magnesium alloy material. The method comprises the following steps: S1, material pretreatment: carrying out surface pretreatment and cleaning treatment on a magnesium alloy material to form a mirror surface on the surface of the magnesium alloy material; s2, preparing a surface microstructure through femtosecond laser, wherein a femtosecond laser processing system with the laser wavelength being 800 nm, the pulse width being 104 fs and the frequency being 1 kHz is selected; processing parameters are set according to the material size and a preset processing scheme, different scanning strategies are adopted, and a microstructure composed of periodic grooves and ridges is prepared on the surface of the magnesium alloy material with the laser power not lower than 100 mW; and S3, heat treatment surface modification is conducted, specifically, the magnesium alloy material with the surface microstructure machined in the previous step is subjected to heat treatment for 2-4 h at the temperature of 250-300 DEG C. According to the process method, the problems that a traditional magnesium alloy corrosion-resistant treatment process is large in difficulty and high in machining cost, the strength of a corrosion-resistant structural layer is insufficient, and the environment is prone to being polluted are solved.

Owner:HEFEI UNIV OF TECH

Surface-Treated Steel Sheet, Organic Resin Coated Metal Container, and Method for Producing Surface-Treated Steel Sheet

InactiveUS20160230301A1Improve adhesionPrevent peelingCellsElectrolytic coatingsSheet steelAqueous solution

Provided is a surface-treated steel sheet with a compound layer containing F and composed essentially or Zr at least on one surface thereof, wherein the Zr amount is 80 to 350 mg / m2 and the F amount is 0.5 to 10 mg / m2 within the layer, and an organic resin coated metal container manufactured using the surface-treated steel sheet. The surface-treated steel sheet of the present invention is manufactured through forming a layer having the Zr amount of 80 to 350 mg / m2 at least on one surface of a steel sheet by cathode electrolytic treatment in an aqueous solution containing a Zr ion and F ion, and subsequently adjusting the surface to control the F amount to 0.5 to 10 mg / m2 by one or more treatments selected from immersion and spraying with an ion-containing aqueous solution and cathode electrolytic treatment in the ion-containing aqueous solution.

Owner:TOYO KOHAN CO LTD +1

Short process carbon steel/stainless steel composite steel wire production method

ActiveCN104028570BStrong adhesionReliable corrosion resistanceExtrusion cleaning devicesCarbon steelToughness

A short-flow production method for a carbon steel / stainless steel composite steel wire is characterized by comprising the following technological steps: step 1, using a machinery steel brush to remove dust; step 2, enabling a carbon steel wire subjected to machinery-steel-brush dust removal to firstly pass a box loaded with a binder and to pass through a stainless steel powder box, so as to attach the stainless steel powder to the carbon steel wire; step 3, enabling the carbon steel wire with the adhered stainless steel powder to pass through an ultrahigh-frequency-induction electric impulse heating apparatus for heating; step 4, enabled the heated carbon steel wire with the adhered stainless steel powder to pass through a mold drawing apparatus with a micro compression ratio for drawing, and then performing cooling processing by arranging a cooling apparatus, so as to form the carbon steel / stainless steel composite steel wire; and step 5, taking up the combined carbon steel / stainless steel composite steel wire by using a take-up apparatus. The composite steel wire prepared by employing the method is smooth, bright, clean and mark-free in the surface, and the stainless steel outer layer is uniform, high in adhesive force, durable in corrosion resistance and good in toughness and elasticity.

Owner:FASTEN HONGSHENG GRP CO LTD

Light partition board and preparation method thereof

The invention relates to a light partition board and a preparation method thereof and belongs to the field of building materials. The light partition board is composed of a panel and a core plate, wherein the panel is formed by pouring raw materials comprising cement, slag and coal ash; and the core plate is a flame-retardant plate which is poured in the panel as an interlayer. According to the light partition board and the preparation method provided by the invention, the fireproof flame-retardant plate is used as the core plate, so that the fireproof insulating property of the light partition board can be greatly improved. Moreover, original gridding cloth is replaced by a galvanized steel wire net, and the galvanized steel wire is better in adhesive force, corrosion resistance, toughness and elasticity than those of the griding cloth, so that a wall body is unlikely to crack and deform and is greater in strength. Original plastic clips are also replaced by reinforcing steel bar clips, and can be recycled, and moreover, the clip parts can be poured to enhance the strength of the wall material at the clip parts, so that the integral strength is improved.

Owner:新疆瑞通市政建设工程有限公司

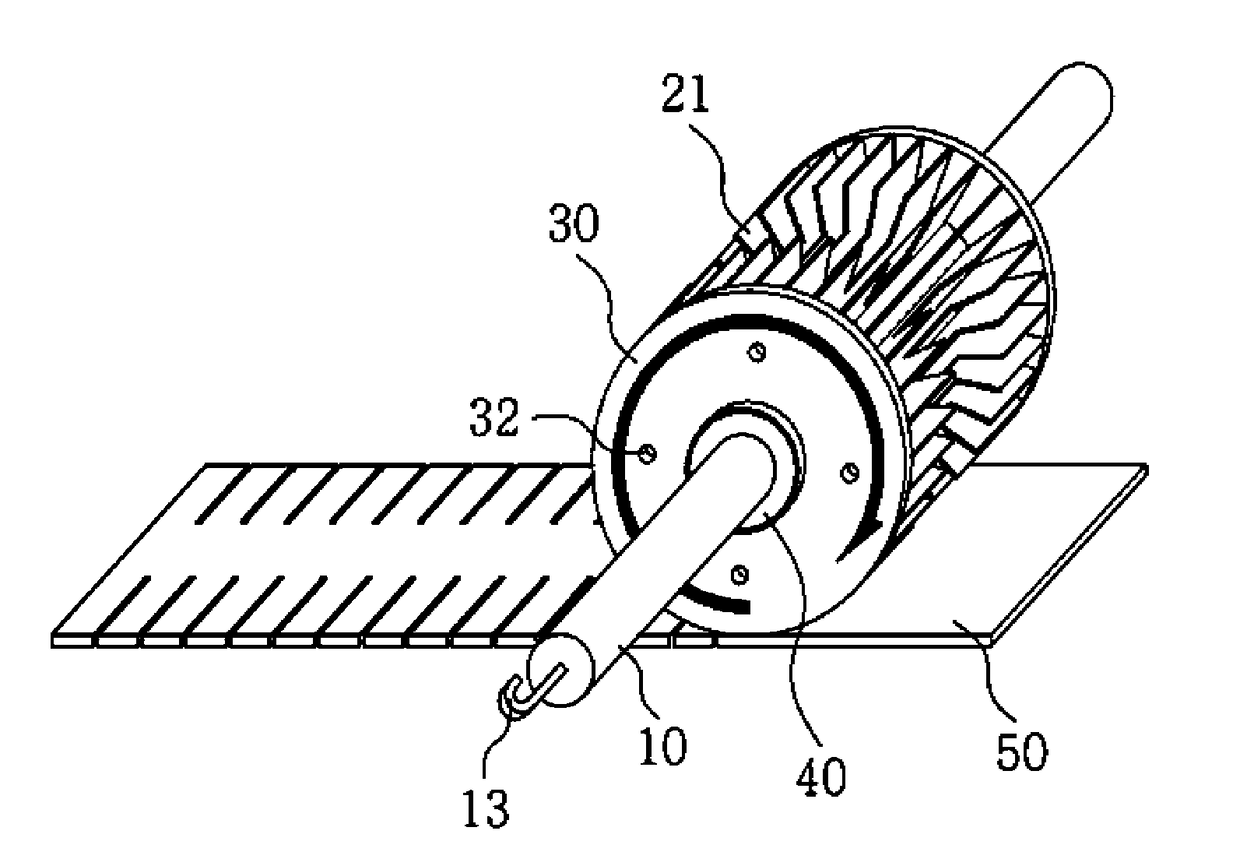

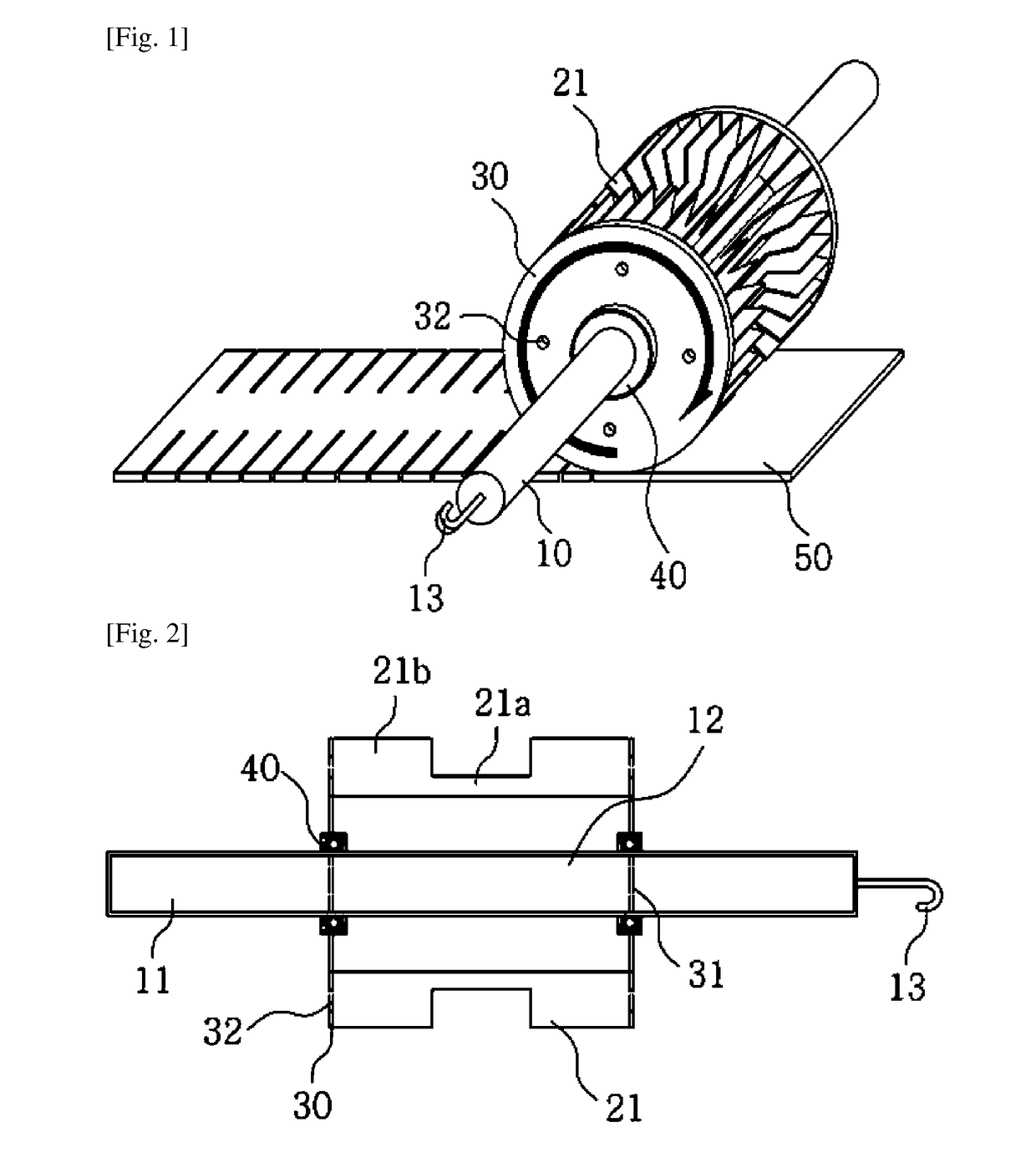

Doughnut dough shaping machine

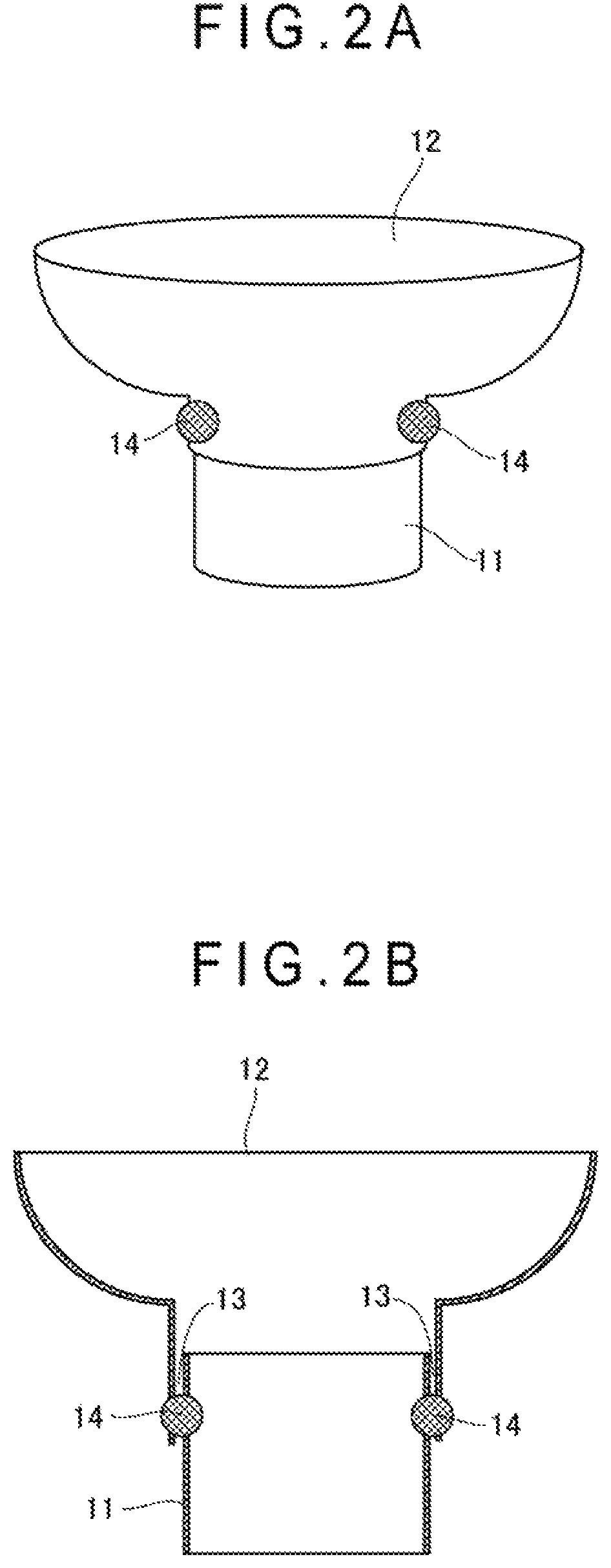

InactiveUS20180110232A1Efficient productionMaximize efficiencyDough embossing machinesDough shaping and dividing combinationEngineeringRing doughnut

A doughnut dough shaping machine, has a plurality of shaping bodies, which constitute a shaping part, arranged at predetermined gaps and coupled between two disc-type shaping support parts; has a cylinder rod-shaped operating part, which comprises a coupling part and a handle part, provided at through-parts perforated at the center of each shaping support part by means of bearing parts, so as to roll the shaping support parts and the shaping part on the upper surface of the doughnut dough, thereby making a uniform doughnut; and cuts only both end sections of the doughnut dough by non-cut shaping parts at the centers of the shaping bodies and cut-shaping parts at both ends thereof, such that the cut doughnut dough is overlapped in a cylinder shape, thereby producing a flower-shaped doughnut.

Owner:KANG JU HUI

Surface treatment solution composition containing trivalent chromium and inorganic compound, and method for manufacturing hot dip galvanized steel sheet surface-treated using same

PendingUS20210388504A1Good alkali resistanceImprove corrosion resistanceHot-dipping/immersion processesAnti-corrosive paintsColloidal silicaChromium Compounds

Provided is a surface treatment solution composition comprising: 30 to 51 wt % of a trivalent chromium compound comprising chromium phosphate (A) and chromium nitrate (B) and having a content ratio of A / (A+B) that satisfies 0.3 to 0.6; 5 to 15 wt % of silane coupling agent; 0.2 to 3 wt % of vanadium-based anti-corrosive rust inhibitor; 3 to 12 wt % of colloidal silica; 0.5 to 5 wt % of polysiloxane copolymer; and 14 to 61.3 wt % of water, a hot dip galvanized steel sheet surface-treated using same, and a manufacturing method thereof. The hot dip galvanized steel sheet treated with the surface treatment solution composition containing trivalent chromium has an excellent corrosion resistance, blackening resistance, pipe-forming oil reactivity, and alkali resistance.

Owner:POHANG IRON & STEEL CO LTD

A kind of manufacture method of cationic water-based chlorine partial metal anti-corrosion coating

ActiveCN103044600BImprove mechanical stabilityGood ion toleranceAnti-corrosive paintsWater basedHigh pressure

The invention discloses a manufacturing method of cationic room-temperature crosslinking water-based vinylidene chloride metal anti-corrosion paint, which is characterized in that resin of the paint is cationic vinylidene chloride latex; an cationic emulsifier is polymerized with high pressure emulsions of a vinylidene chloride monomer and an acrylate monomer; an initiator is mixed by an oil-soluble initiator and a water-based initiator; the prepared vinylidene chloride latex is good in mechanical stability, and can be grinded together with a rust-resistant pigment; the cationic durability is good; cations dissociated from the rust-resistant pigment do not influence the storage stability of the water-based paint; and the anti-corrosion effect is excellent.

Owner:JIANGSU RONGCHANG NEW MATERIAL TECH

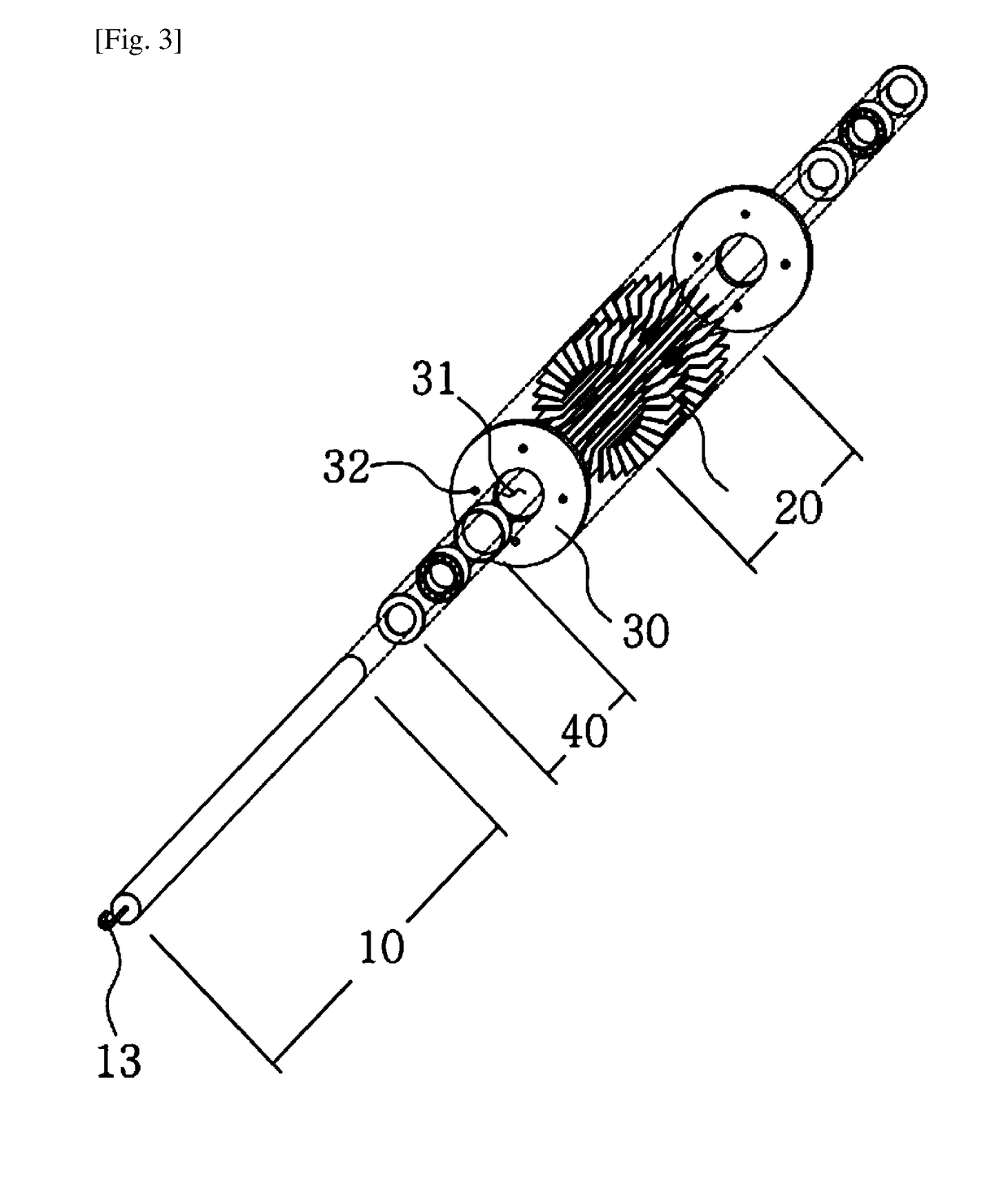

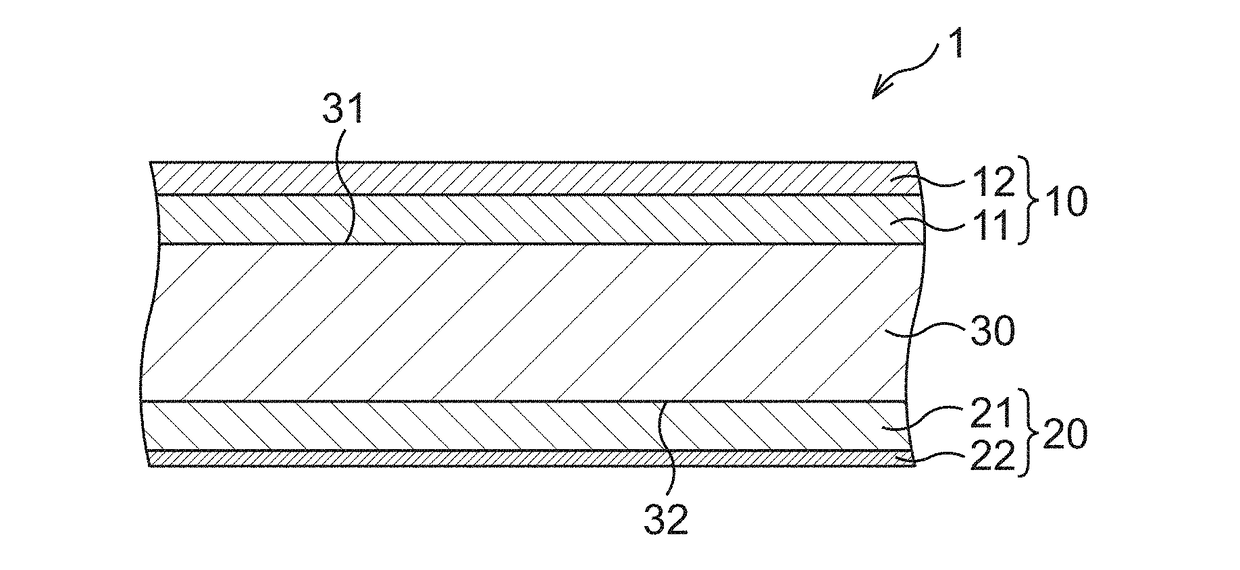

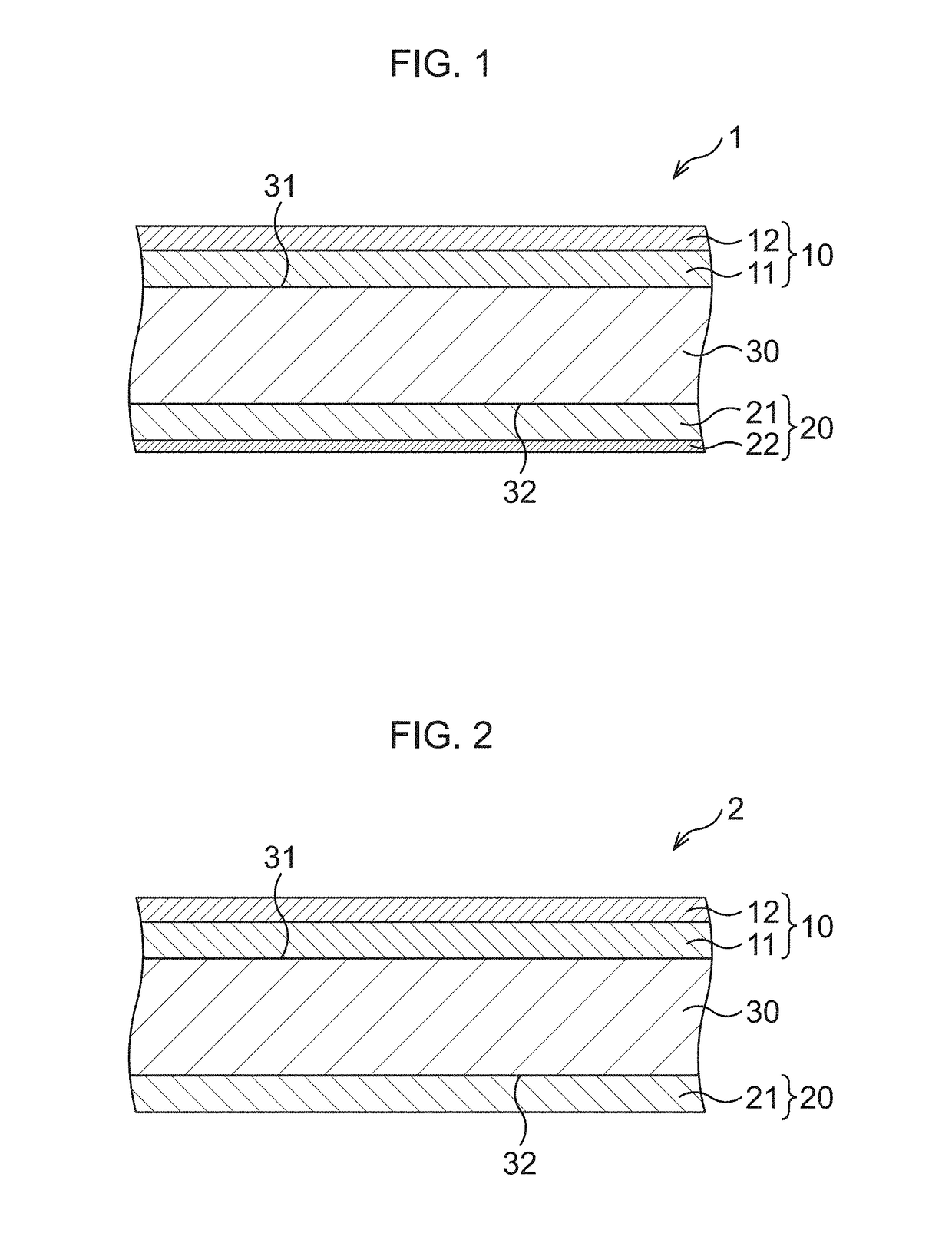

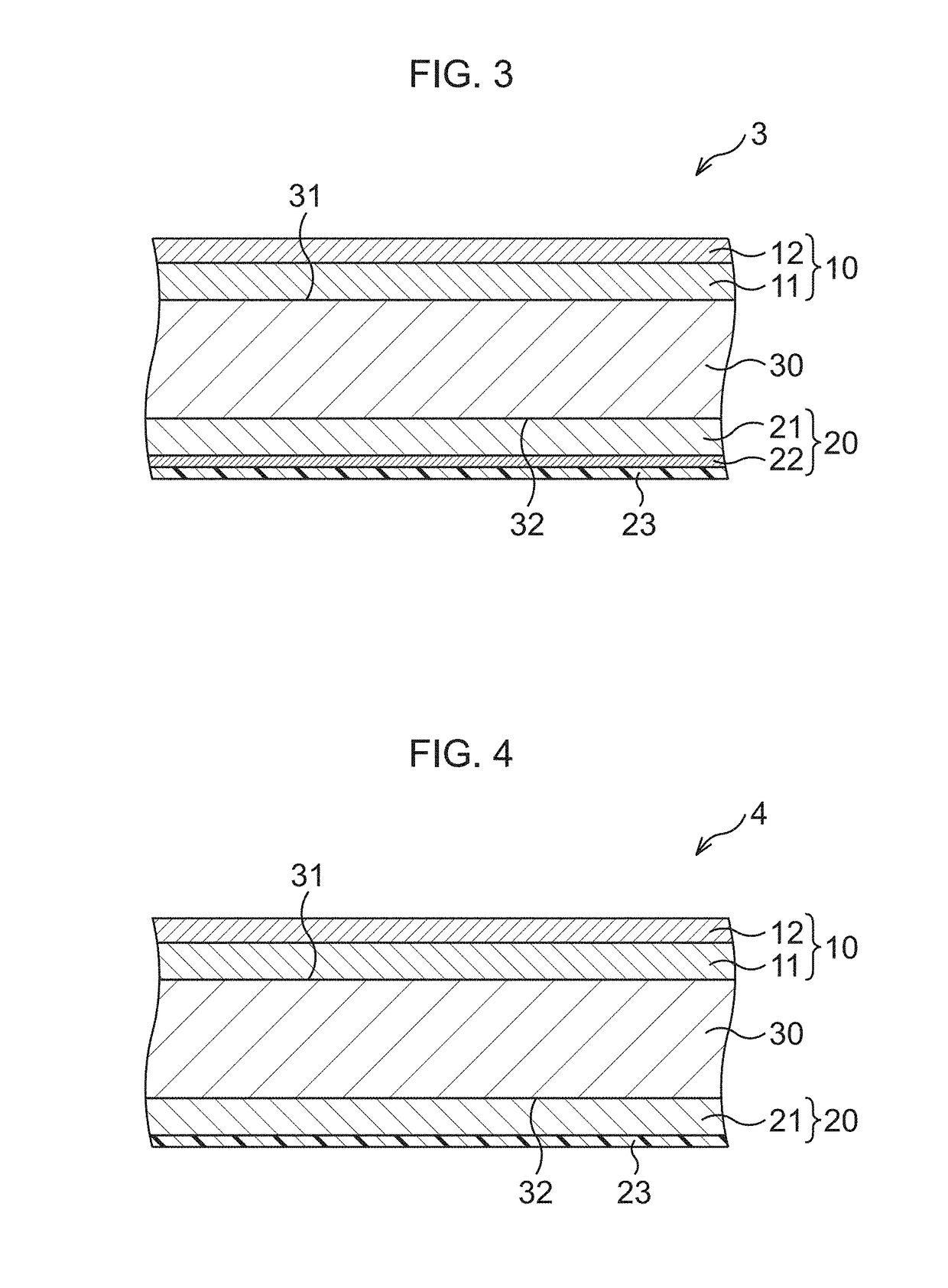

Plated steel sheet and fuel tank

InactiveUS20180201123A1Improve solderabilityReliable corrosion resistanceHot-dipping/immersion processesUnderstructuresFuel tankAlloy

A hot stamp molded body includes: a steel sheet (30); a first plating layer (10) on a first surface (31) of the steel sheet (30); and a second plating layer (20) on a second surface (32) of the steel sheet (30). The first plating layer (10) includes: a first Al—Fe—Si alloy layer (11) on the first surface (31); and a first Al—Si alloy layer (12) on the first Al—Fe—Si alloy layer (11). The second plating layer (20) includes: a second Al—Fe—Si alloy layer (21) on the second surface (32); and a second Al—Si alloy layer (22) on the second Al—Fe—Si alloy layer (21). A coating weight of the first plating layer (10) is 31 g / m2 to 60 g / m2 and a coating weight of the second plating layer (20) is 5 g / m2 to 29 g / m2.

Owner:NIPPON STEEL CORP

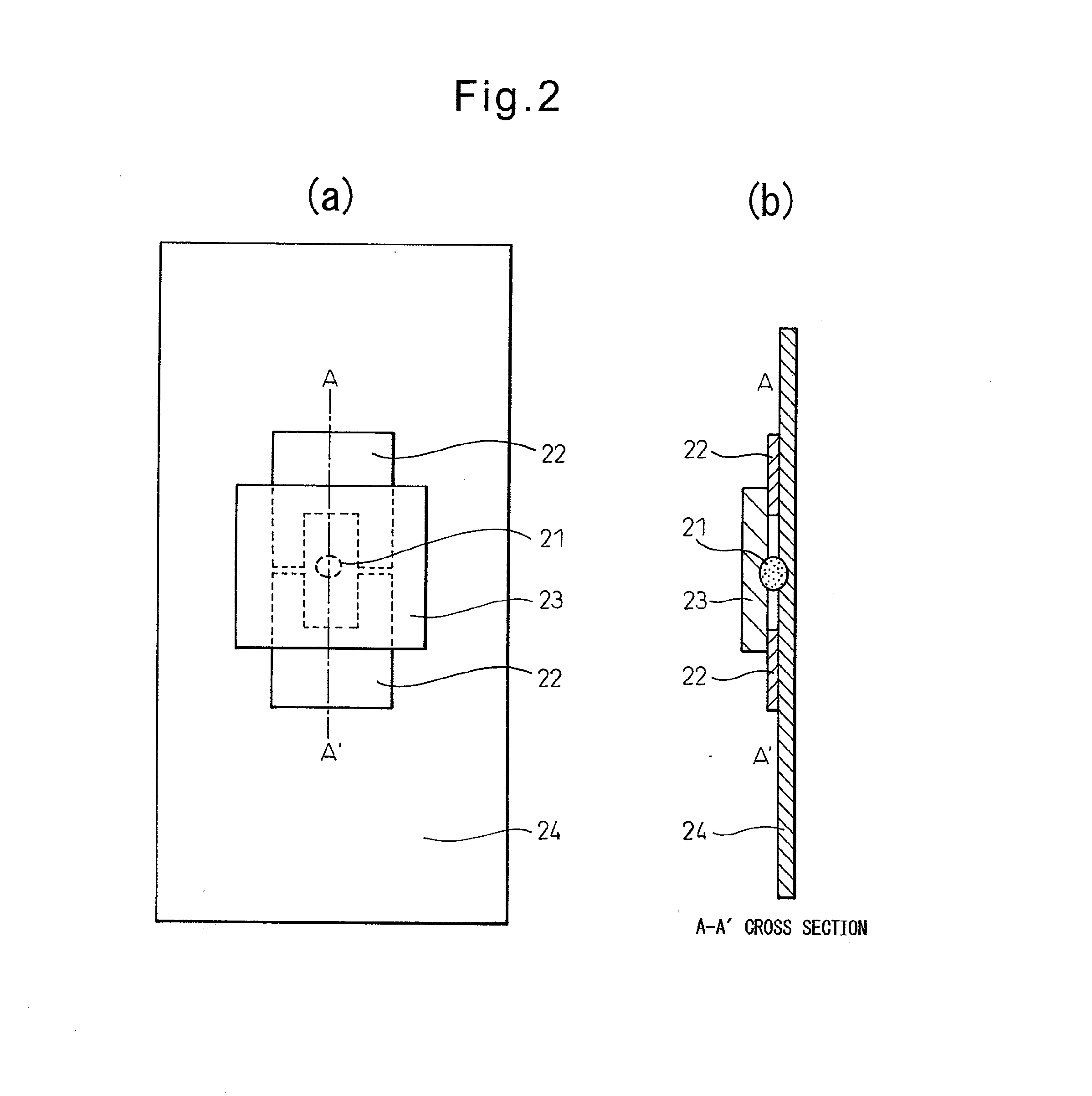

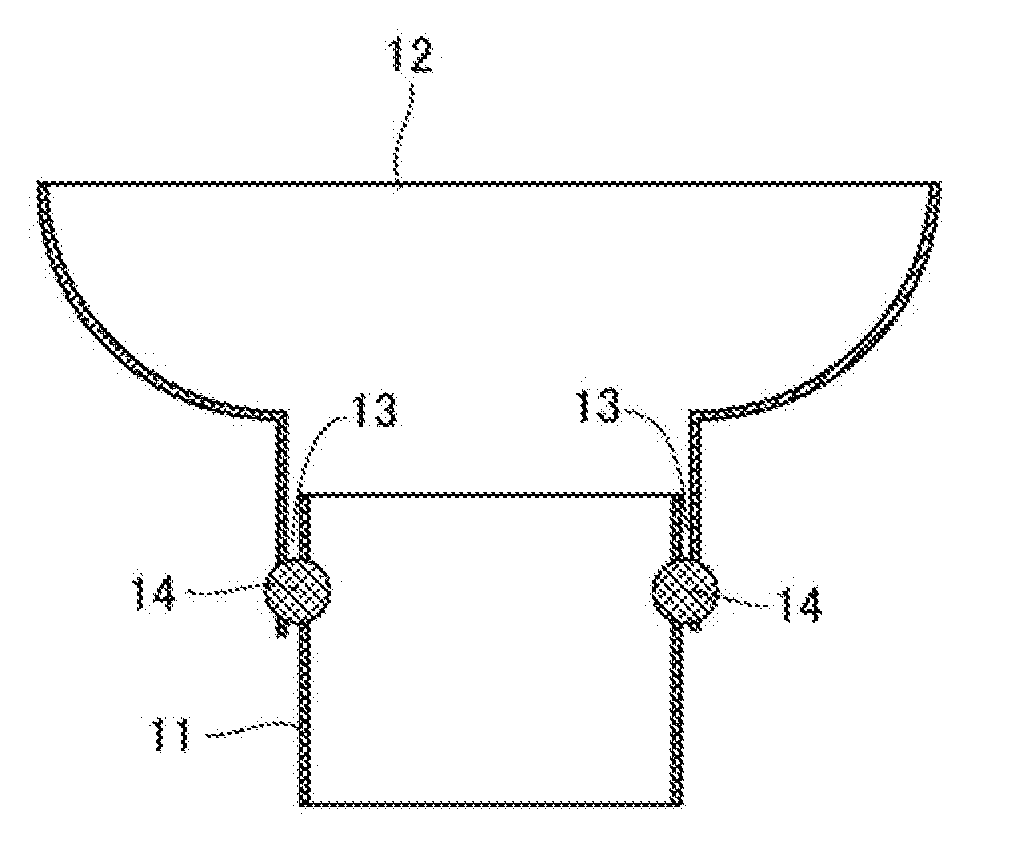

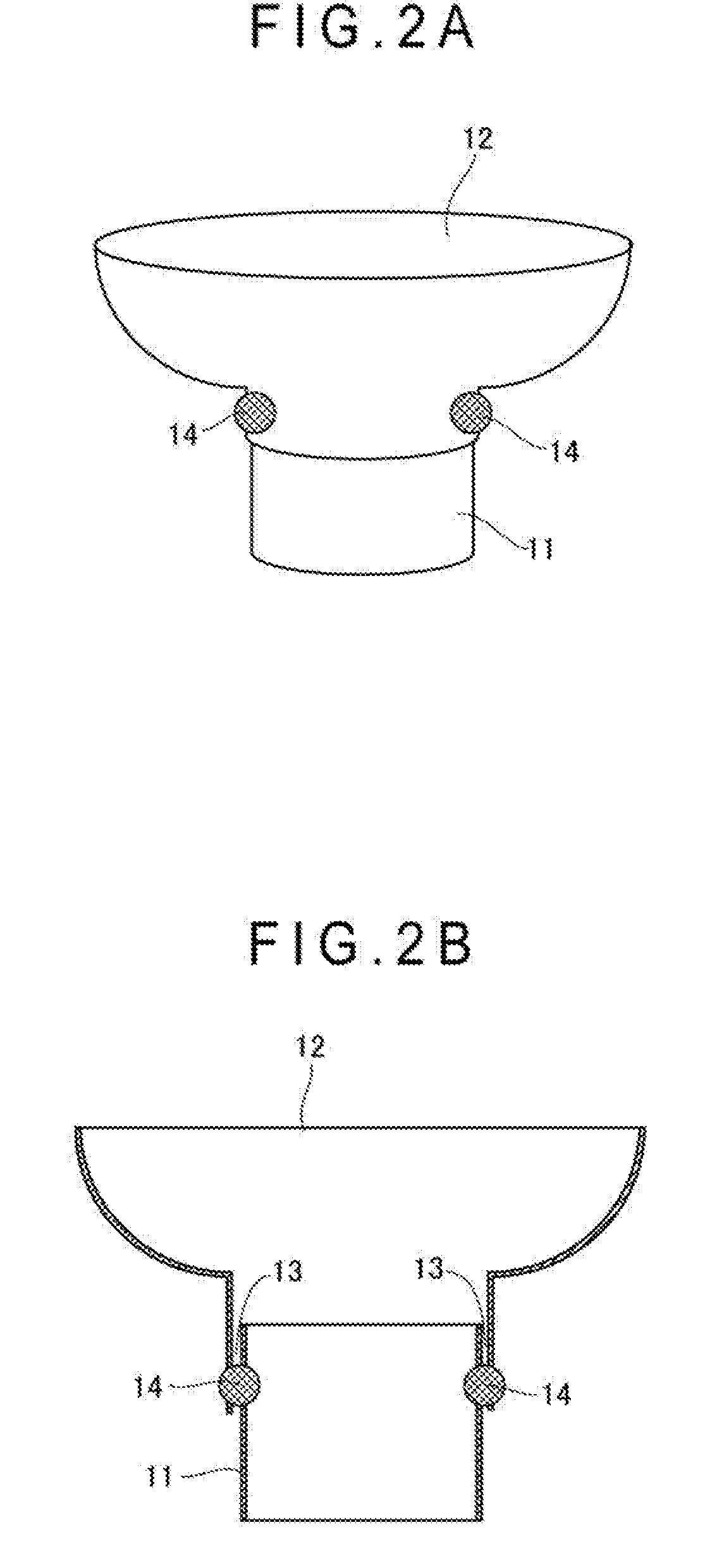

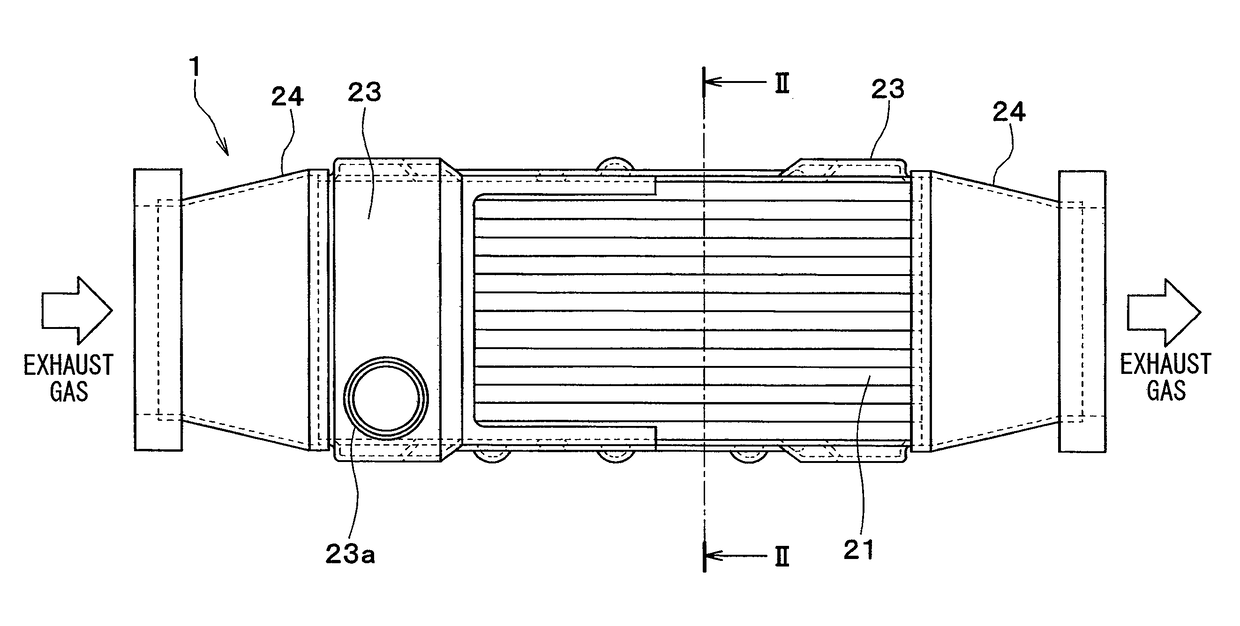

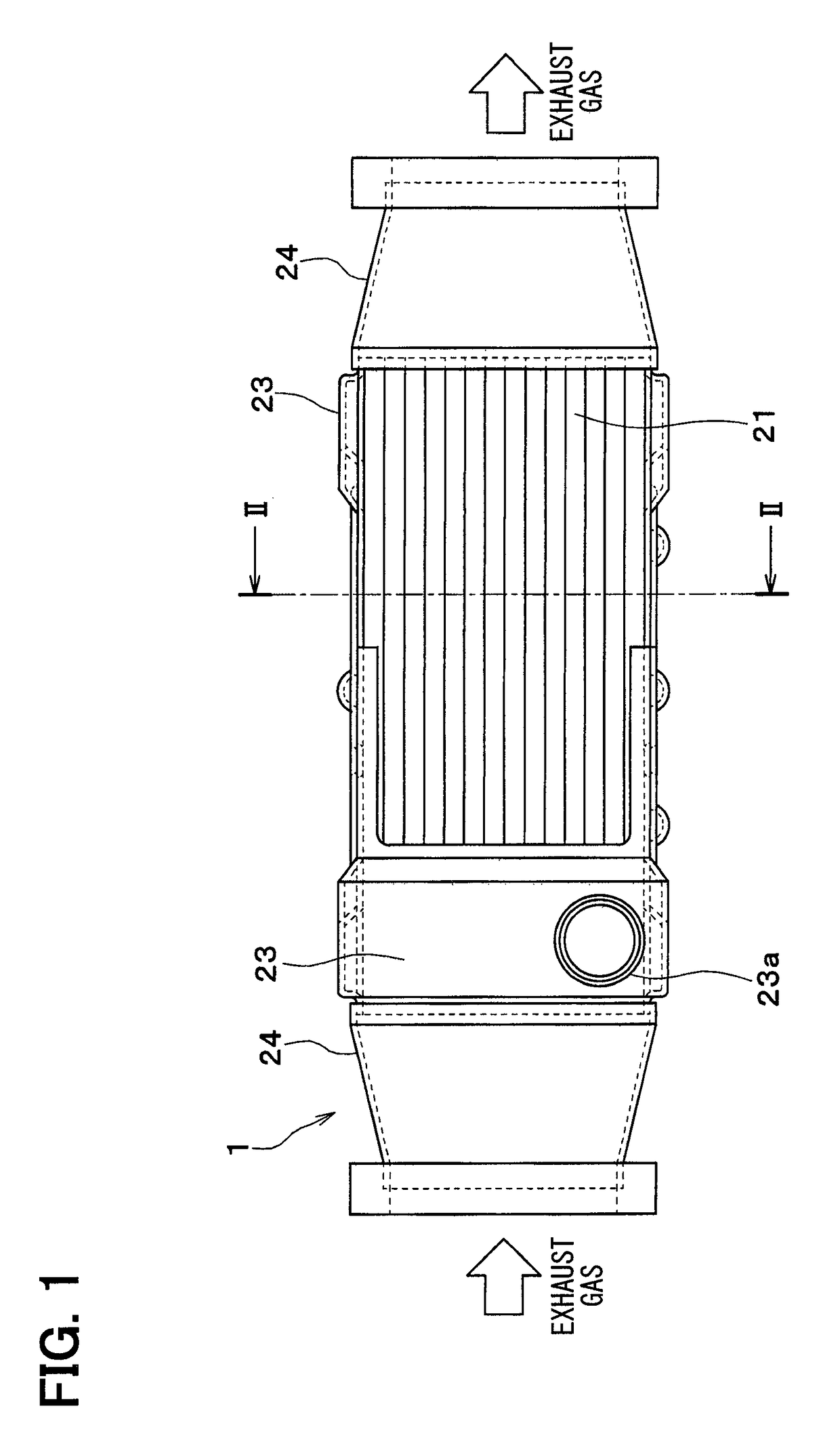

Method for manufacturing heat exchanger, and heat exchanger

InactiveUS9956654B2Reliable corrosion resistanceImprove corrosion resistanceStationary tubular conduit assembliesChemical vapor deposition coatingPlate heat exchangerGas phase

A method for manufacturing a heat exchanger includes: assembling a plurality of heat exchanger components in an assembly step; and forming a film on surfaces of the heat exchanger components using a chemical vapor deposition method in a film formation step after the assembly step. The film can restrict a formation of a through hole due to corrosion. The film can be restricted from being damaged at a delivery or assembling time, because the film formation step is provided after the assembly step. An occurrence of clogging can be restricted at a minute portion inside of the heat exchanger in the film formation step, because the film is formed using the chemical vapor deposition method.

Owner:DENSO CORP

Surface-treated steel sheet, organic resin coated metal container, and method for producing surface-treated steel sheet

ActiveUS10934629B2Increase resistanceEasily exposedCellsElectrolytic coatingsElectrolysisResin coating

Provided is a surface-treated steel sheet with a compound layer containing F and composed essentially or Zr at least on one surface thereof, wherein the Zr amount is 80 to 350 mg / m2 and the F amount is 0.5 to 10 mg / m2 within the layer, and an organic resin coated metal container manufactured using the surface-treated steel sheet. The surface-treated steel sheet of the present invention is manufactured through forming a layer having the Zr amount of 80 to 350 mg / m2 at least on one surface of a steel sheet by cathode electrolytic treatment in an aqueous solution containing a Zr ion and F ion, and subsequently adjusting the surface to control the F amount to 0.5 to 10 mg / m2 by one or more treatments selected from immersion and spraying with an ion-containing aqueous solution and cathode electrolytic treatment in the ion-containing aqueous solution.

Owner:TOYO KOHAN CO LTD

Heat exchanger

InactiveUS20040194931A1Accelerated corrosionCorrosion resistanceSoldering apparatusCorrosion preventionMechanical engineeringHeat exchanger

A heat exchanger comprising a heat exchange core (1) including a plurality of tubes (2) flowing a medium for heat exchange and a pair of tanks (4) to which ends of said tubes are connected, each tube formed by shaping a plate member (200) not clad with a row laminated brazing material and having a sacrifice layer (210) on an outer surface thereof and a plurality of recessed portions (203) formed on an outer surface of said sacrifice layer and filled with a brazing material (R).

Owner:ZEXEL VALEO CLIMATE CONTROL CORP SAITAMA

Inexpensive automobile component and oil feed pipe having excellent salt corrosion resistance

ActiveUS10539264B2Reduce corrosionConservation usefulnessVehicle sub-unit featuresCorrosion preventionSS - Stainless steelChloride

An automotive member or oil filler pipe includes: a member of ferritic stainless steel containing, in mass %, at most 0.015% of C, at most 0.015% of N, 10.5 to 18.0% of Cr, 0.01 to 0.80% of Si, 0.01 to 0.80% of Mn, at most 0.050% of P, at most 0.010% of S, 0.010 to 0.100% of Al, more than 0.3 to 1.5% of Mo, and one or both of 0.03 to 0.30% of Ti and Nb; and a metal fitting of an aluminized stainless steel sheet, which is attached to the member to define therebetween a gap structure to be exposed to a chloride environment, and has an Al-plating weight per unit area ranging from 20 to 150 g / m2 in the gap structure. Surfaces of the metal fitting and member not facing the gap are coated with a cation electrodeposition coating film having a thickness of 5 to 35 μm.

Owner:NIPPON STEEL STAINLESS STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com