Connecting device and connecting method of internal and external anti-corrosion plastic-steel composite pipe

A steel-plastic composite pipe and connecting device technology, which is applied in the direction of pipeline connection layout, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of time-consuming and labor-intensive pipeline connection construction, poor mechanical properties of steel pipe nozzles, and difficult connection and assembly problems. , to achieve the effect of simplifying on-site construction steps, reliable anti-corrosion performance, and avoiding insufficient strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

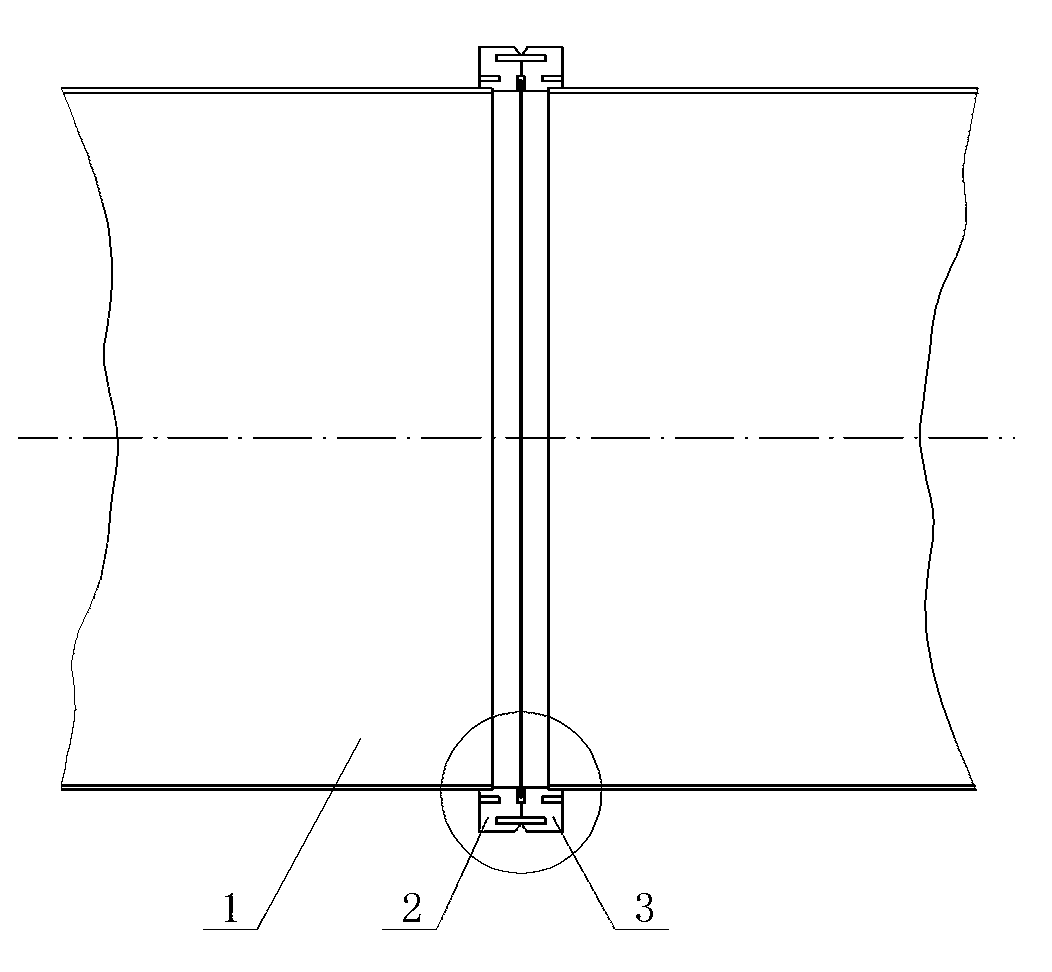

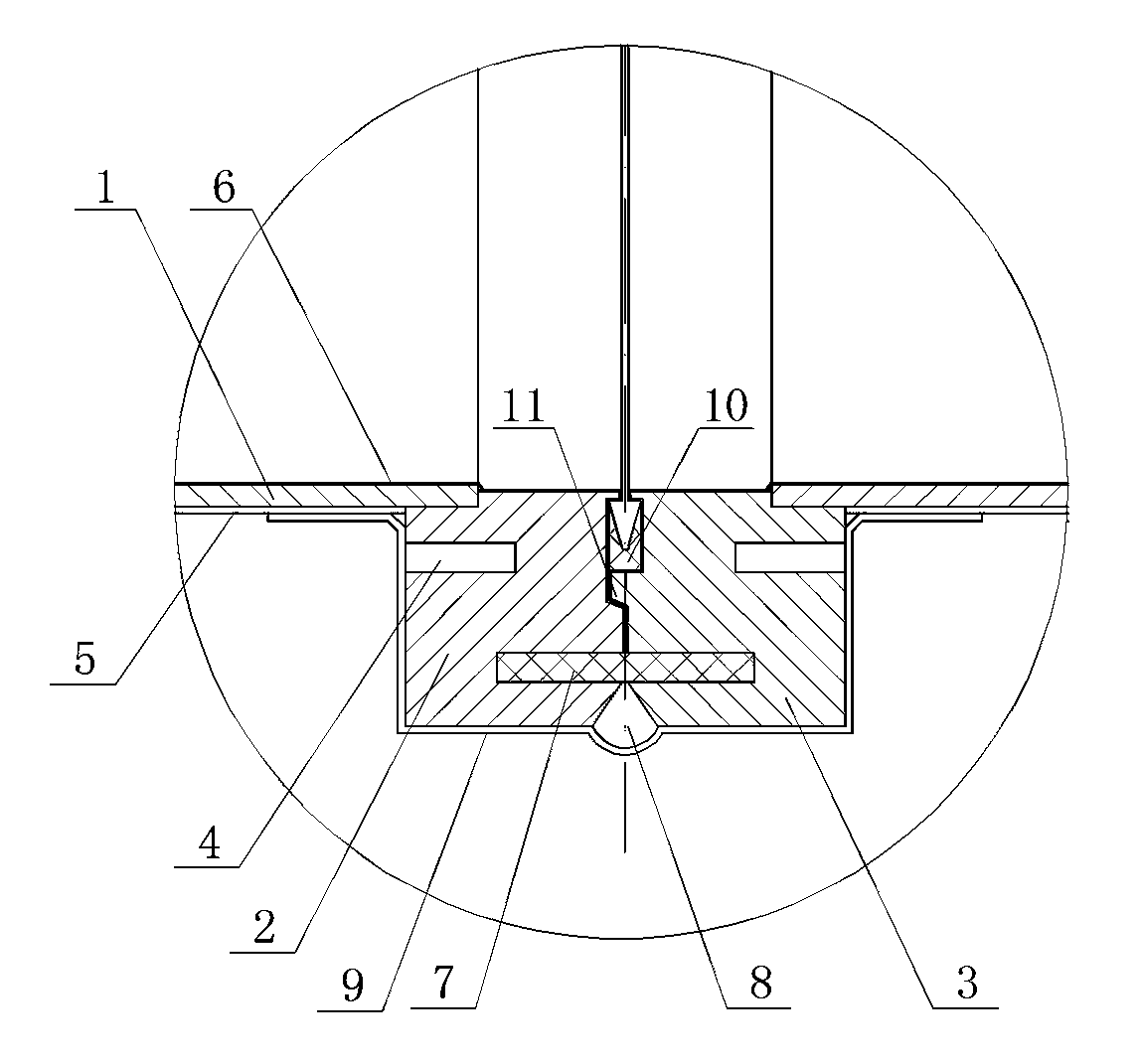

[0027] From Figure 1 ~ Figure 2 It can be seen that including connector A 2, connector B 3, heat insulation lining, sealing ring 10 and anti-corrosion heat shrinkable tape 9; connector A 2 and connector B 3 can be made of Q235B steel, which has good processing performance and low cost , and it is convenient to ensure the quality of on-site welding (ordinary arc welding can meet the welding requirements); the ring-shaped connector A 2 and connector B 3 are respectively fixed on the end of the pipeline 1 by welding, and the connector A 2 and connector B 3 are connected to the The end face of the connecting side of the pipeline 1 is provided with an external heat insulation groove 4; the joint A 2 and the joint B 3 are connected by welding, and the welding port 8 is located at the outer edge of the joint end of the two joints; The inner heat insulation groove 7 and the sealing groove, the inner heat insulation groove 7 is filled with a heat insulation lining layer, and the seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com