Method for in-situ growth of graphene on metal surface based on laser and application of method

An in-situ growth and metal surface technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of inability to provide long-term corrosion resistance, reduce economic losses and the incidence of safety accidents, Effects of reduced processing costs, excellent mechanical properties, and corrosion-resistant friction characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

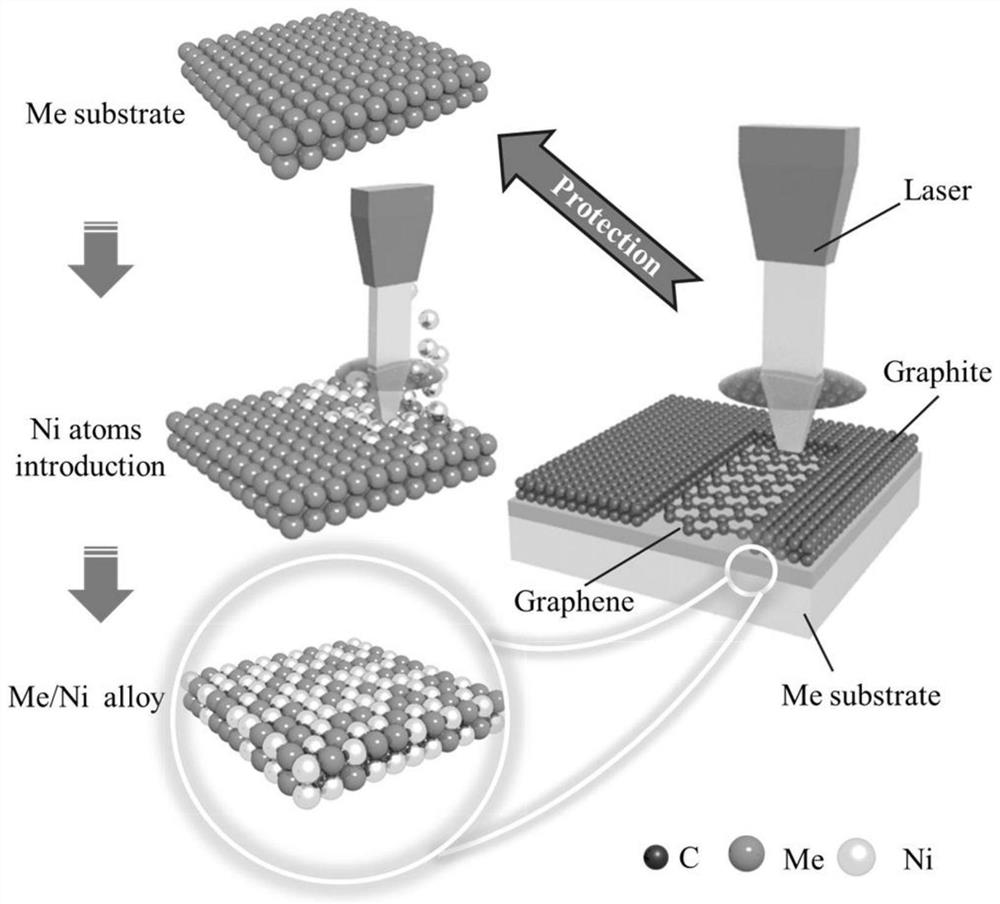

[0047] The Ni / Fe alloy transition layer was prepared on 45# steel with a fiber laser with a maximum power of 2000W, and graphene was prepared in situ on the surface of the Ni / Fe alloy transition layer with a fiber laser with a maximum power of 2000W.

[0048] The preparation steps are as follows:

[0049] (1) Fiber laser preparation of nickel alloy layer

[0050] The surface of 45# steel is irradiated with fiber laser, the powder feeding rate is 5g / min beside the axis, and the particle size of nickel powder is 30μm.

[0051] The laser alloying process parameters are: the laser spot diameter is 0.5mm, the laser power is 1500W, the width of each scanning track is 1mm, and the scanning speed is 10mm / s.

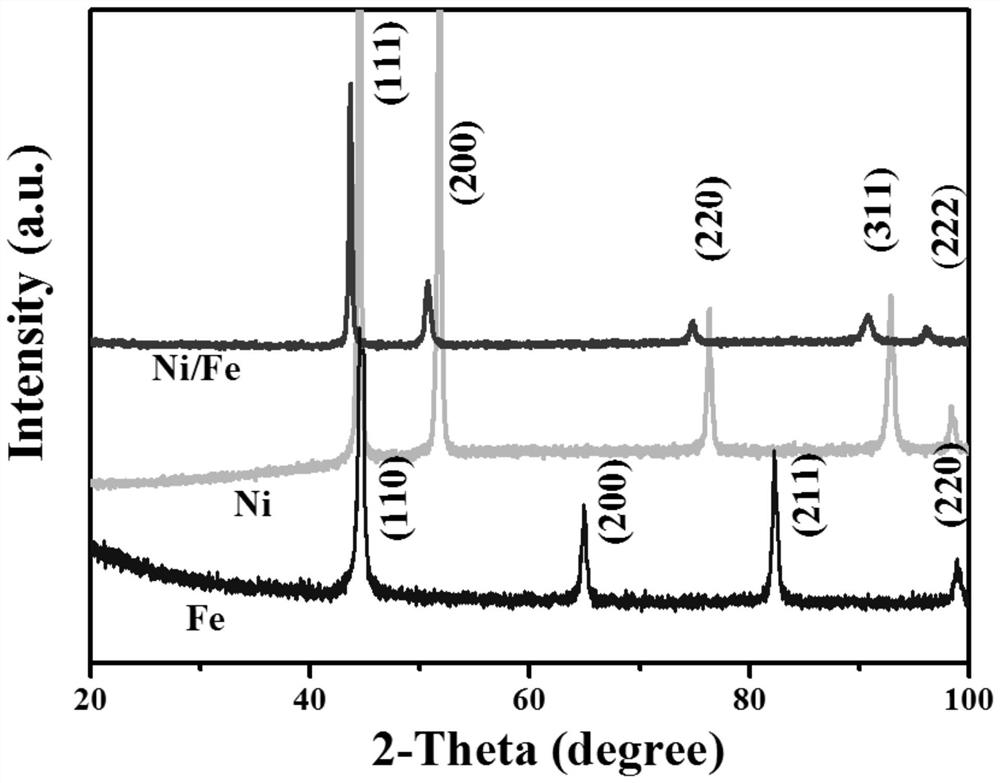

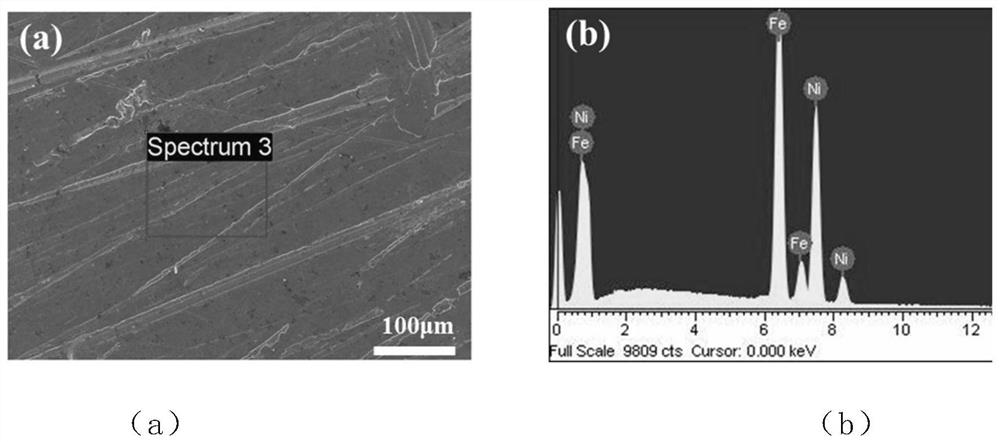

[0052] In order to achieve the full coverage of the surface, the overlapping scanning method is adopted. The second pass and the first pass have a certain overlap, and the overlap rate is 30%. Reciprocating in this way, a large-area Ni / Fe alloy coating is formed, and its XRD pat...

Embodiment 2

[0057] Using a semiconductor laser with a maximum power of 6000W to prepare a Ni / Al alloy transition layer on 6063 aluminum alloy, and then using a semiconductor laser with a maximum power of 6000W to prepare graphene in situ on the surface of the Ni / Al alloy transition layer.

[0058] The preparation steps are as follows:

[0059] (1) Nickel alloy layer prepared by semiconductor laser

[0060] The semiconductor laser was used to irradiate the surface of 6063 aluminum alloy, the feed rate of the side-axis was 10g / min, and the particle size of the nickel powder was 100μm.

[0061] The laser alloying process parameters are: the laser spot diameter is 3mm, the laser power is 5500W, the width of each scanning track is 3mm, and the scanning speed is 50mm / s.

[0062] In order to achieve the full coverage of the surface, the overlapping scanning method is adopted, and the second layer has a certain overlap with the first layer, and the overlap rate is 50%. Reciprocating in this way,...

Embodiment 3

[0067] Using a semiconductor laser with a maximum power of 4000W to prepare a Ni / Ti alloy transition layer on Ti6Al4V titanium alloy, and then using a semiconductor laser with a maximum power of 4000W to prepare graphene in situ on the surface of the Ni / Ti alloy transition layer.

[0068] The preparation steps are as follows:

[0069] (1) Nickel alloy layer prepared by semiconductor laser

[0070] The surface of the Ti6Al4V titanium alloy was irradiated with a semiconductor laser, and the speed of the side-axis powder feeding was 5g / min, and the particle size of the nickel powder was 50μm.

[0071] The laser alloying process parameters are: the laser spot diameter is 2mm, the laser power is 3000W, the width of each scanning track is 2mm, and the scanning speed is 20mm / s.

[0072] In order to achieve full coverage of the surface, the overlapping scanning method is adopted, and the second layer has a certain overlap with the first layer, and the overlap rate is 20%. Reciprocati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com