Short process carbon steel/stainless steel composite steel wire production method

A technology of composite steel wire and production method, applied in the field of metal metallurgy, can solve the problems of high production cost, emission pollution, high energy consumption, and achieve the effects of good toughness and elasticity, long-lasting corrosion resistance and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

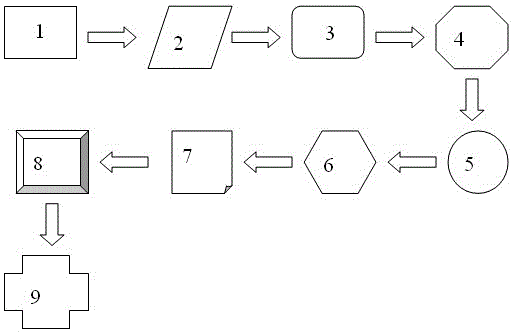

[0020] see figure 1 , figure 1 It is a production process flow chart of the present invention. Depend on figure 1 As can be seen, the short flow process carbon steel / stainless steel composite steel wire production method of the present invention, said method comprises the following processing steps:

[0021] Step 1. Derusting with mechanical steel brush

[0022] After the carbon steel wire on the wire rod is released, it is derusted by a mechanical steel brush through a mechanical steel brush derusting device. The diameter of the carbon steel wire is ¢5.5~13mm, the material is 82A, and the specification is 5.5mm;

[0023] Step two, sticky powder

[0024] The carbon steel wire after derusting by the mechanical steel brush first passes through a box containing an adhesive, and then passes through a 304 stainless steel powder box, so that the carbon steel wire is adhered to stainless steel powder, and the adhesive is polyaldehyde-based bonding agent;

[0025] Step 3. Heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com