High-strength weather-resistant steel with yield strength of 700 MPa and production method thereof

A yield strength and weathering steel technology, applied in the field of preparation of 700MPa grade high-strength weathering steel, can solve the problems of poor processing and forming, shear delamination, large strength fluctuation, etc., to achieve excellent microstructure, stable plate size, toughness and so on. The effect of low brittle transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

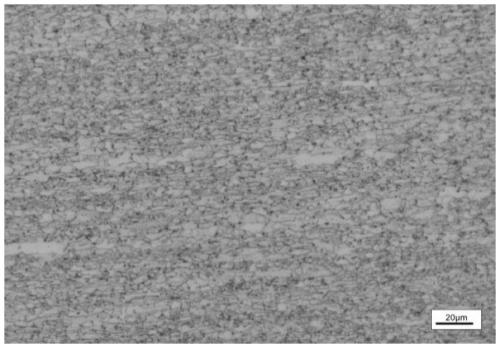

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

[0013] The technical solution of the present invention is: adopting Nb-Ti microalloying process to prepare the components of 700MPa grade high-strength weathering steel, the mass percentages of the chemical components are: C: 0.05-0.09%; Si: 0.25-0.35%; Mn: 1.50-1.60 %; P: ≤0.020%; S: ≤0.005%; Cu: 0.25~0.30%; Cr: 0.30~0.40%; Ni: 0.05~0.15%; : ≤0.006%; O: ≤0.005%; the rest is Fe and unavoidable impurities.

[0014] Based on the design of low carbon and high manganese, the composition of this scheme increases the strength by adding micro-alloying elements Nb and Ti to enhance the strength, and the compounding effect of Nb, Ti and Cr elements, and finally obtains good comprehensive performance.

[0015] If the C content of the steel is too high, although the strength of the steel can be greatly improved, the plasticity of the steel will decrease, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com