Method for enhancing corrosion resistance of magnesium alloy material

A magnesium alloy, corrosion-resistant technology, applied in metal processing equipment, manufacturing tools, grinding machines, etc., can solve the problems of insufficient strength of the corrosion-resistant structural layer, difficult processing technology, and high processing costs, and achieves good prospects for popularization and application. Economic benefits and the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

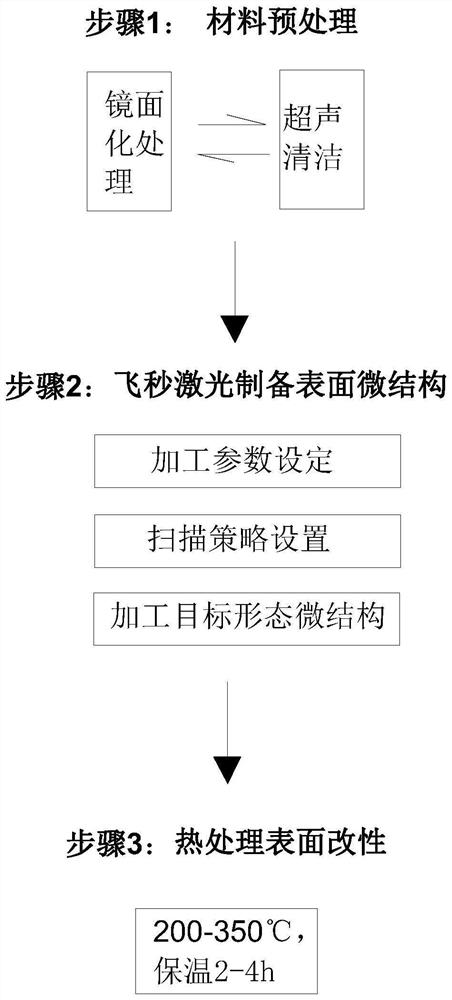

[0040] This embodiment provides a method for enhancing corrosion resistance of magnesium alloy materials, such as figure 1 shown, including the following steps:

[0041] S1: Material Preprocessing:

[0042] Surface pretreatment and cleaning are performed on the magnesium alloy material to form a mirror surface on the surface of the magnesium alloy material.

[0043] Specifically, the surface pretreatment process includes two stages of grinding and polishing and mirror surface treatment. In the process of grinding and polishing, 320, 800, 1200 and 2000 mesh abrasives were used to polish the surface of the magnesium alloy. In the process of mirror treatment, wool cloth and velvet are used for fine polishing in order to process the mirror surface on the surface of magnesium alloy.

[0044] In the cleaning process, acetone, anhydrous ethanol and deionized water are successively used to ultrasonically clean the magnesium alloy material, and then dry.

[0045]S2: Surface micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com