Automotive electric/electronic package

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0107]Examples are given below by way of illustration and not by way of limitation. Note that all parts (pbw) and % are by weight.

preparation examples 1 and 2

[0108]Using the ingredients identified below, perfluoropolyether rubber and gel compositions were prepared as formulated in Table 1.

[0109]The rubber and gel compositions were cured under conditions of 150° C. and 1 hour, following which the hardness of the cured products was measured. The results are also shown in Table 1.

Ingredients

[0110]

TABLE 1(a) Inorganic powder(a-1) copper powder (flake), 3L3 by Fukuda Metal Foil Industry Co.,Ltd.(a-2) synthetic hydrotalcite, Kyoward 500 by Kyowa Chemical IndustryCo., Ltd.(b) Perfluoropolyether oil(b-3)CF3O—(CF2CF2CF2O)e—C2F5e = 27(c) Hydrosiloxane(c-2)(d) Catalyst, toluene solution of platinum-divinyltetra-methyldisiloxanecomplex (platinum content 0.5%)(e) Curing regulator, 50% toluene solution of ethynyl cyclohexanolCompositionIngredients (pbw)12a-1Cu powder (flake)5a-2Kyoward 5002b-1Perfluoropolyether 110055b-2Perfluoropolyether 220b-3Perfluoropolyether 325c-1Hydrosiloxane 12c-2Hydrosiloxane 220dPt compound0.20.12eCuring regulator0.30.15JIS ...

example 1

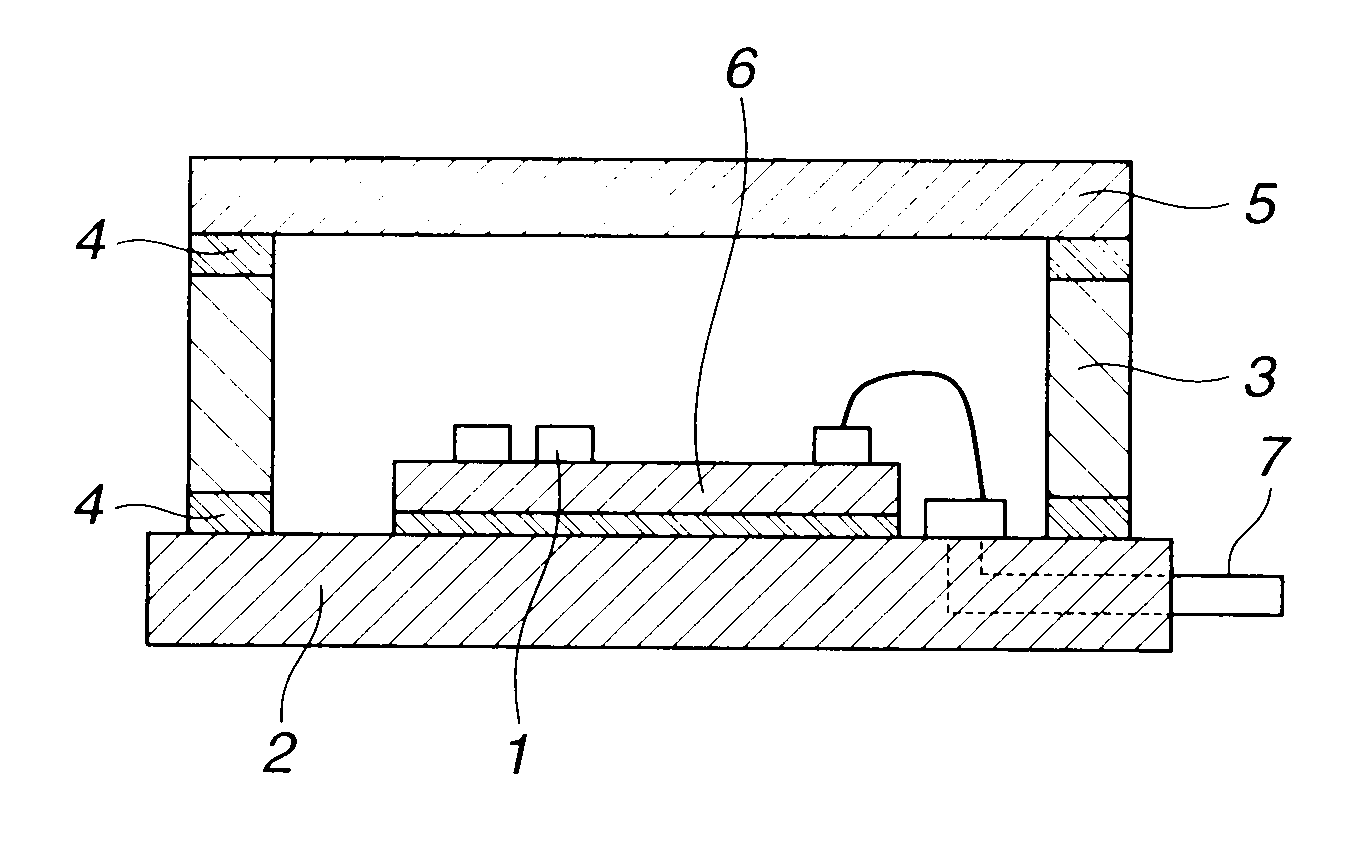

[0111]The perfluoropolyether rubber composition (Composition 1) prepared above was used as an adhesive to provide bonds 4 between base 2 and case 3, between case 3 and lid 5, and between base 2 and substrate 6 in FIG. 1, completing an automotive electric / electronic package as shown in FIG. 1. Note that the circuit 1 on substrate 6 which is received within case 3 and bonded to base 2 is formed using a silver paste.

[0112]This package was held in an atmosphere of 5% hydrogen sulfide (H2S) for one month. Thereafter, with lid 5 removed, the state of the circuit 1 was observed, finding no corrosion on the circuit 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com