Preparation method for corrosion-resistant protective coating on surface of sintered neodymium-iron-boron magnet

A kind of protective coating, NdFeB technology, applied in the direction of coating, metal material coating process, melting spray plating, etc., can solve the problem of waste water heavy metal harming the environment and operators, the electroplating process energy consumption is large, the performance of the magnet is reduced, etc. , to achieve the effect of rapid cleaning in the preparation process, long-lasting corrosion resistance and wear resistance, and improved roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a corrosion-resistant protective coating on the surface of a sintered NdFeB magnet, comprising:

[0027] Step 1. Pretreatment of NdFeB magnets: select thin-sheet NdFeB magnets with specifications of 62mm×52mm×45mm for testing, place NdFeB magnets in distilled water, add metal cleaning solution, and then ultrasonically clean them for 10 minutes to remove the surface Oily dirt, then take out the NdFeB magnet and wash it with distilled water, then pickle the NdFeB magnet to remove the surface scale, the pickling solution used for pickling is nitric acid, its concentration is 5wt%, and the pickling time is 10s. After pickling, take it out and put it in clean water for ultrasonic cleaning, then wash it with distilled water and then soak it in ethanol. The purity of ethanol is 95%, and the ethanol soaking time is 30s. Finally, take it out and dry it, and sandblast it. The sandblasting material is corundum sand , sandblasting air pressure 0.5MPa, sandbla...

Embodiment 2

[0031] A method for preparing a corrosion-resistant protective coating on the surface of a sintered NdFeB magnet, comprising:

[0032] Step 1. Pretreatment of NdFeB magnets: select thin-sheet NdFeB magnets with specifications of 62mm×52mm×45mm for testing, place NdFeB magnets in distilled water, add metal cleaning solution, and then ultrasonically clean them for 10 minutes to remove the surface Oily dirt, then take out the NdFeB magnet and wash it with distilled water, then pickle the NdFeB magnet to remove the surface scale, the pickling solution used for pickling is nitric acid, its concentration is 5wt%, and the pickling time is 15s. After pickling, take it out and put it in clean water for ultrasonic cleaning, then wash it with distilled water and then soak it in ethanol. The purity of ethanol is 95%, and the ethanol soaking time is 30s. Finally, take it out and dry it, and sandblast it. The sandblasting material is corundum sand , sandblasting air pressure 0.6MPa, sandbla...

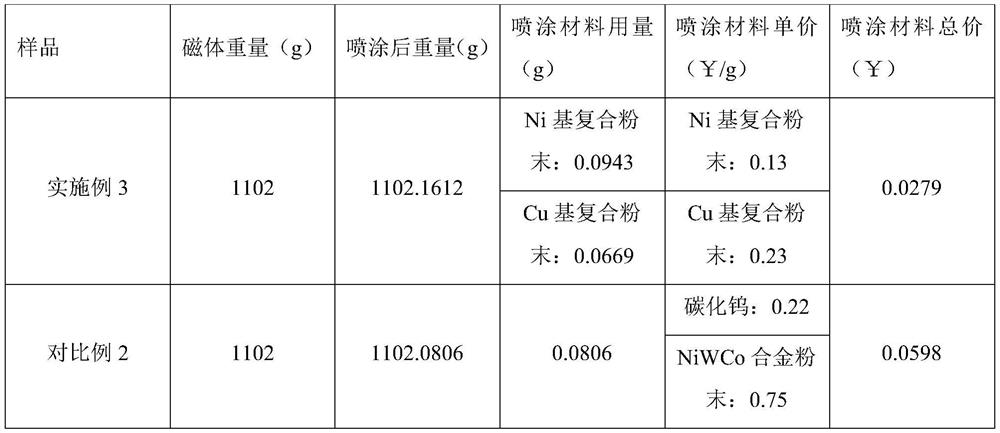

Embodiment 3

[0047] The corrosion-resistant protective coating was prepared by the method of Example 2, and a thin-sheet NdFeB magnet with a specification of 62mm × 52mm × 45mm was selected for testing, and the weight of the magnet was weighed in advance. The coating is weighed again, and then the different spraying material consumptions used for the coating are calculated respectively, and the thickness of each layer of coating is the same as in Example 2 here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com